In gravity separation, which equipment can efficiently separate minerals while significantly reducing production costs? The answer is undoubtedly the mineral shaking table. Through the reciprocating motion of the deck and the action of transverse water flow, it achieves precise separation of mineral particles with different densities. With its excellent separation accuracy and extremely low operating costs, it has become the preferred tool for the beneficiation of tantalum-niobium, tin, gold, copper, and chromium ores worldwide. Whether for the separation of metallic or non-metallic minerals, the shaker table proves its irreplaceable value with a metal recovery rate of over 95%. Next, let’s delve into the working principle, core advantages, and beneficiation application of the shaking table to help you unlock the secrets of low-cost, high-return beneficiation solutions.

Mineral shaking table, with their high precision and low energy consumption, have become a core piece of equipment in the mineral processing industry. It is widely used for the separation of metal and non-metal ores such as gold, tungsten, tin, iron, chromium, tantalum, niobium, and copper. Particularly effective in the recovery of fine-grained minerals, offering simple operation, environmental friendliness, and aligning with the needs of sustainable beneficiation development.

What is a mineral shaking table?

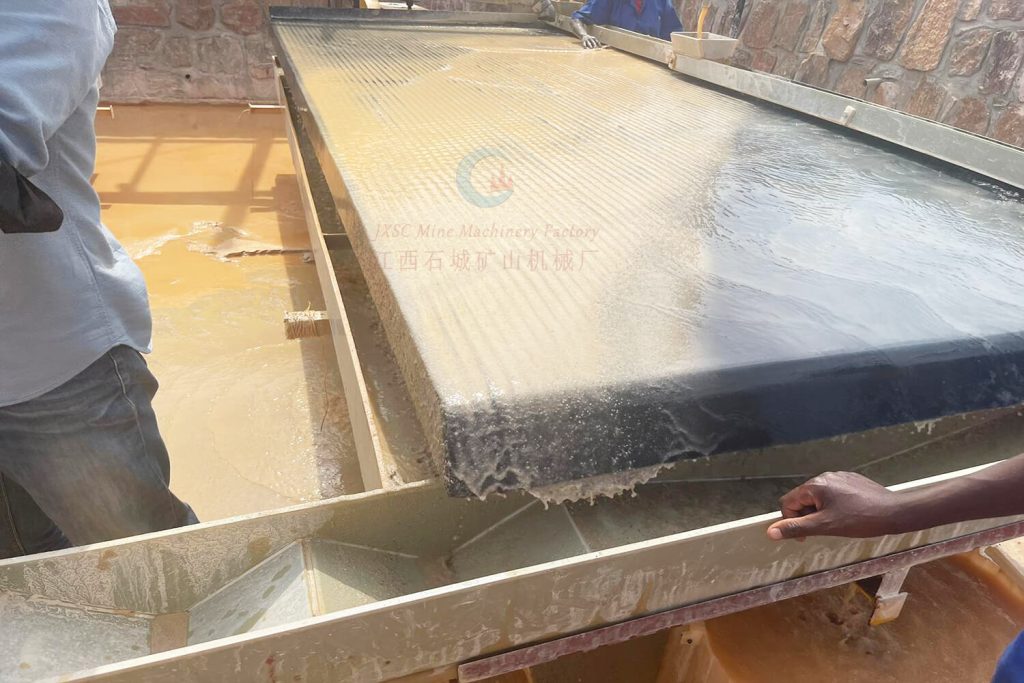

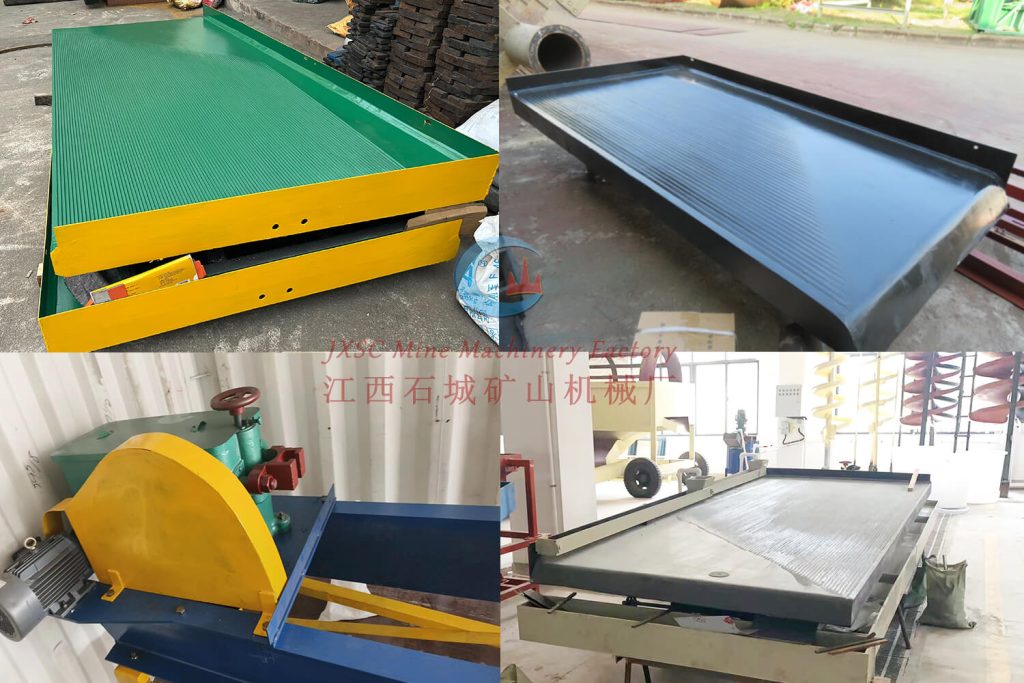

The mineral shaking table is a gravity separation equipment used for sorting fine-grained materials. Its main structure includes the table surface, transmission mechanism, and frame. Unlike traditional flotation or magnetic separation, the shaker table uses precisely controlled reciprocating asymmetrical motion to achieve chromatographic separation of mineral particles of different densities within the grooves of the table surface. The 6S shaking table is the most common type, dominating the African mining market thanks to its double-layer table surface and simplified cam mechanism.

Core Principle:

