Are you worried about choosing the right ore washing equipment in the beneficiation production line? Faced with a wide variety of ore washing equipment, trommel scrubbers and log washer(trough washers) are considered by many companies. Both ore washing equipment occupy a core position in the beneficiation production line. They each have unique advantages and can play different effects in different scenarios. However, for many ore dressing companies, when faced with different types of ores such as clay ore, high mud ore or construction waste recycled materials, whether to choose a drum ore washer or a trough ore washer is really a headache.

In the beneficiation production line, how to choose trommel scrubber and log washer? Trommel scrubber is suitable for medium and low viscosity ores, while log washer performs better in high mud ores. Finally, according to the mud content of the ore, production capacity requirements, and maintenance costs is provided to help you select the most suitable ore washing equipment for the beneficiation line and improve production efficiency.

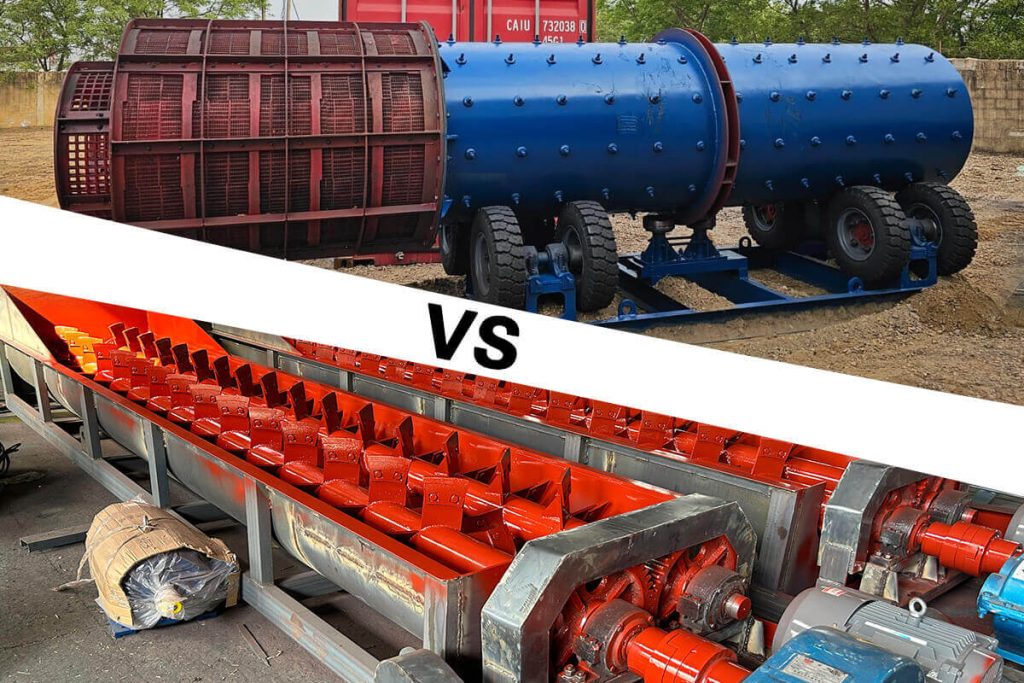

Trommel Scrubber VS Log Washer: Principle & structure

Overview of Trommel Scrubber

In the beneficiation line, trommel scrubbers and log washers are two commonly used mineral washing equipment. They have significant differences in principle and structure, which determine their different application scenarios and performance characteristics.

Working Principle

The rotary scrubber mainly relies on rotation to achieve cleaning. The motor drives the reducer to drive the drum to rotate around the axis. After the ore enters the drum, it rolls, and the ore and the drum wall rub against each other, so that the surface soil impurities are peeled off. At the same time, continuous water injection washes away the impurities. The screen on the drum can also classify the ore during cleaning, allowing the ore that meets the particle size to pass. This working method is simple and efficient, suitable for processing medium and low viscosity ores, and can complete preliminary classification while cleaning.

