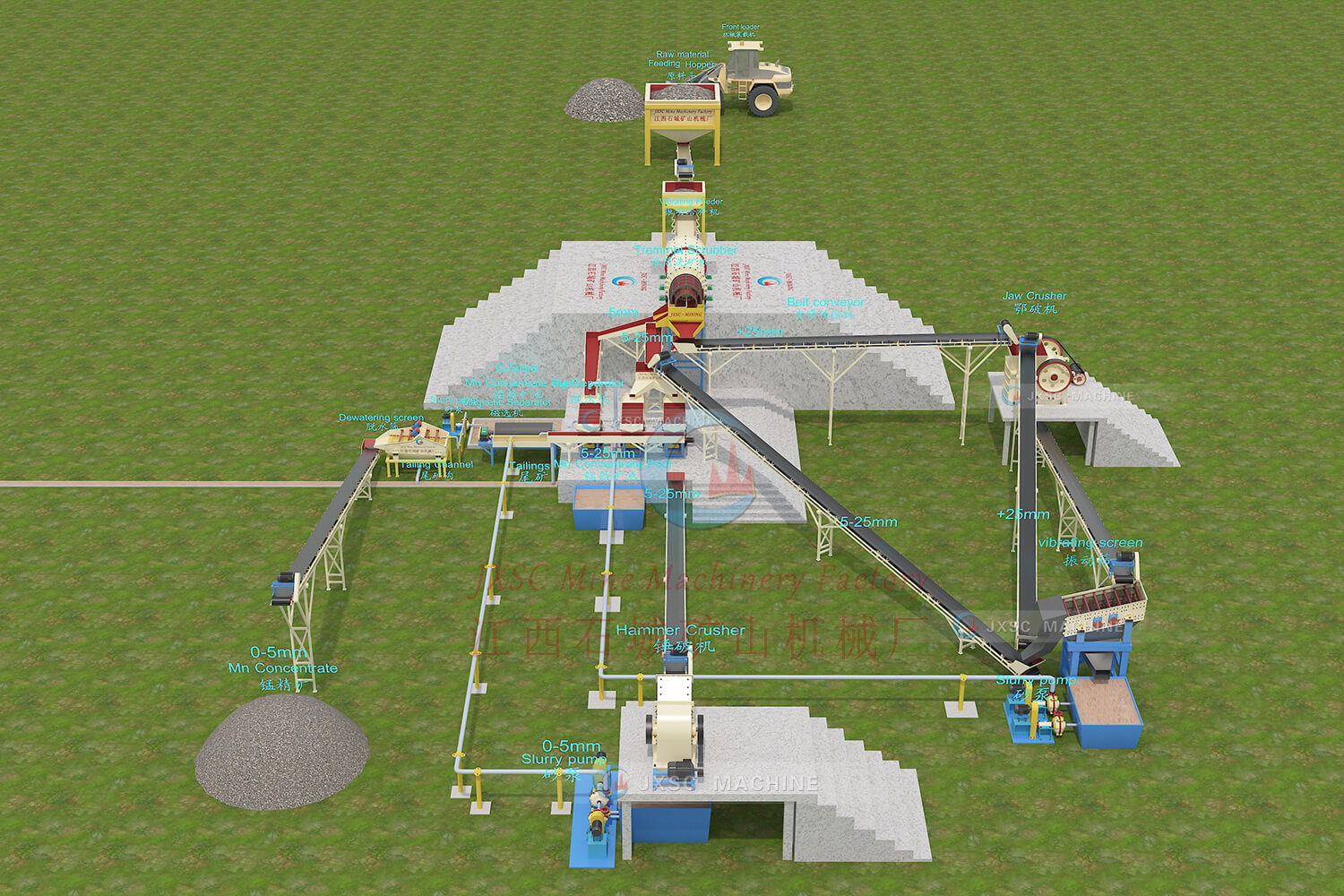

50TPH Alluvial & Rock Manganese Beneficiation Plant In Kenya

We guarantee the high quality machine in the mineral processing industry, established in 40+ years of experience!

Project Info.

