Cylinder gold amalgamator

Application: Cylinder gold amalgamator is mainly used in small-scale gold mining and gold refining process, processing gold-containing heavy sand of placer gold mine and re-selected gold concentrate of vein gold mine, with recovery rate of more than 98%. It can efficiently separate gold and other impurities, and can also recover and reuse valuable metal resources.

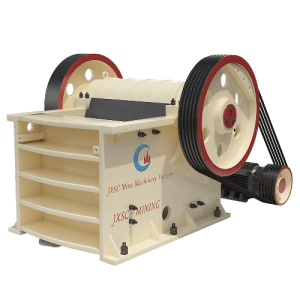

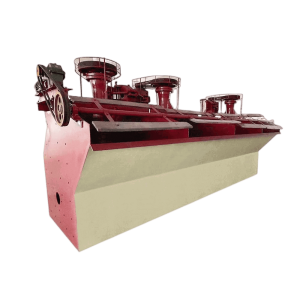

Products display

Introduction of Cylinder gold amalgamator

Cylinder gold amalgamator, also known as cylindrical ball mill, small ball mill, gold mercury mixing machine, alluvial/placer gold mercury mixing machine, gold amalgamation machine, is a kind of internal mercury mixing equipment specially designed for gold ore extraction process. It helps to improve the purity of gold and reduce the waste of valuable mineral resources. It can also be used as a ball mill in laboratory or semi-industry. It is mainly used for amalgamation gold extraction process in the crushing and grinding operation cycle. It adopts advanced processes and technologies to ensure that gold can be extracted in an efficient way with good purification effect. Therefore, the gold ore extraction process becomes more environmentally friendly and economically feasible. Due to its simple operation and low equipment cost, gold mercury mixing machine has become a commonly used gold selection equipment in small mines.

Working principle Of Cylinder gold amalgamator

The process of amalgamation is to chemically react gold with mercury to form a gold-mercury alloy. Its main function is to separate gold from other harmful elements, such as mercury, through repeated movement and friction.

The purpose is to improve the purity of gold through the adsorption capacity of mercury. Mercury can absorb impurities on the surface of gold and separate them through rotation and stirring inside the machine.

why choose JXSC Cylinder gold amalgamator

features & Advantages

1. Small size, simple operation, improve the gold grade and recovery rate;

2. High amalgamation efficiency, good purification effect;

3. Quickly separate gold from other components in the ore;

4. JXSC gold mercury mixing machine can reduce the consumption of mercury during gold amalgamation operation to a minimum;

5. With good sealing, it can effectively control the volatilization of mercury and reduce pollution to the environment;

6. The investment and operation costs are low, suitable for limited small mining plant to extracting gold.

models & specifications

Model | Power |

400*600mm | 2.2kw |

600*800mm | 4kw |

800*1000mm | 5.5kw |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.