Structure

The core structure includes the screen cylinder, support wheel and drive device. The screen cylinder is the main body, made of steel plate and with sieve holes for classification. The support wheel supports the cylinder to ensure its smooth rotation. The drive device consists of a motor, a reducer, etc., which provides power for the rotation of the drum. In addition, there are auxiliary structures such as feeding, discharging and water supply systems. The overall structure is simple, and the operation and maintenance costs are low.

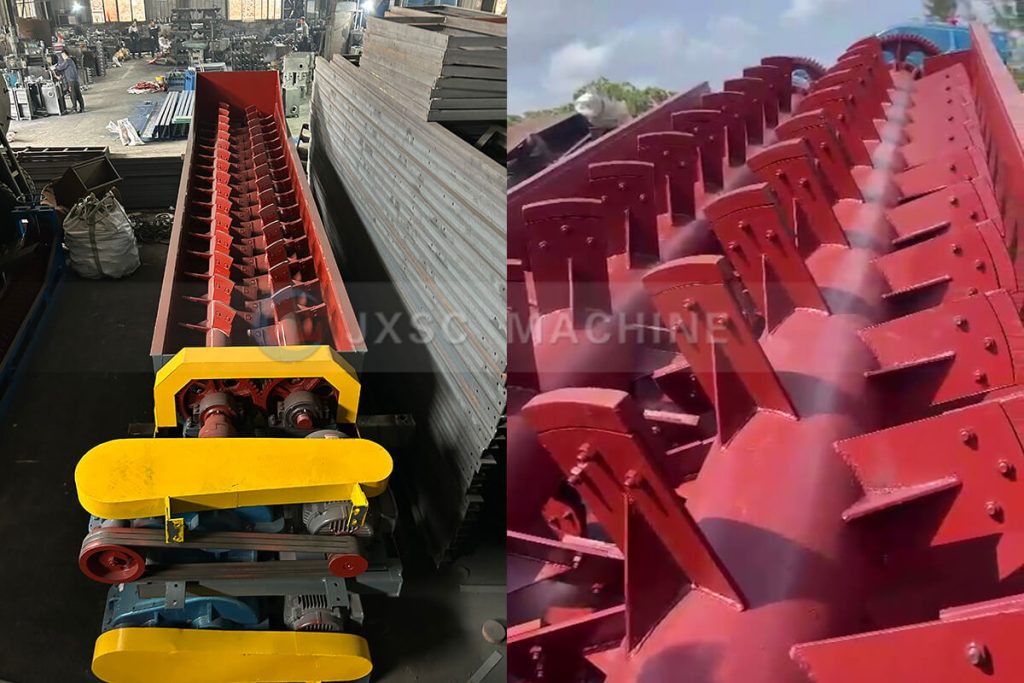

Overview of Log Washer

Working Principle

The trough-type ore washer uses double-shaft blade stirring and water flushing. The double helical shaft rotates in the opposite direction, and the wear-resistant blades on the shaft strongly stir the mixture of ore and water in the trough. During the stirring process, the ore rubs and collides violently with the blades and other ores, effectively removing the surface soil impurities. The continuously injected water flow discharges the impurities. This strong stirring method has a significant cleaning effect on ores with high mud content and high viscosity, and can deeply clean the ore.

Structure

It consists of a trough body, a double helical shaft, and wear-resistant blades. The trough body is used to hold ore and water. The double helical shaft is installed in the trough and connected to the bracket through a bearing. The wear-resistant blades on the shaft are the key to cleaning and are made of high-strength materials. The equipment is also equipped with feeding, discharging and mud discharge ports. Due to the relatively complex structure, installation and maintenance require certain professional knowledge, but it can meet the cleaning needs of complex ores.

