Still struggling to choose the right rock gold crushers? In today’s booming gold mining industry, selecting the best rock gold crushers often determines your production efficiency and profitability. With global gold prices continuing to rise, the market demand for high-efficiency crushing equipment is also constantly increasing. As a core piece of equipment in the gold ore beneficiation process, the market offers a wide range of crushers, from compact and portable mini models to heavy-duty industrial-grade crushing systems, making the selection process inevitably difficult. This article will provide you with a professional 2026 purchasing guide by deeply analyzing mainstream crusher types and comparing the advantages and disadvantages of various brands and models.

Rock gold crushers are available in jaw crushers, cone crushers, hammer crushers, impact crushers, and double roll crushers. First, consider output and ore hardness to match small, medium, or large models. Then, consider your budget; for frequent relocations, choose a mobile crushing plant; for fixed mining sites, prioritize modular designs. Finally, compare durability and after-sales service.

Types of Rock Gold Crushers: Pros VS Cons

1. Jaw Crusher

✔️ Advantages:

The rock gold jaw crusher is one of the most commonly used pieces of crushing equipment in gold mining. It utilizes the principle of “compression crushing,” where large rocks are crushed into uniform particles through the reciprocating motion of the movable and fixed jaw plates. Its greatest advantage lies in its durability, making it particularly suitable for processing high-hardness ores (such as quartz vein gold ore). Under long-term continuous operation, the jaw plates and core components are made of high-manganese steel, providing excellent wear resistance. Furthermore, its simple structure and low failure rate make it popular in small and medium-sized mines.

❌ Limitations:

However, jaw crushers also have significant disadvantages, such as high energy consumption (motor power is generally between 15-200kW, resulting in high operating costs). Additionally, its discharge particle size adjustment range is limited, typically around 10-350mm; further finer crushing requires secondary processing. The single-unit processing capacity is moderate, making it more suitable for combination with subsequent fine crushing equipment such as hammer crushers or cone crushers to form a complete gold crushing production line.

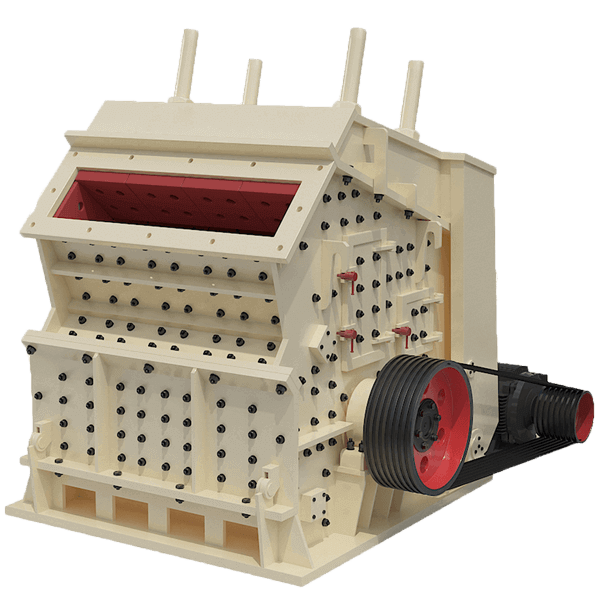

2. Impact Crusher

✔️ Advantages:

The rock gold impact crusher adopts the principle of “high-speed impact crushing,” using a rotor to drive the hammers to rotate at high speed, crushing the ore under impact and counter-attack. This type of machine is very suitable for crushing weathered placer gold deposits or brittle ores with high gold content. Its advantages lie in the good output particle shape, low needle-like and flaky content, and reduced energy consumption in subsequent grinding. The equipment has a compact structure and can be combined with a mobile chassis to form a mobile crushing station, flexibly adapting to the dispersed nature of gold mining sites.

❌ Limitations:

The impact crusher has a high metal wear rate, especially the hammers and impact plates, which are prone to damage under long-term high-load operation. The maintenance and replacement cycle is shorter than that of a jaw crusher. At the same time, its processing capacity for high-hardness primary ores (such as quartzite) is limited, and the crushing efficiency will decrease significantly. In ore environments with high silica content, the wear problem is more serious, leading to increased operating costs.