- Raw ore: alluvial & rock manganese ore

- Capacity: 50 TPH (tons per hour)

- Maximum feed size: 300mm

- Output: 0-5mm

- Location: Kenya

Process

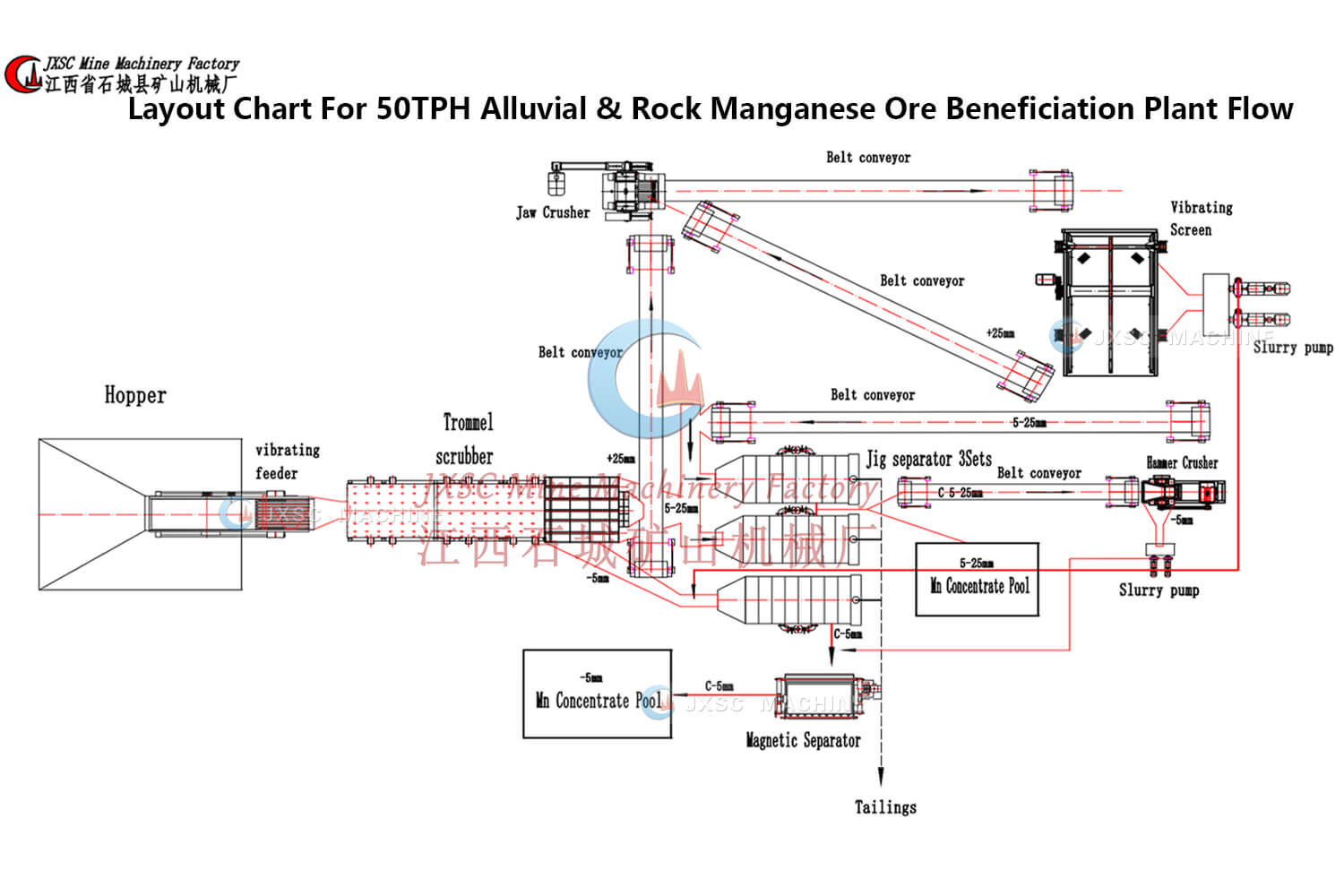

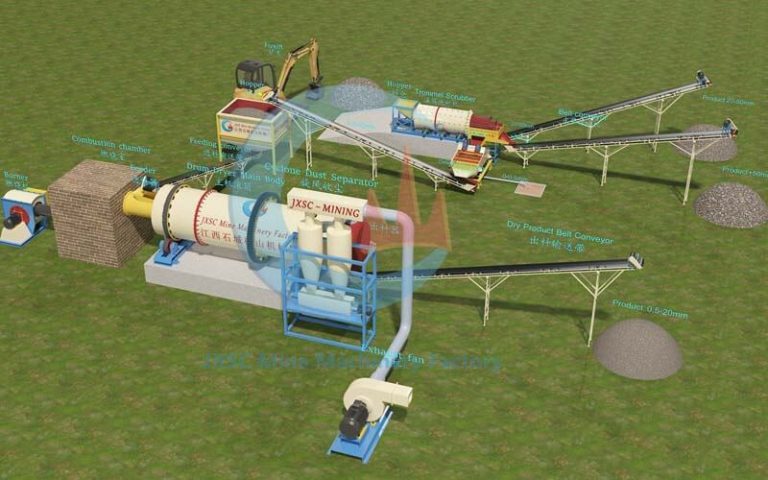

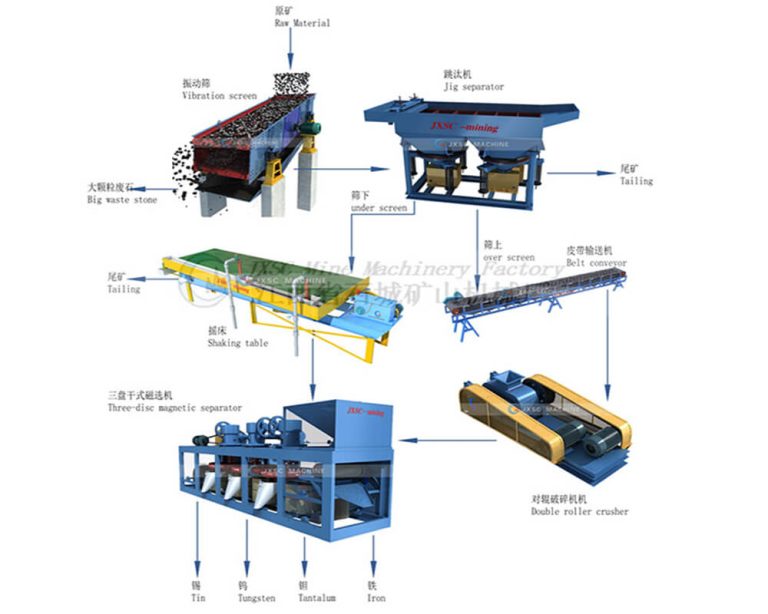

Washing – Coarse crushing – fine crushing – Screening – gravity separation (jig concentrator) – Drum magnetic separator

process flow

50TPH Alluvial & Rock Manganese Beneficiation Flow

This project is a 50 tons per hour (TPH) combined alluvial and rock manganese beneficiation plant in Kenya. JXSC was fully responsible for the design, equipment supply, and process construction. It integrates multiple processes, including crushing, screening, washing, gravity separation, and magnetic separation, enabling the efficient separation and purification of both sand and manganese ore, as well as rock manganese ore, simultaneously. This provides a one-stop solution for the large-scale development and high-value utilization of local manganese ore resources.

1. Alluvial Manganese Beneficiation Flow

(1) Feeding and Washing

The raw ore is uniformly fed from the hopper into the trommel scrubber by a vibrating feeder. Under the combined action of rotation, agitation, and water flushing, the muddy attachments on the surface of the ore are removed, and preliminary particle size classification is completed simultaneously.

(2) Classification and Separation

After washing, the ore is divided into three grades:

- +25mm size: conveyed by a belt conveyor to a jaw crusher for crushing to reduce the ore size.

