Tin Ore Processing

Processing Capacity: 1-500+ T/H Customized

Tin(Cassiterite) ore processing refers to the process of extracting tin from ore. Alluvial tin ore is treated by washing and screening, while rock tin ore is pretreated by crushing and grinding. Gravity separation, magnetic separation, and flotation are mainly used to grade tin concentrate and remove other impurities.

JXSC tin ore processing equipment has gained the trust of popular alluvial/placer tin mines and vein/rock tin mines worldwide, including those in Rwanda, Uganda, Nigeria, Zimbabwe, Tanzania, and South Africa. We will optimize equipment combinations and process flows based on ore grade, capacity scale, and budget.

- Mineral Processing Turnkey Solutions.

- Recovery Rate: 90%-95%+ Guaranteed.

- Mining Equipment 100% Factory Price.

Tin ore beneficiation process

The tin(Cassiterite) ore beneficiation plant mainly completed by crushing, screening, washing, gravity separation and magnetic separation. The specific process and equipment need to be determined according to the characteristics of the ore.

Tin Ore Extraction Process

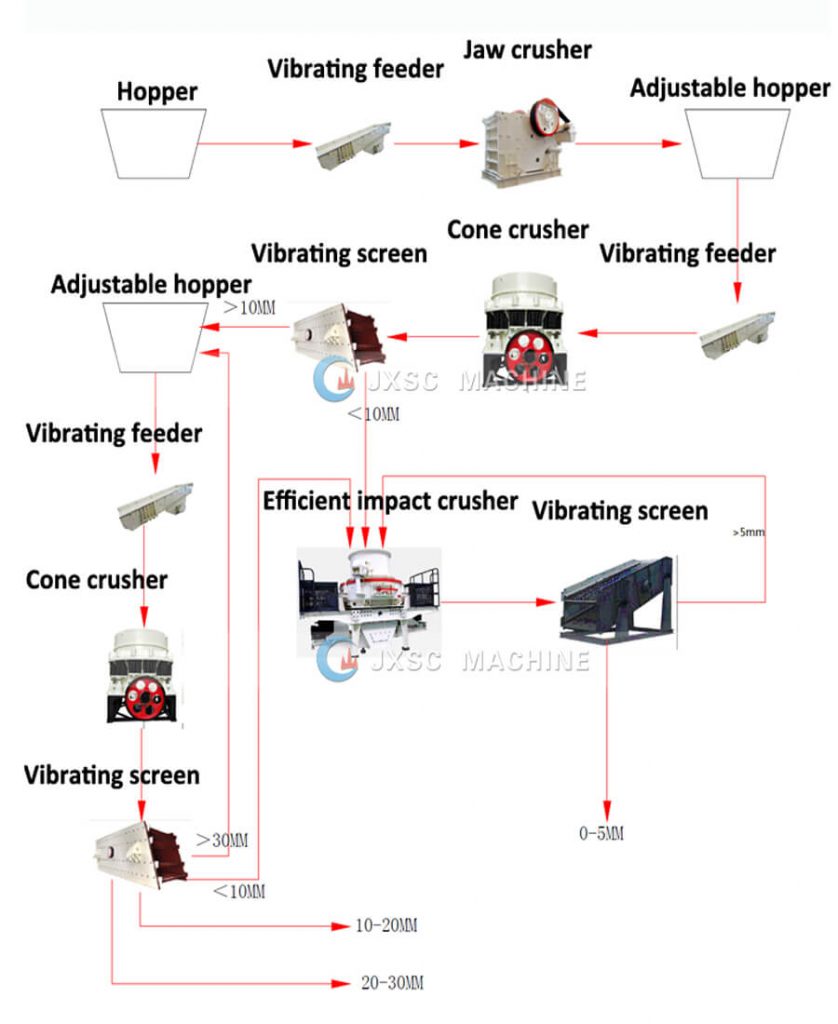

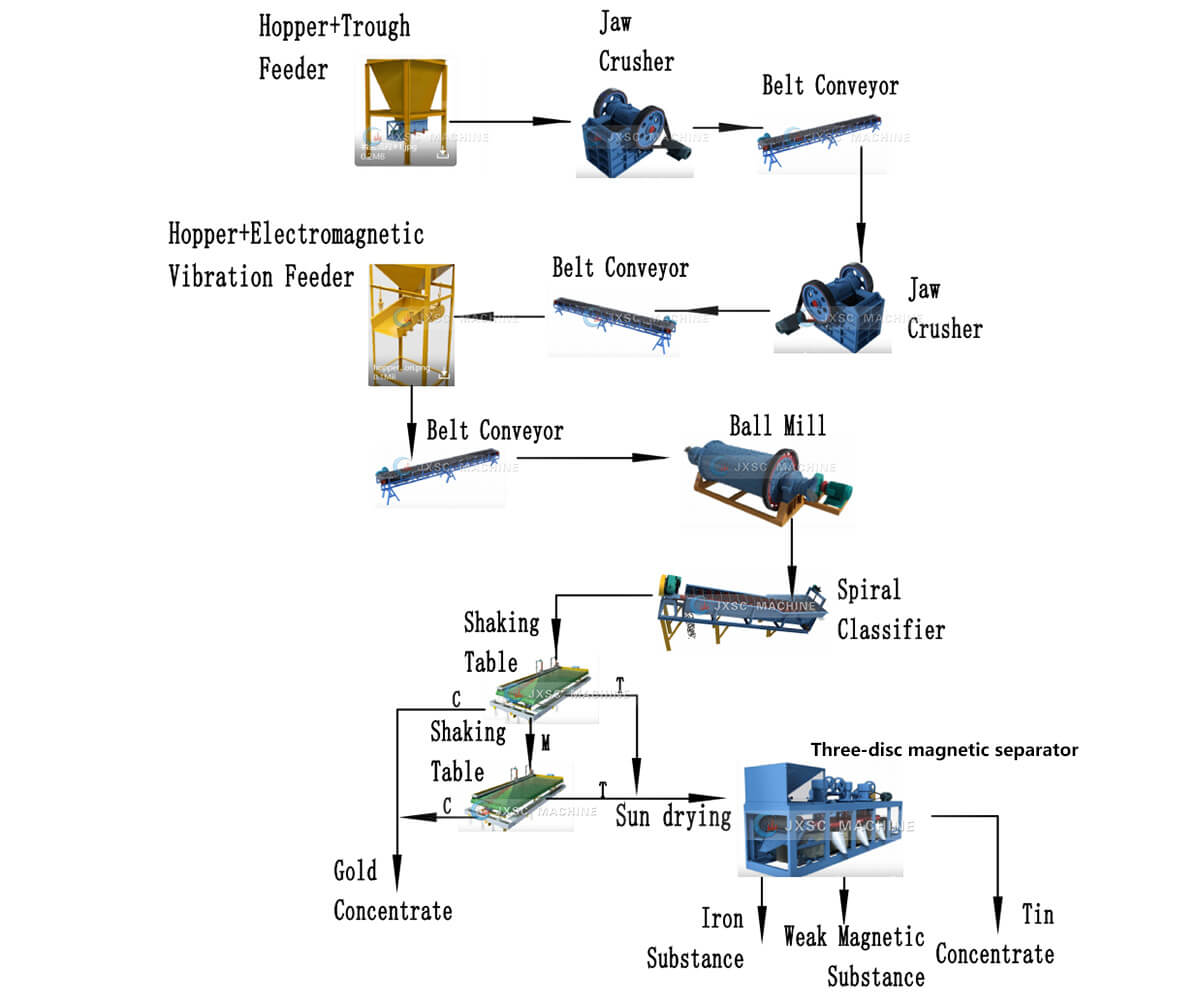

1. Crushing and grinding: The original tin ore is crushed and ground to refine it into an appropriate particle size for subsequent sorting operations. Equipment such as jaw crushers and ball mills are usually used.

2. Beneficiation: The commonly used sorting methods include gravity separation, flotation and magnetic separation.

- Gravity separation: use the density difference of different minerals in the ore to separate the ore by gravity.

- Flotation: Using the difference in hydrophilicity and hydrophobicity between ore and water, ore is separated by bubble adsorption and buoyancy.

- Magnetic separation: For tin ores containing magnetic minerals, using the sensitivity of certain minerals in ore to magnetism, magnetic minerals are separated from non-magnetic minerals through the action of a magnetic field.

- Electric separation: For tin ores containing minerals with different electrical properties, further separation of tin minerals can be achieved by adjusting the electric field strength, current density and processing time.

