200TPH Alluvial Gold Processing Plant In Ethiopia

We guarantee the high quality machine in the mineral processing industry, established in 39+ years of experience.

Project Info

1. Raw ore: alluvial gold ore containing soil, tested to contain black sand (magnetite)

2. Capacity: 200TPH

3. Feed size: 100mm

4. Location: Ethiopia

Process

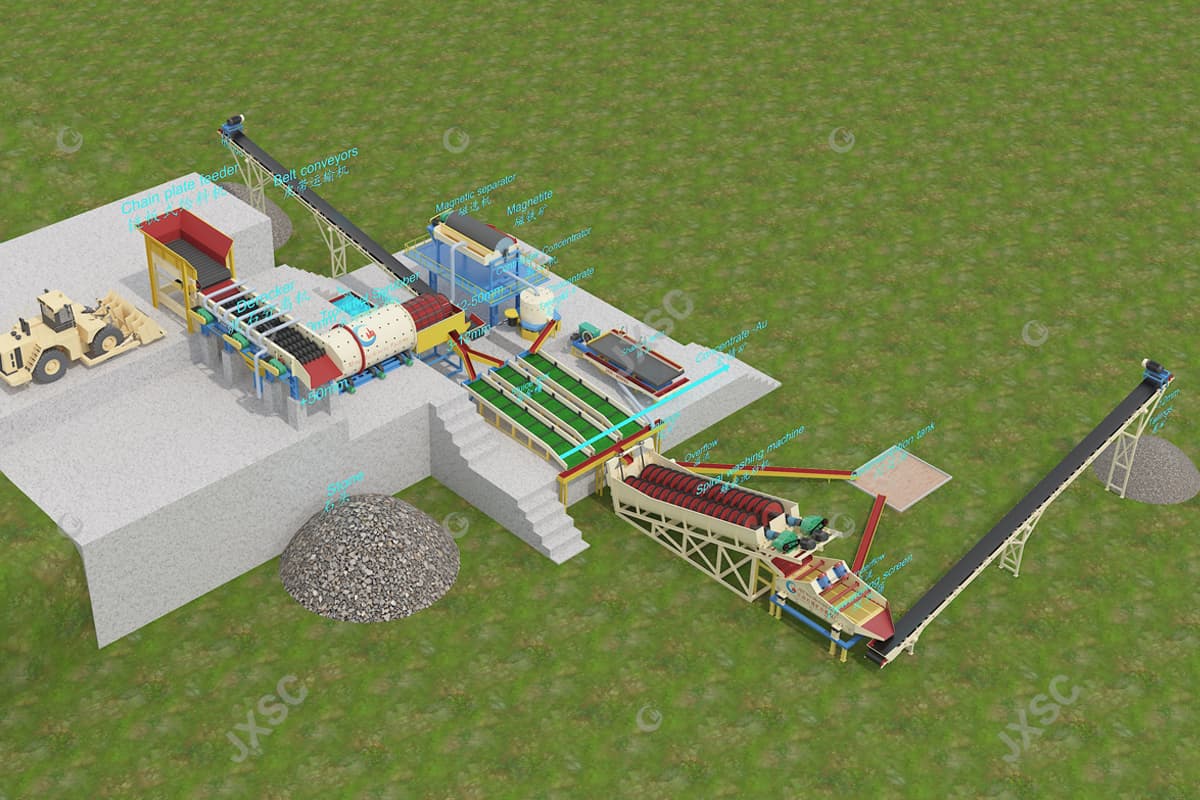

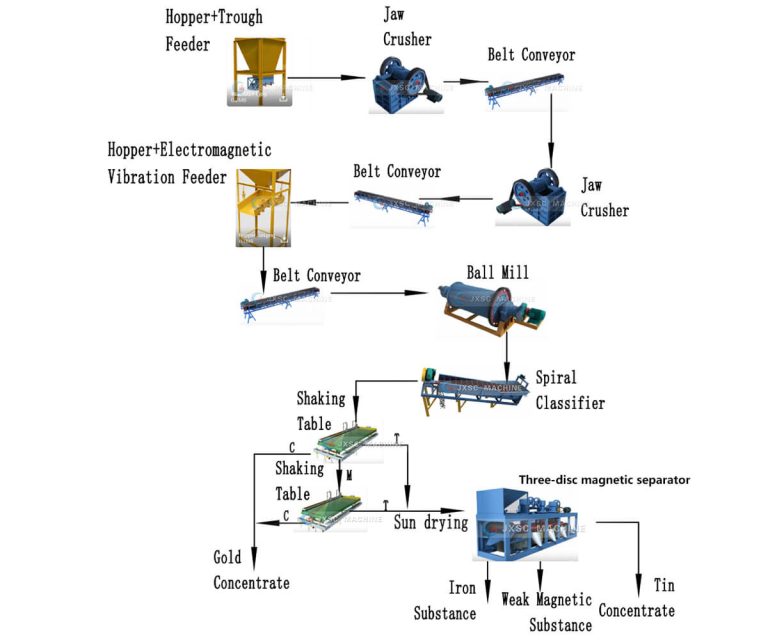

Feeding – Washing- Magnetic separation- Gravity separation – Washing – Dewatering

