Why are traditional lead-zinc separation methods increasingly unable to meet the demands of the modern mining industry? Lead-zinc, as key mineral resources for the national economy, are widely used in core sectors such as battery manufacturing, metal smelting, and the chemical industry. As global resource demand continues to grow, high-grade, easily beneficiated ores are becoming increasingly depleted, making the separation of low-grade, complex inter-existing ores more challenging. Traditional flotation and gravity separation processes often face bottlenecks such as low recoveries and high inter-concentration in concentrates when processing complex inter-existing ores.

This article systematically analyzes modern technological approaches for efficient lead-zinc separation, such as high-efficiency flotation and combined gravity-flotation processes, and provides mining companies with practical guidance for reducing costs and increasing efficiency.

High-efficiency lead-zinc separation technology: New flotation reagents precisely separate lead and zinc ore, increasing recovery rates to 92%. Combined gravity-flotation separation technology reduces subsequent flotation energy consumption and reagent usage. Electrochemical flotation technology maximizes reagent efficiency. This guide primarily provides a selection guide for lead-zinc ore separation technologies that improve beneficiation efficiency and achieve low-carbon production.

Key Challenges of lead-zinc separation

Lead-zinc ores typically occur as co-occurring minerals, with a mineral assemblage far more complex than that of a single mineral species. Galena (PbS) and sphalerite (ZnS) are the two primary minerals, but actual ores are often mixed with pyrite (FeS₂), quartz (SiO₂), and rare metal minerals such as copper and silver.

However, the distribution of these minerals is extremely uneven—from micron-scale disseminated structures to centimeter-scale massive structures—making it difficult to separate individual minerals using traditional crushing and grinding processes. Especially when the iron content of sphalerite exceeds 10%, as in sphalerite, its surface chemical properties undergo significant changes, further complicating the separation process.

Difficulties in separation

- Microscopic differences in the surface properties of lead-zinc minerals: Galena and sphalerite exhibit highly similar flotation behavior, and conventional xanthate collectors adsorb both.

- The “selectivity-cost” trade-off between reagents: Traditional processes rely on large amounts of selective inhibitors (such as cyanide and potassium dichromate). While this improves separation accuracy, cyanide is environmentally harmful and expensive.

- Slurry system: Low-grade lead-zinc ores often have high clay content. Increased slurry viscosity leads to bubble coalescence, reducing flotation speed by over 30%. High-salinity slurries can damage the molecular structure of reagents, shortening the collector’s ineffectiveness period by 50%.

Lead-zinc separation technologies

1. Flotation Technology

Principle:

High-efficiency flotation technology leverages the differences in the surface physical and chemical properties of lead and zinc minerals to achieve selective separation. Although galena (PbS) and sphalerite (ZnS) often coexist closely, their surface electrical properties, hydrophobicity, and chemical reactivity differ significantly. Specific flotation agents, such as collectors (xanthate, nitrosulfate, etc.), are added to selectively adsorb on the target mineral surface to enhance its hydrophobicity. Simultaneously, inhibitors (such as lime for sphalerite and zinc sulfate for pyrite) are used to suppress associated minerals. Furthermore, pH adjusters (lime, sodium carbonate) optimize the slurry environment, further enhancing separation efficiency.

Process Flow:

Typical lead-zinc flotation involves crushing and grinding, roughing, scavenging, and concentrating. After crushing, the ore is finely ground in a ball mill to a desired particle size. Adjusters (such as pH adjusters) and collectors (such as ethyl xanthate or nitrosulfate) are then added to an agitated tank. Lead minerals float preferentially during the roughing stage, while the tailings are subsequently processed for zinc flotation. Lead concentrate is refined through multiple rounds of cleaning, with residual lead recovered through scavenging. Zinc flotation typically requires activation (e.g., with copper sulfate) followed by capture, ultimately yielding qualified lead-zinc concentrate.

Technical Advantages:

- The core advantage of high-efficiency flotation technology lies in its high selectivity, enabling efficient lead and zinc separation, significantly improving concentrate grade and recovery.

- It is highly adaptable and can process complex polymetallic ores (such as lead-zinc ores containing silver and copper).

