In the grand chain of mining, raw ore undergoes multiple stages from extraction to beneficiation, including coarse crushing, medium crushing, and fine crushing. The primary crusher, as the first hurdle, directly determines the processing efficiency and energy consumption of subsequent processes. Globally, up to 40% of mining energy consumption is attributed to the crushing stage, and selecting the wrong primary crusher can result in a 50% increase in maintenance costs. Therefore, a thorough understanding of the technical characteristics and applicable scenarios of the three mainstream primary crushers is crucial for achieving efficient, green, and intelligent mining.

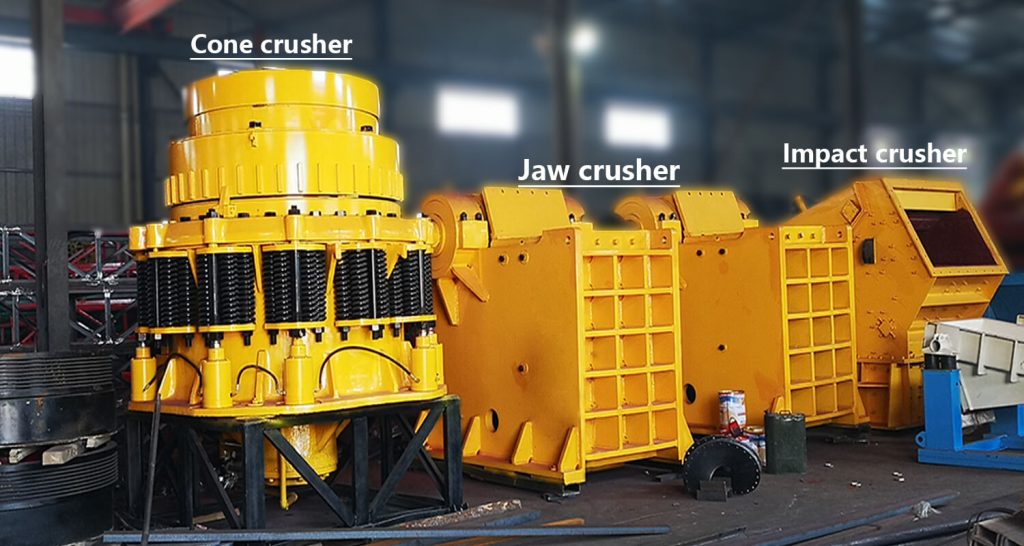

JXSC three types of primary crushers: jaw crushers are suitable for coarse crushing of high-hardness ores, impact crushers are specifically designed for coarse and medium crushing of brittle materials, and cone crushers are designed for special coarse crushing of ultra-hard ores.

What is a Primary Crusher?

As the first crushing equipment in a mining process, a primary crusher not only needs powerful crushing capabilities but also requires precise selection based on ore characteristics and production scale. Its main function is to crush large chunks of raw ore (up to 1-2 meters in diameter) into medium-sized materials (typically 10-30 cm) suitable for subsequent processing. This type of equipment is designed with high strength, wear resistance, and stability in mind to withstand long-term continuous operation under harsh mining conditions.

Common types include PE jaw crushers, impact crushers, and cone crushers, and gyratory crushers.

Detailed Explanation of 3 Types of Primary Crusher

1. PE Jaw Crusher

The Evergreen of Hard Rock Coarse Crushing

Principle:

The jaw crusher‘s “tiger-mouth biting” crushing mechanism originates from its biomimetic design inspiration. The movable jaw plate is driven by an eccentric shaft, moving closer to or further away from the fixed jaw plate at a frequency of 200-300 times per minute, forming a periodic squeezing action similar to an animal chewing. When the ore enters the crushing chamber, it is initially squeezed by the movable jaw plate. As the movable jaw plate continues to advance, the pressure on the ore increases exponentially until its internal structure is completely destroyed.

Structural Features:

This crushing method not only achieves a high crushing ratio of 3-6:1, but also allows for flexible control of the output particle size by adjusting the discharge port gap. Its core advantage lies in its reliability under extreme working conditions. The machine body is integrally cast from high-manganese steel, and key components are equipped with overload protection devices. This jaw crusher can continuously process extremely hard ores with a compressive strength ≤350MPa, and is especially suitable for crushing highly abrasive materials such as gold, copper, manganese, chromium, granite, and basalt, producing uniform cubic particles.

Application Scenarios:

Primary jaw crushers often use PE series components and are widely used in metal mining, non-metal mining, and construction waste recycling. In metal ore processing, it boasts superior structural stability and reliability, and is typically used as a coarse crushing device in combination with hammer crushers, roll crushers, and ball mills in a combined crushing process. Thanks to its powerful compressive crushing capacity, the jaw crusher is suitable for large-scale coarse crushing operations of high-hardness ores.

In sand and gravel production, it is used in conjunction with impact crushers and sand making machines to produce high-quality construction aggregates. Furthermore, it can be designed as a modular crushing plant integrating feeding, crushing, and screening, allowing for rapid site changes and further reducing operating costs.