3. Concentration and dehydration: Concentration is carried out by thickening equipment to increase the solid content of the pulp, which is convenient for subsequent processing and transportation. It is then dehydrated to remove excess water. Common equipment includes thickener, filter press.

The process developed by JXSC can ensure efficient, high-quality and economical operation of tin ore beneficiation. Contact us to customize a tantalum niobium tin processing plant and obtain equipment at 100% factory price!

Tin ore processing plant

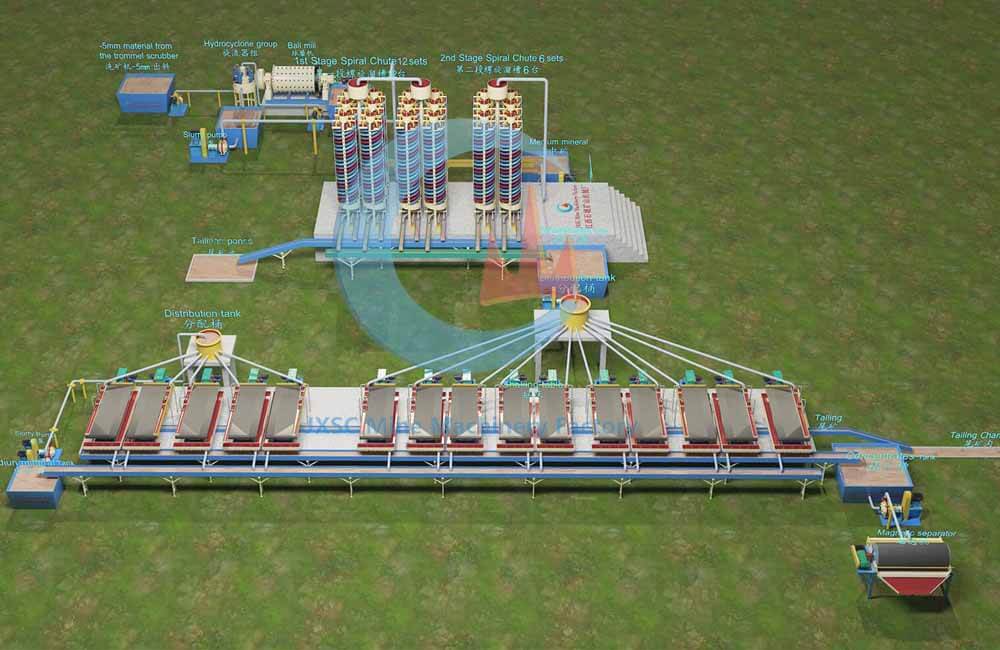

Alluvial Tin Ore Mining plant

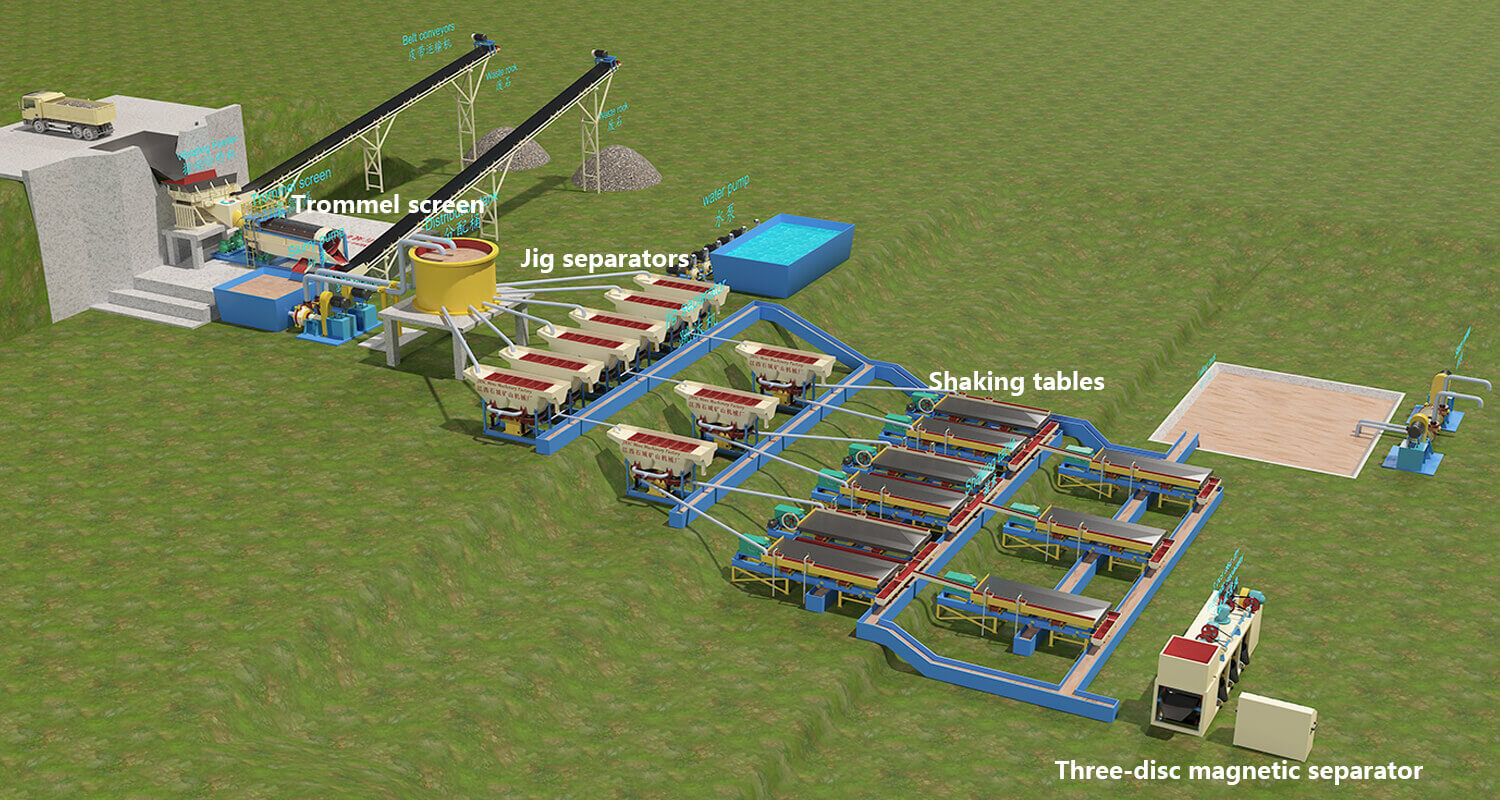

This system is a fully set 120tph alluvial tin ore mining process plant setup. Mainly includes washing, gravity separation, magnetic separation process. Raw ore conditions in this tin project are as follows:

- Raw ore doesn’t contain sticky clay, just alluvial loose soil;

- Tin concentrate size in alluvial ore is 0-5mm;

- The maximum feeding size of raw ore is 150mm;

- Feeding capacity is 120 tons per hour.

120TPH Alluvial Tin Mining Processing Flow

1. Feeding: Use a high-pressure water gun to break up the raw materials on the vibrating feeder (with an 80mm grid). Material over 80mm will be removed and transported to the waste dump. Materials that meet the size requirements enter the hopper through the vibrating feeder and then enter the trommel screen evenly.

