Mineral Separation Equipment

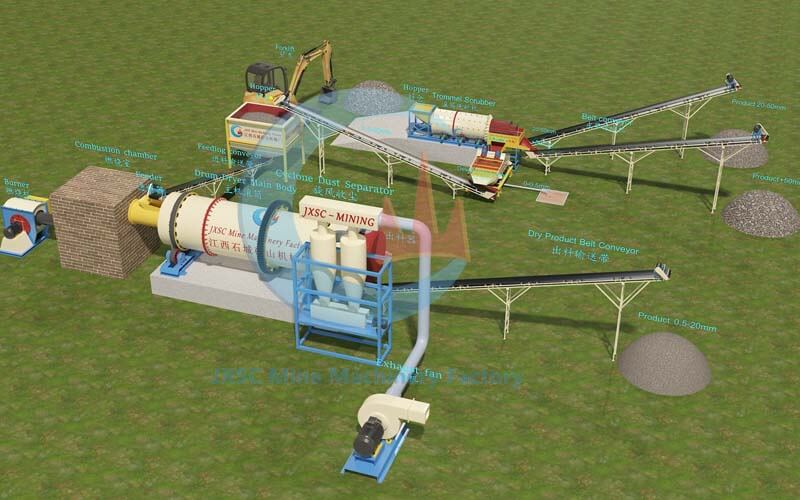

Mineral separation equipment Solution

JXSC is a leading mineral processing equipment supplier specializing in flotation, magnetic separation, and electrostatic separation technologies. We are committed to providing efficient, precise, and environmentally friendly mineral separation solutions to global mining customers. Our mineral separation equipment primarily includes gravity separators, flotation machines, magnetic separators, and electrostatic separators. Our diversified magnetic separators mainly include wet drum, high-intensity, three-disc, flat plate, high-gradient, and slurry magnetic separators. These separators are widely used for removing iron impurities and purifying various metal ores and non-metallic minerals, such as ilmenite, magnetite, chromite, rutile, hematite, coltan, feldspar, quartz sand, tantalum niobium-tin, lithium, gold, copper, manganese, and zircon sand. JXSC mineral separators help customers improve concentrate grade, increase recovery, reduce operating costs, and maximize economic benefits.

