Is washing efficiency for clay-bearing gold ore always unsatisfactory? In gold mining, clay ores are highly viscous and prone to caking, which can cause ordinary equipment to clog and become inefficient, making subsequent gravity separation or flotation processes difficult to implement. In fact, the key to processing clay ore is not blindly increasing reagents or equipment investment, but rather choosing a specialized washing machine that can precisely “remove” the clay. This article will reveal the principles, application scenarios, advantages, and disadvantages of five types of high-efficiency gold washing machines, helping you “recover” more gold from the clay.

5 types of gold washing machines help you efficiently extract gold from clay ores: rotary scrubbers, trommel screens, trough/log washers, spiral washers, and vibrating screens. Mobile washing equipment can also be configured for flexible, portable solutions for remote or dispersed clay gold ores.

Why is a special gold washing machine needed for processing clay ore?

Characteristics of gold ore with Clay

- High Adhesion: In a wet state, this type of ore easily forms a viscous sludge, which not only adheres to the surface of gold particles but also clumps in key areas such as screens and drum walls, making subsequent beneficiation difficult.

- Fine Particle Encapsulation of Gold Particles: Clay particles carry a negative charge, easily adsorbing valuable minerals such as gold particles (e.g., montmorillonite, kaolinite), forming a fine particle encapsulation layer. This isolates the gold particles from subsequent beneficiation, significantly reducing the effective exposed area of the gold ore. Clay ore typically contains a large number of fine particles, and insufficient separation efficiency easily leads to the loss of a large amount of gold particles with the tailings.

Because crushing or grinding cannot completely liberate the gold particles, there is a lack of targeted “washing” or “separation” mechanisms. If unoptimized drum screens or gold troughs are used, clay sludge will gradually accumulate in key areas such as screen holes and baffles, causing a sharp drop in processing efficiency or even a complete shutdown. Therefore, a specialized gold washing machine with strong liberation and fine classification is necessary to achieve effective separation of gold and clay.

The Role of Gold Washing Machine:

Key Technologies for Breaking Clay Encapsulation

The essence of a gold washing machine is to achieve “scrubbing and desliming, clay stripping, and mineral slime separation” through a combination of physical and mechanical force and hydraulic action. Commonly used equipment for processing clay-bearing ores includes rotary scrubbers, trommel screens, trough/log washers, spiral washers, and vibrating screens.

Besides gold mine processing plants, they can also be used for cleaning and impurity removal in mines producing copper, lead-zinc, manganese, chromium, diamond, tantalum-niobium, tin, and other clay-bearing ores.

- Scrubbing and Desliming: High-speed rotating spiral blades or blunt teeth mechanically impact clay clumps, forcibly stripping the surface coating of gold particles.

- Hydraulic Stripping: High-pressure water jets disperse the clay structure, while pulsating water flow carries away suspended mud, causing gold particles to settle.

- Grading and Screening: Multi-layered sieves filter layer by layer, discharging fine clay and mineral slime with the water flow, leaving relatively pure gold ore particles.

Detailed of 5 Types of Gold Washing Machines

1. Rotary Scrubber

A rotary washer is a device that uses a rotating drum to scrub and rinse ore, widely used in the pretreatment stage of coarse-grained clay ore.

Principle:

The drum rotates at a certain speed. The ore inside the drum rotates with it, creating friction and collisions with the inner lining and the ore itself. Simultaneously, an external spray system continuously injects water. Under this dual action, the clay coating is gradually peeled off, and the sludge is discharged through the screen at the end of the drum with the water flow, while the clean ore is collected from the discharge port.

Applicable Scenarios:

Suitable for processing medium-viscosity coarse-grained materials (such as gravel and placer gold ore), especially advantageous in large alluvial gold mines with a processing capacity of 1-400 tons/hour, effectively solving the problem of “sludge clogging subsequent equipment.” However, when the trommel scrubber is used for processing highly viscous ores, multiple cycles of washing can achieve the optimal washing efficiency.

Pros & Cons:

High processing capacity: A single rotary drum ore washer can process up to several hundred tons per day, far exceeding other types.

Simple structure: The core components are only the drum, motor, and liner, resulting in a low failure rate.

Low maintenance cost: The rubber liner replacement cycle is as long as 1-2 years, and routine checks only require bearing lubrication.

Limited fine particle separation: The separation efficiency for fine clay particles with a diameter <0.5mm is less than 60%, requiring subsequent classification equipment.

High energy consumption: The drum rotation must overcome the gravity and frictional resistance of the ore, resulting in higher energy consumption per unit processing capacity compared to spiral washing machines.

2. Trommel Screen

A trommel screen is a classic screening and preliminary washing device. It uses a rotating drum and built-in screens to classify ore by particle size, and is commonly used for the preliminary separation of clay gold ores.

