100TPH Alluvial Gold Processing Plant In Ghana

We guarantee the high quality machine in the mineral processing industry, established in 40+ years of experience!

Project Info

1. Raw ore: alluvial gold with less sticky mud

2. Capacity: 100TPH

3. Location: Ghana

4. Input size: >300mm boulders

5. Output size: 0-3mm

Process

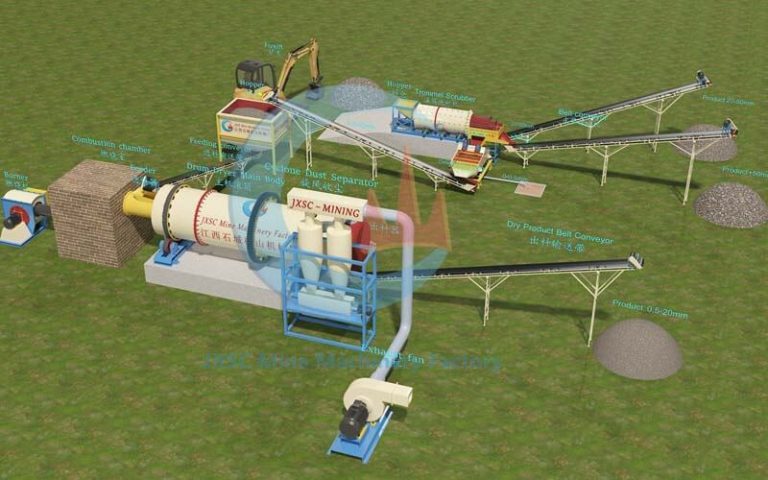

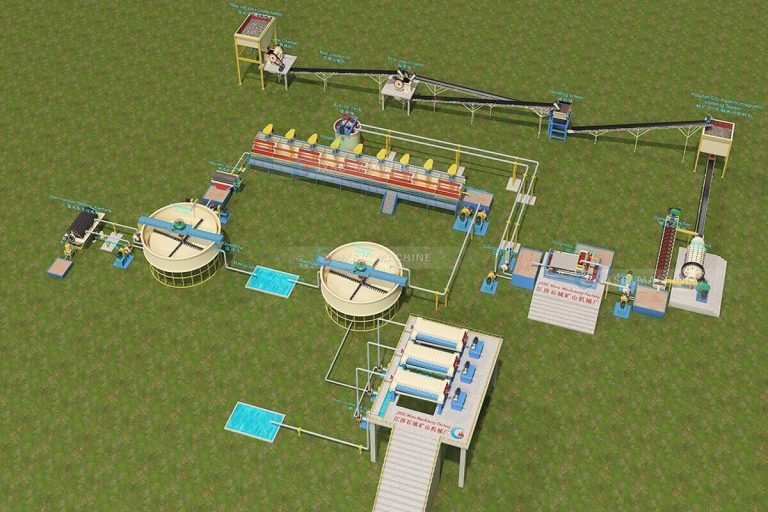

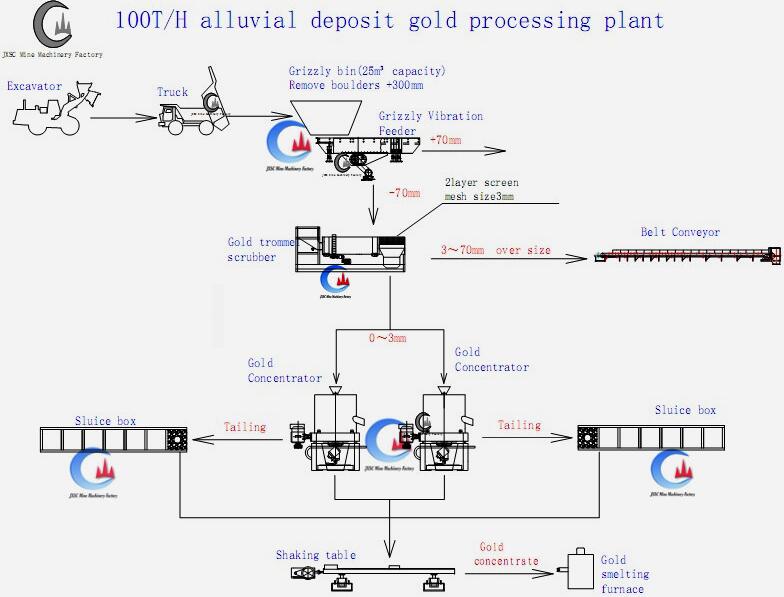

Feeding – Washing – Gravity separation – Melting

process flow

100TPH Alluvial Gold Processing Plant

This is a complete 100tph alluvial gold processing plant flow, the customer didn’t need mobile equipment, and wanted economical and practical’s solution. Because the alluvial gold with less sticky mud, so we designed a simple flowchart. When we set the plant details and cost to customers, they accepted this solution.

- The raw materials contain >300mm boulders, so the first step is remove them.

- Gold trommel scrubber uses to washing and screen materials which screen 0-3mm and 3-70mm size.

- Gold concentrator and shaking table to obtain gold concentrates. The tailings transport to sluice box to recycle gold.

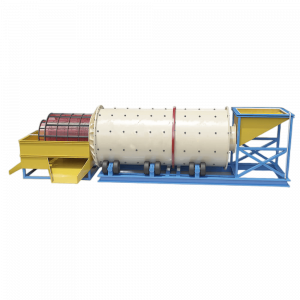

1. Washing stage: trommel scrubber

Boulders larger than 300mm enter the vibrating feeder with a grid screen to remove materials larger than 70mm. The material smaller than 70mm enters the trommel scrubber with two layers of screens to wash away the sludge, and the material of 3-70mm is transported to the side by a belt conveyor.

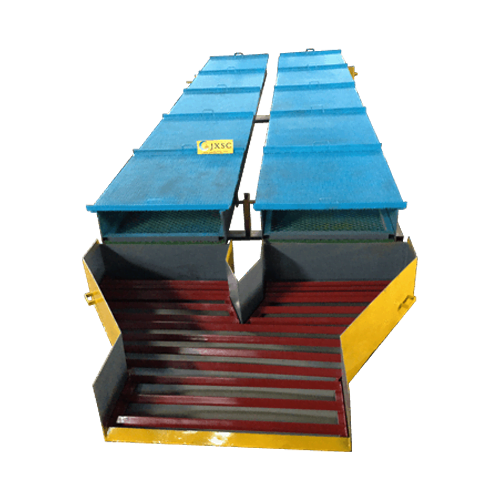

2. Gravity separation: gold centrifugal concentrator, sluice box, shaking table, gold melting furance

The 0-3mm material enters two centrifugal concentrators respectively for separation, and the tailings are arranged on the gold chute to obtain gold concentrate. The concentrate is sorted again by a shaker to obtain high-grade concentrate, which is put into a gold melting furnace to be smelted into gold bars.

Main Equipment

Our service

Free Installation Guidance

Wherever you are, we will send professional engineers to mine site for equipment installation and commissioning guidance, or phone-video guidance.

After-sales Service

All of our mining equipment are supported One-year Warranty service, and provide technical support & problem solution& improvement advising during production.

Free Design Solution

Provide whole mineral processing plant flowchart and machine layout according to mine site conditions. All processing machines and accessories factory price.

Export the World

Shipping all machines to global port. We have 39+ years of export experience, exported to more than 60 country.

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.