Feeding & Conveying Equipment

Mineral Processing » Equipment » Feeding & Conveying

Feeding & Conveying Equipment Solution

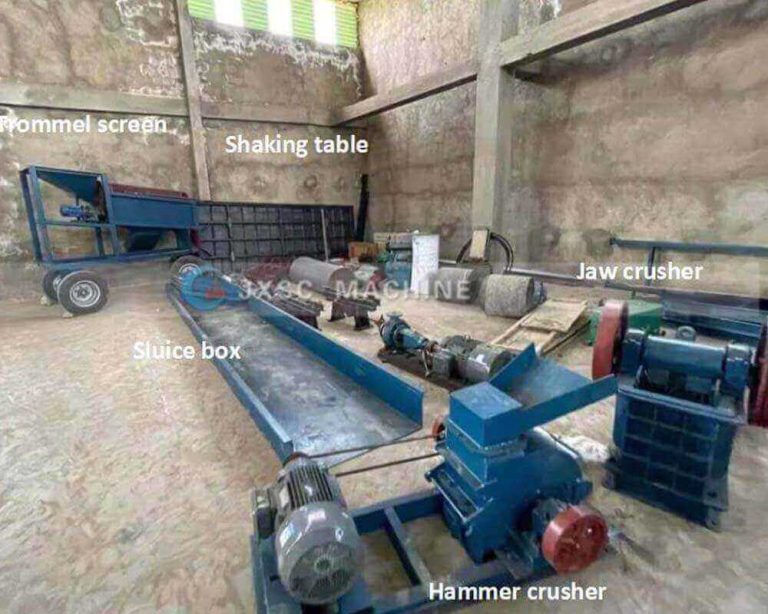

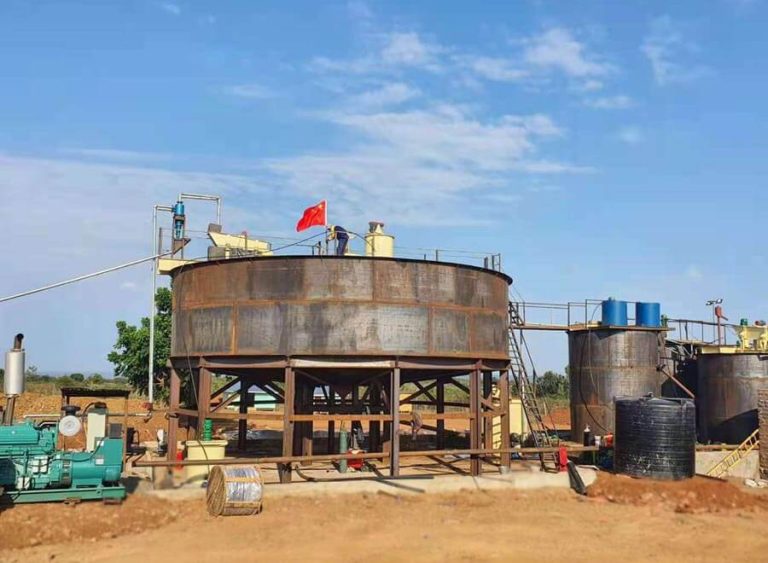

JXSC provides mines with full-process feeding and conveying equipment solutions from “raw materials entering the factory” to “finished products leaving the factory.” Feeding equipment is responsible for evenly and continuously feeding ore, slurry, and other materials into core equipment, such as crushing, grinding, and sorting, thereby ensuring the stable operation of subsequent processes. Conveying equipment is responsible for transferring materials between various links, realizing the full-process material flow from the raw material bin to the tailings pond. It mainly includes vibrating feeders, belt conveyors, disc feeders, trough feeders, heavy-duty plate feeders, belt feeders, electromagnetic vibrating feeders, swing feeders, tubular screw feeders, etc. Our feeders and conveyors are suitable for metal mines, coal mines, sand and gravel aggregates, building materials, and chemical industries, ensuring continuous, stable, and low-consumption material transportation in all links of ore from crushing and screening to beneficiation.

