We guarantee the high quality machine in the mineral processing industry, established in 40+ years of experience!

Project info

1. Raw ore: rock tin ore

2. Capacity: 5TPH

3. Location: Uganda

Process

Crushing – Screening – Gravity separation

process flow

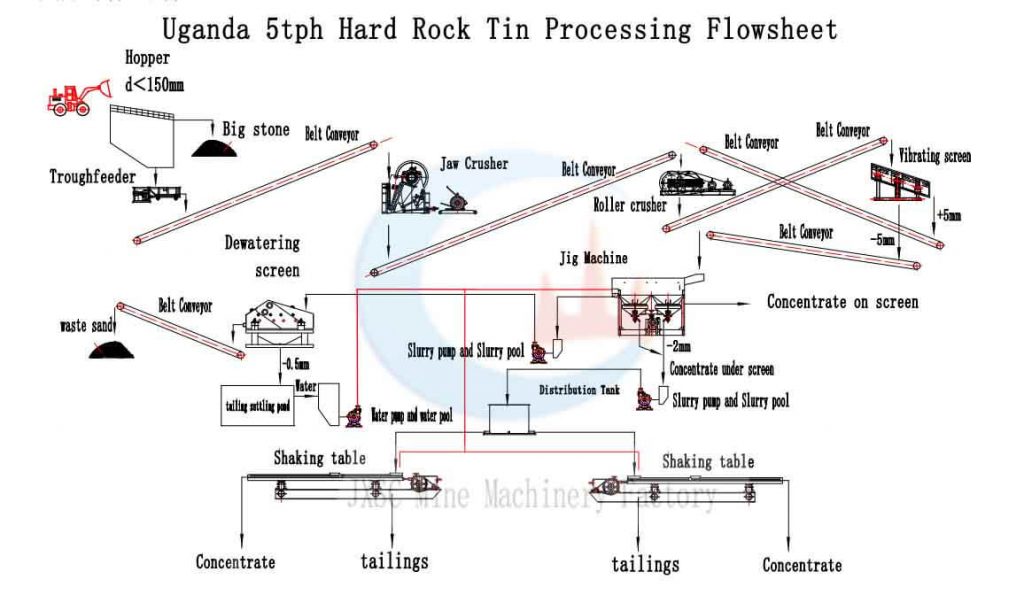

5TPH Rock Tin Ore Processing Plant Flow

JXSC has designed a complete set of rock tin ore processing plant machines, flowcharts, and accessories for Uganda customers. The client has its own engineering team to set up this plant. We offer a detailed layout design with base construction drawings accordingly.

