As an important natural resource, seaside/beach sand is widely distributed near coastlines worldwide. Due to its unique physical and chemical properties, it has important application value in many industrial fields. Whether in construction, glass manufacturing or casting, or in the ceramic industry, chemical industry, and environmental protection engineering, beach sand is one of the important raw materials for production. However, in addition to common light minerals such as quartz and feldspar, beach sand also contains a small amount of heavy minerals with high economic value, such as ilmenite, zircon, rutile, etc. These heavy minerals are important in high-tech materials, aerospace, and special alloys. Therefore, how to effectively extract these heavy minerals has become the key to the efficient use of beach sand resources.

The emergence of gravity separation technology has provided a new option for the processing of beach sand. Among them, beach sand gravity separation mainly includes spiral chute, shaking table or other equipment, which can efficiently separate heavy minerals from light minerals. As a multi-purpose natural resource, the efficient use of beach sand is inseparable from the participation of gravity separation equipment, which is also a key tool for extracting high-value minerals.

Beach Sand Introduction

Beach sand refers to sand distributed near the coastline, including sand sediments in areas such as beaches, shallow seabeds and intertidal zones. It is mainly composed of minerals such as quartz, feldspar, and mica. It is a sediment formed by long-term natural weathering, erosion and transportation, and has unique physical and chemical properties. Its particle size is uniform, but its composition is complex, and it contains a small amount of heavy minerals, such as ilmenite, zircon, and rutile. Although these minerals are low in content, they all have high economic value.

Economic value of beach sand

- Construction sand: as the main component of concrete and mortar.

- Industrial minerals: extract ilmenite, zircon, rutile, etc. for special material production.

- Rare metals: contain a small amount of rare metal elements and have high economic value.

The beach sand beneficiation flow can effectively enrich heavy minerals, such as ilmenite, zircon, rutile, etc. In particular, gravity separation can extract high-purity quartz sand, silica sand and other construction and industrial sand from beach sand. These high-value minerals can be concentrated and recycled and utilized, thereby improving the market value and benefits of beach sand.

Beach Sand Gravity Separation Application

Common heavy minerals in seaside placer mines include rutile, ilmenite, magnetite, etc. The density of these minerals is greater than that of light minerals, so the use of gravity separation method for extraction and mineral processing is the best solution.

Gravity separation equipment

Specifically, beach sand gravity separation equipment mainly includes spiral chutes and shaking tables, which can quickly and accurately separate high-density heavy minerals (such as ilmenite, zircon, rutile, etc.) in beach sand from low-density gangue minerals such as quartz and feldspar. This process not only improves the recovery rate and purity of heavy minerals, but also significantly improves the economic value of beach sand beneficiation. Through multi-stage beneficiation processes such as roughing, concentrating and scavenging, the target minerals can be enriched to the maximum extent to ensure the effective use of resources.

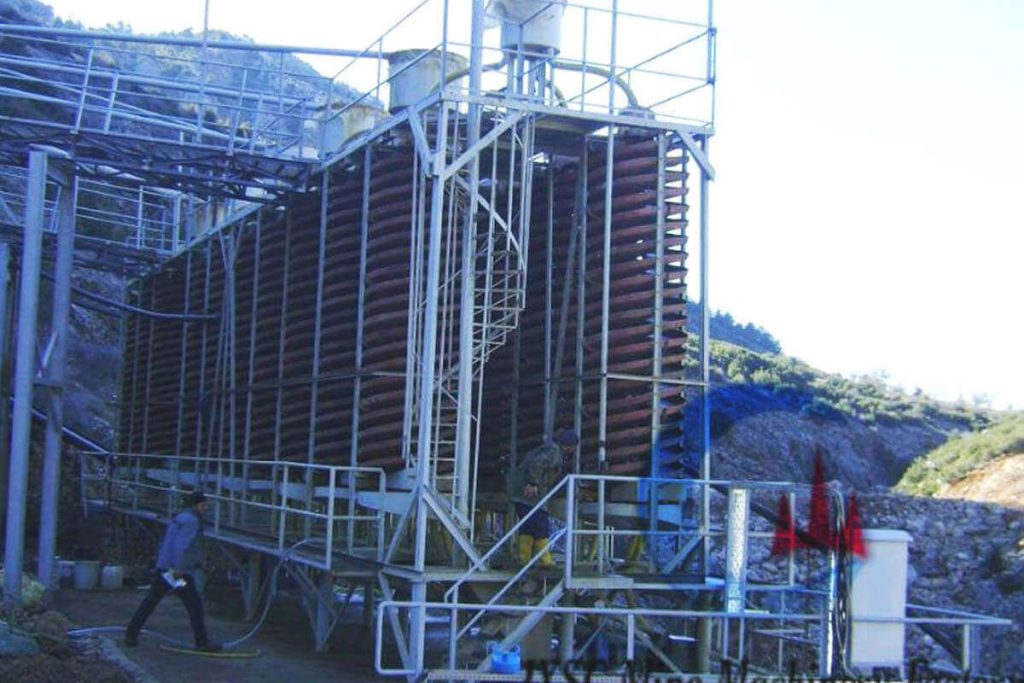

- The spiral chute uses the centrifugal force and gravity in the spiral trough to separate the minerals. It is suitable for the separation of coarse-grained and fine-grained beach sand.

- Shaking table separates minerals of different densities through the inclined bed surface and the action of water flow. It is suitable for processing fine-grained beach sand and separating heavy minerals.

Specific applications

(1) Separation of high-density minerals:

Gravity separators can accurately separate heavy minerals (such as ilmenite and zircon) from light minerals in seaside sand to ensure the effective recovery of target minerals.