Mineral separation equipment for sale

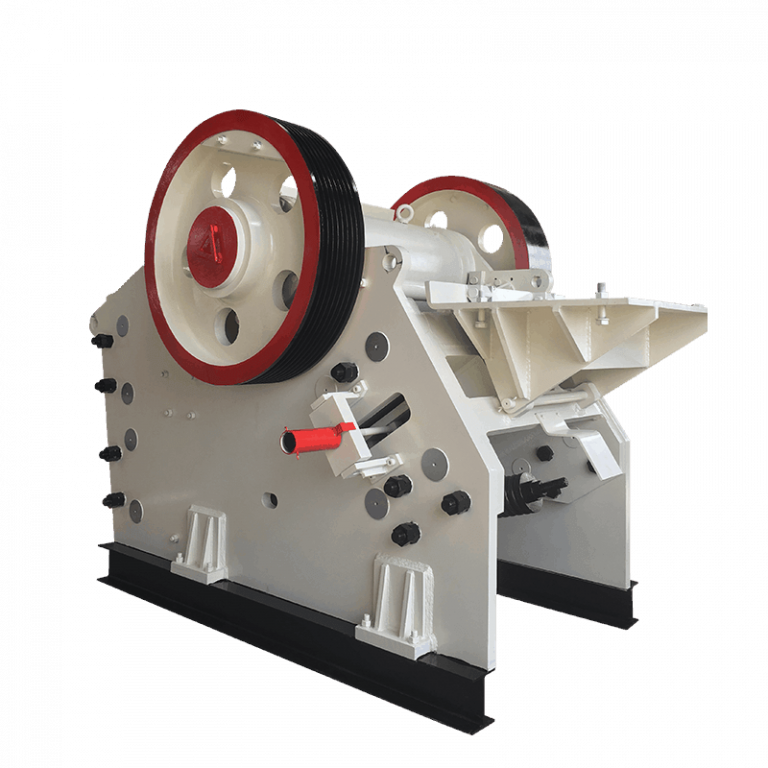

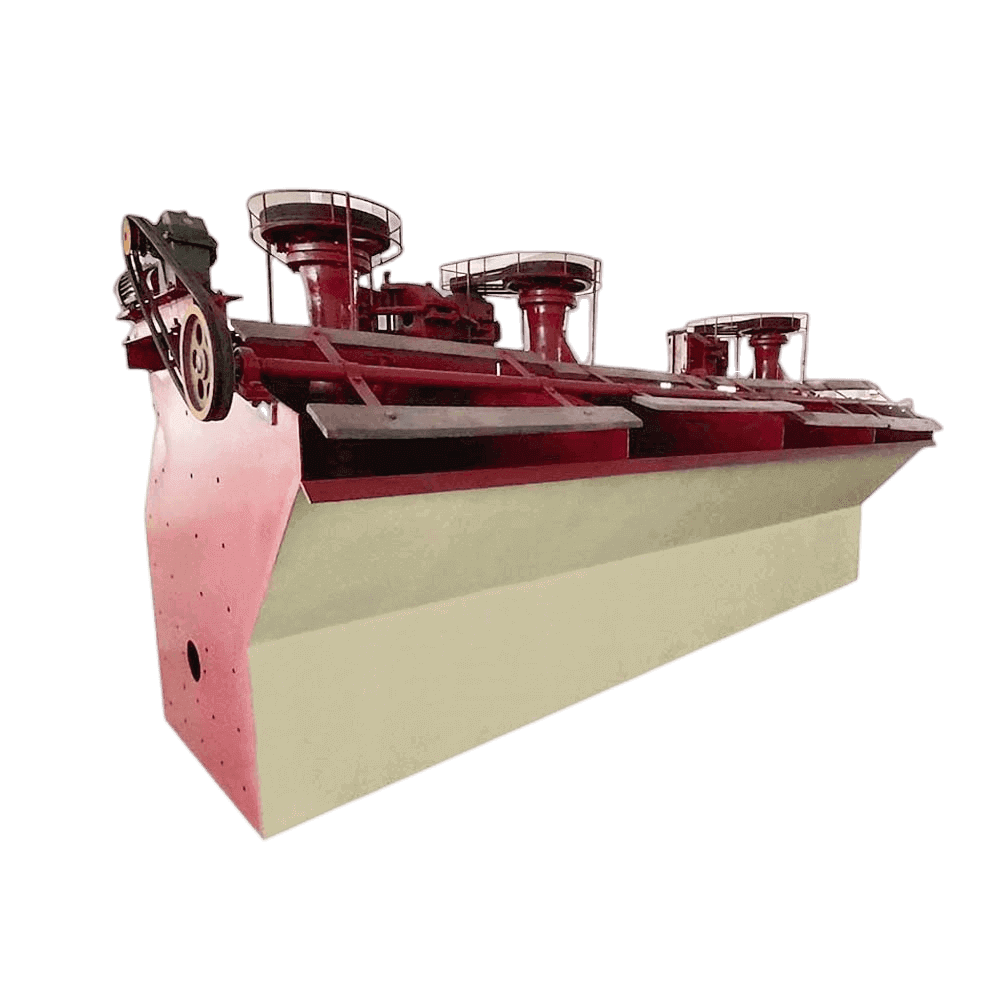

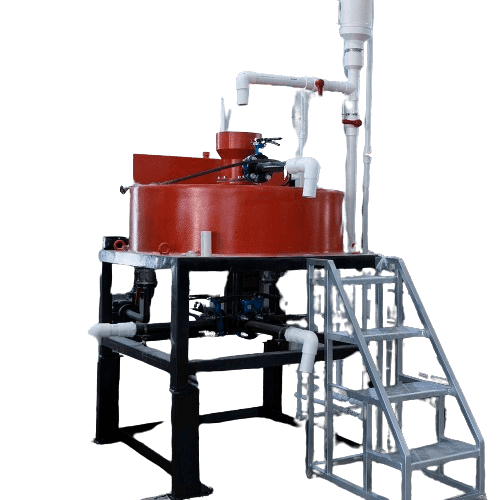

flotation machine

Capacity: 0.18-50m³/min per cell

Types: mechanical stirring type, aerated stirring type, aerated flotation machine, etc.

Application: Flotation machine is widely used for separating copper, gold, zinc, lead, nickel, fluorite, molybdenum ore, nickel ore, barite, antimony, feldspar, phosphate rock, lithium and other mineral processing plants.

