Silica sand, also known as quartz sand, is a common non-metallic mineral raw material. It is distinguished according to the different SiO2 content. The SiO2 content above 98.5% is called quartz sand, and the SiO2 content below 98.5% is called silica sand. With the advancement of science and technology, high-purity silica sand is the basis of high-end application fields. For example, high-tech industries such as aerospace, atomic energy technology, laser, optical cable communication, and military industry have extremely strict requirements on sand quality. The purity of silica sand determines its value, and silica sand beneficiation is the most important step. Its process mainly includes scrubbing, screening, washing, classifying, gravity separation, magnetic separation, dehydration, etc. The key is to improve the quality of silica sand and increase the added value of products.

What is silica sand beneficiation?

Silica sand beneficiation is the processing of natural silica sand, a key process aimed at improving the quality of silica sand and meeting the needs of diversified industries. It mainly removes metal oxides such as iron, aluminum, titanium, and removes impurities such as clay and mica in silica sand. Improve the purity of the product to obtain high-quality sand.

However, the silica sand beneficiation flow is the key to producing high-quality sand. Specifically, there are scrubbing, screening, washing, grading, gravity, magnetic separation, dehydration, etc. This series of processes can transform the originally mixed silica sand into high-purity, high-performance high-quality raw materials, achieve efficient utilization of resources, avoid waste of resources, and enhance the economic value of silica sand.

Finally, silica sand after mineral processing can provide raw materials that meet high standards for various industries, such as the electronics industry for manufacturing precision electronic components such as chips; in the foundry industry, improve the quality of castings and reduce casting defects; in the construction industry, as a high-quality building aggregate, improve the performance of building materials. In short, silica sand beneficiation is the core process of tapping the value of silica sand and meeting the needs of various industries.

Importance of silica sand beneficiation

Silica sand in nature often contains various impurities, such as metal oxides such as iron, aluminum, titanium, and clay. These impurities will significantly affect the application effect of silica sand in different fields. For example, electronic grade silica sand is used to manufacture integrated circuit boards, and its purity requirements are extremely high. Only through beneficiation and purification can these impurities be removed in a targeted manner to meet the high-purity product requirements of various applications.

The quality requirements of silica sand in different industries vary greatly. Usually, purified silica sand can be used to manufacture optical glass, high-end ceramics and other products, while silica sand that has not been effectively beneficiated may only be suitable for ordinary construction sand. Extracting silica sand through the beneficiation process can broaden the market application and meet the needs of more fields. Secondly, a reasonable and efficient beneficiation process can improve the recovery rate of silica sand and accurately remove impurities. It can avoid the waste of resources caused by poor product quality due to the use of low-quality silica sand, and maximize the recovery rate of high-quality sand.

