50TPH Rock And Alluvial Gold Recovery Process Plant In Mali

We guarantee the high quality machine in the mineral processing industry, established in 40+ years of experience.

Project Info.

- Raw ore: gold ore with more slime on the surface, and also large rock gold ore

- Capacity: 50TPH

- Feed size: >100mm

- Output size: 0-2mm

- Location: Mali

Process

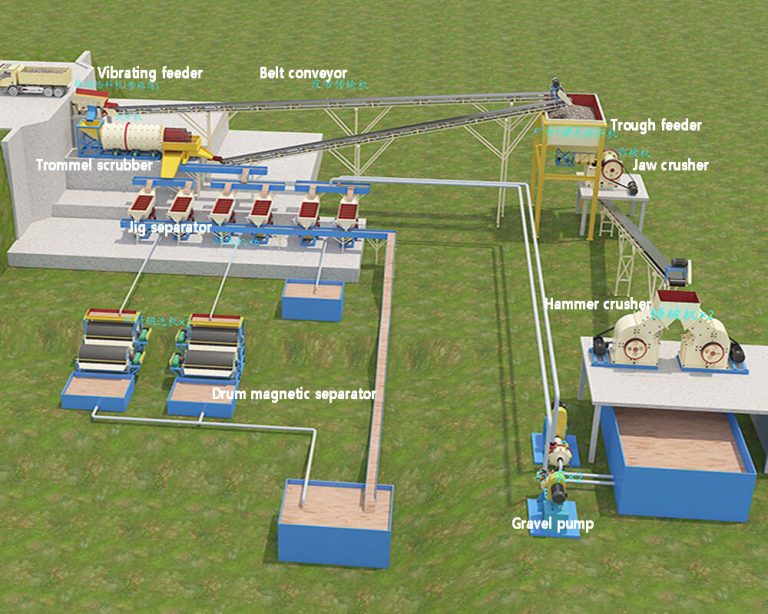

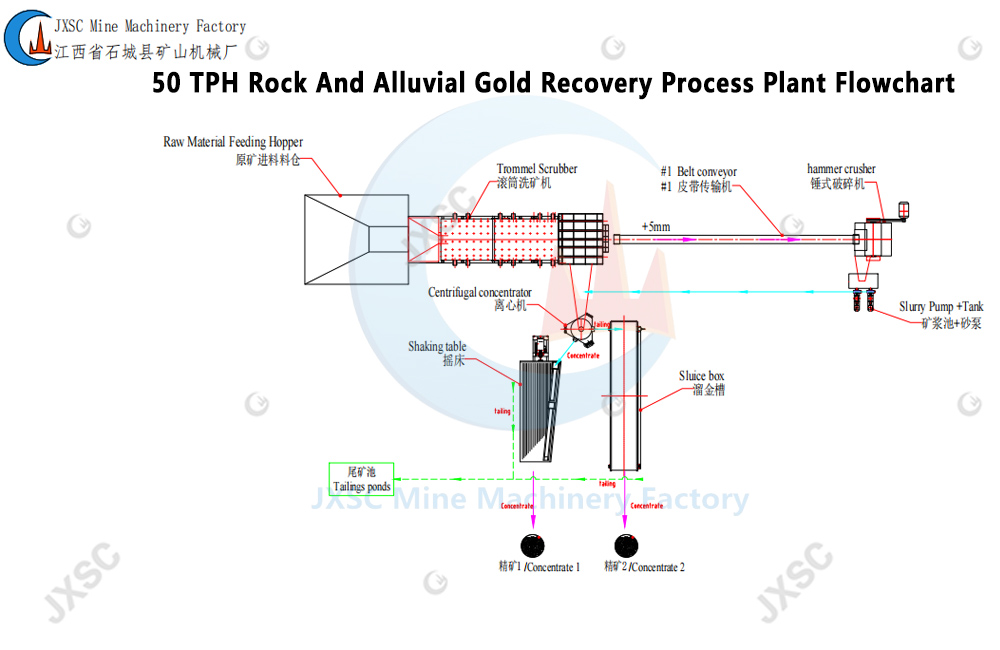

Feeding – Washing & screening – Crushing – Gravity Separation (centrifugal concentrator, shaking table, sluice box)