Principle:

As the drum rotates, fine particles (<5mm) pass through the screen openings and are discharged under the influence of centrifugal force and gravity, while coarse particles move axially along the drum to the discharge end. Simultaneously, a low-pressure water spray system inside the drum washes away loose clay on the ore surface, and the clay is discharged through the screen openings with the water flow. The classified ore is collected from the corresponding discharge port.

Application Scenarios:

Suitable for processing low-viscosity loose clay ores (clay content <10%). Especially suitable for small to medium-sized placer gold mines processing (daily processing capacity 1-200 tons/h), gold mining projects requiring classification or with limited space, such as roughing in placer gold mining, where the trommel screen can serve as a pretreatment step for subsequent washing equipment.

Simple structure, low investment cost, is only 60% of that of a traditional trommel scrubber.

Screening and washing are completed simultaneously, saving subsequent processes. Its small size makes it suitable for mines with limited space.

However, its washing efficiency is weak; it can only remove loose surface clay and cannot handle highly viscous clumps.

It easily causes screen clogging with highly viscous clay, resulting in low screening efficiency (60%-75%) and requiring frequent shutdowns for cleaning.

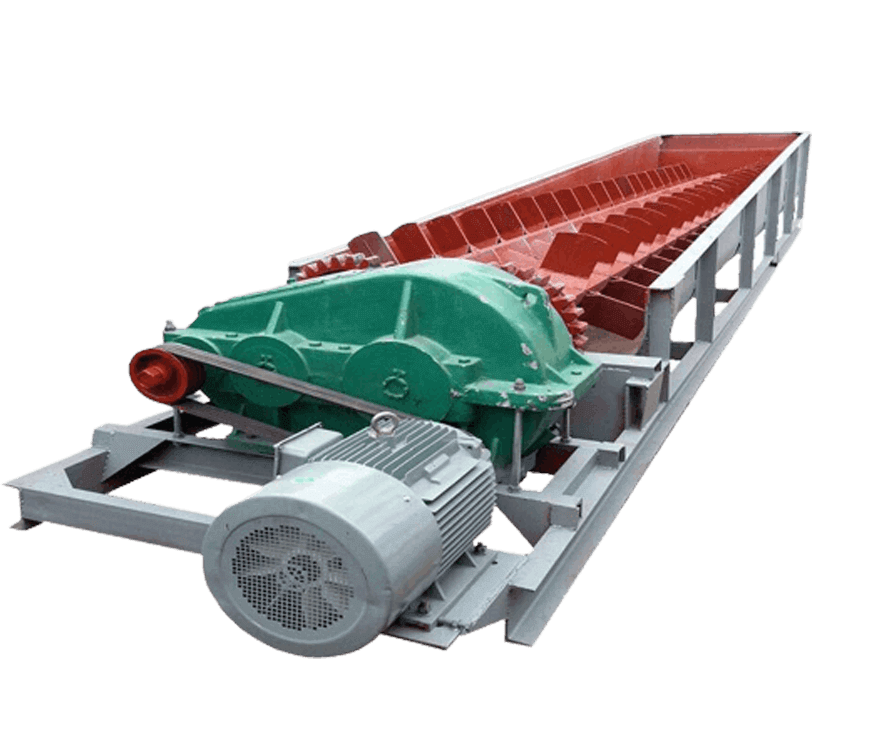

3. Log Washer

A trough-type ore washing machine is a device that achieves powerful scrubbing through impeller agitation. It is specifically designed for high-viscosity clay ores, and its core principle is the dual action of “friction + agitation.”

Principle:

After the ore enters the trough, the high-speed rotation of the impeller drives the slurry to be violently agitated. Strong friction is generated between the ore particles and between the ore and the impeller blades. Simultaneously, the water flow injected at the bottom of the trough creates an upward washing force. The clay sludge is broken up under the combined action of mechanical scrubbing and hydraulic washing and is discharged with the slurry from the overflow port of the trough. Coarser ore is pushed out from the discharge end by the impeller.

Applicable Scenarios:

The trough-type ore washing machine is specifically designed for processing high-viscosity clay ores, such as laterite and argillaceous oxide ores, which are difficult to process. It is particularly suitable for processing fine-particle materials (diameter <2mm) and is widely used in gold and manganese mining areas such as Indonesia, Kenya, Ghana, Zimbabwe, and Zambia.

Pros & Cons:

High Washing Efficiency: Separation efficiency for highly viscous clay can reach over 90%, far exceeding that of drum washing machines.

Strong Fine Particle Processing Capacity: Effectively removes the clay layer adhering to the surface of fine gold particles, increasing subsequent gravity separation and flotation recovery rates by 15%~20%.

Smaller Processing Capacity: A single trough washing machine typically has a daily processing capacity of 1-100 tons, suitable for small to medium-sized mines.

Impeller Wear: Long-term friction between the impeller and ore can lead to blade wear and deformation, requiring regular replacement.

