Rock Crushing Equipment

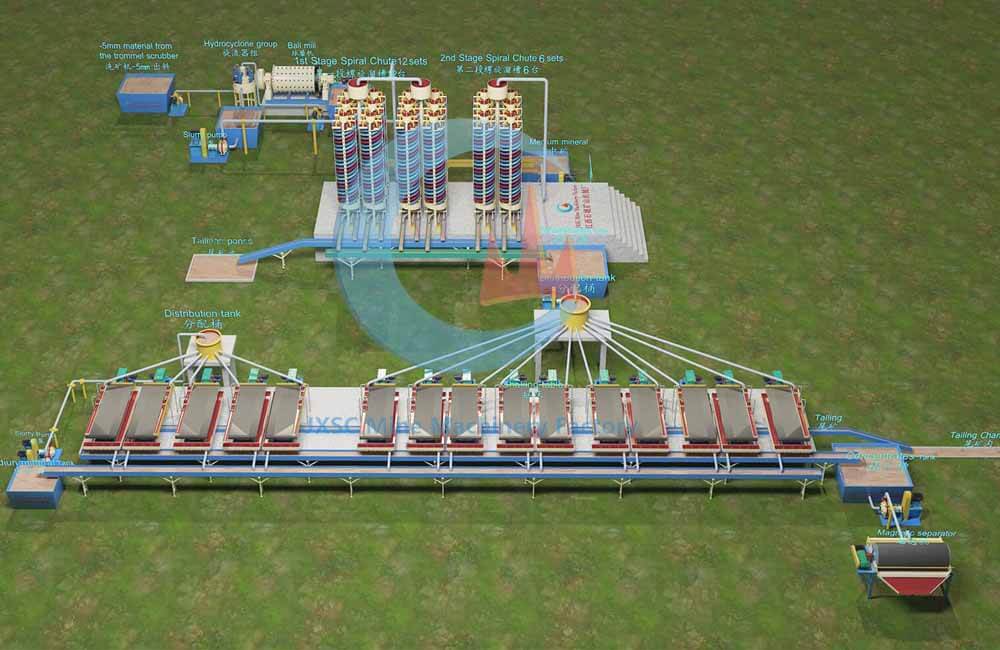

JXSC is a leading manufacturer of rock/ stone crushing equipment. We provide fixed and mobile types of rock crushers, including jaw crushers, cone crushers, impact crushers, hammer crushers, roll crushers, heavy hammer crushers, VSI sand-making machines, compound crushers, glass bottle crushers, etc. Among them, fixed rock crushers are suitable for large-scale stable production, while mobile rock crushers are ideal for temporary operations and renewable resource processing due to their flexible transfer and ready-to-use crushing advantages.

Application of Rock Crushers:

- Quarry stone crushing: cobblestone, basalt, limestone, granite, talc, river pebbles, dolomite, marble, quartz stone, etc.

- Mine rock ore crushing: iron ore, copper ore, gold, lead-zinc, coal, manganese ore, silica sand, etc.

- Solid waste recycling and crushing stage: tailings, slag, construction waste, etc.

Mineral Processing » Equipment » Rock Crushing Equipment

Fixed Rock Crusher For Sale

Rock crushing equipment and crushers are essential for construction, mining and mineral processing. Its main function is to produce sand for road construction or concrete aggregate. It can crush various materials, including granite, limestone, basalt, river pebbles, gold ore, copper ore, and other stone or ore crushing plants. In addition to having quality and durable rock/stone crushers, JXSC manufacturers prioritize optimal customer service. Crushing equipment installed in a fixed site requires infrastructure (concrete foundation) and is usually used for long-term, large-scale sand and gravel aggregate processing plant.

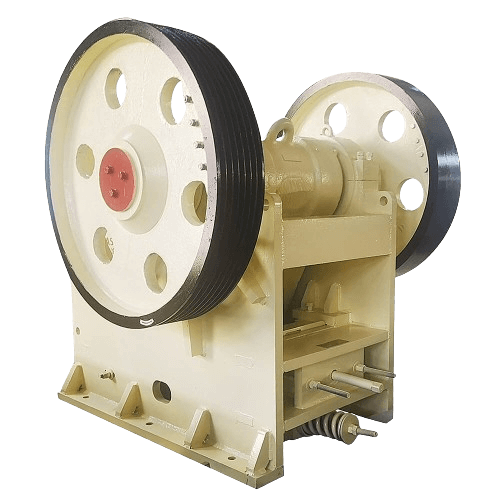

PE Jaw crusher

Capacity: 1-1120t/h

Feeding size: <1200mm

Application: Primary crushing, which is the first step coarse crushing in mineal processing.

- Cost-effective crushing solution.

- Core equipment for aggregate production.

PEX jaw crusher

Capacity: 1-140t/h

Feeding size: <300mm

Application: Secondary crushing, medium crushing and fine crushing.