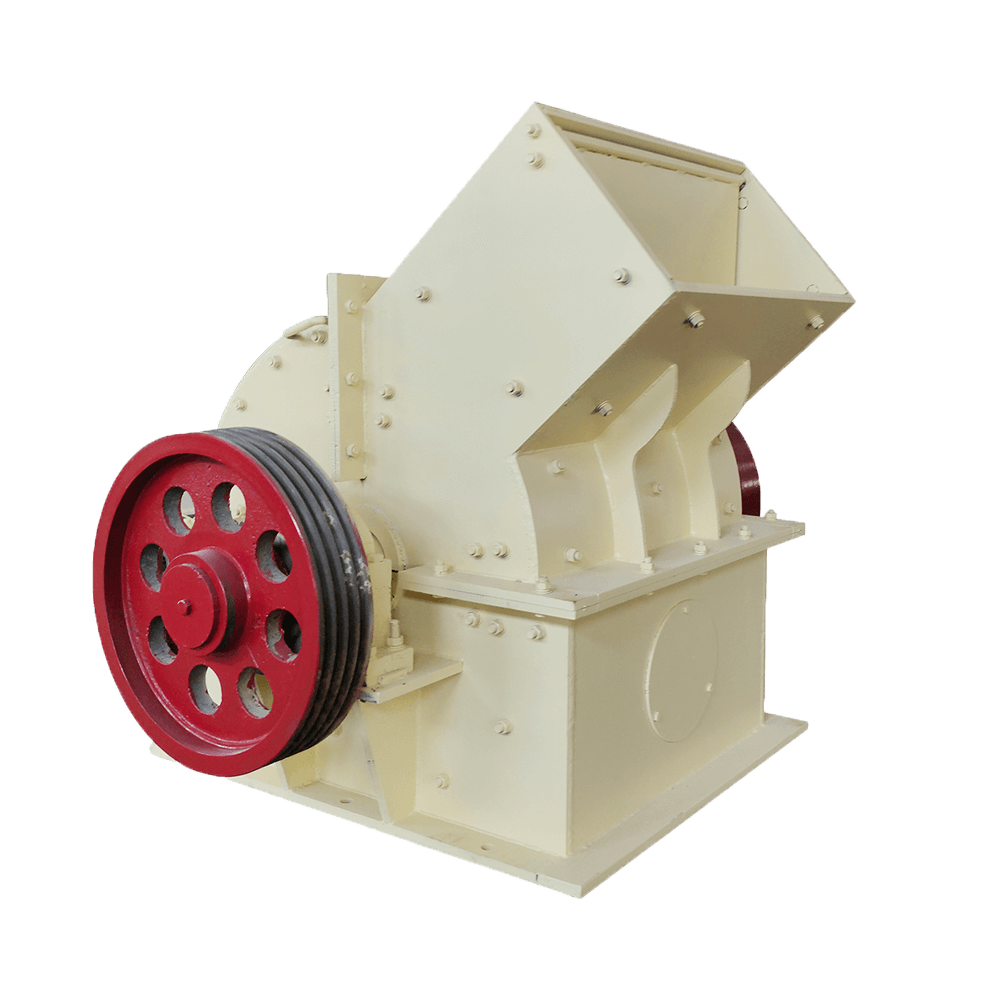

3. Hammer Crusher

✔️Advantages:

The working principle of a rock gold hammer crusher is similar to that of an impact crusher, but its overall structure is simpler, making it commonly used in low-budget scenarios. It relies on high-speed rotating hammers to directly strike the ore, suitable for medium to fine crushing of medium-hardness gold ores. The biggest advantage of this equipment is its economical price, making it suitable for small mines or individual gold prospectors with limited budgets. Its single-machine processing capacity is flexible, serving as both primary and secondary crushing.

❌ Limitations:

Hammer crushers have significant disadvantages, particularly in handling large, hard rocks. Furthermore, the hammers wear out quickly and require regular replacement, resulting in considerable long-term operating costs. Due to its open rotor design, dust and noise pollution are severe, and mines with high requirements for the working environment may need to install additional dust removal and noise reduction devices.