Feeding and conveying equipment for sale

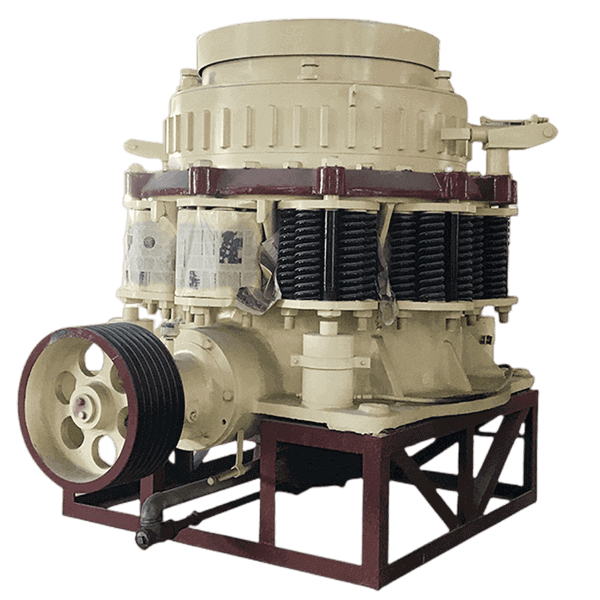

Vibrating feeder

Capacity: 20-1200TPH

Feeding size: <1000mm

Application: Sand and gravel aggregate and ore feeding to stone crusher, screeners, or other material receiving equipment.

Electromagnetic Vibrating Feeder

Capacity: 5-150TPH

Feeding size: <200mm

Application: transport ore, coal powder, clinker, limestone, granular & block materials.

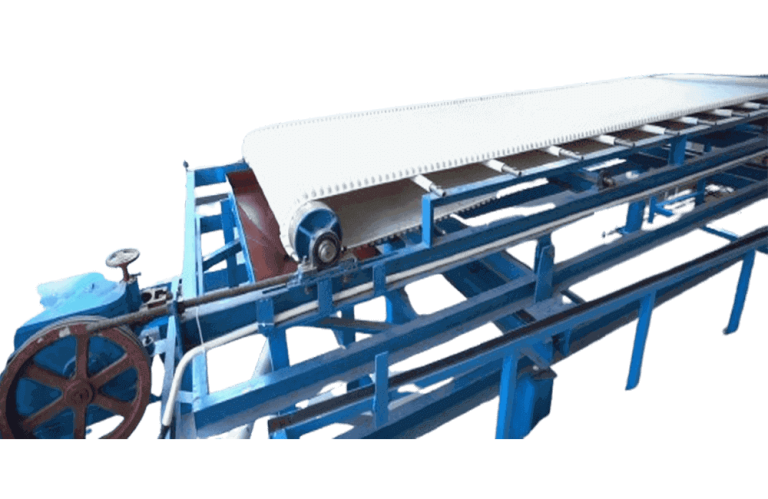

belt conveyor

Capacity: 10-350TPH

Feeding: <800mm

Application: Transport of all kinds of material: ore, sand and gravel, aggregate, stone, waste, tailings, steel slag, etc.

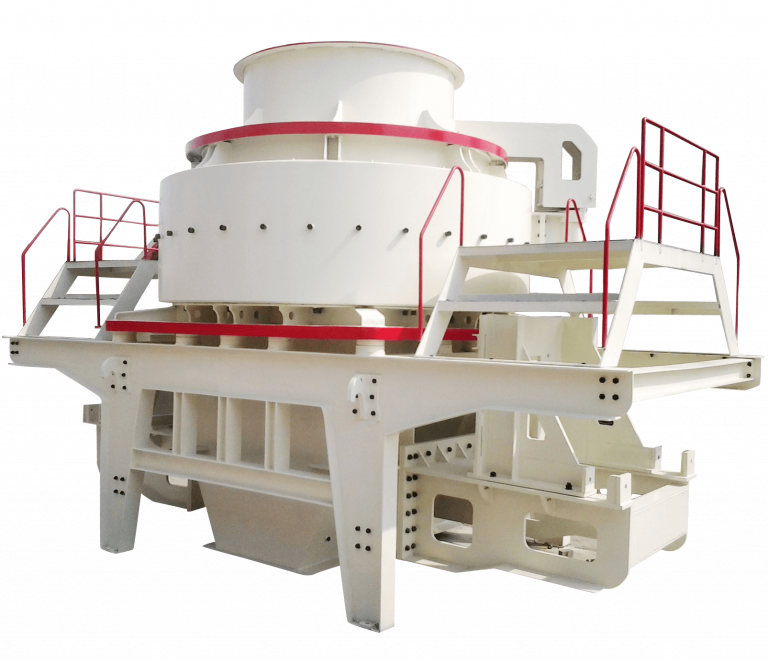

Disc feeder

Feeding capacity: 1.8-88 t/h

Max feeding size: ≤80mm

Application: coal powder, cement, limestone, shale, coal gangue, rare earth, sand and other materials are continuously supplied and transported to next various equipment.