process flow

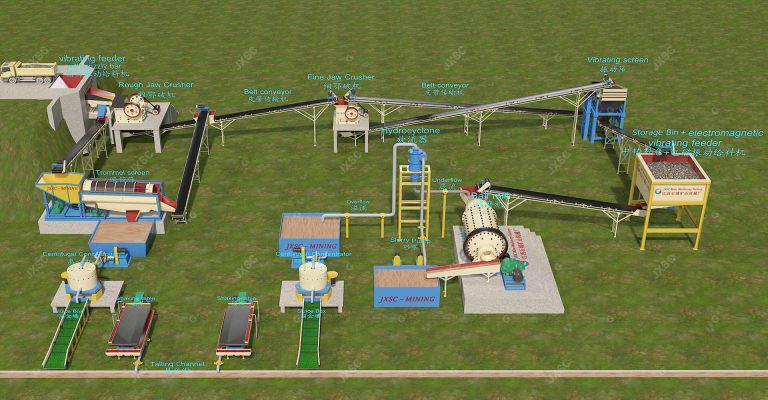

200TPH Alluvial Gold Processing Plant flow

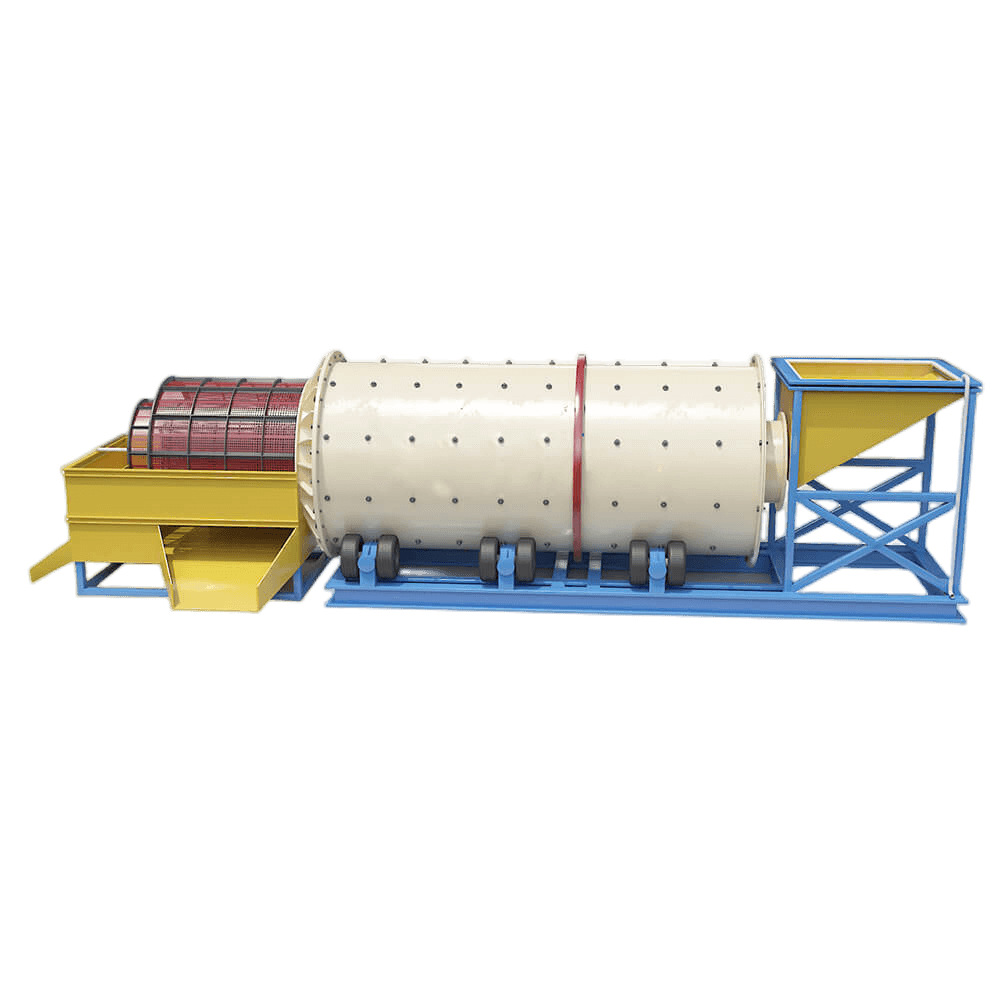

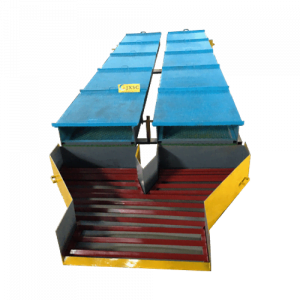

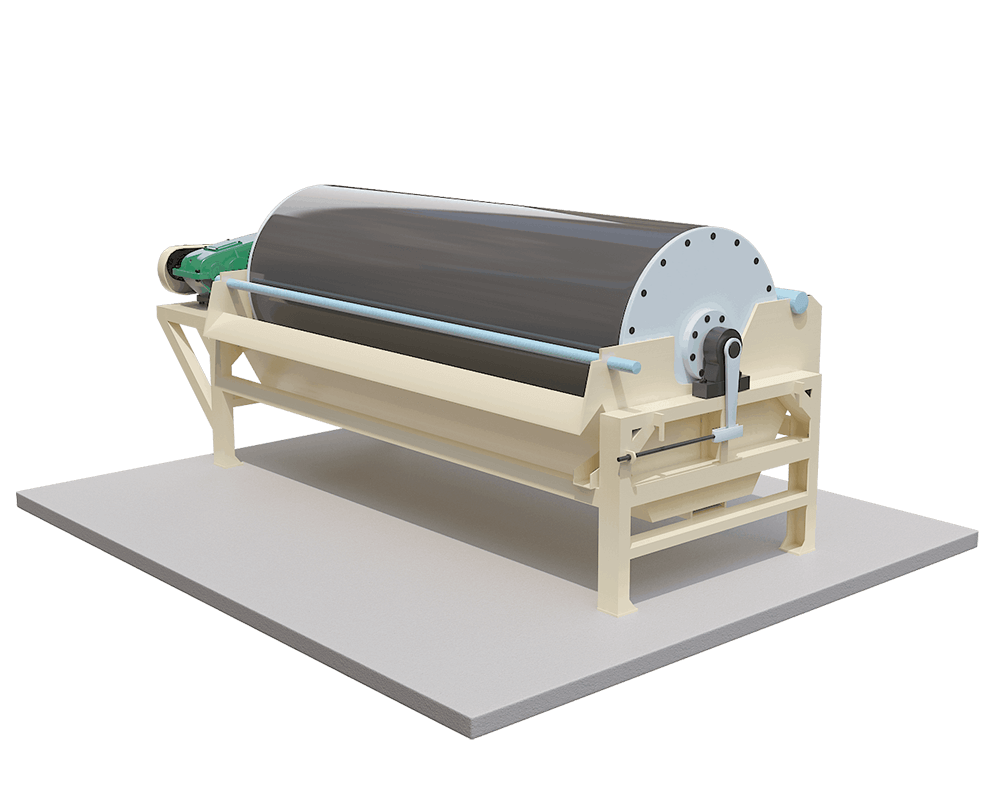

According to the customer’s requirements, we are equipped with a complete set of 200TPH alluvial gold processing plant. The main equipment is a drum scrubber for removing oversized rocks; a wet drum magnetic separator for removing black sand; and centrifugal concentrators, shakers and sluice boxes to capture fine gold concentrates and gold nuggets.