The working principle of a mineral shaking table is based on utilizing the density differences of mineral particles and the asymmetrical reciprocating motion of the table surface, combined with the scouring action of a transverse water flow, to achieve stratification and separation of the mineral particles. This results in different products such as concentrate, middlings, and tailings.

Detailed Process:

- Stratification: The water-mineral mixture is spread across an inclined surface. The reciprocating motion of the surface loosens and stratifies the mineral particles; denser particles settle to the bottom layer, while less dense particles float to the upper layer.

- Longitudinal Movement: The reciprocating motion of the surface applies a thrust force to the mineral particles. Denser particles, due to their greater inertia, experience a larger longitudinal displacement relative to the surface and gradually move towards the concentrate end.

- Transverse Water Flow Flushing: The transverse water flow flushes the low-density, fine-grained particles in the upper layer, carrying them to the tailings side of the surface.

- Fan-shaped Separation: Mineral particles of different densities and sizes eventually accumulate in different areas of the surface, forming fan-shaped distribution zones, thus achieving the separation of concentrate, middlings, and tailings.

Types of mineral shaking tables

Classification by Processed Raw Materials:

- Coarse sand shaking table: Designed for coarse-grained ores with a particle size of 2 – 0.5 mm, the riffle height on the table surface is higher, allowing for the formation of a thicker ore layer.

- Fine sand shaking table: Suitable for fine-grained ores of 0.5 – 0.074 mm, with a lower riffle height on the table surface and more uniform water flow distribution, enabling precise separation of fine-grained valuable minerals.

- Slime shaking table: Specifically designed for slime materials with a particle size smaller than 0.074 mm, the table surface uses a special grooved or coated structure to slow down the settling speed of the slime and enhance the stratification effect between mineral particles.

