Electrolysis copper recovery system

-Concentrate deep processing and purification

after copper beneficiation

Our copper electrolysis recovery systems extract 99.99% pure copper — for converting copper concentrate into high-purity cathodes.

Why Use Electrolysis for Copper Recovery?

Is copper beneficiation efficiency low?

-- Upgrade to electrolysis process for 99.99% purity, which is extremely pure.

-- Using copper electrolysis equipment boosts profit by 30%!

-- Various types of copper ores, waste circuit boards & other complex copper-containing waste.

-- Reduce harmful gas emissions, recyclable electrolyte, better pollution control.

-- If the purity reaches the standard, it can be directly used in industrial production such as electronics and electricity.

Electrolytic copper recovery process

The electrolytic copper recovery process is also called copper electrolysis refining (electrorefining), copper cathode production process, copper refining process, extraction and purification of copper, or copper electrowinning solutions.

It is the process of extracting and purifying copper from other metals in copper-containing waste (waste wires, waste copper materials, etc.) through electrolytic refining technology. The copper concentrate or other copper-containing materials obtained after copper beneficiation are the raw materials of the copper electrolysis system/equipment. Through the ⇓⇓⇓ copper electrolytic system/ equipment ⇓⇓⇓ to produce highly pure copper cathodes. The copper refining & purification rate can reach 99.99%, and its products can be directly used in the production of electrical-grade materials.

Application of copper electrolysis process:

- Scrap copper recycling plant: scrap copper recycling, mineral smelting, and other industries, such as copper extraction from scrap wires and circuit boards.

- Copper smelting enterprises: copper concentrate → high-purity cathode copper.

- Precious metal refining: such as gold, silver, and platinum contained in anode mud.

Electrolytic Copper recovery system For sale

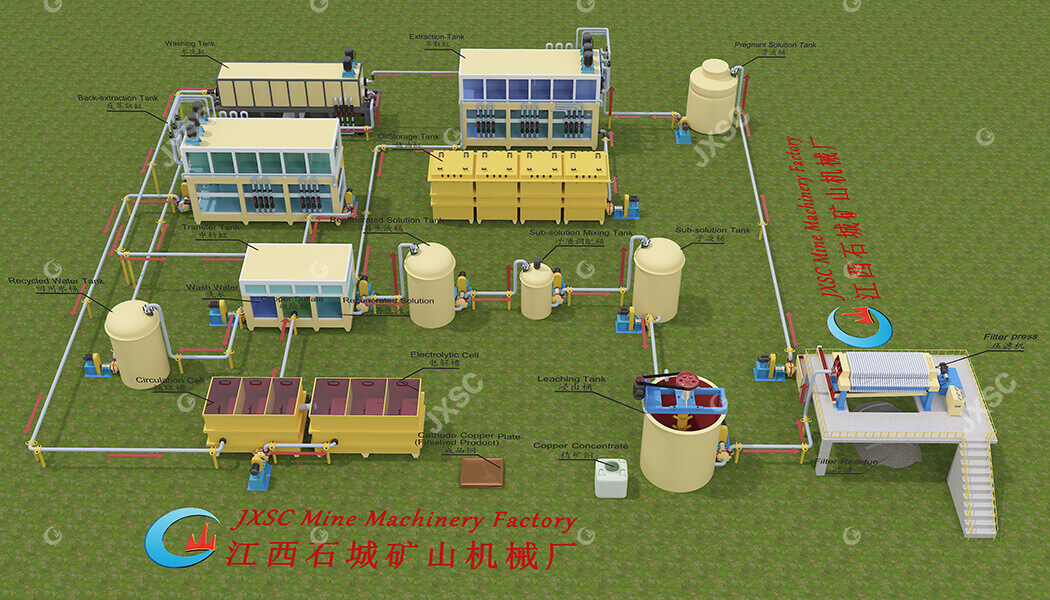

The electrolytic copper recovery system, also called copper electrolysis equipment, is the key machine for further processing of copper ore beneficiation products to obtain high-purity copper products. Through electrochemical refining technology, copper-containing raw materials (such as crude copper, scrap copper, ore copper, etc.) are purified to 99.99% high-purity copper (cathode copper) while considering environmental protection.