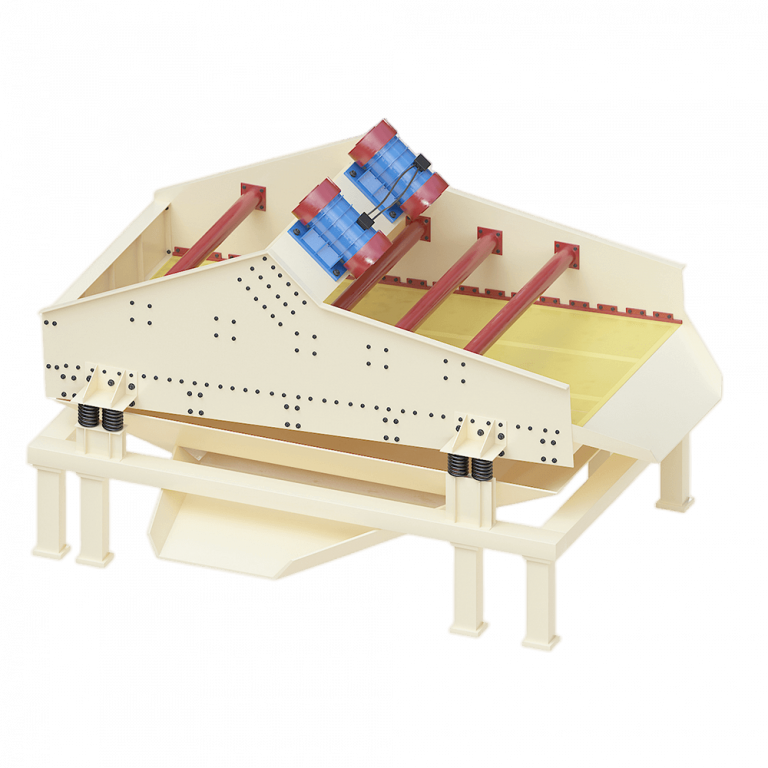

2. Washing & screening: The trommel screen has two layers of mesh. The inner mesh is a 30mm bar steel mesh, and the outer mesh is a manganese steel mesh with a pore size of 5mm. Among them, +5mm materials are screened out and transported to the waste pile. -5mm materials are pumped to the distributor together with sand.

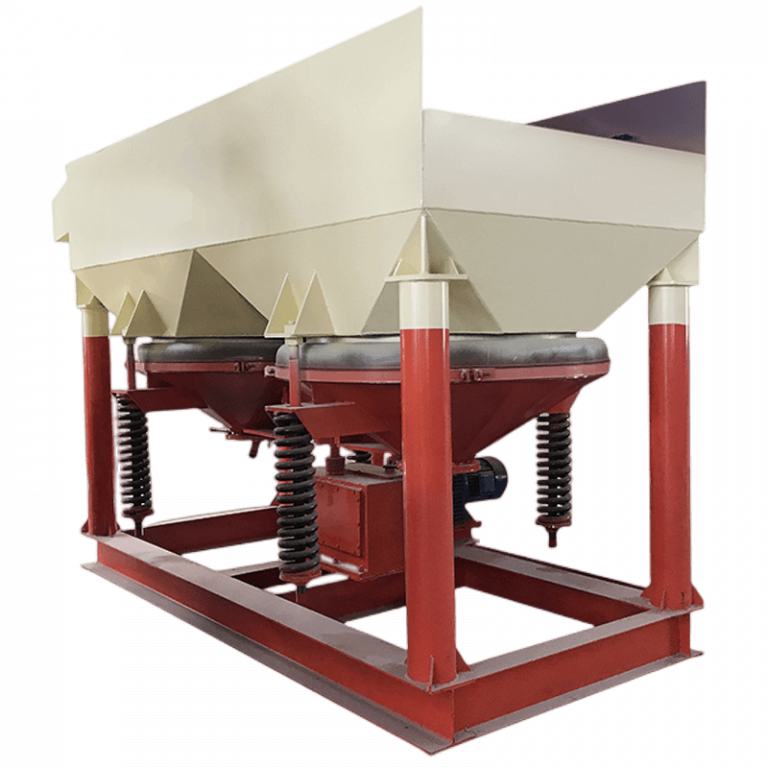

3. Jig separation: -5mm materials in the distributor enter 6 4m2 jig concentrators (15-20TPH) for primary separation of tin concentrate. The concentrate comes from six 4m2 jigs and enters three 2m2 jigs (5-10TPH) by gravity to select the tin concentrate.

4. Shaking tables separation: The concentrate in three 2m2 jigs enters six shaking tables by gravity, mainly to further refine the concentrate and improve the grade of the finished product. The shaking table produces three outputs: tin concentrate, middlings, and tailings. The medium may also contain some tin, then sent to three shakers (second stage) for reprocessing. All tin concentrates coming out of the shaking table are finished products, and their tailings enter the tailings pond.

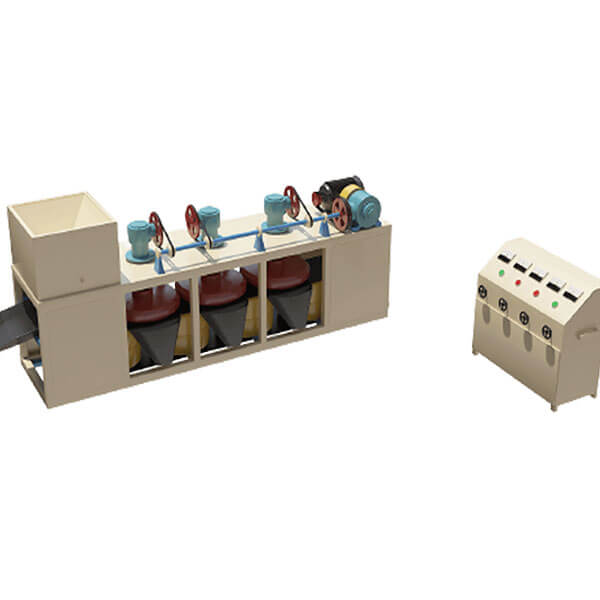

6. Magnetic separation: After the tin concentrate is naturally dried, it is sent to a three-disc magnetic separator for dry separation to remove tin, iron, coltan, and other weak magnetic minerals.