Silica Sand Beneficiation Flow

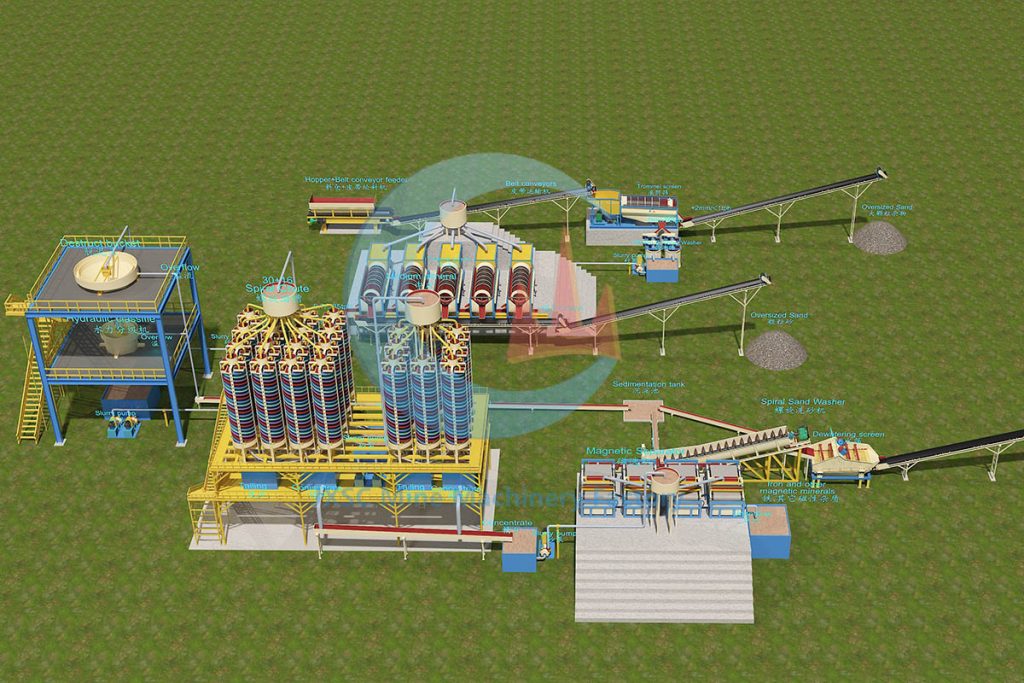

Take this complete set of 100 TPH silica sand washing, screening and purification process as an example. The entire silica sand beneficiation process includes feeding, screening, washing, particle size classification, gravity separation, magnetic separation and dewatering systems. The main equipment includes belt feeder, drum screen, wear washer, spiral sand washer, concentration cone, hydraulic classification drum, spiral chute, plate-type high-intensity magnetic separator, dewatering screen, etc.

100 TPH silica sand Beneficiation Plant

1. Feeding system: utilize a belt conveyor to evenly feed raw sand to the trommel screen.

2. Primary screening: use one big model trommel screen with a 2mm mesh size to remove impurities larger than 2mm in sand.

3. Scrubbing: attrition scrubber is used to scrub 0-2 mm sand to better separate clay from silica sand.

4. Size screening: After scrubbing, use a sand pump to send 0-2mm to 5 sets of trommel screens with 0.7mm mesh size to remove bigger than 0.7mm waste sand.

5. Washing removing mud water: 0-0.7mm sand from 5 sets of trommel screens goes to the spiral sand washer machine to further wash and remove mud water. So we can get clean silica sand.

6. Size classification system: use a sand pump to send cleaned 0-0.7mm silica sand to the classification system which is equipped with a thickening cone and hydraulic classification drum to further remove mud and remove micro-fine powder less than 0.1mm.

7. Gravity separation: after we get very clean 0.1-0.7mm silica sand from the classification system, use a sand pump sent to the spiral chute to remove impurities and iron by gravity separation principle.

8. Magnetic separation: the customer has higher requirements for the iron content in silica sand, so need to send the pure silica sand from spiral chutes to plate strong magnetic separator to further remove Fe2 O3 in silica sand. After that, we can get a very high grade of silica sand product in the end after magnetic separation.

9. Dewatering system: send the final product of 0.1-0.7mm silica sand to the screw dewatering machine, its underflow goes to the dewatering screen for further removal water, then dewatered silica sand through the belt conveyor to the finished product stockpile.

Silica sand beneficiation is mainly to purify high-quality sand. Its process usually includes scrubbing, screening, washing, grading, re-selection, magnetic separation, dehydration, etc. Sometimes it can be combined with crushing, grinding, flotation, drying and other processes for beneficiation, with high efficiency to remove impurities and provide high-quality sand raw materials for many industries such as electronics, construction, and casting. Since silica sand is mainly quartz, it often contains different impurities, such as iron, aluminum, titanium, phosphorus, calcium, mica, etc. JXSC will tailor mineral beneficiation processes and equipment according to specific mineral composition information, production requirements, and other conditions. Contact us for more design process details, precise extraction of high-grade silica sand allows your investment to recoup quickly!!