Are you still relying on time-consuming, labor-intensive, and inefficient traditional gold mining methods? Statistics show that by 2025, over 60% of global placer gold mines will utilize gravity separation as their core gold extraction method. Facing increasingly stringent environmental regulations and declining gold ore grades by 2026, gravity sorting avoids the high costs and environmental risks associated with chemical leaching, purely utilizing the significant density difference between gold and gangue minerals for physical separation. Gravity gold sorting machines, as the key technology in this process, not only significantly improve gold enrichment and recovery rates but are also the inevitable choice for moving towards green mining.

Gravity gold sorting machines utilize the density difference between gold and gangue minerals. Separation is achieved through equipment such as jigs, shaking tables, centrifugal concentrators, and spiral chutes. This physical separation process is non-polluting and complies with environmental regulations, making it an ideal choice for large-scale gold processing plants in 2026.

Basic principle of Gravity Gold Sorting Machines

(1) Density Difference Separation Theory

Gold has a density of 19.3 g/cm³; while gangue minerals, such as quartz, have a density of 2.65 g/cm³. This significant density difference is the core basis of gravity gold sorting. This density difference enables gold particles to settle significantly faster than gangue particles in the same fluid environment, thereby achieving optimal separation.

(2) Particle Stratification Mechanism

In gravity sorting, particle stratification depends not only on density differences but also on fluid dynamics. Bagnold’s inter-particle shear repulsion theory verifies this behavior. When a group of particles is subjected to different flow fields, such as vertical flow, inclined flow, and rotational flow, high-density particles (like gold) accumulate downwards due to inertia, while low-density particles (like quartz) are pushed to the upper layer.

(3) The Role of the Medium

The buoyancy of water reduces the effective weight of the mineral particles, making them easier to move in the flow field. The dynamic action of the fluid can loosen the particle group, creating conditions for particle stratification. In addition, in some special mineral processing scenarios, such as the separation of tungsten-tin co-existing ores, heavy medium separation is used. This involves a suspension mainly composed of high-density solid particles and water. By adjusting the density of the medium, gold settles while lighter minerals float.

Types of Gravity Gold Sorting Machines

In the field of gravity gold sorting, different equipment plays a crucial role in various mineral processing scenarios due to its unique performance characteristics. Understanding the advantages and applicable scope of each type of equipment is essential for optimizing the mineral processing process and improving gold recovery rates. The following will provide a detailed analysis of 4 mainstream gravity gold sorting machines: jigs, shaking tables, spiral concentrators, and centrifugal concentrators.

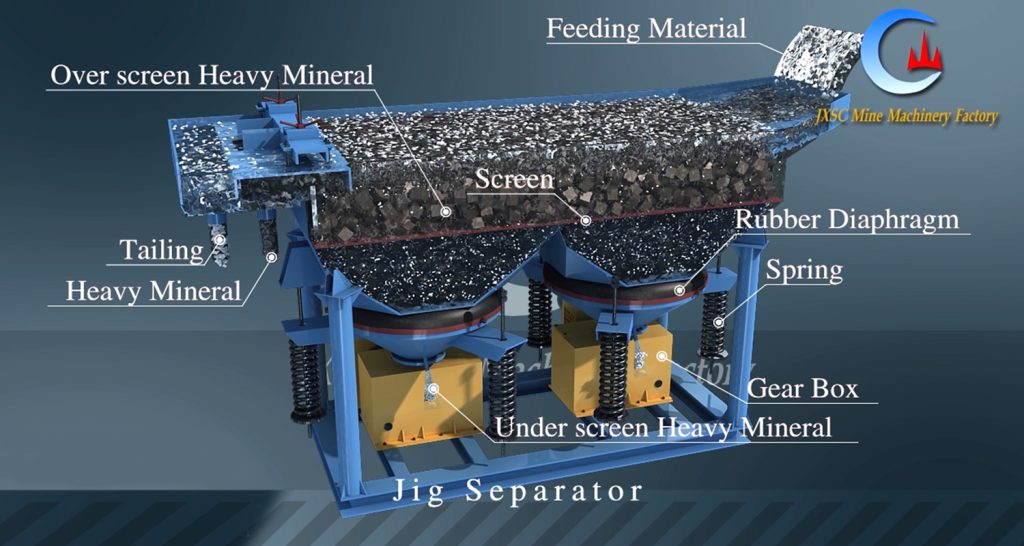

1. Jig Separator

Jig separators primarily utilize pulsating water flow to cause mineral particles to periodically loosen and compact within the bed, separating gold from gangue based on density differences. Their core advantage lies in the efficient processing of coarse gold particles, and they are often used as a primary separation method for placer gold or vein gold deposits. In large-scale gold mining operations, jig separators can serve as roughing equipment, quickly concentrating most of the gold particles and reducing the burden on subsequent refining processes.