- First, use a loader to feed the raw materials into the hopper, and the stone enters the chain feeder from the lower part of the hopper; the material is sent to the mud and stone separator. Since the stone contains large mud, this equipment is used to separate soil and ore. Then the +50mm waste material will be separated by the unloader and transferred to the ground as a waste pile, and the -50mm material will enter the trommel scrubber.

- We made 2 screens on the trommel scrubber, 3mm and 12mm respectively. After cleaning and screening, the 12-50mm material is transported away by the belt conveyor as waste sand. Materials with a size of 3-12mm will flow to 2 sets of gold sluice boxto capture gold particles.

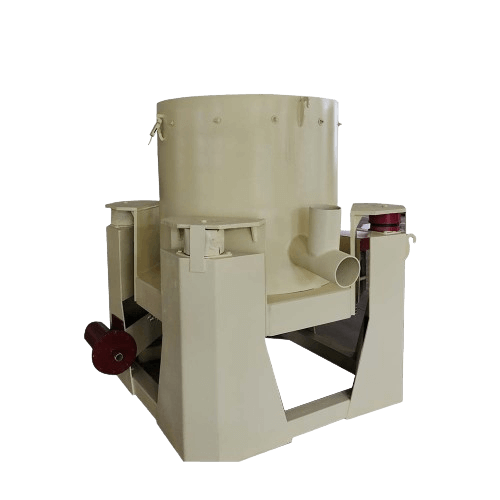

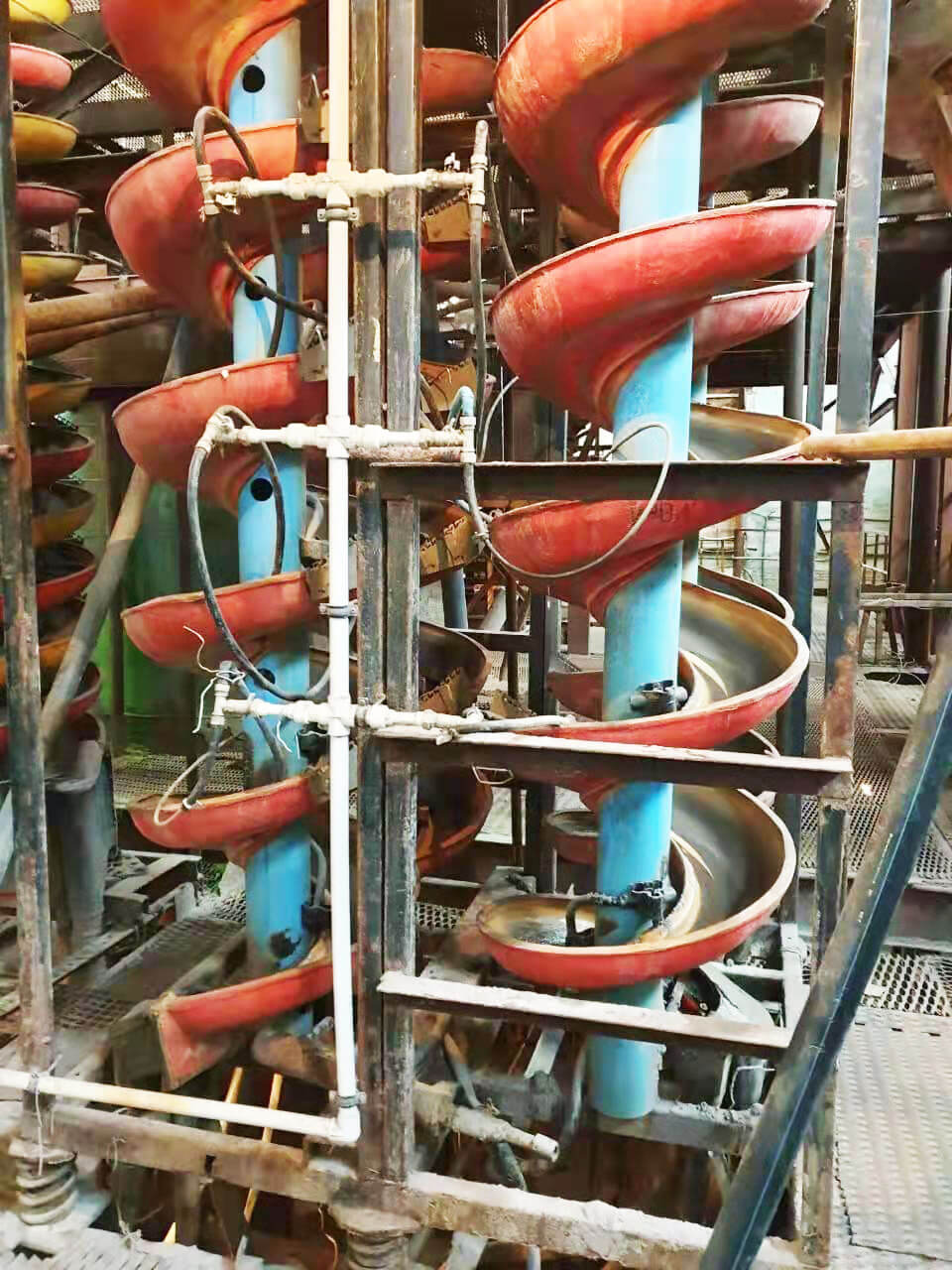

- Then input the cleaned 0-3mm material into the slurry tank. The slurry pump is then used to pump the final material 0-3mm to the wet drum magnetic separator to remove black sand (magnetite). After removing the magnetite, its tailings will be sent to a centrifugal concentrator, which can concentrate 0-3mm gold particles. The tailings may contain fine gold, so they will flow to the sluice box again for capture.

