Mineral Processing » Solutions » Chrome Processing plant

Chrome Processing plant

Small-Large Chrome Washing Plant & Laterite Chromite Process Solutions

- Chrome (chromium, chromite) processing plant, alternative name: chrome recovery plant, or chrome wash plant.

- Processing Capacity: 1-500+ T/H Customized

- Application: Widely used to handle chromium spinel mineral, alluvial chrome ore, laterite chromite (weathered oxide ore), lumpy chrome, complex associated minerals, and rock chromite ore, etc.

Chrome beneficiation is used to extract & enrich valuable ore, upgrading low-grade raw ore into high-grade chromite concentrate (typically with a Cr₂O₃ content of ≥48%) to meet the needs of metallurgical, foundry, and other industries. It encompasses the entire process of washing, screening, crushing, grinding, classifying, gravity separation, flotation, magnetic separation, dewatering, and tailings treatment. It is suitable for various chromium ore characteristics in South Africa, Turkey, Kazakhstan, Zimbabwe, and other countries worldwide.

- Mineral Processing Turnkey Solutions.

- Recovery Rate: 90%-95%+ Guaranteed.

- Mining Equipment 100% Factory Price.

Chrome Beneficiation Process

Chrome usually refers to the metallic chromium itself or its coating; chromite is a chromium-containing ore; and chromium is a metallic element (Cr). Usually, chrome ore contains a certain amount of iron; chrome ore beneficiation aims to extract chromium minerals from raw ore and remove impurities by gravity and magnetic separation to obtain a high-quality concentrate.

Key Process of Chrome Ore Beneficiation

- Gravity separation: The high density (4.2-4.8g/cm³) characteristics of chromite are used to separate low-density gangue (quartz, feldspar), with a recovery rate of more than 80%. Gravity concentration is used for processing high-density chromite, coarse-grained alluvial ore.

- Magnetic separation: Effectively remove clay and iron oxide impurities in laterite, and the grade of concentrate is increased to 45%-55%. Adapt to process fine-grained chromite and laterite.

- Flotation: Purify low-grade ores by positive flotation; remove silicon and improve quality by reverse flotation, and optimize the chromium-iron ratio. Suitable for the recovery of complex embedded ores, fine particles or associated silicate ores.

Our chrome plant process primarily involves washing, crushing, grinding, and core beneficiation (gravity separation, magnetic separation, and flotation), which is suitable for processing various alluvial/placer deposits, hard rock, and laterite ores. For small mining areas or geographically remote locations, we offer mobile, modular chrome wash equipment with flexible transport and rapid deployment capabilities. Contact JXSC expert to custom full chrome process turnkey plant and mining equipment based on ore characteristics (particle size, paragenetic minerals, degree of oxidation, etc.).

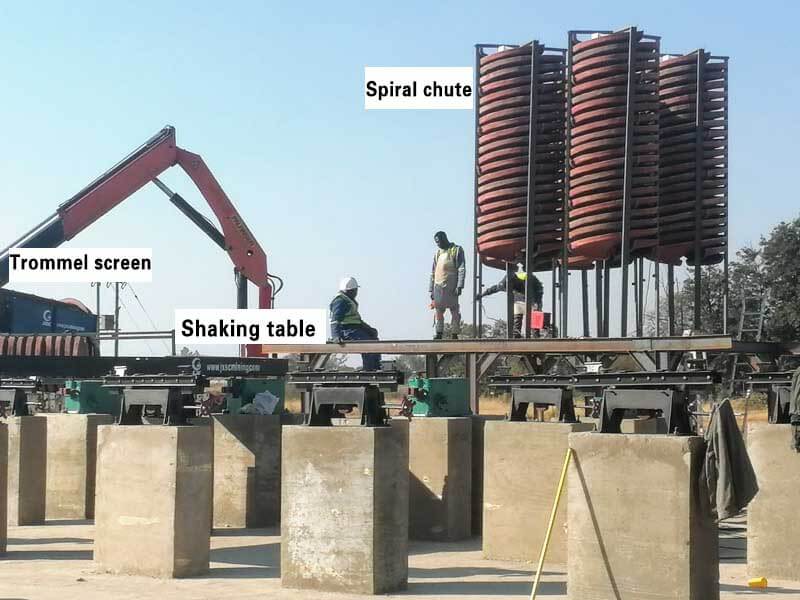

chrome ore processing plant

1. Alluvial Chrome Wash Plant

150TPH Chrome wash plant process flow

1. Feeding: The excavator or truck sends raw ore into the hopper through a vibrating feeder and evenly feeds the trommel screen. The vibrating feeder with grizzly bar, gap 75mm, and over 75mm rock will be sent to the waste stockpile via belt conveyor.