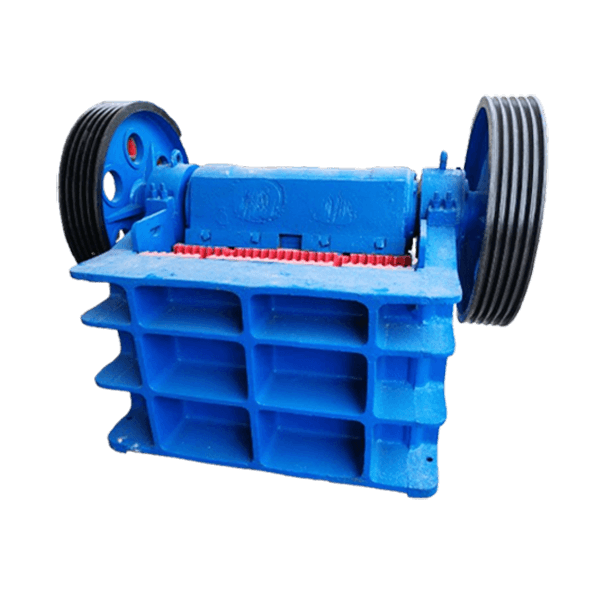

wet drum magnetic separator

Capacity: 0.5-180 t/h

Application: The wet drum magnetic separator commonly used for wet magnetic separation, removal and purification of pyrite, magnetite, ilmenite, manganese, iron ore, chromite, hematite, coltan, and other materials with particle size below 3mm.

Three disc magnetic separator

Capacity: 100-800 Kg/h

Material Size: ≤2mm

Application: Suitable for dry separation of various metal minerals such as titanium ore, tungsten, tin ore...It can separate a variety of minerals such as strong magnetic, weak magnetic and non-magnetic at one time.

High Intensity Dry Magnetic Separator

Capacity: 0.2-9 t/h

Application: It is suitable for the separation of weakly magnetic minerals and non-magnetic minerals such as tantalum niobium, tin, manganese ore, chromium ore, rutile, zircon, beach sand, etc.

plate magnetic separator

Capacity: 8-35 t/h

Application: Mainly used for iron removal and purification of quartz, feldspar, nepheline ore and kaolin; wet separation of various weakly magnetic metal ores such as hematite, limonite, ilmenite, manganese ore, siderite and wolframite.