Advantages:

Superior compressive strength, capable of easily handling extremely hard ores with a compressive strength up to 320MPa.

With an ultra-large feed size of up to 1200mm, it is an ideal piece of equipment for processing large ore blocks, especially suitable as the first crushing stage (primary crusher) in a mining production line.

A single unit can meet the primary crushing requirements, reducing the pressure on secondary crushing and resulting in low maintenance costs.

2. Impact Crusher

A Versatile and Efficient Material Shaping Tool

Stone-on-Stone Crushing Principle:

The core of the impact crusher lies in high-speed impact crushing: after entering the impeller, the material is accelerated to 60-70 m/s, and then violently collides with the material layer or impact plate in the vortex chamber (“stone-on-stone”). This crushing method can efficiently dissociate minerals and shape the finished aggregate into particles closer to cubic shapes through multiple collisions, significantly reducing the content of needle-like and flaky particles (generally ≤10%), which is 20%-30% better than traditional jaw crushers.

Designed for Brittle Materials:

The impact crusher is particularly suitable for processing medium-to-low hardness brittle ores, such as limestone, gypsum, and coal (Mohs hardness ≤5). Its hammers are made of high-chromium alloy, which has strong impact resistance and can be flipped after wear, increasing utilization by more than 50%. Compared with the layered crushing of cone crushers, the impact crusher consumes 15%-20% less energy, making it an energy-saving choice for sand and gravel aggregate production lines.

Applicable Scenarios:

Impact crushers, with their efficient impact crushing technology and excellent finished product particle shape, are particularly suitable for key engineering projects such as highways and high-speed railways where strict particle shape requirements are necessary. Their “stone-on-stone” impact crushing method can simultaneously complete coarse crushing and shaping. They are commonly used in medium-sized sand and gravel production lines or primary crushing in mineral processing plants. However, compared to jaw crushers and cone crushers, impact crushers experience faster wear in coarse crushing of high-hardness ores, making them more suitable for the primary crusher of brittle materials with a Mohs hardness ≤5.

Advantages:

Very large crushing ratio, up to 50:1, capable of directly crushing large pieces of ore into fine aggregate. No need for multiple crushing stages, greatly simplifying the process.

The finished product particle shape of impact crushers is excellent, with a cubic content of over 90% and a low content of needle-like and flaky particles, meeting the requirements of high-standard building aggregates.

The discharge particle size can be flexibly adjusted by adjusting the gap between the impact plate and the rotor, replacing the screen plate with one of different specifications, and adjusting the rotor speed. The operation is convenient.

3. Cone crusher

High-Efficiency and Intelligent Crushing Expert

Principle and Features:

The cone crusher employs advanced layered crushing technology, distinct from traditional single-particle crushing. It utilizes the material itself as the crushing medium, forming a layer within the crushing chamber. Crushing is achieved through mutual compression and grinding between these layers.

Applicable Scenarios:

While cone crushers are primarily used for medium and fine crushing, they can still be used as primary crushers in certain special circumstances, especially when processing high-hardness, highly abrasive ores (such as iron ore and copper ore). In the hard rock field, it can effectively process medium to high hardness materials such as iron ore, diamond, copper ore, and granite, etc. In aggregate production, cone crushers are used for shaping operations, producing high-quality concrete aggregates to meet the construction needs of key projects such as highways and high-speed railways. However, due to their high investment cost, cone crushers, as primary crusher, are typically suitable for special working conditions requiring strict particle shape requirements and extremely hard ore.

Advantages:

The hydraulic system adjusts the discharge gap in real time, ensuring stable and uniform output particle size to meet production needs under different working conditions.

Equipped with an automatic overload protection device, the hydraulic system automatically widens the discharge opening when encountering uncrushable objects, allowing the foreign objects to be discharged and preventing equipment damage, ensuring reliable and safe operation.

The equipment is equipped with a PLC control system, enabling remote monitoring and automated operation. Operators can monitor the equipment's operating status in real time and adjust production parameters accordingly.

Selection Guide for Three Types of Primary Crusher: How to Match Mining Needs

When selecting a primary crusher, factors such as material properties, capacity requirements, and output particle size must be comprehensively considered to choose the appropriate model and chamber type to achieve optimal crushing effect and economic benefits. Simultaneously, factors such as energy consumption, maintenance costs, and level of intelligence should also be taken into account to achieve sustainable development of mine production. Jaw crusher is a ideal primary crusher for processing extremely hard ores; impact crushers are the first choice for producing high-quality building aggregates; and cone crushers are suitable for primary crushing operations of extremely hard rocks and ores.

The key differences are: jaw crushers offer high cost-effectiveness, impact crushers offer a high crushing ratio and good particle shape, and cone crushers offer high wear resistance and automation.

Conclusion

Each type has its advantages, and a reasonable combination can increase the efficiency of the crushing production line by more than 30%. Whether you are processing metal ores, sand and gravel aggregates, or a large-scale mining project, we can provide you with customized equipment. Want to know which one is best for you? Contact us now to design the most efficient and intelligent rock/ore/aggreate crushing solution!