Trommel Scrubber VS Log Washer: Application and Performance

1. Applicable mineral types

Trommel scrubbers are suitable for washing and separating medium and low-viscosity ores. For example, in placer gold ore, the gold particles are not tightly combined with sand and soil. During the rotation of the drum, the impurities can be removed by friction between the ore and the drum wall, combined with water flow flushing. The loose weathering layer of weathered gravel can also be easily peeled off under the action of the drum, and can also be preliminarily screened.

Log washers are used for high-mud ores and agglomerated ores. Clay manganese ore has high mud content and high viscosity. The strong stirring of the double-axis blades causes the ore to roll violently, destroying the bonding force between the clay and the manganese ore, and the water flow carries away the clay. The recycled aggregates of construction waste are agglomerated, and the impurities are dispersed and washed away by stirring to achieve resource recycling.

2. Cleaning intensity

The drum ore washer (trommel scrubber) relies on gravity and friction for cleaning. The drum rotates to make the ore roll and rub, but the cleaning intensity is mild. It takes multiple cleanings to process high-mud ore, and it is difficult to clean impurities in the gaps, and the cleaning effect on high-viscosity ore is limited.

The trough ore washer(log washer) relies on the mechanical force of the double-axis blades for cleaning. When working, the blades rotate at high speed to stir the ore strongly. When processing ore with the same mud content, the clay stripping efficiency is 40% – 50% higher than that of the drum ore washer. For example, for ore with 30% mud, the mud content can be reduced to less than 5% after one cleaning by the trough machine.

3. Processing capacity and energy consumption

Trommel scrubber: Capacity: 1-400 TPH.

It has low unit power consumption and simple structure. It can process several tons to tens of tons per hour when processing medium and low viscosity ores. However, it is easy to agglomerate when processing sticky ores, which affects rolling and friction, reduces the cleaning efficiency, and requires slowing down the feeding speed, which reduces the processing capacity.

Log washer: Capacity: 1-100TPH.

However, the power consumption is high, which is about 20% higher than that of the drum ore washer, but it can ensure the cleaning effect and processing volume of high-difficulty ores, and the overall benefits are considerable.

4. Product purity

The trommel scrubber has its grading screen, which can be used for preliminary grading while cleaning. The mud content of the discharge is ≤5%, which can meet the production of sand and gravel for construction with low purity requirements.

The log washer has strong stirring to dissociate the minerals well, but the discharge contains a lot of water and impurities, and needs to be matched with a dewatering screen. In the production of metal ore purification and other productions with high purity requirements, the mud content of the product can be reduced even lower after treatment.

5. Difficulty of equipment maintenance

The trommel scrubber has a simple structure and consists of a drum, a supporting wheel, a drive device, etc. It is easy to install and disassemble, and daily inspection of rotation, wear and operation status is sufficient. The working environment is mild, the parts wear slowly, the maintenance cost is low, and the wearing parts are easy to replace.

The log washer has a complex structure, and the double-axis blades, trough body, etc. are easy to wear. It is necessary to regularly check the blade wear and replace it, and check and maintain the inner wall of the trough body. The transmission system, bearings, etc. must also be regularly lubricated and maintained, which is cumbersome and costly, and requires professional operation.

Which one is better to choose?

Your Needs | Recommended equipment |

High clay ore (mud content > 30%) | Log Washer |

Construction waste/recycled aggregate cleaning needs | |

Medium and low mud ore + classification needs | Trommel Scrubber |

Budget cost: trommel scrubber > log washer | |

In the beneficiation line, trommel scrubbers and log washers have their advantages and disadvantages. Drum washers (trommel scrubbers) are suitable for medium and low viscosity ores, with low cleaning energy consumption and self-classification, but the effect of processing high mud ores is not good. Trough washers (log washers) are good at processing high mud and agglomerated ores, with high cleaning intensity and high mineral dissociation degree, but with high energy consumption. When making a decision, please consider your ore type, required product purity, and budget. We also provide washing equipment such as drum screens and sand washers. JXSC supports you in choosing the high-quality equipment that best suits your beneficiation line. Contact us now to improve your production efficiency!