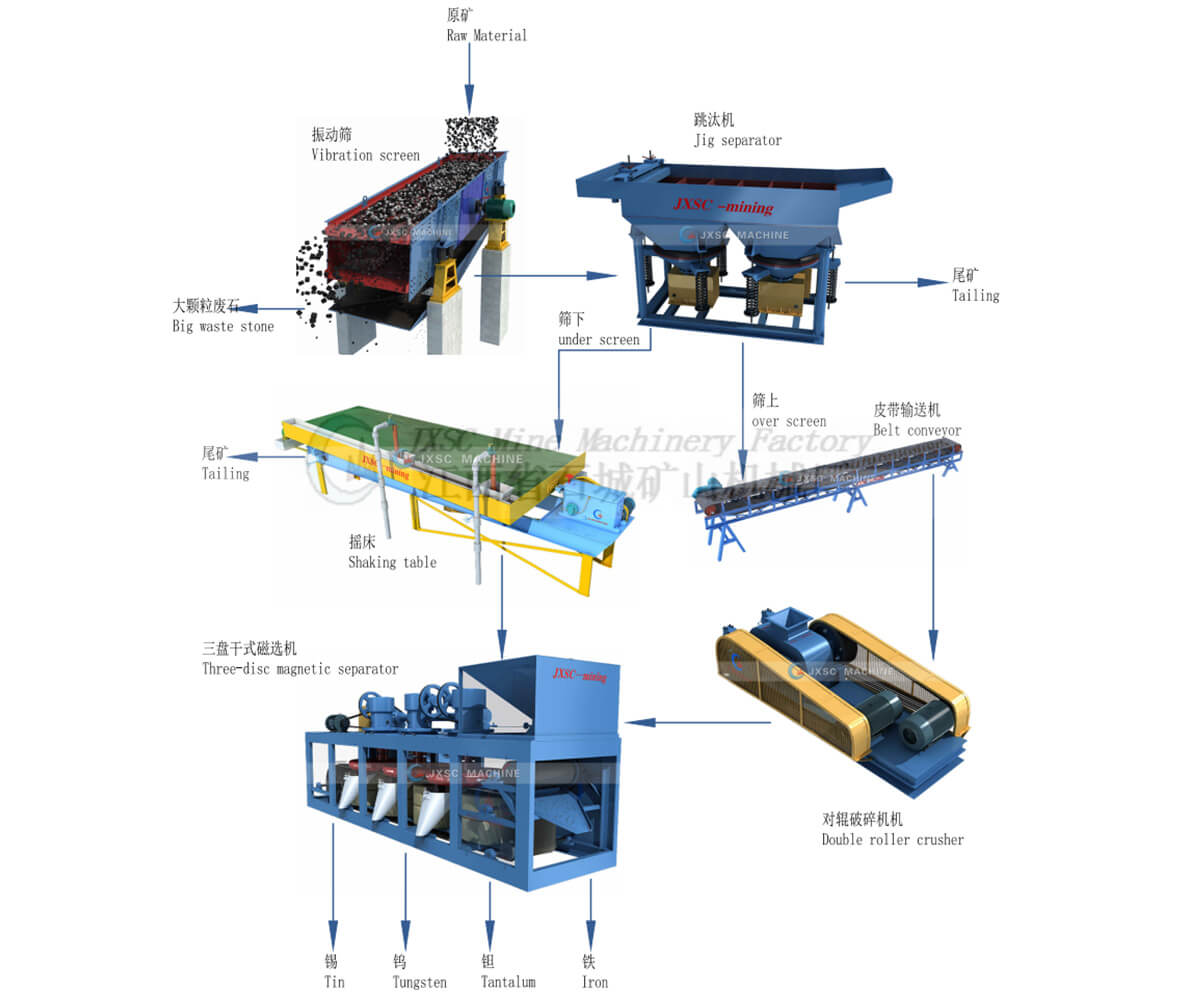

Rock tin ore processing plant

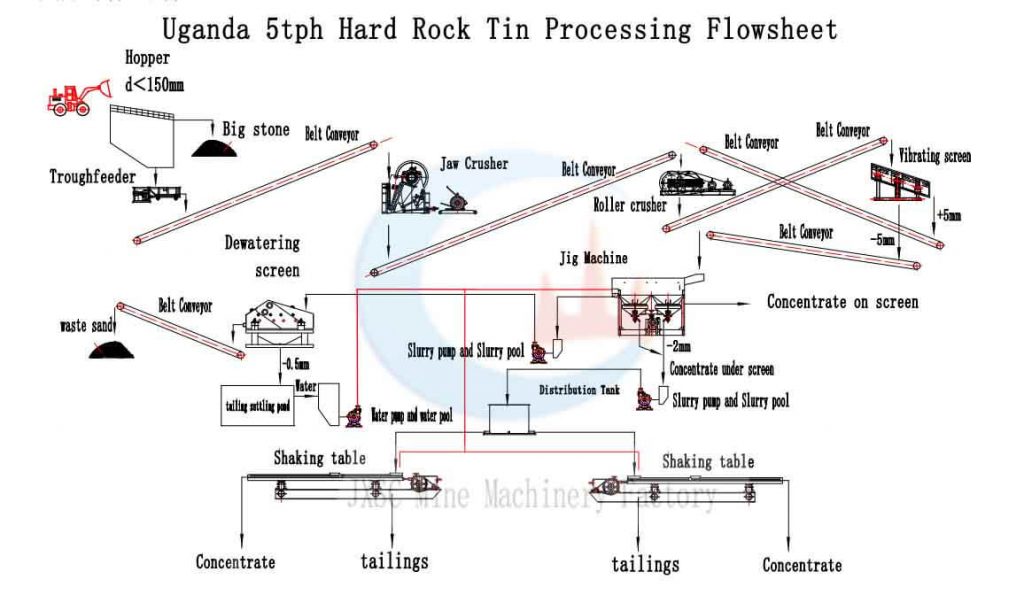

5TPH Rock Tin Processing Flow

1. Crushing & Screening: There is a smaller hopper above the jaw crusher and a chute feeder below the hopper. The stone is evenly fed into the jaw crusher and then screened with a vibrating screen. Materials larger than 5mm enter the next double-roller crusher through the belt conveyor for fine crushing. The output materials will be transported to the vibrating screen for re-screening.

2. Gravity separation: Material smaller than 5 mm is conveyed to the jig. The concentrate <2mm below the screen of the jig separator is directly transported to the distribution tank by the slurry pump, and then enters the shaking table for separation to obtain high-grade tin concentrate.

3. Tailings processing: The customer requires the use of dewatering screens and the recovery of jig tailings water. The dehydrated waste sand is transported away by a belt conveyor.

Mixed tin ore processing solution

30TPH Rock And Alluvial Tin Process Plant

150TPH Sand Tin + Rock Tin Ore Dressing plant

Main flow: Washing ( trommel scrubber, spiral washing machine) –> Crushing (jaw crusher, double roll crusher) –> Gravity separation (jig separators, shaking tables, spiral chutes) –> Magnetic separation (three-disc magnetic separator).

1-3TPH Ilmenite, tin, coltan and zircon sorting plant

50TPH Alluvial Tantalum, Niobium, Tin Wash Plant

Upgrade Your Tin Ore Recovery Rate

JXSC provides customized solutions for various types of tin ore, including placer/ alluvial tin deposits, vein/rock tin deposits (sulfide/oxide), and polymetallic tin deposits. Our core processes include crushing, grinding, washing, screening, gravity separation, flotation, magnetic separation, and tailings treatment. It has been successfully applied to multiple tin mining projects in Uganda, Rwanda, Nigeria, Tanzania, Zimbabwe, and other countries. We offer free customization of tin ore processing flows and can purchase mining equipment at factory prices! Our processes meet all environmental standards, ensuring a recovery rate of 90%-95%+ and a stable concentrate grade of 63%+, helping you maximize resource value and achieve a rapid return on investment!

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.