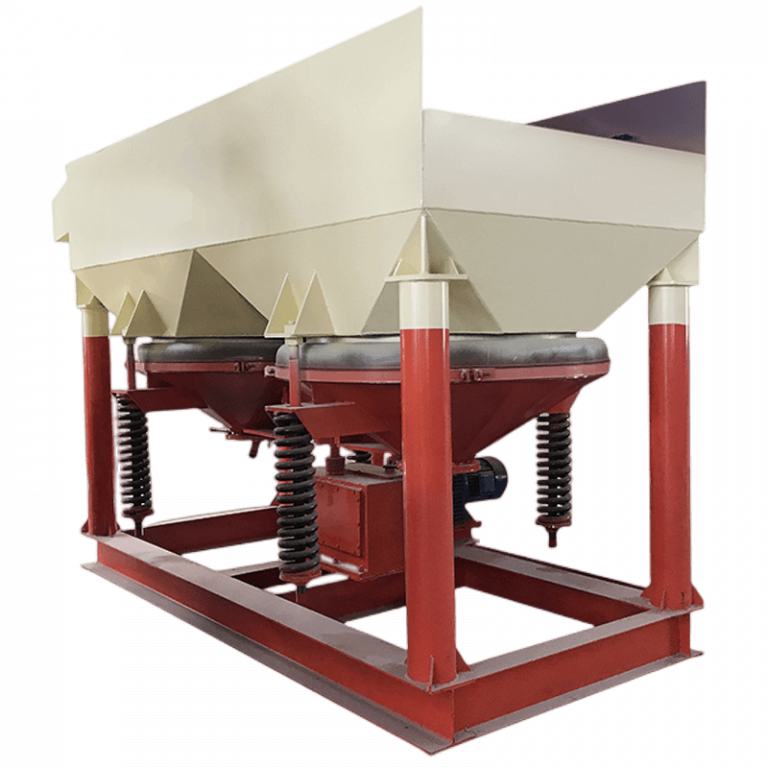

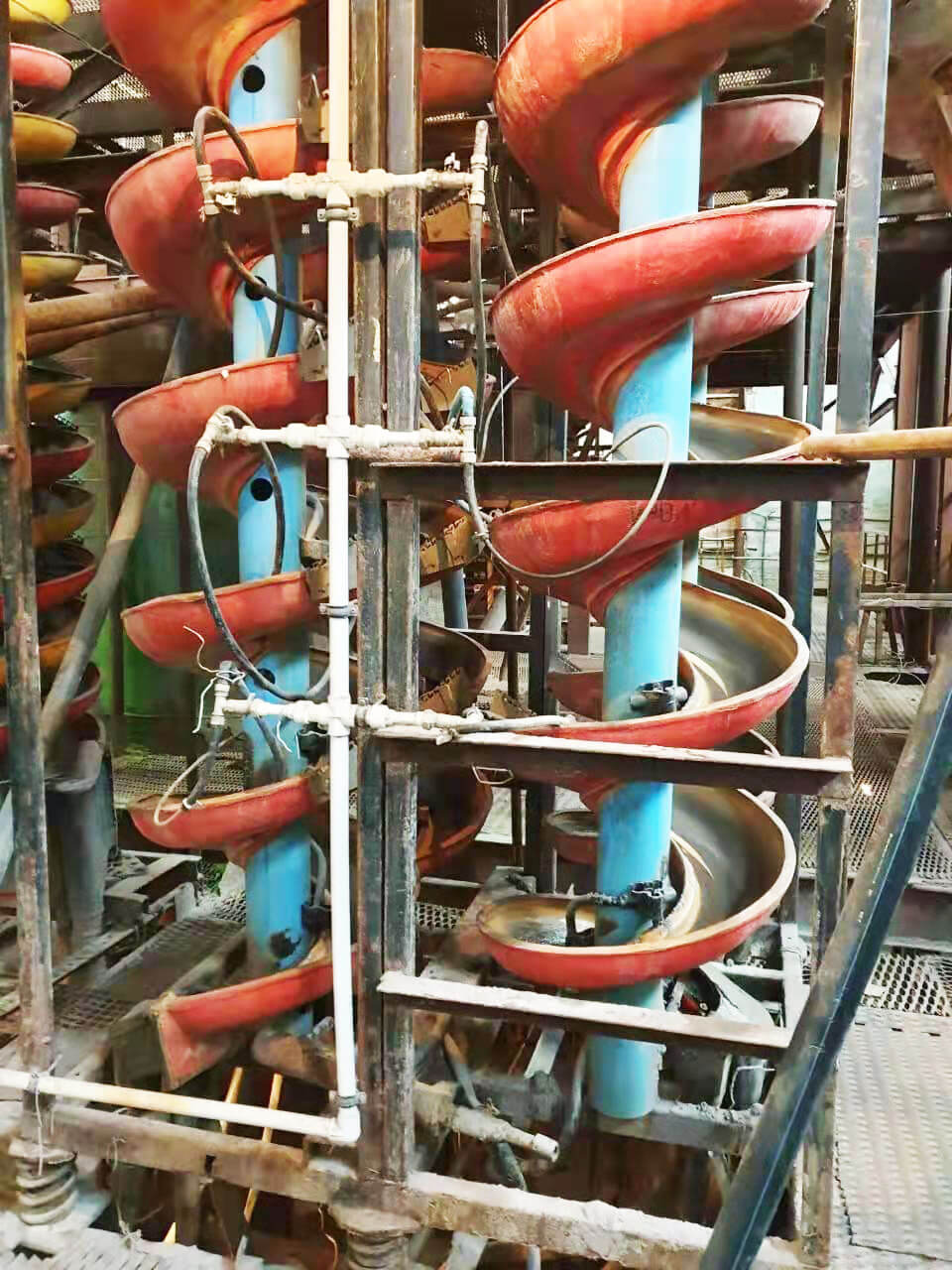

- 5-25mm size: enters three jigging machines for gravity separation, utilizing the density difference between manganese ore and gangue to enrich the manganese concentrate. The concentrate enters the 5-25mm manganese concentrate pool, and the tailings enter the subsequent magnetic separation process.