2. Wash & screen stage: 0-75mm material is sent to the trommel screen for sieving out 0-2mm and 2-75mm. The belt conveyor sends 2-75mm material to the waste stockpile. Then, 0-2mm material is sent to the slurry tank.

3. Spiral separation: Chrome concentrate from the two stages of spiral chute groups is sent to the concentrated pool. Use the slurry pump to send 0-2mm to the first stage spiral chute group to separate chrome concentrate, middling, and tailing. And tailing enters the tailing pool. Middling from the first stage spiral chute group to the second stage spiral chute group by slurry pump to recover more concentrate.

Contact us to design reasonable small-to-large chrome washing plants to improve the grade of concentrate and maximize the mineral recovery rate.

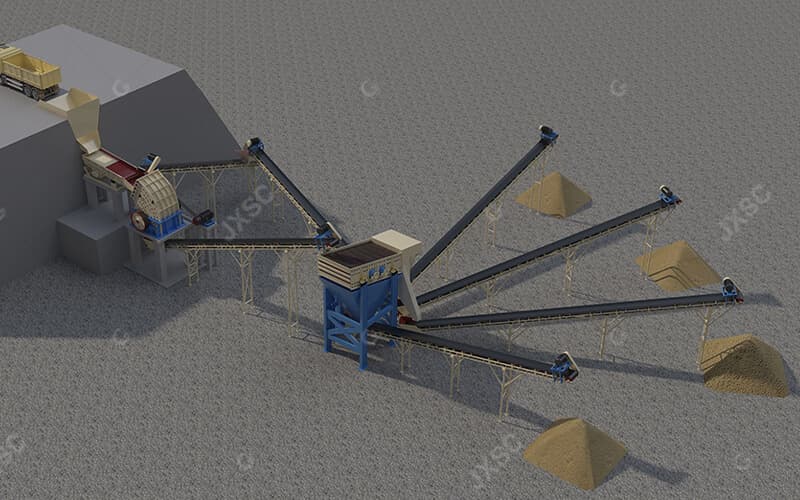

2. Rock Chromite Processing Plant

Chromite Processing Plant Flow

1. Crushing stage: The vibrating feeder evenly feeds the raw ore into the primary jaw crusher. The primary jaw crusher is used to crush large pieces of chromium ore into smaller sizes, and its output enters the cone crusher for fine crushing, thereby improving the crushing effect.

2. Screening stage: The material is sent to the vibrating screen through the belt conveyor with iron remover, and more than 20mm is returned to the cone crusher for crushing. Material with a 0-20mm particle size under the sieve enters the storage bin before entering the ball mill.

2. Grinding stage: The electromagnetic vibrating feeder and belt conveyor send the material into the ball mill and grind it to a 0-20mm fine powder. It is combined with a spiral classifier, and about 80% of the slurry overflowed by the classifier is 200 mesh powder. The oversized particles will be returned to the ball mill to form a closed-loop mill.

3. Gravity separation recovery stage: 200-mesh slurry is pumped into the spiral chute and shaking tables. The spiral chute is used for primary concentration, and all the heavy concentrate discharged from the secondary spiral group enters the shaker for re-concentration to obtain higher-grade ore.

4. Magnetic separation: If need higher-grade chrome concentrate is needed, it can be considered to add a magnetic separator at or before the gravity separation or final stage.

JXSC Design Highlights:

- Cr₂O₃ recovery rate increased by 10%-15%.

- Modular Customized Process.

- Advanced, Eco-friendly Technology.