process flow

50TPH Rock And Alluvial Gold Recovery Process Plant

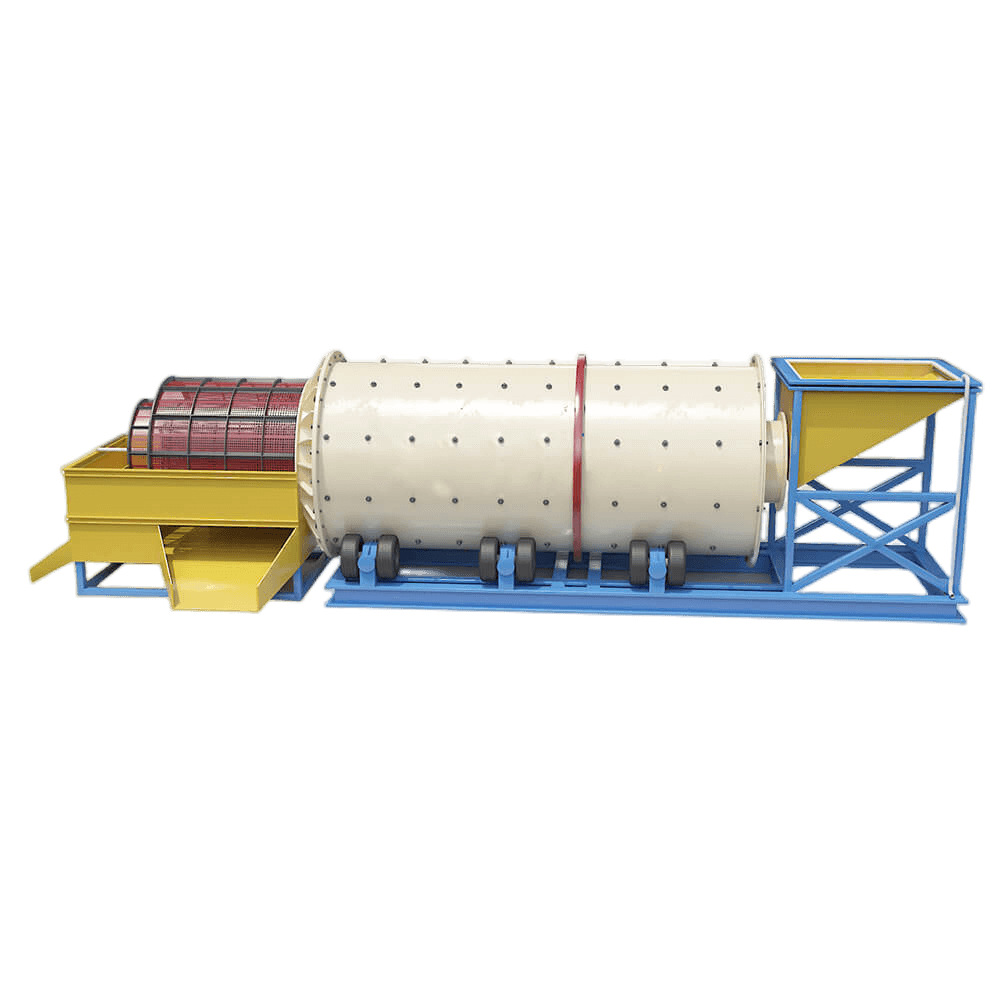

JXSC has successfully customized a complete set of rock gold and alluvial gold recovery process plant equipment for Mali customers, mainly including trommel scrubber, hammer crushers, and gravity separation equipment. The specific process is as follows:

1. Washing & screening stage:

First, the large pieces of material enter the feed bin, and then the trommel scrubber mainly wash away the slime and impurities on the surface. Then, the preliminarily screen is used to remove the coarser stones.