- -5mm size: directly sent to the magnetic separator, where the concentrate is separated using the weak magnetic properties of manganese ore and sent to the -5mm manganese concentrate pool, and the tailings are finally discharged.

2. Rock Manganese Ore Beneficiation Flow

(1) Crushing and Screening

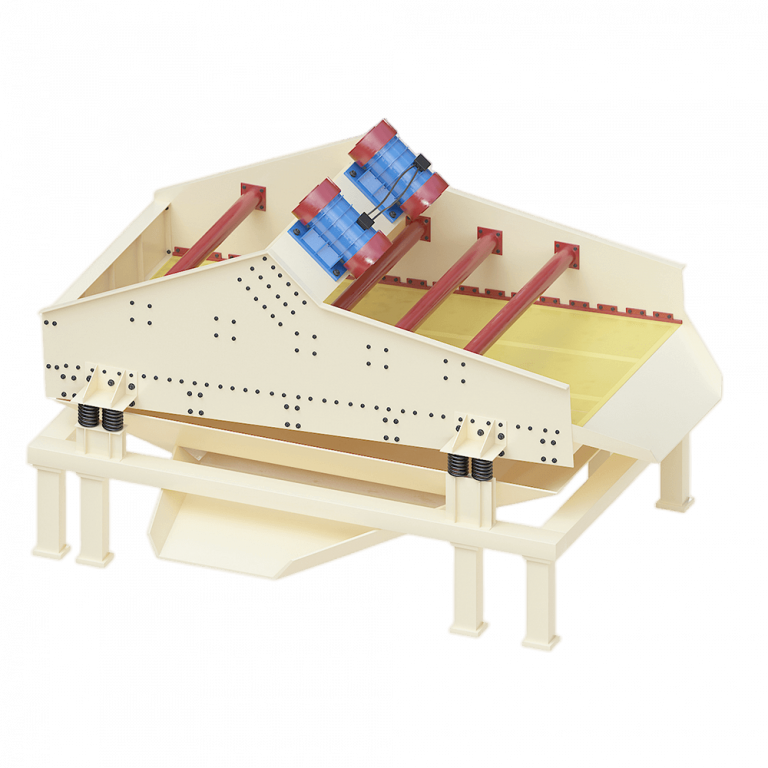

The raw ore is coarsely crushed by a jaw crusher and then transported by a belt conveyor to a vibrating screen for classification.

(2) Secondary Crushing and Grinding

+25mm particle size: Returned to the jaw crusher for further crushing.

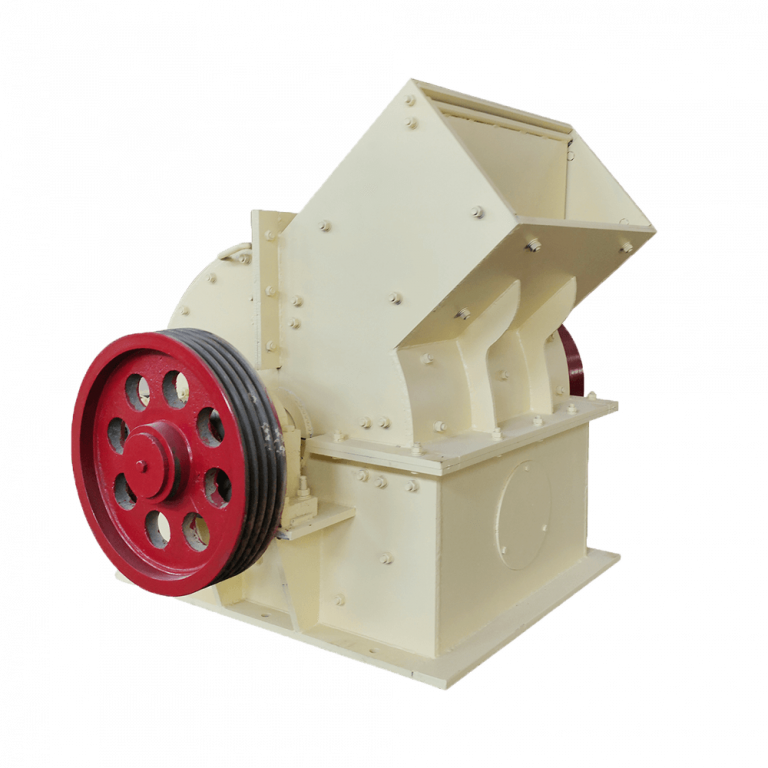

5-25mm particle size: Transported by a belt conveyor to a hammer crusher for further fine crushing to -5mm, and then transported to a magnetic separator by a slurry pump.