Technical Features:

Processing Capacity: Each unit can process 1-25 tons of ore per hour, suitable for large-scale production.

Low Energy Consumption: Primarily driven by mechanical or air pulse mechanisms, consuming over 30% less electricity than centrifugal equipment.

Applicable Scenarios: Suitable for placer gold deposits, weathered gold deposits, or used in combination with shaking tables or spiral chutes to improve recovery rates.

Limitations:

Poor recovery efficiency for fine gold particles (<0.074mm), requiring secondary concentration using shaking tables or centrifuges.

Requires regular cleaning of the screen to prevent clogging, resulting in higher maintenance frequency.

2. Centrifugal Concentrator

The centrifugal concentrator is a device specifically designed for the recovery of fine-grained gold. It utilizes a centrifugal force field to enhance the separation process, effectively recovering extremely fine gold particles. Under the action of centrifugal force, the centrifugal force acting on the mineral particles is far greater than gravity, allowing fine-grained gold to settle rapidly and be recovered. The recovery rate is over 90%, making it particularly suitable for recovering “floating gold” that is difficult to capture with other gravity gold sorting machines.

Technical Features:

High recovery rate: Significant recovery effect on fine gold particles smaller than -200 mesh (74 microns).

High degree of automation: Can be integrated with a PLC control system to adjust rotational speed and flushing water pressure in real time.

Applicable scenarios: Tailings reprocessing, low-grade oxidized ores.

Limitations:

High energy consumption: The motor power is 3-5 times that of a jig concentrator, resulting in higher operating costs.

Complex structure: Requires high manufacturing precision, leading to higher maintenance costs.

3. Spiral Chute

The spiral chute is a simple and energy-efficient gravity-based gold sorting machine, primarily used for processing gold ore with a particle size of 0.02-0.2 mm. It utilizes the centrifugal force, gravity, and friction generated as the ore slurry flows through the spiral channel, causing mineral particles of different densities to move along different areas of the channel surface. Gold particles gradually concentrate towards the inner edge of the channel. In the roughing stage of placer gold and low-grade vein gold mining, the spiral chute can achieve efficient pre-concentration, reducing the amount of ore processed in subsequent beneficiation steps. It is widely used in small and medium-sized mines and gold mining operations in remote areas.

Technical Features:

No power source is required, resulting in low operating costs.

It has a simple structure, occupies a small footprint, and consumes little energy.

Limitations:

The sorting accuracy is relatively low, making it difficult to obtain high-grade concentrates; therefore, it needs to be used in conjunction with shaking tables or other beneficiation equipment.

The fixed spiral diameter results in a limited range of throughput adjustment.

4. Shaking Table

The shaking table primarily utilizes the combined action of the reciprocating differential motion of the table surface and the transverse water flow to separate mineral particles based on differences in density and particle size, resulting in a fan-shaped distribution on the table surface, with gold particles gradually concentrating at the concentrate end. Its separation accuracy can reach over 90%, effectively recovering fine gold particles missed by other equipment. However, the processing capacity of a single unit is relatively small, and it is typically used as a subsequent refining device after jigs and spiral concentrators.

Technical Features:

It offers optimal separation performance for gold ore in the 0.074-2mm particle size range.

The unique riffle groove design generates secondary vortices, improving the capture rate of fine gold particles.

Limitations:

Low processing capacity per unit area, requires a multi-layer arrangement to increase throughput.

The equipment occupies a large area and requires specialized feeding and discharge devices, resulting in high infrastructure costs.

The shaking table is sensitive to the degree of ore slime content; if the pulp contains too much slime, it will cause mineral particles to adhere to the table surface, severely affecting the separation effect.

New Trends in Gravity Gold Sorting Technology in 2026

In 2026, with the increasing depletion and lower grade of mineral resources and the continuous improvement of environmental protection requirements, gravity gold separation technology will develop towards intelligence, high efficiency, and low carbon emissions. On the equipment side, there will be a deeper integration with sensor technology; for example, traditional equipment such as jigs and shaking tables will be able to dynamically adjust parameters such as stroke and slope in real time based on ore particle size and composition. In addition, modular and mobile gravity gold sorting machines will become increasingly popular, flexibly adapting to the operational needs of small mines and remote mining areas, reducing infrastructure costs and resource waste.

Conclusion

Gravity gold sorting machines remain the core stage for gold beneficiation due to their advantages of low energy consumption, high recovery rate, and environmental friendliness. Jigs, shaking tables, centrifugal concentrators, and spiral chutes each have their own characteristics and are suitable for different particle sizes and ore types.

If you are looking for a customized gold ore processing solution, our team of experts can recommend the optimal equipment combination and process flow based on your ore characteristics, production capacity requirements, and budget. Contact us today for personalized technical support and efficient recovery solutions!