Our following advanced electrolysis systems/equipment can maximize the recovery rate and commercial value of copper. It mainly includes smelting system, electrolytic cell, rectifier power supply, circulation filtration equipment, wastewater treatment system, power supply and other purification equipment. Contact us to configure a series of copper refining or extraction equipment for small-large copper plants.

Types of Copper Electrolysis system/equipment

Acid etching fluid recycling copper extraction system

Commonly used in the printed circuit board industry, it mainly involves the electrolysis of acid etching fluid to regenerate and recover copper metal.

Advantages: The entire system can achieve stable etching effect, automatic control, and can safely complete the recycling process.

Alkaline Etching Liquid Recovery Copper Extraction System

Widely used in the PCB industry, the electrolysis or chemical replacement method is used to apply the regenerated alkaline etching fluid to the production line and recover high-value copper.

Advantages: Extract high-purity copper from waste liquid, turn waste into treasure, and improve purification and utilization rate.

Micro-etching Waste Liquid Copper Recovery System

Equipment that uses electrolytic oxidant removal-electrodeposition copper process to treat waste liquid generated by micro-etching system on copper surface.

Advantages: It can effectively refining high-purity copper and reduce the pollution of micro-etching waste liquid to the environment.

Tin stripping waste liquid recycling system

It is mainly used in the recycling of copper and tin resources in the printed circuit board manufacturing industry, and can also recycle other components in the tin stripping waste liquid.

Advantages: It has a fast stripping speed, the substrate is smooth and clean after stripping, and there is no pollution or corrosion.

Brown Chemical Waste Liquid Electrolytic Copper Recovery System

A method for recovering copper from brown waste liquid generated in the printed circuit board (PCB) electronic equipment manufacturing industry or the electronics industry by electrolysis and adsorption.

Advantages: The cathode copper obtained by electrolysis has a high purity and a good refining effect, which can reach more than 96%.

Ammonia Nitrogen Electrolysis Water Treatment System

The method of removing pollutants from water by oxidizing catalytically active electrodes mainly involves the electrocatalytic treatment of high-ammonia nitrogen wastewater.

Advantages: No toxic gas emissions, no concerns about high temperature and high pressure, and the whole process is clean and environmentally friendly.

Swirl electrolytic copper recovery system

Mainly used for copper metal refining, especially suitable for selective electrolysis (electrodeposition) separation and purification of low-content solutions and complex solutions in the metallurgical industry, as well as refining heavy metal ions in wastewater.

Advantages: closed space, no harmful gas discharge, good operating environment.

Copper Powder Recovery Water Treatment System

It mainly recycles the discharge water generated by the circuit board grinding machine, water washing machine and the bottom of the water tank to collect the copper powder and clean water in the discharge water so that it can be recycled.

Advantages: fully automatic operation, high filtration accuracy.

Precious Metal Extraction And Recovery System

The principle of electrolysis is used to reduce metal ions in wastewater into metal blocks or powders. It can efficiently extract precious metals such as gold, silver, and platinum from raw materials such as electronic waste treatment and waste jewelry recycling.

Advantages: highly automated and intelligent, 99.9% purification rate.

Copper Electrolysis Process Solutions

The electrolytic copper recovery process solution is a core process for efficiently purifying copper from copper-containing scraps (such as wires, circuit boards, scrap copper alloys). Whether your operation uses flotation, gravity separation, or another copper processing solution, our turnkey leaching and extraction electrolysis machines provide the perfect next step, refining copper concentrate into high-purity cathode copper while minimizing waste and maximizing efficiency.