- New, highly effective reagents (such as environmentally friendly inhibitors) can be used to reduce their dosage, while wastewater recycling systems can be integrated to reduce pollution.

- The introduction of automated control further improves process stability, reduces energy consumption, and reduces costs, making it a mainstream method for modern lead and zinc beneficiation.

2. Gravity-Flotation Technology

Principle:

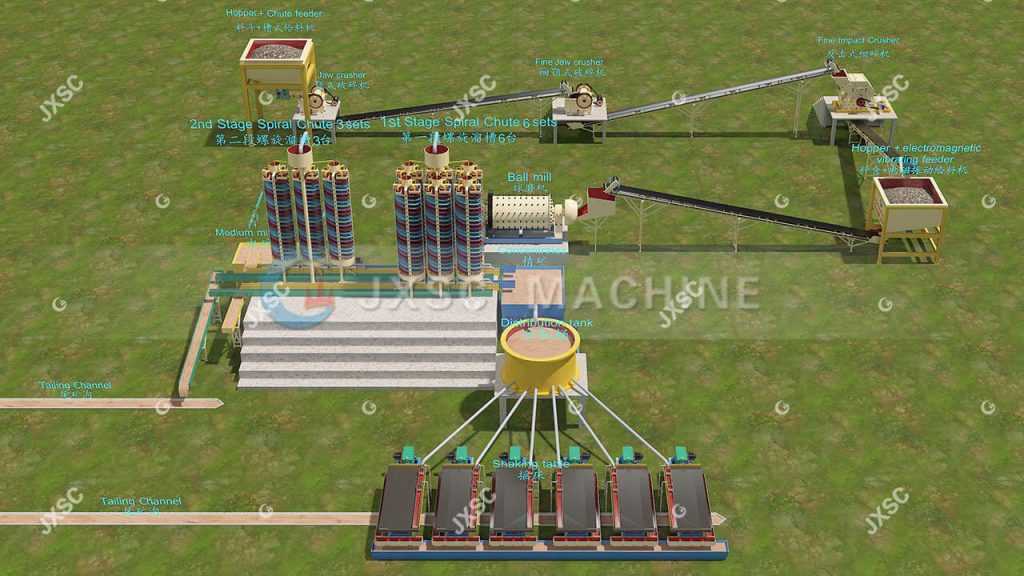

Combined gravity-flotation technology combines the advantages of gravity separation (density separation) and flotation (surface chemical separation). It is particularly suitable for lead-zinc ores with coarse-grained or significantly different densities. Gravity separation (e.g., shaking tables and spiral chutes) first utilizes mineral density differences for pre-enrichment, reducing the subsequent flotation processing load. Flotation then performs fine separation to improve the quality of the final concentrate. For example, after gravity separation, the coarse concentrate of lead-zinc ore is further purified by flotation, reducing reagent consumption and improving overall recovery.

Process Flow:

- Gravity Pre-enrichment: After the raw ore is crushed to -2mm, it is separated using a spiral chute or jig separator to obtain a high-density coarse lead-zinc concentrate. The tailings are directly discarded or reground.

- Flotation Refinement: The gravity concentrate is finely ground to -150 mesh, with lead preferentially flotated (lime to inhibit zinc and xanthate to capture it). Copper sulfate is added for activation before zinc flotation. Middlings can be returned to gravity separation or processed separately.

Technical Advantages:

- Energy savings and consumption reduction: Pre-discarding tailings during gravity separation reduces flotation throughput, saves over 20% in reagents, and reduces overall energy consumption by 15%-25%.

- Recovery improvement: Coarse lead and zinc minerals are recovered earlier during gravity separation, avoiding metal loss caused by over-crushing during flotation and improving overall recovery.

- Applicability for complex minerals: Effectively processes mixed oxidized and sulfided ores and low-grade ores (Pb+Zn <5%), optimizing dissociation through staged grinding.

- Green benefits: Reduces flotation tailings volume, and when used with dry gravity separation (such as a wind-driven shaker), can save over 30% in water.