4. Spiral Washer

The spiral washer combines hydraulic classification with scrubbing, using rotating spiral blades to clean and classify ore. It is suitable for the deep processing of fine-grained clay ore. The spiral angle, a key parameter, needs to be adjusted according to the clay’s plasticity index: an 18° angle is recommended for high-plasticity clay, while a slightly larger angle can be used for low-plasticity clay.

Principle:

Ore is fed from the top of the spiral trough. The rotating blades move the ore downwards along the trough. Simultaneously, rising water is injected from the bottom of the trough, using the buoyancy difference to separate particles. Coarse particles (high density) slide down the blades to the discharge port, while fine clay particles (low density) are discharged from the overflow port with the water flow. The friction between the blades and the ore also helps to remove some of the clay coating.

Applicable Scenarios:

Suitable for processing fine-grained clay, placer gold or gold tailings. For larger-scale or more powerful scrubbing capabilities, a customized double-spiral washer is also available. The spiral washer is especially suitable for scenarios requiring simultaneous “washing + grading,” such as grading ore into coarse, medium, and fine (slurry) grades.

High grading effect: Capable of separating ore into 3-5 particle sizes with a grading accuracy of ±5%.

Small footprint: Each unit occupies less than 10 square meters, suitable for mines with limited space.

Weak handling capacity for coarse clay particles; if the ore contains large clay clumps, the spiral blades are prone to clogging.

The spiral blades are in constant contact with the slurry, making them susceptible to corrosion and wear.

5. Vibrating Screen

A vibrating screen washing machine is a device that cleans ore through high-frequency vibration. Essentially, it combines vibrating screening with hydraulic washing, making it suitable for the rapid processing of low-viscosity clay ores.

Principle:

A vibrating motor drives the screen surface to vibrate at a high frequency. The ore moves forward in a “jumping” motion on the screen surface, during which the clay coating is detached due to the vibration. Simultaneously, a high-pressure water jet is injected from the spray system above the screen surface, washing away the detached clay and sludge through the screen holes. The clean ore is collected from the end of the screen surface.

Applicable Scenarios:

Suitable for processing low-viscosity clay ores, such as placer deposits and weathered ores, especially suitable for pre-processing operations in small and medium-sized mines. It is widely used, particularly in small-scale placer gold mines in Africa and in the washing of construction sand. The vibrating screen is especially effective for the pre-processing of fine-grained ores with a clay content of less than 30%, separating more than 80% of the fine clay.

Anti-clogging design: Includes a flexible screen support and intermittent spray pipes, continuously removing clay from the screen surface.

High screening efficiency: Separation efficiency for low-viscosity clay can reach over 85%, while simultaneously removing impurities (such as sawdust and stones).

Poor handling of high-viscosity clay: Poor handling of high-viscosity clay; clay easily clogs the screen holes, leading to decreased screening efficiency.

Screens are prone to wear: High-frequency vibration and friction with the ore shorten the screen's lifespan.

Furthermore, we also support customized mobile gold washing machines integrating trommel scrubbers/drum screens and gold sluices. Their modular design allows for rapid site relocation and assembly, making them very popular in clay gold mining projects in South Africa, Zambia, Ghana, Kenya, Indonesia, Tanzania, and Congo. They can be driven directly to the mine site, suitable for space constraints and areas with weak infrastructure, providing a “one-stop solution” for remote mining areas.

Buyer's Guide: How to Choose the Right Gold Washing Machine?

Gold Washing Machine Types | Applicable Clay Viscosity | Processed Material Size | Processing Capacity (TPH) | Core Advantages |

Medium viscosity | Coarse particles (gravel, placer gold) | Large (1-400) | High capacity, low maintenance cost | |

High viscosity | Fine particles (laterite, argillaceous ore) | 1-100 | High scrubbing efficiency, thorough fine particle separation | |

Medium-fine viscosity | Fine particles (placer gold, tailings) | 20-400 (higher for double-spiral models) | Excellent classification, low energy consumption, small footprint | |

Low viscosity | Small-medium particles (placer ore, weathered ore) | 10-250 | Compact structure, high screening efficiency | |

Low viscosity | Wide particle size range (placer gold, tailings) | 1-100 (small-medium mines) | Combined classification and washing, easy maintenance |

Conclusion

Gold recovery from clay-rich ores demands precise gold washing machine selection. Rotary scrubbers excel at high-volume, medium-clay ores; log washers tackle sticky red clay; spiral washers optimize sand-clay separation; vibrating Screens handle fine-grained pre-processing; and trommel screens suit low-clay sites. Each type balances efficiency, cost, and clay adaptability.

Ready to maximize gold recovery? JXSC experts analyze your ore type, throughput, and budget to recommend the best-fit washing system. —Contact us today for customized ore washing solutions—let’s turn your clay challenges into profitable returns!