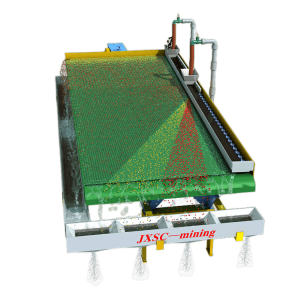

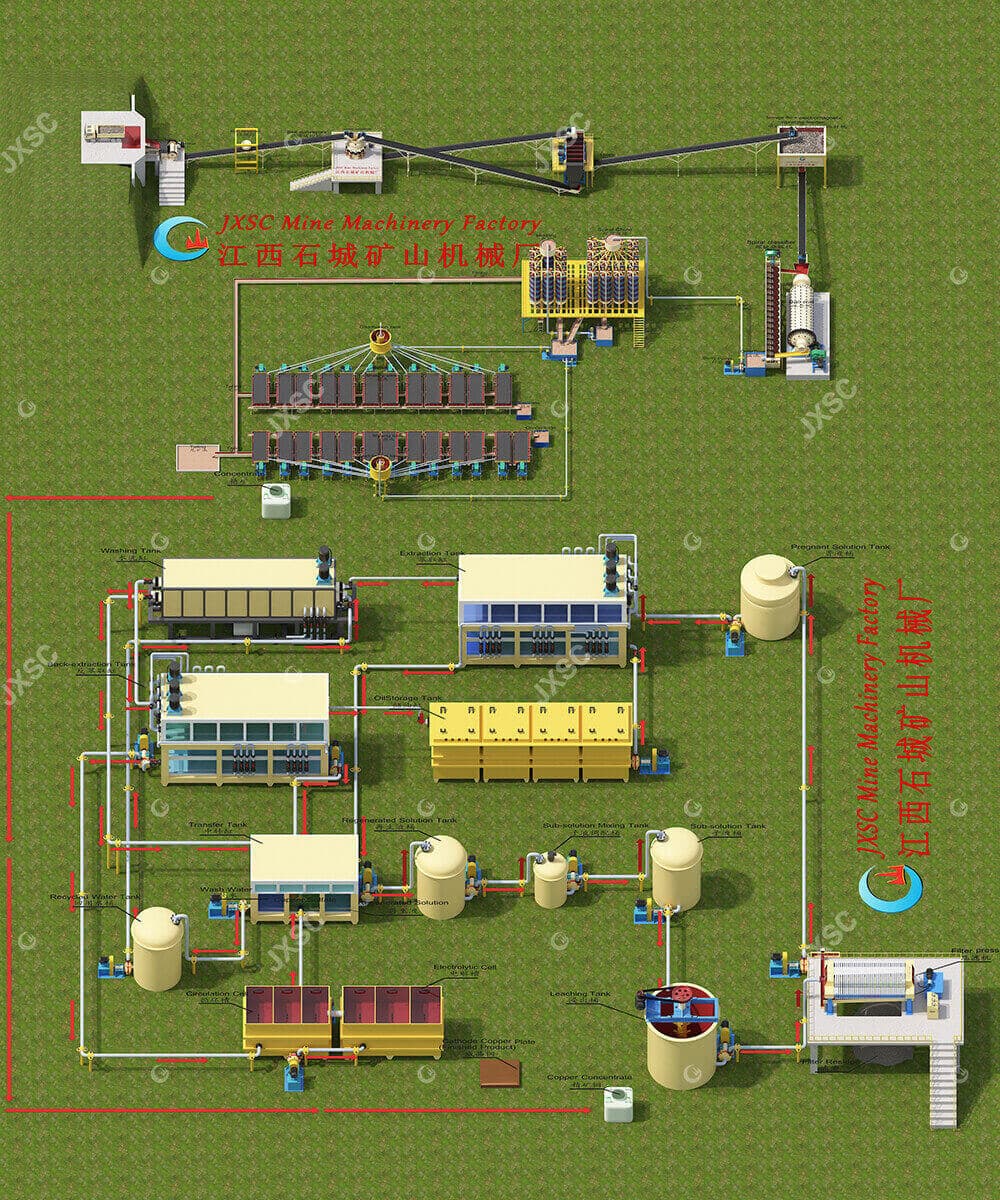

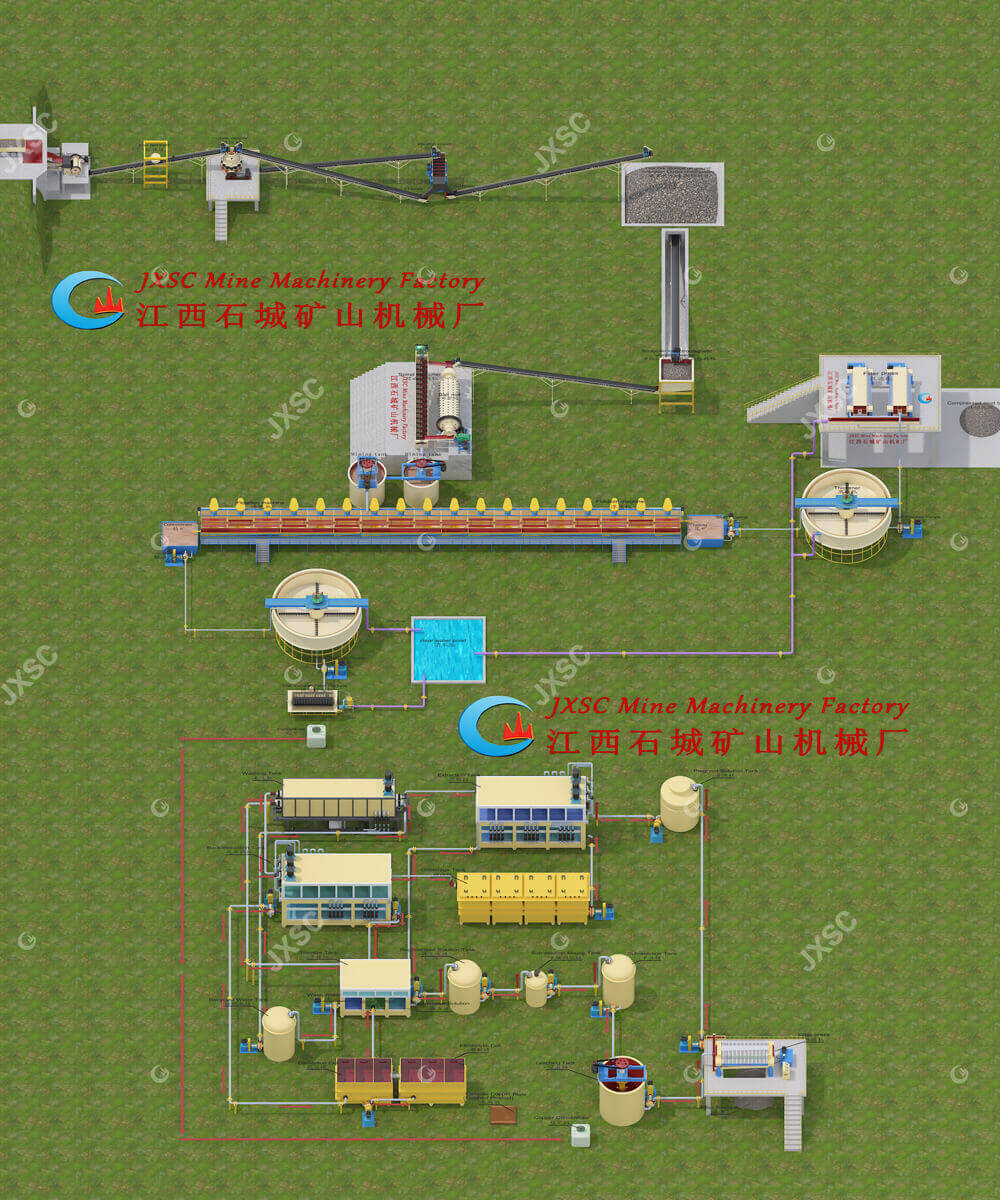

Copper gravity separation + purification electrolysis plant

Increasing profits by 18-30%.

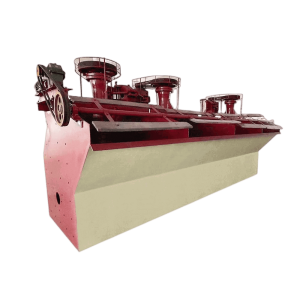

Copper ore flotation + leaching extraction electrolysis plant

Total production increased by 12-20%.

JXSC specializes in post-beneficiation refinement—transforming your copper concentrates (from flotation/gravity processes) into 99.99% LME-grade cathode copper; faster, cleaner, and more profitably than traditional smelting. Our electrolysis process can seamlessly integrate with your existing copper beneficiation (gravity separation, flotation) plant backend.

Not sure how to configure your copper electrolysis plant equipment? – Let us efficiently custom full copper solutions according to your needs.

Why choose JXSC copper Electrolysis plant

- Higher Copper Recovery Rates – Extract up to 99.99% pure copper from concentrates with electrowinning technology.

- Environmentally Sustainable – Sulfur dioxide emissions are reduced by 80%+; wastewater & exhaust gas are controllable and meet standards.

- Compliant Processes – The finished product using optimized electrolysis technology can be directly used in high value-added industries such as wires and cables.

- Modular & Scalable Designs – Customize systems to fit small, medium, or large-scale production process without costly overhauls.

