Gyratory Swing Vibration Screen

Layer: 1-5 or customized

Screening Area: 3-6.48m²

Application: Gyratory swing vibration screen is widely used in raw material factories, ceramsite, plastic chemical industry, metallurgy, non-ferrous metals, non-ferrous metals, food, abrasives and other industries; screening and classification of silica sand, quartz sand and other granular and mineral powders.

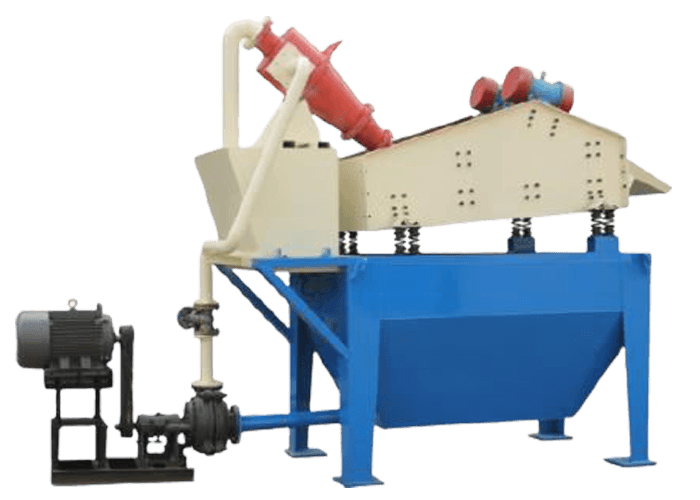

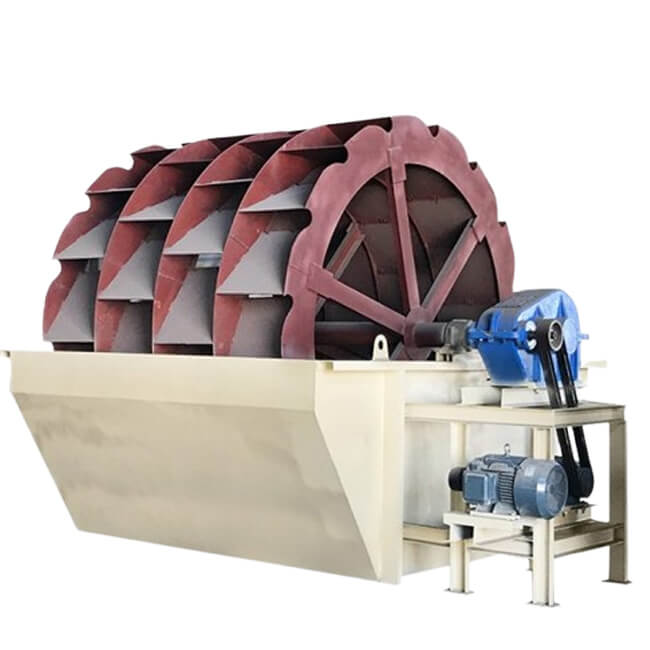

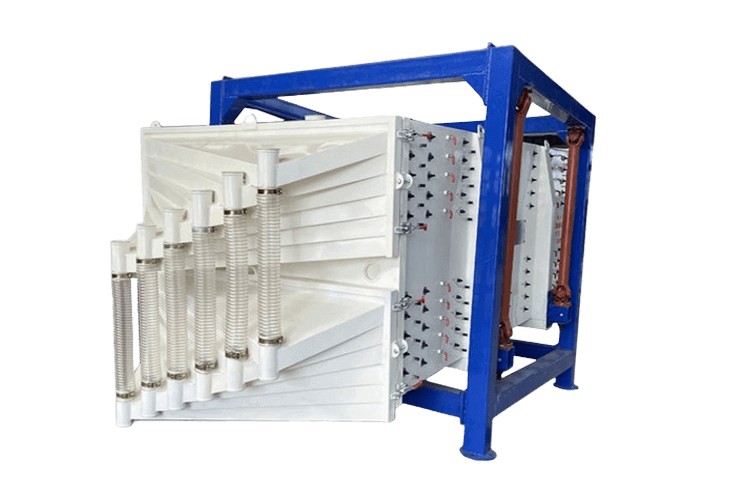

Products display

Introduction Of gyratory swing vibration screen

The gyratory swing vibration screen, also known as the square gyratory screen or square swing screen, is an efficient and fine screening equipment with a unique multi-layer grading design. It is commonly used for screening and classifying powdered materials such as quartz sand, silica sand, perlite, mica powder, talcum powder, river sand, machine-made sand, fertilizer, etc. This gyratory swing screen is equipped with an automatic tensioning and automatic cleaning screen installation system, which ensures the screen has a long service life and high screening efficiency. It mainly simulates the effective principle of manual screening movement. Under the same specifications, the processing capacity is 1.5-10 times that of ordinary screening machines.