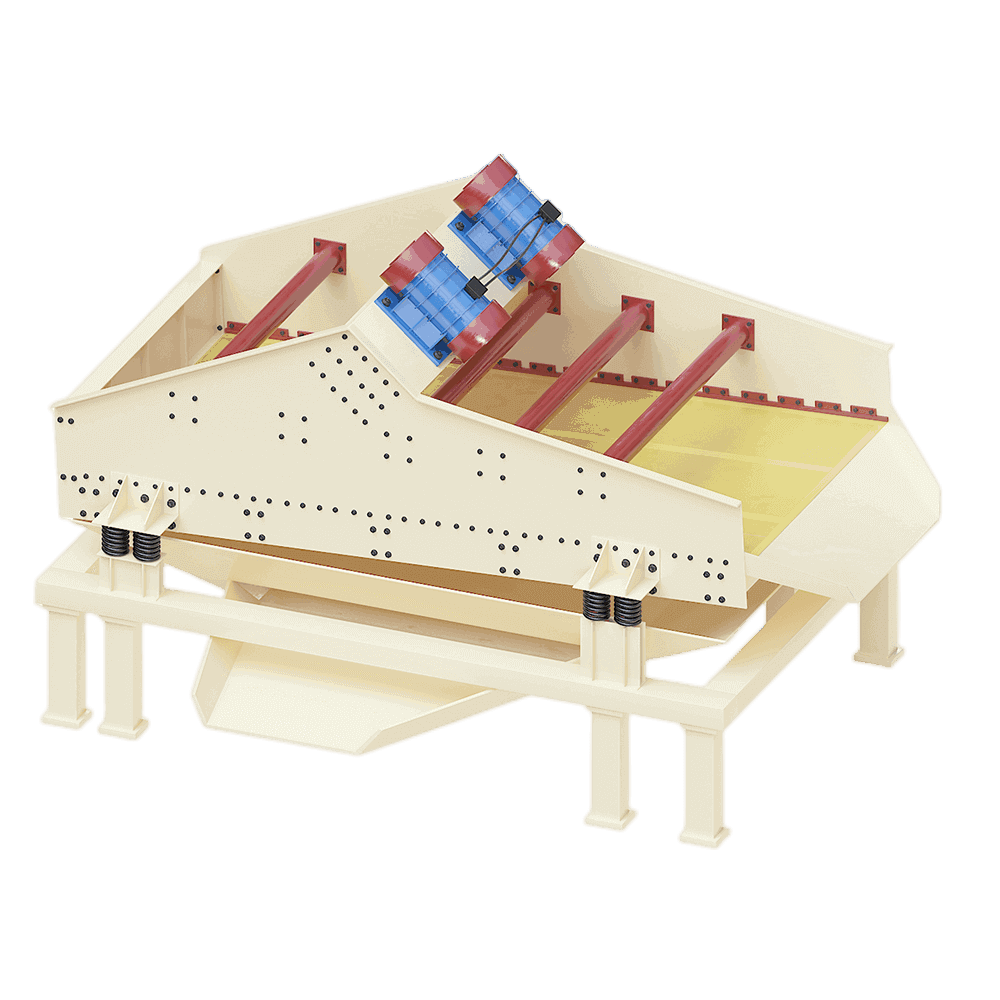

- The concentrate after the centrifugal concentrator enters the shaking table through the pipeline, and the shaking table can concentrate the gold powder to between 0-2mm. Finally, use the gold melting furnace to get gold bars (available if needed).

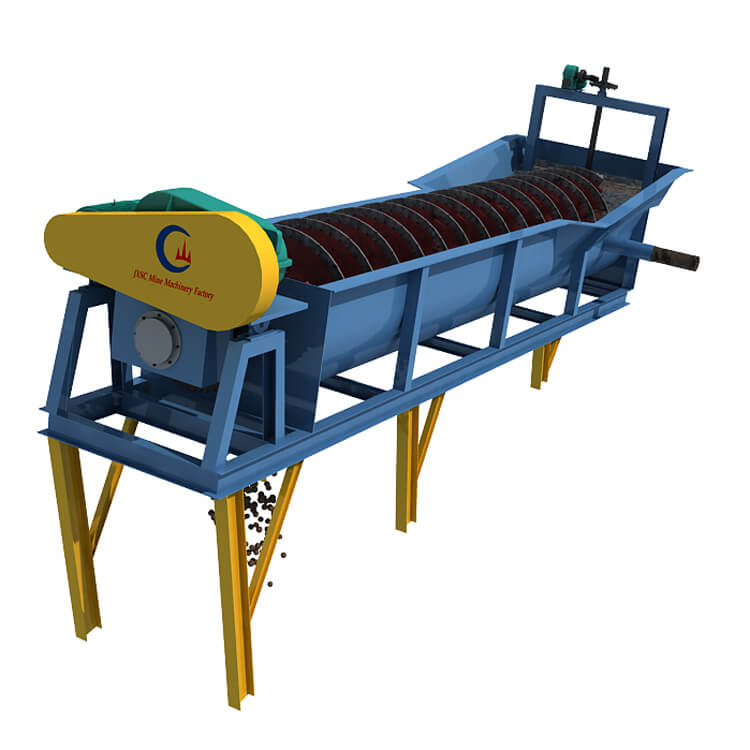

- After all the gold concentrate is obtained, the tailings in the three sets of lock boxes will be sent to the spiral sand washing machine, and then the 0-12mm dry tailings sand will be sent out using a belt conveyor; the overflow will be clean water. A drain box can be used in the trommel scrubber or dewatering screen, and the clean water flows to the sedimentation tank.

- The particle size of 0-3mm sand is very small, so an extra dewatering screen is used to dehydrate it again, and finally a belt conveyor is used to send out the tailings dry sand.

The placer gold processing plant has high production efficiency and is suitable for recycling placer gold ore containing sticky clay. All the above equipment can be replaced with different models and increased in quantity according to different production capacities. JXSC supports customized gold processing plants and equipment, contact us for more details!

Main Equipment

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.