1-6KG Manual-Pour Platinum Melting Machine

- Capacities: 1 kg, 2 kg, 3 kg, 4 kg, 5 kg, and 6 kg are available.

- Maximum temperature: 2100°C-2600°C.

- Melting time: 2-8 minutes.

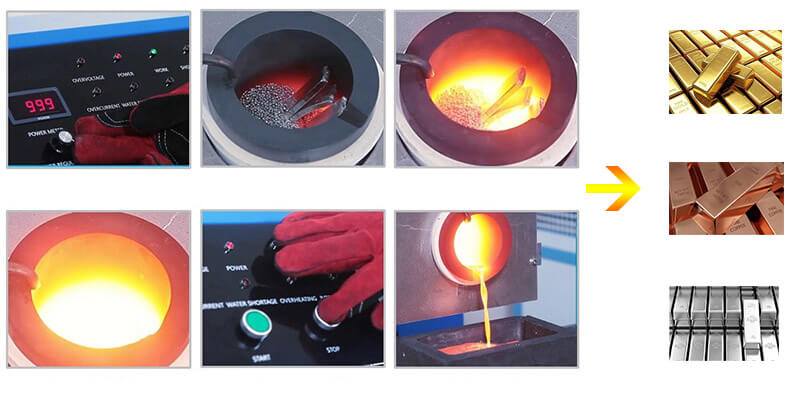

The 1-6KG manual-pour platinum melting machine is an industrial-grade melting device designed for small to medium-sized precious metal processing. Utilizing IGBT frequency conversion technology, combined with a high-temperature resistant graphite crucible and a closed-loop temperature control module, it can heat platinum, palladium, rhodium, gold, silver, copper, karat gold, or alloys to their melting point within 2-8 minutes, meeting the requirements for high-purity metal melting.

Introduction of 1-6KG Manual-Pour Platinum Melting Machine

The 1-6KG manual-pour platinum melting machine, also known as a hand-titling platinum casting furnace, is a small-scale melting device specifically designed for precious metal processing (especially platinum). It is suitable for laboratories, jewelry workshops, or small-batch production. Its core function is to melt solid high-melting-point metals, such as palladium, gold, palladium gold, rhodium, karat gold, silver, copper, and alloys, into a liquid state at high temperatures and then manually pour the melt into shape. This type of equipment uses IGBT electromagnetic induction heating technology, improving heating efficiency and temperature control accuracy within ±1℃. Combined with a high-temperature resistant graphite crucible and a water-cooling system, temperatures can reach above 2100°C-2600°C within 2-8 minutes, meeting the melting point requirements of platinum, while also featuring precise temperature control and safety protection mechanisms. It is widely used in jewelry processing, precious metal recycling, and laboratory material preparation.

Compared to fully automatic melting machine, its core features lie in the manual pouring operation mode and the 1-6 kg capacity range, reducing equipment costs and operational complexity. This manual platinum melting furnace features flexible casters, making it ideal melting equipment for small-batch, multi-batch, customized production needs. For example, jewelers can use it to create complex components such as platinum rings and pendants, while research institutions can use it for small-scale precious metal alloy experiments. Its “manual casting“ design means the operator must transfer the metal by tilting the crucible or using a pouring spoon. While this requires some skill, it allows for better control of the pouring speed and direction, reducing the introduction of air bubbles and impurities, making it suitable for casting complex molds.

Core Functions:

- Jewelry manufacturing: This equipment can rapidly melt 1-6 kg of platinum raw material. The molten metal is manually poured into plaster molds for custom jewelry making, antique jewelry restoration, or the creation of precision wax castings.

- Precious metal recycling: Platinum can be purified from waste circuit boards and catalysts. The manual pouring design allows for direct casting of the molten metal into standard 99.9% gold ingots.

- Research and education: High-temperature materials experiments and research on the properties of precious metal alloys can be conducted, demonstrating metal phase transformation processes.

- Small-scale precious metal processing: For example, gold bar and platinum coin mints can utilize the equipment’s continuous operation capabilities for standardized product production.

Principle of 1-6KG Manual-Pour Platinum Melting Machine

Working principle

This platinum melting machine primarily converts electrical energy into heat energy, utilizing electromagnetic induction heating technology to melt platinum into a liquid state. During operation, the platinum raw material is first placed in a high-temperature resistant crucible, then heated electrically to steadily raise the temperature to platinum’s melting point. To ensure metal purity, an inert gas (such as argon) is typically used for protection against oxidation. Once the platinum is completely melted, the operator manually controls the pouring process, pouring the molten metal into a preheated mold by tilting the crucible or using a pouring tool. The entire process relies on a precise temperature control system (PID control) to ensure stable melting temperature, while also featuring over-temperature protection and melt monitoring functions to enhance safety and process accuracy.

Structural features

- Heating System: The core component is a high-temperature resistant heating element or induction coil, coupled with a PID temperature control module (error ±1°C).

- Crucible Assembly: Typically made of alumina or graphite, corrosion-resistant and non-reactive with platinum.

- Cooling Device: Water chiller or tap water (pump) ensures the equipment does not overheat during prolonged operation.

- Safety Features: Leakage protection, over-temperature alarm, and emergency stop switch; some models are equipped with an observation window to monitor the melting state.

- Frame and Tilting Mechanism: A stainless steel outer shell supports the entire unit; manual levers or gear sets achieve precise crucible tilting.

why choose JXSC 1-6KG Manual-Pour Platinum Melting Machine

features & Advantages

√ High efficiency and energy saving, fast melting speed: Utilizing IGBT electromagnetic induction heating technology, the energy conversion efficiency reaches over 90%, ensuring uniform platinum melting without oxidation.

√ Multifunctional: This furnace supports multiple metals and allows for rapid material switching by changing the crucible, meeting the melting and casting needs of high-value metals such as palladium, rhodium, gold, silver, and copper.

√ Precise temperature control, low metal loss: Temperature error can be controlled within ±1℃, preventing platinum oxidation due to overheating.

√ Easy to use: No complex installation required; can be driven with 380V voltage, suitable for studio or mobile operations.

√ Suitable for multiple scenarios: The 1-6 kg melting range meets the needs of small-batch customization (such as jewelry stores) and medium-batch production (such as precious metal recycling plants).

√ Manual-pouring advantage: Compared to fully automatic equipment, manual operation is more suitable for casting irregular molds (such as complex jewelry castings), and reduces maintenance costs, increasing process freedom.

models & specifications

Model No. | JXSC-TFQ1 | JXSC-TFQ2 | JXSC-TFQ3 | JXSC-TFQ4 | JXSC-TFQ5 | JXSC-TFQ6 |

Power | 15KW | 15KW | 20KW | 20KW | 30KW | 30KW

|

Voltage | 380V, 50Hz, 3 phases | |||||

Max Temp | 2100°C-2600°C | |||||

Melting Time | 2-3mins | 2-5mins | 3-6mins | 3-6mins | 4-8mins | 3-6mins

|

Temp Accuracy | ±1°C | |||||

PID temp control | Optional | |||||

Capacity (Pt) | 1KG | 2KG | 3KG | 4KG | 5KG | 6KG |

Application | Platinum, Gold, K Gold, Silver, Palladiu, Rhodium, Copper And Other alloys | |||||

Cooling type | Water chiller(sold separately) or Running water (water pump), water temperature: 18-28°C | |||||

Heating type | Germany IGBT Induction heating technology | |||||

Dimensions | 900x480x1000mm | |||||

Net Weight | 100KG | |||||

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.