- High-precision medium/ fine crushing.

- Core equipment for aggregate production.

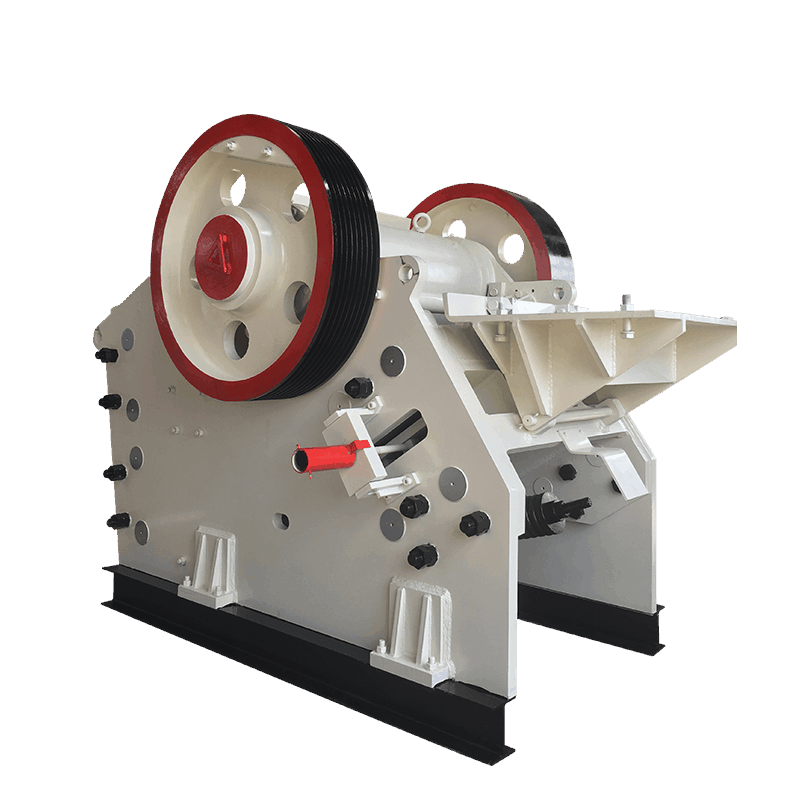

Eupropean type jaw crusher

Capacity: 55-675t/h

Feeding size: <150mm

Application: PEV series used for crushing rocks, ores, slag, concrete, etc

- High degree of intelligent adjustment.

- Core equipment for aggregate production.

Single cylinder cone crusher

Capacity: 35-175t/h

Feeding size: <220mm

Application: Ideal for secondary and tertiary crushing applications.

- Automatic cavity clearing function.

- Iron overload protection function is safer.

Multi-cylinder cone crusher

Capacity: 90-1200t/h

Feeding size: <353mm

Application: Excellent in crushing large-scale materials such as granite and basalt.

- High-end cone crusher representative.

- More stable crushing force.

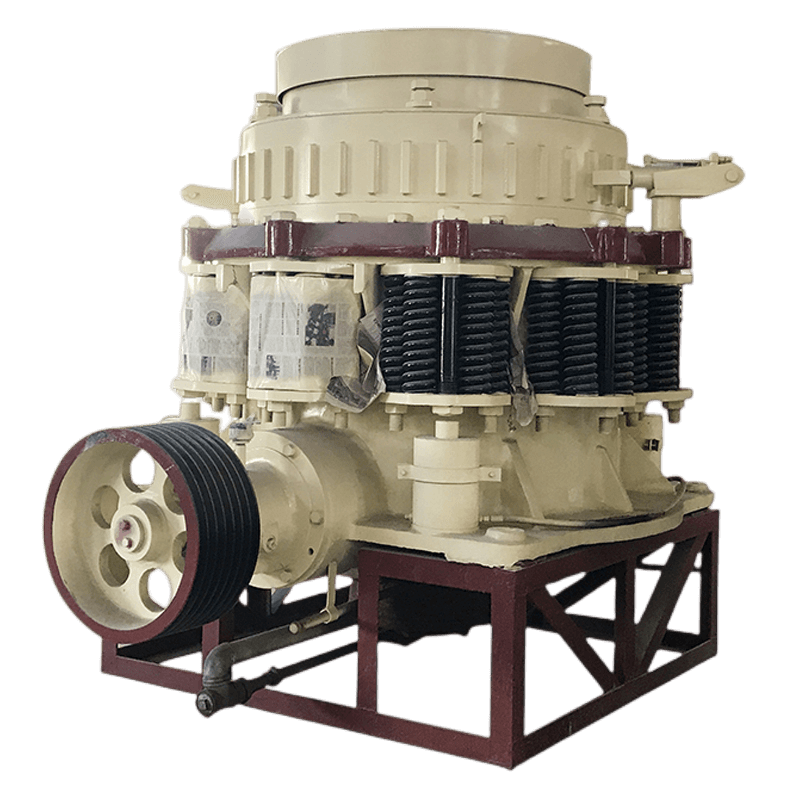

Symons cone crusher

Capacity: 27-1450t/h

Feeding size: <425mm

Application: Crushing materials ranging from hard rocks to ores and minerals.