3. Electrochemically Controlled Flotation Technology

Principle:

Electrochemically controlled flotation technology modulates the slurry potential (Eh) by applying an external electric field or chemical oxidizing/reducing agents, thereby altering the surface electronic state and hydrophobicity of lead-zinc minerals. For example, in high-sulfur lead-zinc ores, pyrite (FeS₂) can interfere with flotation. By controlling the potential, pyrite can be selectively suppressed while simultaneously promoting the hydrophobicity of galena. Potential regulation also optimizes the adsorption efficiency of collectors (such as xanthate) and avoids overdosage. This technology is particularly suitable for the selective separation of sulfide minerals and, in principle, is an electron transfer-induced surface modification.

Technical Advantages:

- Enhanced selectivity: The lead-zinc separation coefficient is increased, making it particularly suitable for complex, high-sulfur ores (such as arsenic-bearing pyrite).

- Environmentally compatible: Reduces toxic reagents, facilitates wastewater treatment, and meets green mining standards.

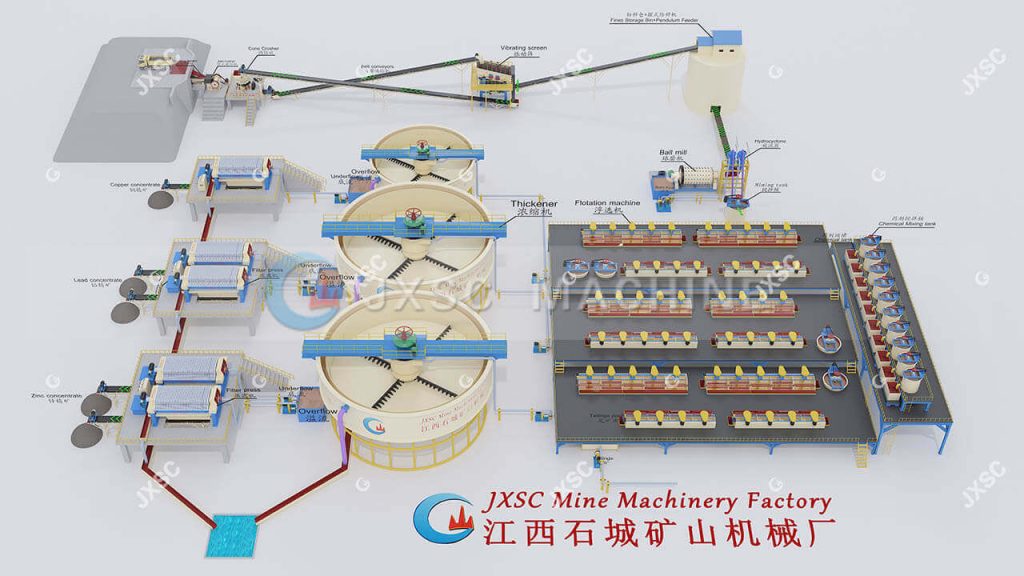

4. Combined Lead- Zinc Separation Technology

Principle:

For low-grade lead and zinc or complex co-existing ores (such as copper-lead-zinc-silver), a single technology is difficult to economically separate. The lead-zinc combined process utilizes a cascade recovery process consisting of “gravity separation pre-discarding tailings – flotation purification – magnetic separation for impurity removal“:

- Gravity separation: Recovers coarse lead and zinc, discarding 30%-50% of tailings.

- Flotation: Processes the gravity separation ore, prioritizing lead flotation and then activating zinc flotation.

- Magnetic separation: A high-gradient magnetic separator (1.2T) separates interfering minerals such as pyrrhotite.

In actual application, the process mix can be adjusted based on ore characteristics. For example, silver-containing ores may require the addition of a cyanide leaching step.

Technical Advantages:

This solution offers low energy consumption (reducing overall energy consumption by 20%-30%) and strong adaptability, making it particularly suitable for processing complex polymetallic ores. By synergizing multiple technologies (gravity separation, flotation, and magnetic separation), it maximizes resource utilization.

The development of modern technologies such as high-efficiency flotation, electrochemically controlled flotation, and combined process optimization has significantly improved the efficiency, economy, and environmental performance of lead-zinc ore separation. These technologies not only significantly reduce reagent and energy consumption but also increase the recovery rate of complex ores, providing strong support for the sustainable development of the mining industry. If you require customized high-efficiency mineral separation solutions or advanced equipment, please contact our technical team for exclusive service! We can help your mine achieve efficient and green production.