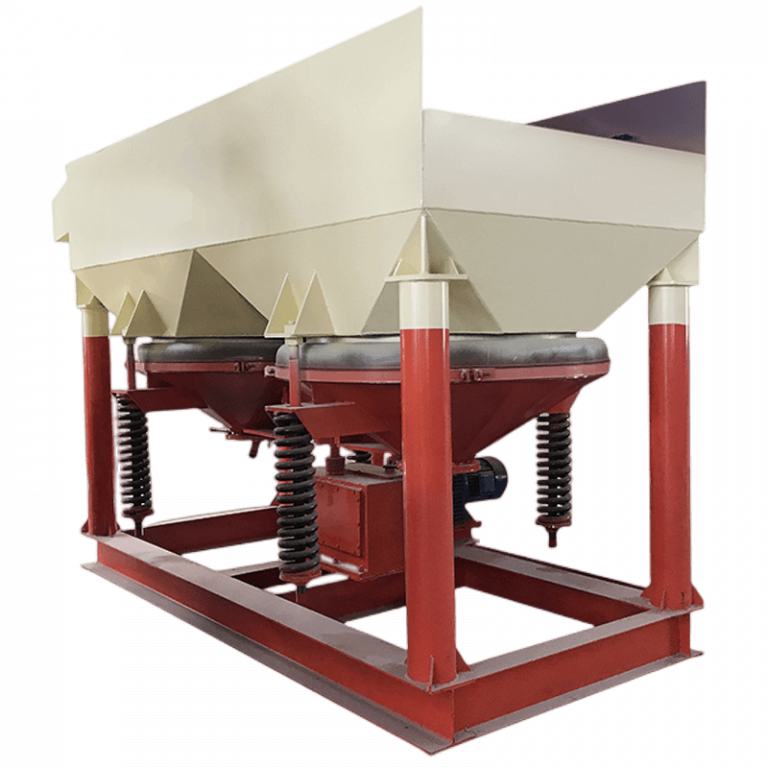

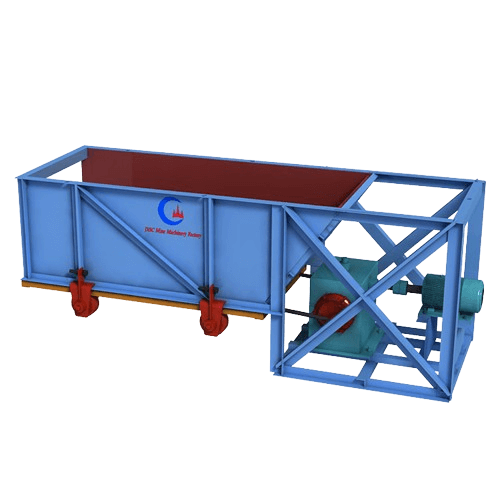

Trough feeder

Capacity:5-30t/h

Application: Transports various types of block, granular, suitable for short-distance transportation of iron ore, copper, gold, coal, limestone, gravel, sand, aggregate, stone, etc.

Heavy Duty Apron Feeder

Feeding Capacity: 100-400m³/h

Application: The heavy feeder is suitable for large scale conveying and feeding rock aggregates or ores, such as gold, copper, iron ore, limestone, river pebbles, granite, basalt, or heavy construction waste.

Belt feeder

Feeding Capacity: 10-450TPH

Application: Commonly used in mining, mineral processing, construction, sandstone plant industries, such as feeding and conveying of ore, sandstone, aggregate, coal, etc.