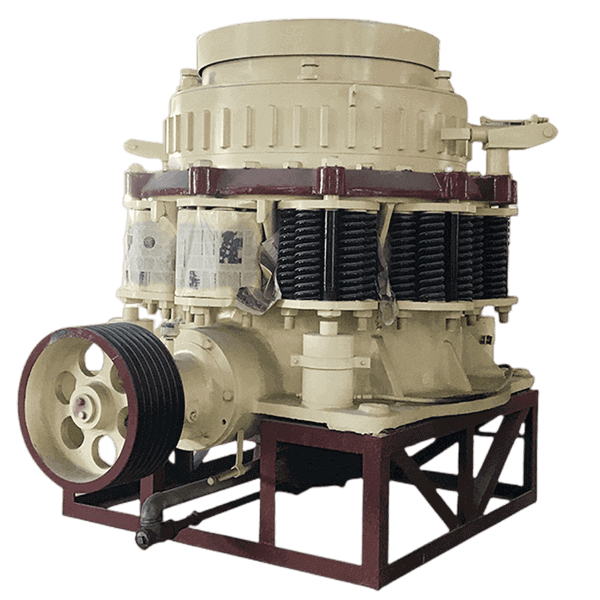

4. Cone Crusher

✔️ Advantages:

The cone crusher is a highly efficient medium-fine rock gold crushing equipment suitable for large and medium-sized gold mine beneficiation plants. It adopts the principle of layered crushing, achieving progressive compression of the ore through the relative movement between the moving and fixed cones, producing finished products with uniform particle size and cubic shape, which is beneficial for subsequent gravity separation or leaching processes. It has a higher throughput (up to 1200 t/h), suitable for large-scale production. Its advantage lies in the advanced models equipped with an automated control system, which can adjust the discharge port size and crushing force in real time.

❌ Limitations:

The initial investment cost of a gold-bearing cone crusher is relatively high, and it requires a high level of expertise from operators and maintenance personnel. Regular replacement of wear parts such as the mantle and crushing wall is necessary. Small mines may find it difficult to afford. The equipment structure is relatively complex, and maintenance and adjustment require certain professional technical support. Furthermore, it is sensitive to the moisture content of the ore, and is prone to clogging when processing ores with high mud content, requiring the use of a vibrating feeder or ore washing equipment.