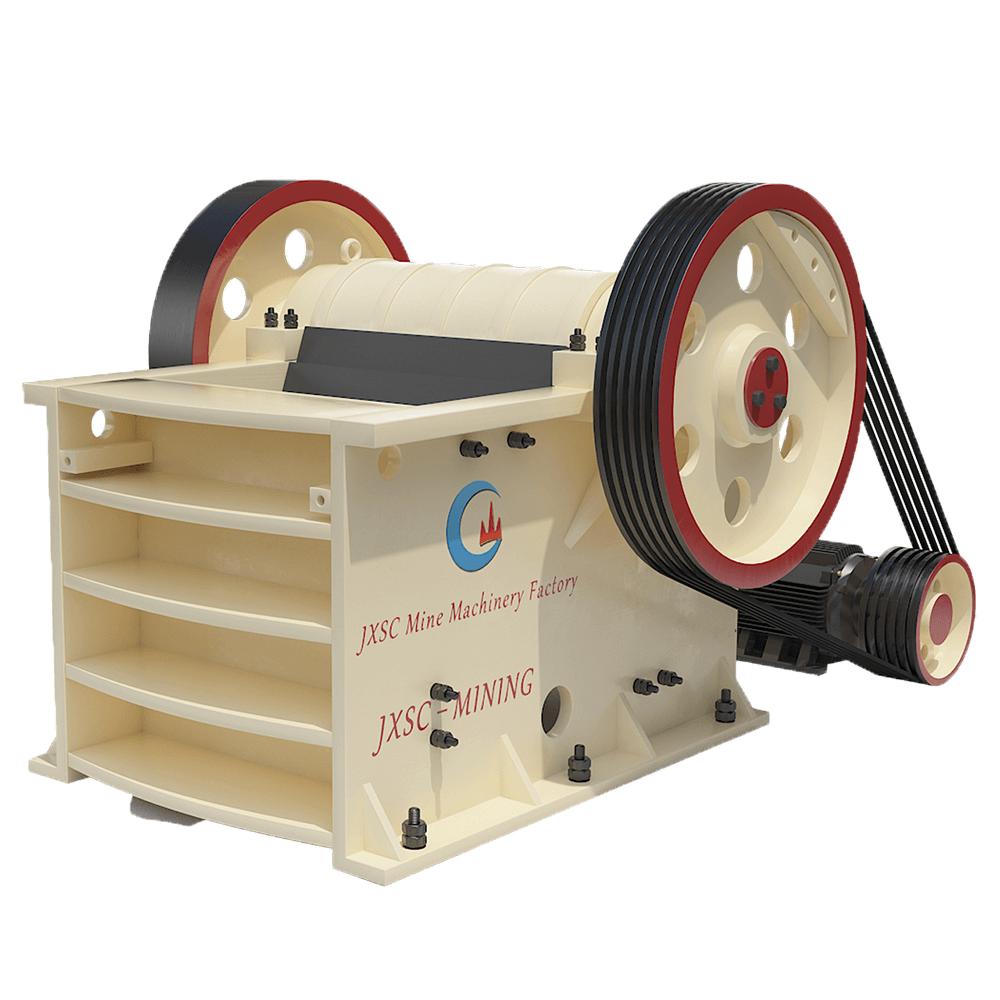

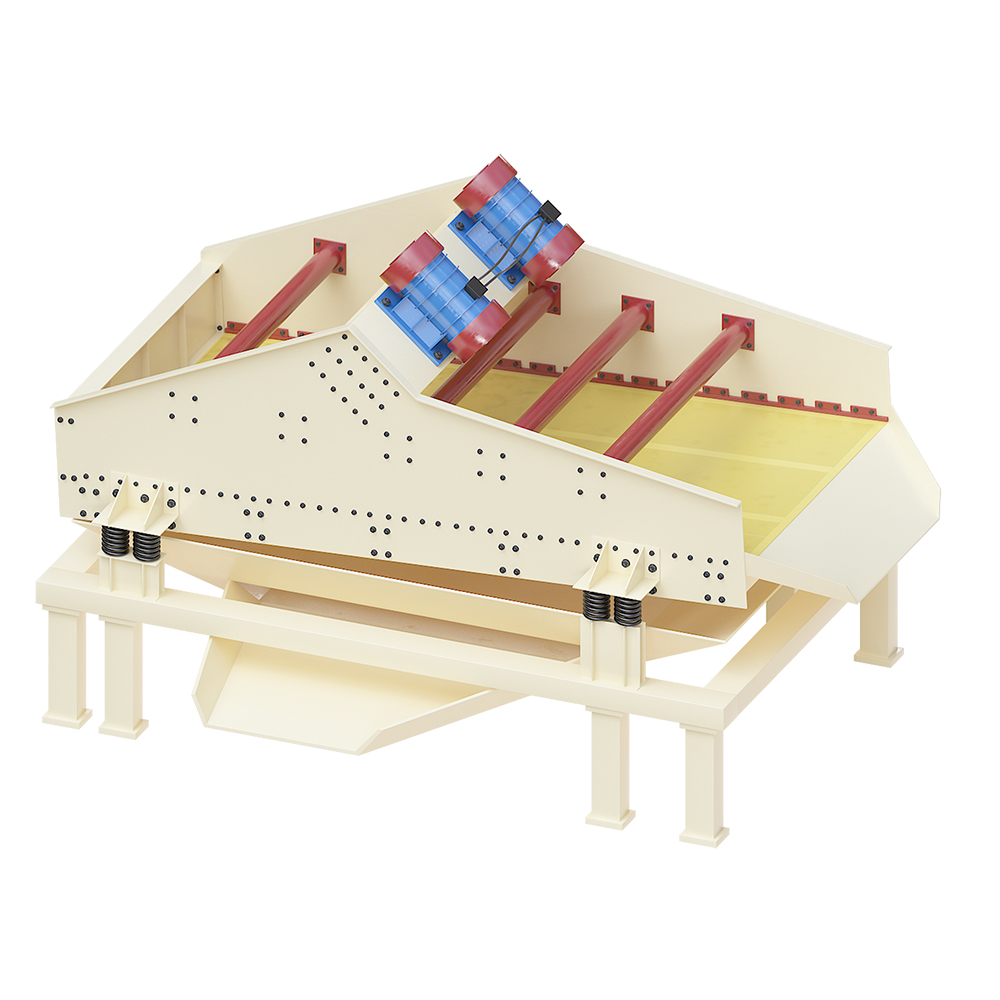

1. Crushing & Screening: jaw crusher, roll crusher

There is a smaller hopper above the jaw crusher and a chute feeder below the hopper. The stone can be fed into the jaw crusher more evenly and smoothly. The output of the jaw crusher is small and then screened with a vibrating screen. Materials larger than 5mm enter the next double-roll crusher for fine crushing through the belt conveyor. The material output from the roller crusher will be transported to the vibrating screen for re-screening.