- A reliable choice that will last a long time.

- Best price/performance ratio.

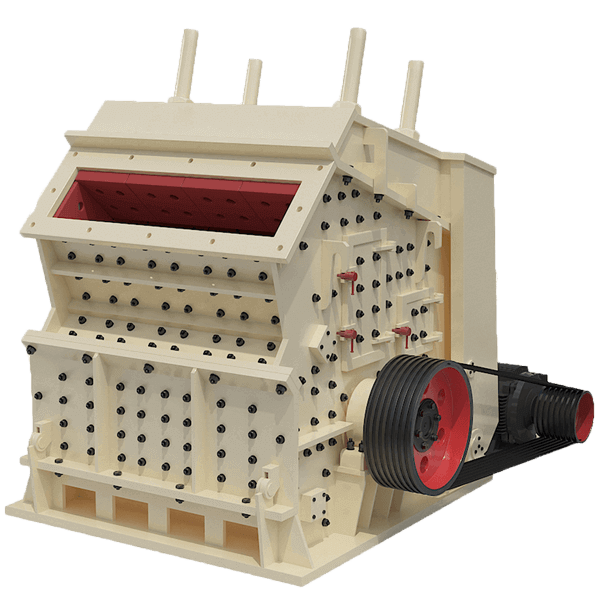

Impact Crusher

Capacity: 30-500t/h

Feeding size: <700mm

Application: Suitable for crushing medium hardness and low abrasive materials to produce coarse aggregate.

- Cubic shaped end products.

- Core equipment for aggregate production.

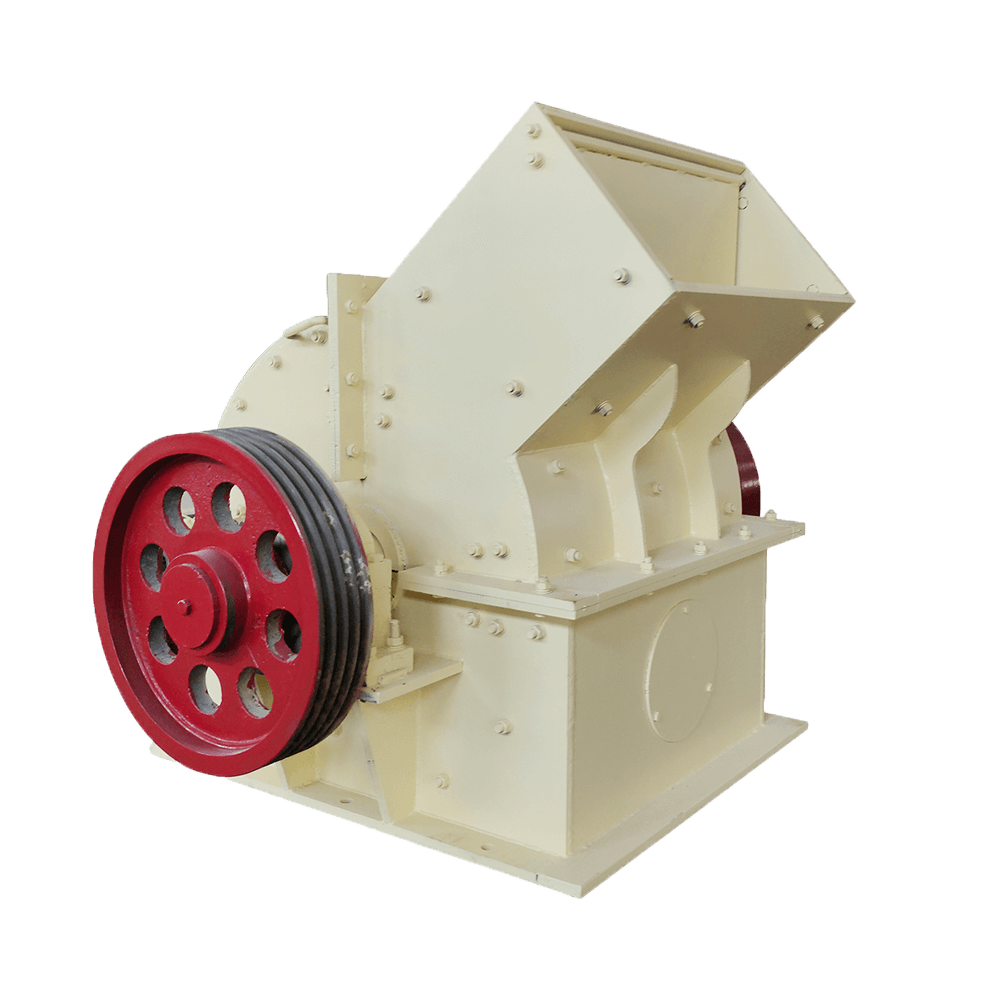

Hammer Mill

Capacity: 1-110t/h

Feeding size: <10-35mm

Application: Suitable for crushing medium hard materials such as limestone, gold, copper, iron ore, tin, manganese ore, marble.