(3) Magnetic Separation and Enrichment

The finely crushed ore slurry enters the drum magnetic separator for separation. The concentrate is transported to the -5mm manganese concentrate pool, and the tailings are discharged.

This 50 TPH alluvial & rock manganese beneficiation plant utilizes a combined process route of washing, screening, crushing, gravity separation, and magnetic separation. It is primarily designed to achieve precise separation based on the characteristics of both sandy and rocky manganese ores, ensuring stable production capacity while effectively improving the grade and recovery rate of manganese concentrate. The process design prioritizes both practicality and economic efficiency, and the equipment configuration is mature and reliable. JXSC manganese ore beneficiation equipment has been successfully used in mining areas in South Africa, Australia, Zimbabwe, and other regions. We can also provide customized solutions based on your ore characteristics, production capacity requirements, site conditions, and budget. Please feel free to contact us to configure a manganese beneficiation process and equipment tailored to your specific needs.

Process Site

50TPH Alluvial & Rock Manganese Beneficiation Plant Site

Highlight Of JXSC Design Manganese Beneficiation Plant

√ Strong Process Compatibility: Compatible with both sand manganese ore and rock manganese ore, achieving efficient sorting of different ore types through modular design.

√ Refined Classification: Utilizes a three-stage particle size classification process (+25mm, 5-25mm, -5mm), matching the optimal sorting equipment for each size fraction to improve beneficiation efficiency and concentrate recovery rate.

√ Efficient Combined Process: Combines gravity separation and magnetic separation processes; gravity separation efficiently enriches coarse particles, while magnetic separation recovers fine-grained manganese ore, maximizing resource utilization.

√ Optimized Equipment Configuration: The combination of jaw crusher and hammer crusher meets both coarse and fine crushing requirements, and the combination of jigging machine and magnetic separator ensures high sorting accuracy for different particle sizes.

√ Compact Process Layout: The equipment layout is scientifically and rationally designed, with conveyor belts and slurry pumps effectively connecting each process step, reducing material transfer costs and time.

√ Energy Saving and Environmental Protection: Water used for washing and sorting can be recycled, and the dry tailings discharge design reduces water consumption and environmental pollution.

Main Equipment

Equipment List For 50TPH Alluvial & Rock Manganese Beneficiation Plant

| Item No. | Main Equipment(Model) | Detailed Description of Product | Quantity (Sets) |

| 1 | Vibrating feeder (380*96) |

| 1 |

| 2 | Trommel scrubber (JXSC-1200) |

| 1 |

| 3 | Belt conveyor (500*10m) |

| 1 |

| 4 | Fine jaw crusher (PEX250*1000) |

| 1 |

| 5 | Belt conveyor (500*10m) |

| 1 |

| 6 | Vibrating screen (2YK-1548) |

| 1 |

| 7 | Belt conveyor (500*12m) |

| 1 |

| 8 | Belt conveyor (500*10m) |

| 1 |

| 9 | Slurry pump (4/3 inch) |

| 1 |

| 10 | Jig separator (JT4-2) |

| 1 |

| 11 | Jig separator (JT4-2) |

| 2 |

| 12 | Drum magnetic separator (380*1500) |

| 1 |

| 13 | Back wash water pump (4inch) |

| 3 |

| 14 | Water pump (8inch) |

| 1 |

| 15 | Belt conveyor (500*10m) |

| 1 |

| 16 | Hammer crusher (PC-800*600) |

| 1 |

| 17 | Slurry pump (4/3 inch) |

| 1 |

| 18 | Belt conveyor (650*15m) |

| 1 |

| 19 | Belt conveyor (500*10m) |

| 1 |

| 20 | Slurry pump (4/3 inch) |

| 1 |

| 21 | Dewatering screen (DN1530) |

| 1 |

| 22 | Belt conveyor (500*10m) |

| 1 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.