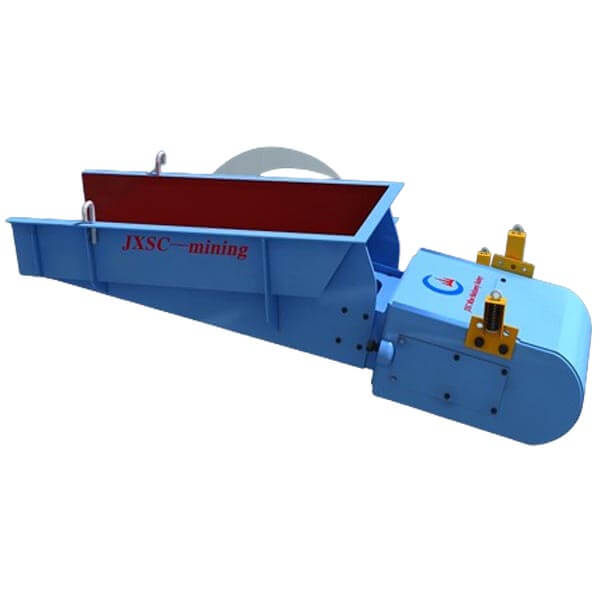

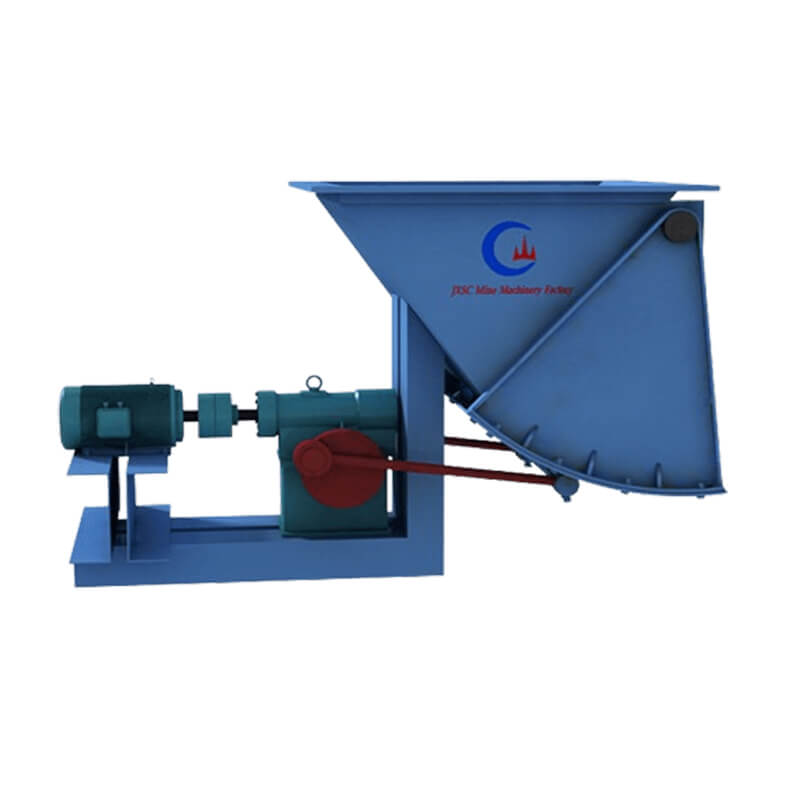

Swing Ore Feeder

Feeding capacity: 4.5-80 TPH (tons per hour)

Motor power: 0.55-1.5 KW

Application: commonly used in mining, cement, and aggregate plants; such as high specific gravity, dryness, and non-caking properties ore.

Tubular Screw Ore Feeder

Feeding Capacity: 6-50 m³/h

Spiral Speed: 34-59 r/min

Application: It's mainly suitable for conveying powdery, granular, and small lump materials; such ore powder, lime, cement, and coal.

- Feeding equipment primarily uses mechanical vibration and gravity feed to precisely control ore feed rate and conveying speed, ensuring stable operation of subsequent mining equipment (crushers, ball mills, screens, etc.).

- Conveying equipment enables efficient, long-distance ore transport and can accommodate dry, wet, and sticky materials. Customized transfer solutions are provided based on material form (lumps, powders, slurries) and conveying path (horizontal, inclined, or vertical).

JXSC feeding and conveying equipment are linked through a PLC system, achieving a seamless transition from precise feeding at the front end to efficient transfer at the mid-end and buffer storage at the back end. Together, they form the “logistics artery” of the beneficiation plant, widely applicable to large-scale production scenarios in industries such as metal ores, non-metallic minerals, and building materials. Whether it’s configuring a small or medium-sized beneficiation plant or designing large-scale transportation for aggregate processing, contact us to create the optimal feeding & conveying solution.

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.