Fluorite Mineral Jig Process Flow

The main component of fluorite ore is calcium fluoride, which is mainly used in metallurgy and chemical industries. Metallurgical grade fluorite mines are mostly granular or lumpy high-grade fluorite ore. Fluorite for chemical industry is mainly used to produce hydrofluoric acid, called acid-grade fluorite ore, which is high-quality fluorite fine powder. Here is a detailed introduction to the mineral jig process of metallurgical grade fluorite ore for reference!

fluorite

fluorite process flow

Metallurgical grade fluorite ore is mostly granular or lumpy, which requires fluorite ore beneficiation equipment to be able to sort coarse fluorite ore.

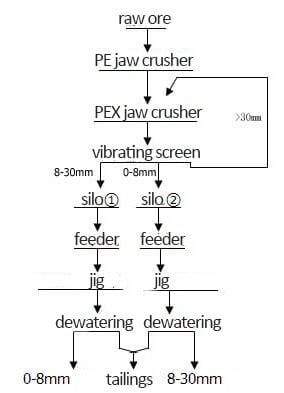

The jig machine can sort fluorite ore with a size of 0-50mm. Most metallurgical grade fluorite mines usually adopt gravity separation equipment. The following is the metallurgical grade fluorite ore production process flow chart.

1. crushing

Metallurgical grade fluorite ore concentrate is required to be granular high-quality fluorite ore, but fluorite is brittle and fragile. Therefore, the crushing process must be considered to be able to crush the raw ore to the selected particle size range of the beneficiation equipment without producing too much powder. .

The simple and practical jaw crusher is the main equipment for fluorite ore crushing. The crushing process uses PE series and PEX series jaw crushers to coarsely and finely crush the raw ore, which not only crushes the raw ore to the effective size range of the jigging machine, but also avoids the generation of powdery fluorite ore.

2. screeing

The screening equipment of fluorite ore needs to be determined according to the mud content of the original ore.

If the raw ore contains a large amount of sticky mud, slime, it is recommended to use a trommel scrubber to minimize the blockage of the screen holes. In addition, adding water to the trommel can play the role of washing ore. If the raw ore does not contain mud, it is a rock and the water content is very low, and the circular vibrating screen can be used for efficient screening.

The process flow in the above figure uses a vibrating screen, which divides the crushed materials into three levels, 0-8mm particle size enters the silo ②, 8-30mm enters the silo ①, and the material larger than 30mm returns to the crushing process to be crushed again.

3. jig processing

This process uses two different specifications of jig machine equipment to sort 0-8mm and 8-30mm fluorite ore. In order to improve the beneficiation effect and processing capacity, it is recommended to set up the silo and feeder before the jig to ensure the normal and stable operation of the jig.

4. dewatering

The jig machine uses water as the beneficiation medium, so the concentrate and tailings discharged by the jig machine have a large water content, and simple dehydration operations are required. We recommend the use of high-efficiency dewatering screens, which can greatly reduce the surface moisture of the minerals and play a dewatering effect . The excess water is returned to the circulation tank for continued use.

conclusion

JXSC is a professional manufacturer of diaphragm jigs and auxiliary equipment, and is very expert in the production process of metallurgical grade fluorite ore. Our products are sold to 40+ countries and regions.

Support customization, engineer site inspection, installation and commissioning services. We can carry out small-scale ore washing tests for customers free of charge, design process flow and equipment configuration, and welcome you to inquire. Please contact us.