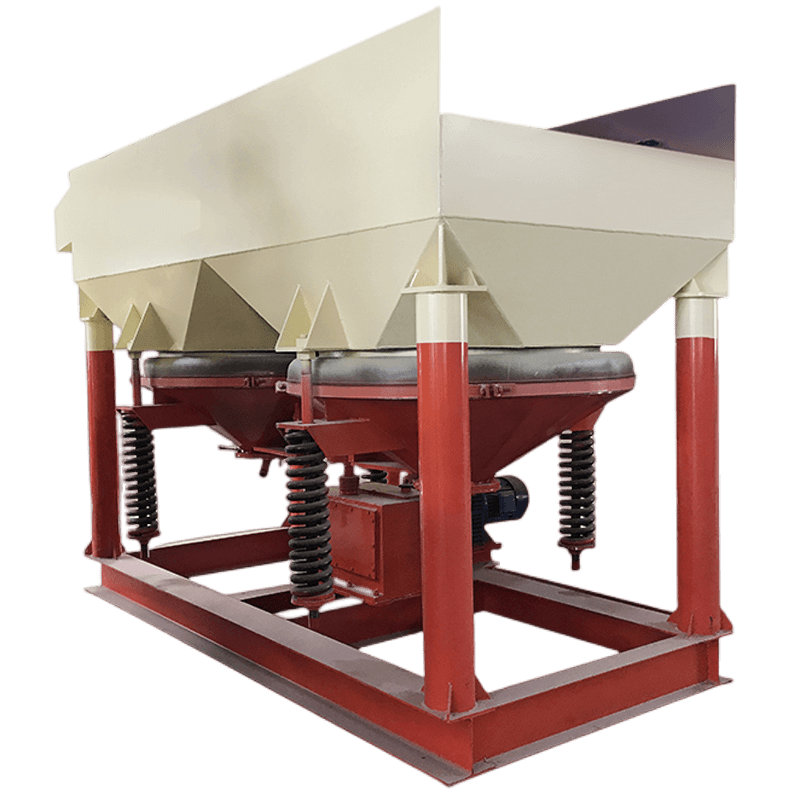

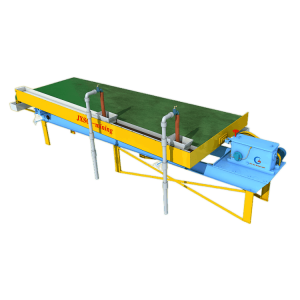

2. Gravity separation: jig separator, shaking table

Materials smaller than 5 mm enter another belt conveyor into the jig. The slurry pump directly transported the concentrate <2mm under the jig screen to the distribution tank. Then enter the vibrating table for separation to obtain high-grade tin concentrate.

3. Water recycling

The customer requires a dewatering screen and needs to recycle the tailings water of the jig machine. The belt conveyor transports the dehydrated waste sand away.

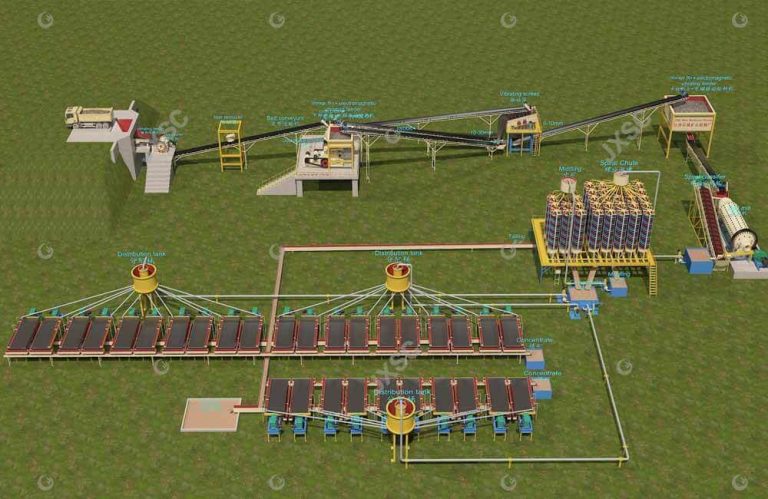

Process Site

5TPH Rock Tin Ore Processing Plant Site

Main Equipment

5TPH Rock Tin Ore Processing Plant equipment list

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.