- Lower Operational Costs – Reduce energy consumption, reagent use, and labor costs compared to traditional smelting methods.

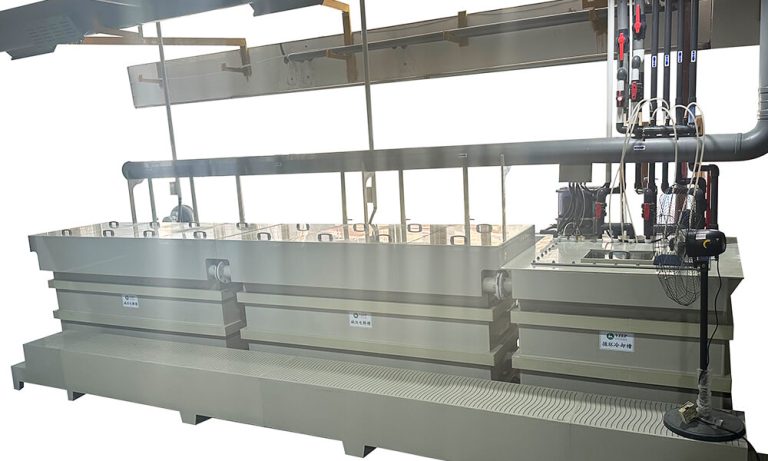

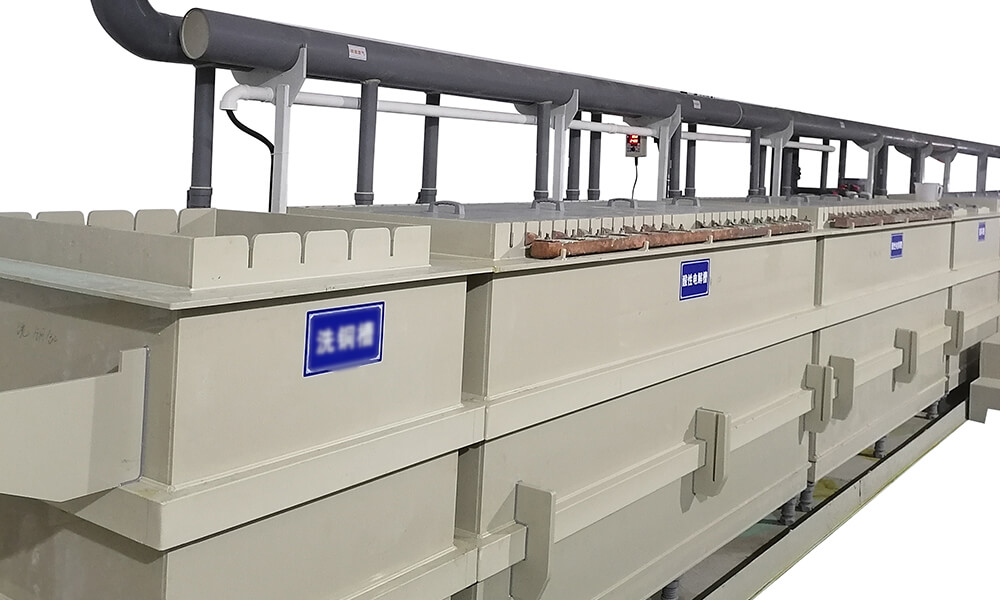

Copper electrolysis Plant equipment display

Copper electrolysis equipment

0:30

0:37

0:56

Two-tank electrolysiscell, recover 50 KG cathode copper production capacity per day.

Four-tank electrolysis cell, recover 100 KG cathode copper production capacity per day.

The leaching and agitation tank’s function is to mix the copper concentrate powder with the sulfuric acid.

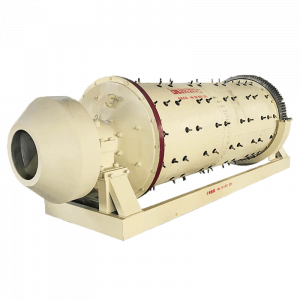

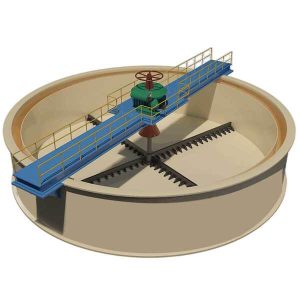

Related Equipment

Other Mineral Processing Solutions

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.