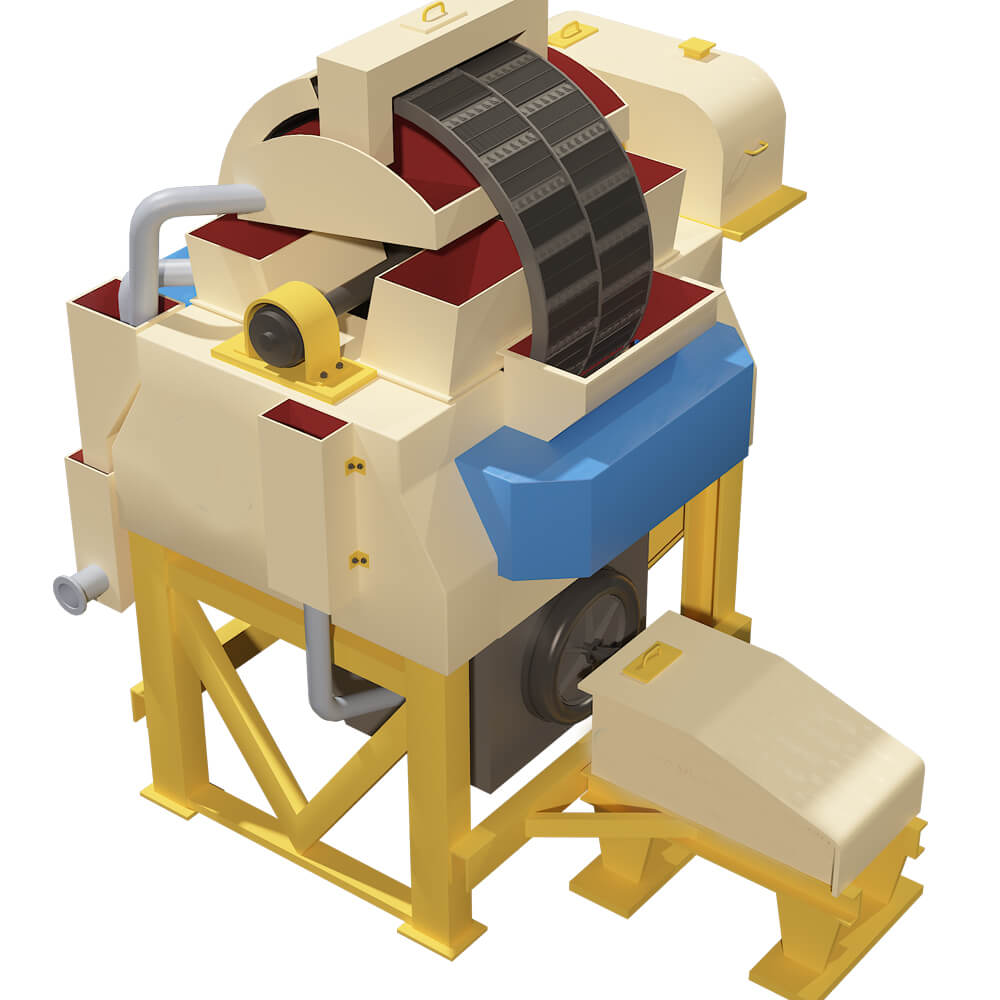

High Gradient Magnetic Separator

Application: separation of black and white tungsten ore and tungsten-tin ore; it can also be used for impurity removal and purification of non-metallic minerals such as kaolin, feldspar, nepheline, garnet and quartz sand.

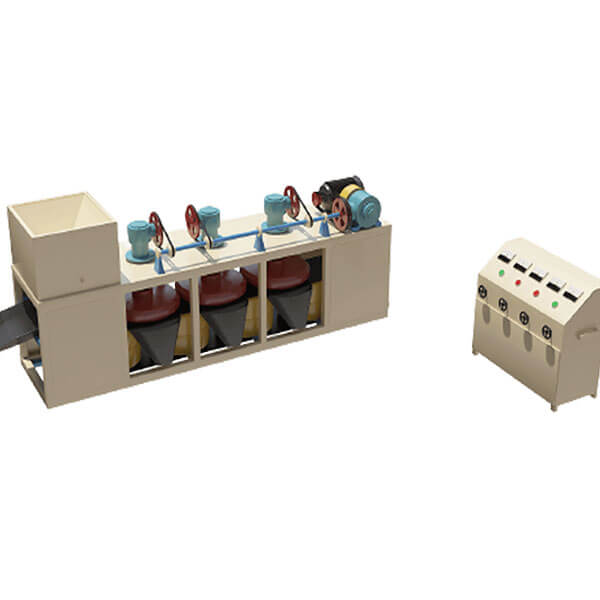

Slurry Magnetic Separator

Capacity: 10-100m³/h

Application: slurry magnetic separator is widely used for separation of weak magnetic substances or iron impurities in slurry and glaze; remove impurities such as iron and titanium in kaolin beneficiation; purification of non-metallic minerals such as feldspar, quartz sand, fluorite, spodumene, etc.

Electrostatic Separator

Capacity: 1-3T/H or customizable

Feeding: 0-3mm

Application: Electrostatic separators mainly used to separation of heavy minerals such as rutile, zircon, monazite, beach sand, and titanium ore; purification of quartz sand and iron-containing impurities; deep purification of minerals such as feldspar and kaolin.

Roller Electrostatic separator

Capacity: 1.5-3TPH

Feeding size: 0-2mm

Application: Roller electrostatic separator is mainly used to achieve conductor-semiconductor-non-conductor step dry separation. For example, the selection of conductive heavy minerals such as ilmenite, zircon, rutile, and beach sand.

- Flotation machines are separation devices based on differences in mineral surface floatability. By introducing air bubbles into the slurry, the target mineral selectively adheres to the bubble surface and floats to form a froth product, separating it from the gangue. Flotation equipment is suitable for processing fine-grained and complex intergrowth ores.

- Magnetic separation equipment utilizes the magnetic force of a magnetic field to separate magnetic minerals (such as magnetite and pyrrhotite) from non-magnetic gangue (such as quartz and feldspar), or from strongly or weakly magnetic minerals. These separations are categorized as dry and wet.

- Electrostatic separators primarily utilize differences in the electrical conductivity of mineral particles to achieve separation. It’s suitable for the purification and recovery of non-metallic ores such as titanium, zirconium, rutile, scheelite, and potassium feldspar.

Flotation machines, magnetic separators, and electrostatic separators are the core separation equipment in mineral processing plants. They precisely separate target minerals from gangue by leveraging the minerals’ physical and chemical properties (floatability), magnetic properties, and electrical conductivity. It is also a key link in improving the grade of concentrate and reducing subsequent smelting costs. Contact us for customized full-process mineral separation equipment and solutions!

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.