2. Crushing stage:

The +5mm rocks are conveyed by belts into two hammer crushers to be crushed into smaller particles, which is convenient for the subsequent gravity separation process.

3. Gravity separation stage:

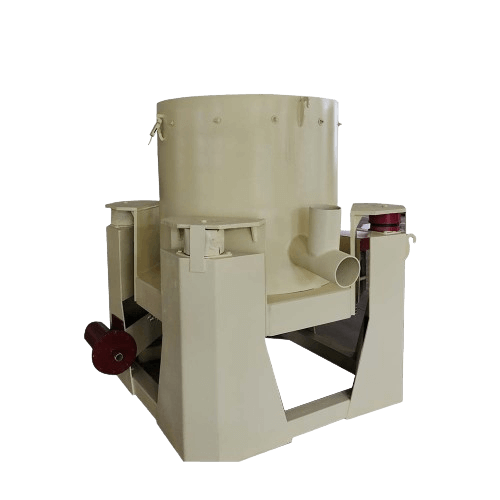

- The materials that meet the feed size are sent to the centrifugal concentrator. The materials are first separated by gravity in the centrifugal concentrator. Since the density of gold is much greater than that of other substances, the gold particles will sink to the bottom of the centrifugal concentrator, thereby achieving initial enrichment.

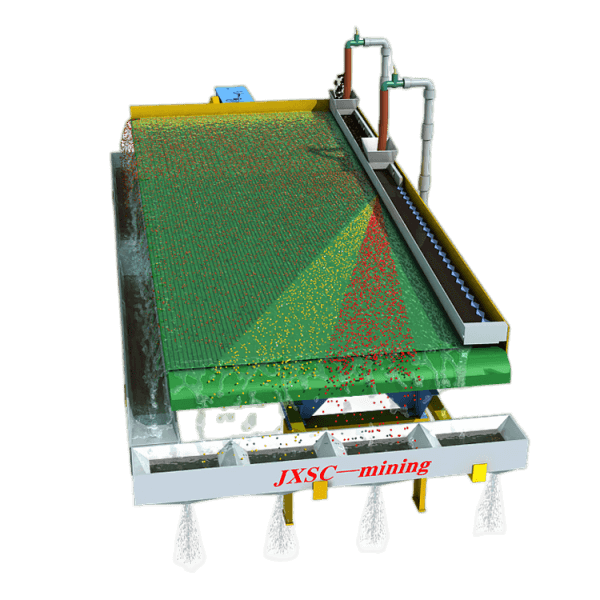

- Then, the concentrate from the centrifuge enters the shaking table, mainly to further separate the gold particles in a more refined way. The shaking table uses the synergy of water flow and vibration to sort out gold particles by using the density difference between mineral particles. Due to their high density, gold particles will settle in certain areas of the bed surface.

- Finally, the tailings from the centrifuge and shaking table go into the gold sluice box, which uses water flow to reovery more gold from light minerals.

Process Site

50TPH Rock And Alluvial Gold Recovery Process Plant Site

The gold sluice box can usually be set with steps of different lengths and angles, and the water flow rate and direction will be finely adjusted to ensure that the gold particles can be deposited in the appropriate position. This is just a basic process of rock gold and alluvial gold recovery process plant. In actual operation, it needs to be adjusted and optimized according to specific mineral characteristics and process requirements. JXSC supports customized gold recovery process and equipment, contact us for you to customized gold processing plant equipment and more details!

Main Equipment

Equipment name | Model | Quantity |

Raw material feeding hopper | Customer made | / |

Ø1500×4000 | 1 | |

Belt conveyor | B500*11m | 1 |

Ø400×600 | 2 | |

6/4 | 1 | |

STLB-80 | 2 | |

1000X6000 | 2 | |

LY2100, New & heightened | 1 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.