- One-time Crushing.

- Overload protection device, safe operation.

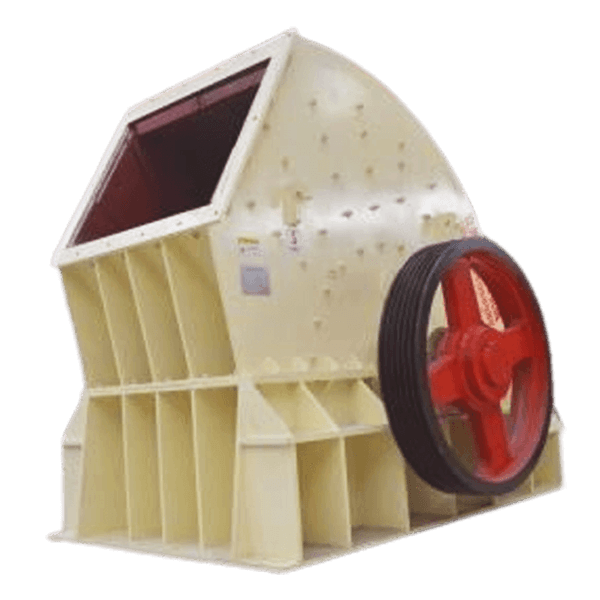

heavy hammer crusher

Capacity: 50-1200t/h

Feeding size: <400-1200mm

Application: Capable of crushing highly abrasive materials with high moisture content, such as granite and quartz.

- High capacity with large feed size.

- Large crushing ratio.

Spring roller crusher

Capacity: 1.5-70t/h

Application: The double roll crusher is suitable for fine crushing medium to hard, or brittle materials such as coal and limestone.

- Ultra-quiet operation, eco-friendly.

- Low Maintenance & Cost.

VSI Sand Making Machine

Capacity: 20-180m³

Application: For construction projects: hard and abrasive materials such as granite, basalt, iron ore; limestone and river pebbles.

- Excellent finished product shape.

- Producing high-quality sand.

vertical shaft compound crusher

Capacity: 5-200t/h

Application: Crush various types of hard and abrasive rocks, limestone, coal, quartz, granite.

- No screen bar design, never blocked.

- Continuous operation without cleaning.

Why Choose JXSC?

Advantages of Stationary & Fixed Rock Crusher

✅ High production capacity: a single device can produce 50-2000 tons per hour, suitable for large projects.

✅ Strong stability: fixed base + optimized structure, low failure rate in long-term operation.

✅ Accurate material control: with the screening system, the particle size of the finished product can be controlled (for example, 3-5mm for sand making).

✅ Long life: heavy steel + wear-resistant parts (such as manganese steel jaw plate) have a life of 5-10 years.

✅ Strong scalability: Fexibly upgraded to multi-stage crushing (such as “jaw crusher + cone crusher + sand making machine”).

Mobile Rock Crusher For Sale

We also provide mobile/portable stone crushers. They are divided into wheel-type and crawler-type crushing plants, including mobile jaw crushers, cone crushers, impact crushers, vibrating screens, etc. The equipment provides efficient, low-cost. Usually the jaw crusher can be equipped with a vibrating screen or a belt conveyor to form a small portable crushing plant. It also supports customized mobile jaw crushers, impact crushers, cone crushers, sand making machines, etc. Crushing equipment with built-in tires or crawler chassis and flexible transfer, suitable for temporary crushing, construction waste treatment and other scenarios.

Mobile Crusher

Capacity: 1-450 t/h or customizable

Main equipment: Vibrating feeder + rock crusher + vibrating screen

Application: Mobile crushers are widely used in mining crushing plants, sand-making production, and construction waste recycling.

Why Choose JXSC?

Advantages of Mobile Rock Crusher

✅ No infrastructure required: crawler/tire drive, production can be started upon arrival at the site.

✅ All-in-one machine: The vehicle-mounted equipment integrates feeding, crushing, screening and conveying, with modular design and easy maintenance.

✅ Energy saving and environmental protection: diesel/electric dual power, reducing dust and noise pollution.

✅ Lower cost: save material transportation costs (especially suitable for demolition waste disposal).

✅ Intelligent control: remote monitoring + automatic adjustment, 1-2 people can operate.

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.