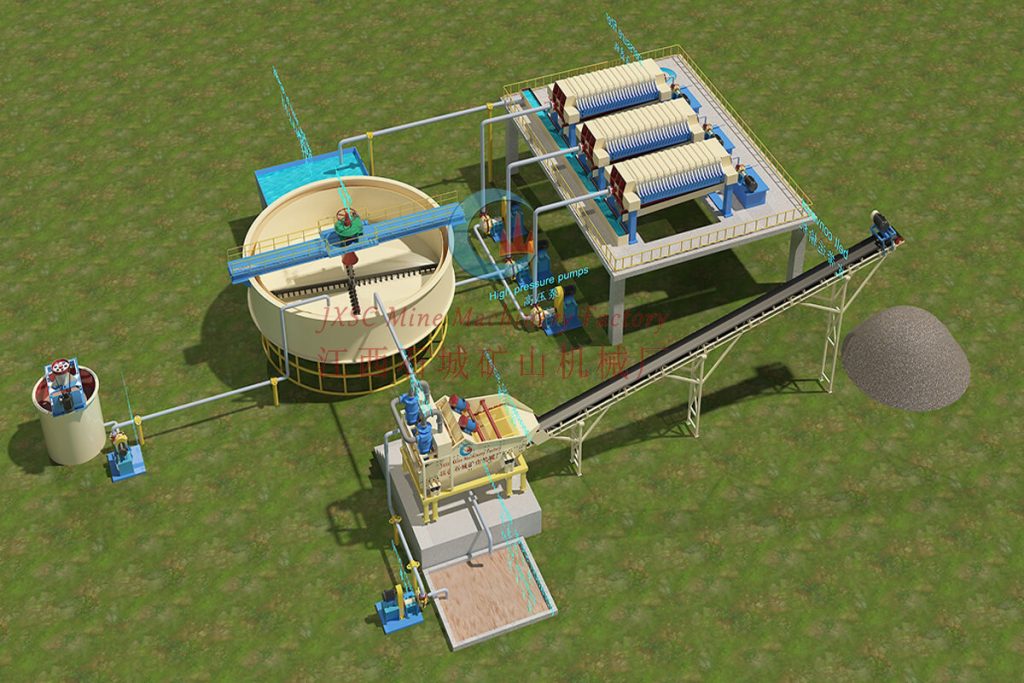

3. Laterite Chrome Processing Plant

Lateritic chromite deposits, characterized by high iron content, clay-bound structures, and variable moisture (2-8%), often contain impurities such as nickel and iron. JXSC specializes in advanced laterite chrome extraction process designed to recover chromium efficiently from complex ores.

Lateritic Chrome Processing Plant Flow

1. Ore Pre-Treatment & washing – High-pressure rotary scrubbers remove sticky clay coatings and reduce moisture to <3%, critical for downstream processes.

2. Crushing & screening – Three-stage crushing circuit with dual vibrating screens achieves 95% -3mm particle size.

3. Gravity separation – Spiral concentrators + shaking tables recover 82-88% Cr₂O₃.

4. Magnetic separation – High-intensity drum magnets upgrade concentrate to 44-48% Cr₂O₃.

5. Flotation optimization: Reverse flotation with anionic collectors removes residual silica.

6. Tailings management & water recycling – Produce dry tailings by thickener and filter press for safe disposal or repurposing.

Tailor-made Lateritic Chrome process plant:

- 95%+ Recovery Rate.

- The concentrate grade increased to over 48%.

- Water & energy consumption are 25% lower vs. competitors.

Maximize your chrome plant recovery rate = higher profit

Our chrome processing plant uses a multi-stage process including washing and screening, crushing and grinding, gravity separation, and magnetic separation to purify the Cr₂O₃ content from 20-30% to over 48%, meeting industrial-grade requirements.

JXSC mineral processing covers the entire process from roughing to fine separation to tailings treatment, and has been successfully applied for alluvial, rock, or laterite chromium ore projects in South Africa, Kazakhstan, Turkey, Zimbabwe, and other countries around the world. From laboratory testing to industrial-grade production lines, we not only meet one-stop small-large turnkey solution needs, but also help you reduce costs, increase capacity, and comply with environmental regulations.

Chrome Plant Equipment

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.