This vibrating screen can achieve accurate classification of micron-level materials and separate multiple particle sizes at one time. It has core advantages such as anti-blocking net design, intelligent regulation and multi-process adaptation, and is the preferred solution for precision grading and special material processing.

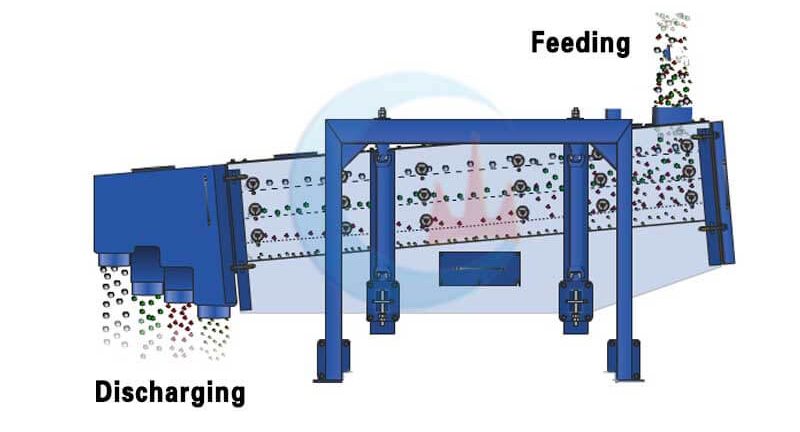

Working principle Of Gyratory Swing Vibration Screen

The screen surface of the gyratory swing vibration screen is horizontal or inclined between 5-8 degrees. After opening, the screen box reciprocates under the action of inertia and then drives the screen surface to make a periodic swinging motion. The rotational motion of the exciter is transmitted to the screen surface, and the material on the screen surface jumps and disperses quickly with the screen box. Materials smaller than the screen hole fall to the lower layer. Materials larger than the screen hole continue to roll and are transported to the discharge port. The materials are screened continuously in multiple layers and graded from multiple discharge ports. Finally, materials with the same mesh size are gathered at the discharge port to complete the screening.

why choose JXSC Gyratory Swing Vibration Screen

features & Advantages

1. The screen is large in size and has a multi-level screening design, which is suitable for screening a variety of materials and can meet a variety of customer needs.

2. Using three-dimensional motion mode, the material is made into a “fluidized” state, and the screening efficiency reaches over 95%.

3. The motor power of the vibrating screen is small, and the fully enclosed design reduces dust spillage and meets environmental protection requirements.

4. Adjustable amplitude, frequency and vibration trajectory, which is more flexible, faster, with high screening accuracy and large output.

5. The screen of the gyratory swing screener is wear-resistant and rust-proof, non-clogging, easy to replace, and operate.

6. The fully enclosed structure has low noise, no dust pollution, and the operating environment meets environmental protection requirements.

models & specifications

| Model | Screening Area (m²) | Layer | Lateral Slope | Motor Power (kw) | Number of Revolutions (r/min) | Screen Box Stroke (mm) |

| FYBS1030 | 3 | 1-5 | 5-8° | 3 | 180-260 | 25-60 |

| FYBS1036 | 3.6 | 1-5 | 5-8° | 3 | 180-260 | 25-60 |

| FYBS1230 | 3.6 | 1-5 | 5-8° | 4 | 180-260 | 25-60 |

| FYBS1236 | 4.32 | 1-5 | 5-8° | 4 | 180-260 | 25-60 |

| FYBS1530 | 4.5 | 1-5 | 5-8° | 5.5 | 180-260 | 25-60 |

| FYBS1536 | 5.4 | 1-5 | 5-8° | 5.5 | 180-260 | 25-60 |

| FYBS1830 | 5.4 | 1-5 | 5-8° | 7.5 | 180-260 | 25-60 |

| FYBS1836 | 6.48 | 1-5 | 5-8° | 7.5 | 180-260 | 25-60 |

| FYBS2030 | 6 | 1-5 | 5-8° | 7.5 | 180-260 | 25-60 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.