Nickel ore has good chemical stability, ductility, melting resistance, high temperature resistance and other high-quality characteristics. It is a very important non-ferrous metal raw material, which is used to manufacture stainless steel, high-nickel alloy steel and alloy structural steel. It is widely used in various military manufacturing industries such as aircraft, radar, missiles, tanks, ships, spacecraft, and atomic reactors. When the nickel content exceeds 3%, it can be directly smelted and used for the production of various materials. However, when it is less than 3%, it can only enter the smelting process after the nickel ore beneficiation process and the supporting equipment are used for separation and purification. Depending on the composition of nickel ore, the selected process methods are also different.

Nickel ore beneficiation Process

Nickel ore mainly includes sulfide copper-nickel ore and nickel oxide ore (latterite nickel ore). The beneficiation and processing methods of the two are quite different: different beneficiation methods are selected according to the grade of nickel sulfide ore, and then nickel is prepared in different ways; the smelting methods of nickel oxide ore are generally divided into two types: fire method and wet method.

- In copper-nickel sulfide ore, copper mainly exists in the form of chalcopyrite; while nickel mainly exists in the form of free nickel sulfide such as pyrite, goethite, and pyrite. A considerable part of nickel occurs in pyrrhotite in a similar manner, and there is also a small amount of nickel silicate. The most important beneficiation method is flotation, magnetic separation and gravity separation are usually auxiliary beneficiation methods. In the flotation of copper and nickel sulfide ores, collectors and foaming agents for copper sulfide minerals flotation process are often used. The nickel in the copper concentrate is lost in the smelting process, while the copper in the nickel concentrate can be recovered more completely.

- Nickel oxide ore mostly uses processes such as crushing and screening to remove the bulk bedrock with weak weathering degree and low nickel content in advance. Because the nickel in the nickel oxide ore is often dispersed in the gangue minerals in a similar manner, and the particle size is very fine. Therefore, it cannot be enriched by mechanical beneficiation methods, and can only be directly smelted.

Nickel ore processing plant

When process copper-sulfide nickel ore, collector and frother will be used in order to better results. For it is easier to recover cooper from nickel concentrate. Nickel ore processing usually requires three processes of crushing, grinding and beneficiation. Magnetic separation and gravity separation are usually auxiliary beneficiation methods.

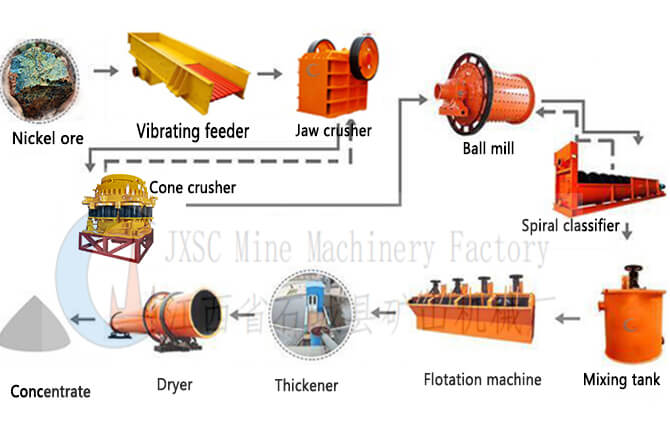

- Crushing and screening: The mined copper sulfide ore is sent to the jaw crusher by the feeder for rough crushing. The coarsely crushed copper-nickel sulfide ore particles are then sent to the cone crusher by the conveyor for secondary crushing treatment. The copper sulfide ore after the secondary crushing treatment is screened by the screening equipment, and the qualified ore particles can be directly sent to the next grinding process. The unqualified ones should be returned to the cone crusher to be crushed again.

- Grinding and screening: The qualified copper-nickel sulfide ore particles are sent to a ball mill for grinding, and the ore particles are ground to form ore powder. It is sent to the spiral classifier for sorting, and if the particle size meets the requirements, the next step of flotation and purification can be carried out. Those that do not meet the requirements need to be returned to the ball mill for secondary grinding.

- Flotation separation: The graded qualified copper-nickel sulfide ore is sent to the mixing tank to be fully stirred, and then sent to the flotation machine, and reasonable flotation reagents are added. The specific flotation method needs to find a professional beneficiation manufacturer to conduct beneficiation test analysis of its mineral properties. After professional analysis, the flotation purification process flow that is in line with the actual situation is customized.

- Dehydration and drying: After flotation, the water content of the material is relatively large, and the flotation concentrate material is sent to the thickener for initial concentration and sedimentation. In order to speed up the drying speed of the product, a concentrator is usually used to dehydrate and separate it, and then it is dried with a dryer to obtain the finished product.

Nickel ore beneficiation equipment

For the above nickel ore beneficiation process, JXSC provides you with a complete set of mining equipment.

♦Jaw crusher is the main equipment for coarse crushing of nickel ore. It not only has a large processing capacity in the crushing and processing of materials, but also the crushed nickel ore particles are uniform and complete, which can effectively improve the efficiency of the equipment in production.

1. The crushing cavity is deep, and the nickel ore can be crushed comprehensively, which improves the unit processing capacity of the equipment for the nickel ore and increases the output of the equipment.

2. Through the wedge adjustment device, the discharge granularity of the equipment can be adjusted within a certain range, so as to meet the production needs of different users.

3. The equipment has a good sealing system, which avoids the pollution of dust to the environment during production, and creates a good working atmosphere for the operators.

♦ Ball mill is an important equipment for grinding nickel ore. It can not only be used for grinding nickel ore, but also has a good grinding effect on materials in construction, chemical and other industries. Its performance characteristics are as follows:

1. Bearings with larger specifications and strong wear resistance are used, and rolling bearings are used instead of sliding bearings in the operation. Reduce friction, reduce energy consumption, increase the service life of the bearing, and reduce the user’s cost of equipment maintenance.

2. The equipment has high stability in the process of operation, thereby reducing the maintenance frequency of the equipment and enabling users to obtain greater economic benefits in production.

♦ Flotation machine is a necessary equipment for nickel ore processing. It can effectively separate and purify materials according to their different properties. The outstanding advantages of flotation machine in production are:

1. The impeller of the equipment is always in motion, which can effectively remove the accumulated materials and sundries in the body, thereby reducing the damage to the equipment parts and increasing its service life.

2. Compared with the conventional mechanical stirring flotation machine, it can save a third of electricity, thereby increasing the profit of users in production.

The level of economic benefits of specific nickel ore beneficiation has an important relationship with the conditions of the mineral itself. Of course, scientific and reasonable mineral processing technology and advanced and excellent mineral processing equipment are naturally the main plus points for the user’s economic benefits. JXSC can tailor the beneficiation process suitable for your nickel ore. At the same time, our equipment is complete in model, hard in quality, excellent in performance and low in price.