(2) Multi-stage mineral processing:

Through multi-stage processes such as roughing, concentrating and scavenging, gravity separation equipment can maximize the enrichment of target minerals and improve the overall mineral processing efficiency.

- Roughing stage: Use spiral concentrator for preliminary separation to remove most of the light minerals and obtain rough concentrate. Large processing capacity, low cost, and can quickly enrich heavy minerals.

- Concentration stage: Use shaking table to further separate the rough concentrate to obtain high-grade heavy mineral concentrate. High separation accuracy can effectively remove impurities and improve the purity of heavy minerals.

(3) Efficient utilization of resources:

The gravity separation process can effectively extract valuable minerals from seaside sand, reduce resource waste, and improve the comprehensive utilization level of resources.

(4) Environmental protection:

Gravity separation mainly relies on physical methods, without the use of chemical agents, reducing pollution to the environment, and meeting the requirements of green mineral processing and sustainable development.

Therefore, gravity separation plays the most critical role in seaside sand beneficiation, which not only improves the beneficiation efficiency and product quality, but also promotes the efficient utilization of resources and environmental protection.

Beach Sand Beneficiation plant

100TPH beach sand gravity separation plant

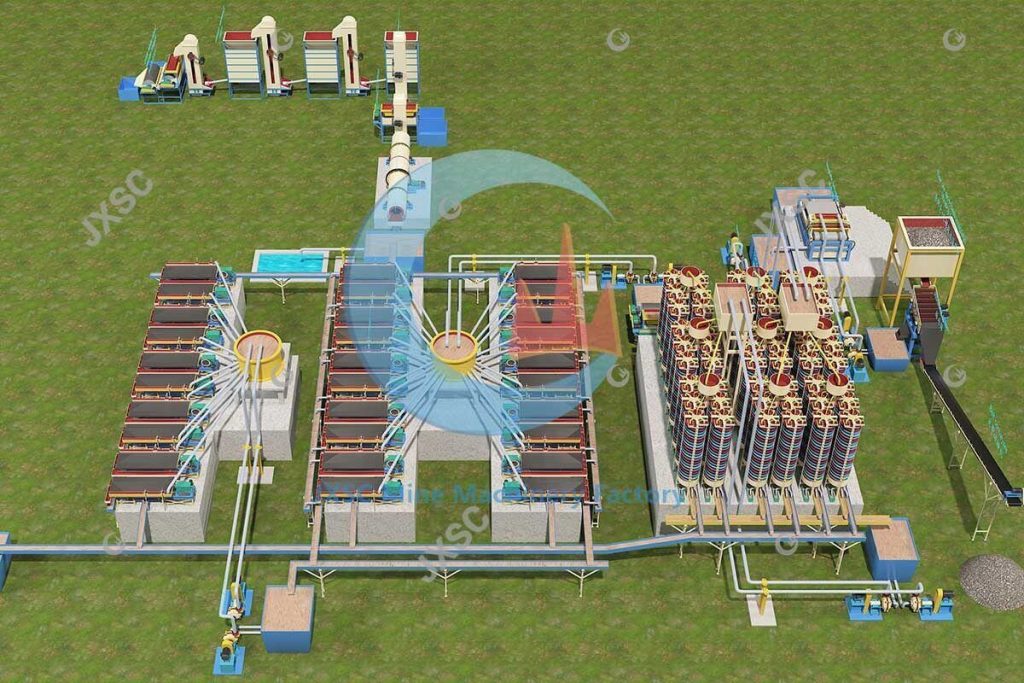

This is a 100 t/h beach sand processing plant, complete plant is configured with the below machines and flowchart:

- Excavator or Loader feed raw sand to raw ore bin, then through the electromagnetic vibrating feeder to feed vibrating screen (with one layer screen with 2mm mesh size, in order to remove above 2mm impurities).

- Below 2mm go to magnetic separator by slurry pump for separating out magnetite. Output of magnetic separator are sent to spiral chute by a slurry pump. Through gravity separation method to remove light minerals.

- Spiral chute has two stages: the middling from first stage spiral chute plant go to second stage spiral chute for reprocessing.All concentrates from two stages spiral chute groups are sent to 1st double drum magnetic separator for separating out ilmenite.

- Output of 1st double drum magnetic separator are sent to shaking table by slurry pump for removing light minerals by gravity principle.

- The 8sets shaking table has two stages: the middling from the first stage shaking table is sent to the second stage shaking table for further processing by a slurry pump. All concentrate from two stages shaking table is sent to the rotary dryer for drying material. After drying, dry materials through hoist machine to 2nd double drum magnetic separator for separating out ilmenite.

- Other minerals from 2nd double drum magnetic separator go to 1st, 2nd, 3rd electrostatic separator through hoist machine for separating out rutile.

- Then,materialsfrom the 3rd electrostatic separator go to the double roller strong magnetic separator via hoist machine for separating out zircon and monazite.

Gravity separation plays an irreplaceable role in the beach sand mineral processing process. Its high efficiency separation, strong adaptability, low energy consumption, and environmental friendliness make it a key technology to enhance the economic value of beach sand and achieve efficient resource utilization. In addition, it is usually necessary to use magnetic separation, electrostatic separation, dehydration or drying processes to jointly separate beach sand to improve the purity and recovery rate of minerals. How to determine the beach sand beneficiation process and equipment depends mainly on each type of ore. It is usually necessary to conduct mineral type analysis, find out the mineral composition, and then conduct mineral processing experiments to determine the best beneficiation solution. Contact us for the latest details!