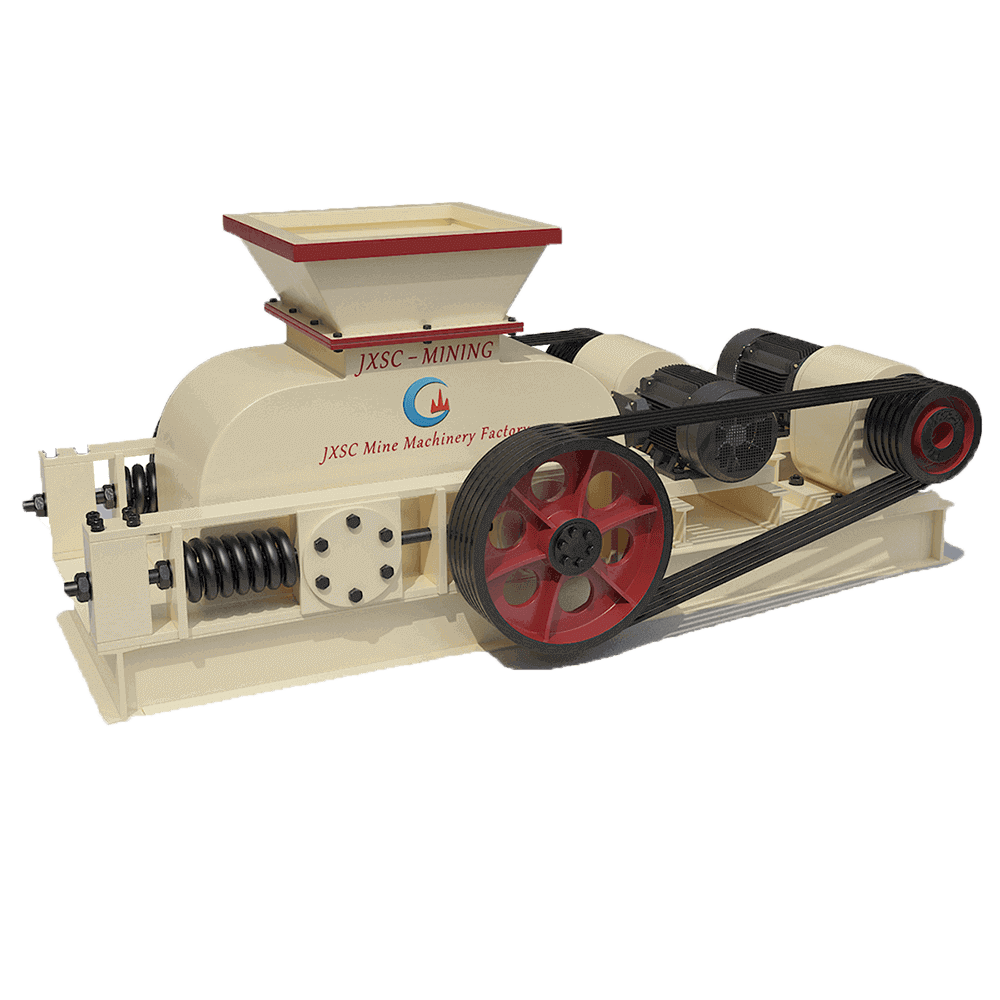

5. Double Roll Crusher

✔️ Advantages:

The double roll crusher uses two opposing rotating rollers to crush materials. It is a fine processing type of rock gold crushers that still plays a role in gold ore beneficiation, especially suitable for processing brittle and soft gold ores, and for beneficiation processes with strict requirements on product particle size. Its advantages include simple structure, low operating noise, low dust pollution, and precise control of the output particle size. By adjusting the roller spacing, a uniform product within the range of 1-50mm can be obtained. The equipment operates stably and is easy to maintain, requiring only periodic checks of roller wear and the lubrication system.

❌Limitations:

However, since the roller surface directly contacts the ore, wear is a significant issue, requiring regular repair or replacement of the roller surface. The processing capacity is relatively low compared to other models (generally not exceeding 150t/h), making it unsuitable for large-scale production lines. There are strict limitations on the feed particle size (usually not exceeding 50mm), and it must be used in conjunction with pre-screening or primary crushing equipment to achieve the best results.

Rock Gold Crushers For Sale: 5 Key Buying Guide

(1) Production Capacity

- Small-scale gold mines (<50t/d) can use hammer crushers or small jaw crushers, which are low-investment and easy to operate.

- Medium-sized gold mines (50-500t/d) are recommended to use a combination of jaw crusher and cone crusher, balancing efficiency and cost.

- Large-scale gold production lines (>500t/d) require a multi-stage crushing system; it is recommended to choose high-end models with automated control.

When purchasing rock gold crushers, a 20% capacity margin should be reserved to avoid overloading.

(2) Ore Hardness

- Soft gold ore (hardness <5) or small-scale laboratory crushing scenarios: Hammer crushers are used to achieve efficient crushing at low cost.

- Medium-hard ore (5-7): Impact crushers are preferred to obtain better output particle shape.

- Extremely hard ore (>7): Such as quartz vein type gold mines, jaw crushers and cone crushers must be used, as their high-strength crushing chambers and wear-resistant liners provide greater stability. For ores with high silicon content, special attention should be paid to wear-resistant design; rock gold crushers models with high-chromium liners are recommended.

(3) Budget Range

- Small mines or individual gold miners with limited budgets can choose domestic hammer or small jaw crushers in the 50,000-150,000 RMB range to meet basic crushing needs.

- With a budget of 200,000-500,000 RMB, medium-sized jaw crushers or cone crushers are available, offering stable performance and high cost-effectiveness.

- With a budget of over 500,000 RMB, consider imported brand equipment or mobile crushing plants, which feature advanced automated control systems and longer service life.

(4) Portability

Do you need mobile rock gold crushers? It’s suitable for operations requiring frequent relocation, but the price is 30%-50% higher than that of stationary crushers. Tracked crushers are mainly suitable for complex terrain, while wheeled crushers are convenient for road transport.

(5) Durability & After-Sales Support

International brands are durable but have higher maintenance costs; leading domestic brands offer better value. The key is to consider the bearings, hydraulic system, and wear-resistant parts configuration. When purchasing, comprehensively compare brand reputation and after-sales service systems. JXSC has 40 years of experience in equipment manufacturing and supply. We welcome you to visit our rock gold crushers at any time to inspect the materials and usage.

Conclusion

When selecting rock gold ore crushers, five core factors need to be considered: output requirements, ore hardness, budget range, site portability, and after-sales service. A proper comparison of the advantages and disadvantages of different models will help you significantly improve production efficiency and reduce losses. The design of the mobile or stationary rock gold crushers should be flexibly selected based on the operating scenario. JXSC provides professional selection guidance and customized crushing solutions to help you accurately match your production needs. For further consultation or to obtain configuration information for mineral processing equipment, please contact our technical team!