Classification by Structural Form:

- Single-layer mineral shaking table: Simple structure, small footprint, suitable for small and medium-sized beneficiation plants or production scenarios with limited space. Easy to operate and maintain, with low initial investment costs, meeting the needs of rough and fine separation of precious metal ores such as gold and silver.

- Multi-layer suspended shaking table: Features a design with two or more superimposed decks, significantly increasing the processing capacity per unit area and effectively saving space. Often used in large-scale beneficiation operations, it can process multiple batches of ore simultaneously, significantly improving production efficiency, especially suitable for batch separation of ores such as tin, tantalum-niobium, and tungsten.

Why is the shaking table the best choice for beneficiation?

5 Major Advantages of Mineral Shaking Tables

✔️High Separation Accuracy:

Whether it’s placer gold, tin(cassiterite), wolframite, tantalum-niobium ore, or zircon sand, the shaking table can achieve a concentrate recovery rate of over 95%, with a stable concentrate grade of over 60%. Spiral chutes typically have a recovery rate of around 80%, with significant fluctuations in concentrate grade. While centrifuges have high processing efficiency, their separation accuracy for fine-grained minerals is slightly inferior, potentially leading to the loss of valuable minerals. Furthermore, it can effectively separate minerals with even small density differences (such as tungsten and tin), which is difficult for other mineral processing equipment.

✔️ High Enrichment Ratio:

The key factor lies in the asymmetrical reciprocating motion of the mineral shaking table, allowing mineral particles to undergo multi-stage separation on the table surface, rather than relying solely on centrifugal force or gravity sedimentation. This highly enriches valuable minerals from the ore, improving resource utilization.

✔️ Intuitive and Controllable:

Operators can directly observe the stratification on the table surface and easily control the separation process by adjusting parameters such as stroke, frequency, slope, and water flow.

✔️ Strong Adaptability:

It can process various types of ores, including materials of different particle sizes such as coarse sand (2 – 0.5mm), fine sand (0.5 – 0.074mm), and slime (-0.074mm). Whether it’s roughing, cleaning, or scavenging operations, the mineral shaking table is capable of meeting the needs of different mineral processing processes.

✔️ Environmentally Friendly and Energy-Saving:

Mining shaker tables utilize the principle of gravity separation, a purely physical separation method that does not require the use of chemical reagents, making it environmentally friendly and relatively low in energy consumption.

Applications of mineral shaking tables in beneficiation

Precious Metal Ore Beneficiation:

The Gold Panning Master Tool

For gold, silver, and other precious metal ores, it is used for roughing, cleaning, and scavenging operations to improve metal recovery rates. It is especially effective in placer gold mining, where the shaking table can directly separate placer gold to obtain high-grade gold concentrate. It can also be configured with a trommel scrubber, a trommel screen, and centrifugal concentrators to form a one-stop mobile gold wash plant. In hard rock gold processing, the mineral shaking table is usually used in conjunction with other beneficiation equipment, such as centrifugal concentrators and flotation, to further improve gold recovery rates.

Ferrous and Non-ferrous Metal Ore Beneficiation:

Dedicated Separation Expert

For copper, lead-zinc, tungsten, tin, iron, chrome, manganese ores, etc., the shaker table can be used to remove impurities and maximize concentrate recovery rates.

Non-metallic Mineral Beneficiation:

Quality Improvement Expert

For fluorite, barite, phosphate ores, etc., it removes impurities and improves ore grade.

Rare Metal Ore Beneficiation:

Key Extraction Equipment

With its unique separation principle and efficient separation capabilities, the mining shaking table has become the preferred equipment for the beneficiation of rare metals such as tantalum and niobium.

Conclusion

Among the numerous gravity separators, why has the mineral shaking table become the gold standard? The answer lies in its unparalleled separation accuracy, extremely low operating costs, and wide applicability. It is equally effective for oxidized ores, weathered ores, fine-grained ores, and coarse-grained ores, making it a true “all-rounder.” If you are looking for a full mineral processing solution and equipment that combines high efficiency, low cost, and strong adaptability, JXSC Mining Machinery Factory is definitely the top choice!