With the development of industry, fluorite is increasingly used in chemical industry, metallurgy and other fields. The price of its fluorspar continues to rise, and its value has begun to approach that of scheelite. Scheelite is an associated mineral, accounting for 43% of the total fluorite reserves, but the resource utilization rate needs to be improved. The two minerals have different properties, so they must be separated to ensure the highest quality of both ores.

Scheelite is a tungsten-containing mineral with high application value in various industries such as electronics and machinery manufacturing. Fluorite ore, on the other hand, is essential for the production of hydrofluoric acid, which has a variety of industrial uses. Among them, the comprehensive utilization of fluorite is of great significance, so how can scheelite and fluorite ore be successfully separated?

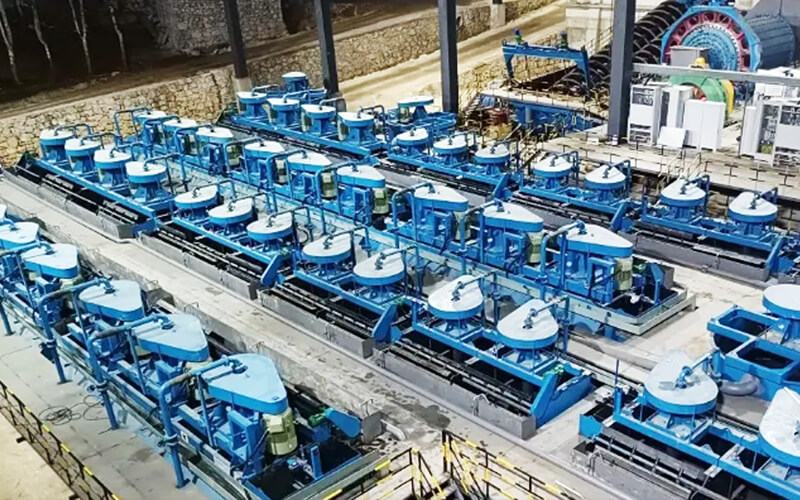

1. Flotation Method

A practical method is selectively separating two minerals based on their surface properties through flotation. Adding specific reagents to the slurry allows the scheelite particles to be made hydrophobic while the fluorite particles remain hydrophilic, allowing for easy separation.

An exciting approach to enhancing the flotation separation of fluorite ore and scheelite is selective inhibitors. By carefully selecting chemicals that inhibit one mineral while promoting the floatability of another, miners can increase the overall efficiency of the extraction process. Additionally, advances in froth flotation technology allow for more precise control of particle interactions, resulting in higher recoveries and purer concentrates.

2. Gravity separation method

This method is beneficial when processing coarser-grained ores. By carefully adjusting parameters such as feed rate and water flow, effective separation of scheelite and fluorite can be achieved, paving the way for high-quality concentrates of each mineral.

When gravity separates fluorite ore and scheelite, the difference in specific gravity between the two minerals must be considered. Fluorite has a relatively low specific gravity of about 3.2-3.3, while scheelite has a higher specific gravity of 5.9 to 6.1. This significant difference allows efficient separation using jig separators, shaking tables, or spiral chutes.

3. Magnetic separation method

Magnetic separation uses the magnetism of minerals such as scheelite to separate them from non-magnetic minerals such as fluorite. By applying a magnetic field, the ore mixture can be separated into different parts based on their magnetic susceptibility. This method provides a more efficient and environmentally friendly way to process scheelite and fluorspar ores compared to traditional methods such as chemical treatment.

Scheelite and fluorite are valuable minerals often found together in mineral deposits. Differences in their surface properties are exploited through flotation. Gravity, flotation, or magnetic separation methods are frequently used to separate these ores or high-quality concentrates. Mineral processing can effectively improve the overall efficiency of mining operations and ensure that each mineral can be processed appropriately according to its intended use. Separating scheelite and fluorite ores also helps prevent contamination between the two minerals, thereby reducing waste production. JXSC has advanced technologies optimize recovery rates and reduce the energy consumption and environmental impact associated with mineral processing operations.