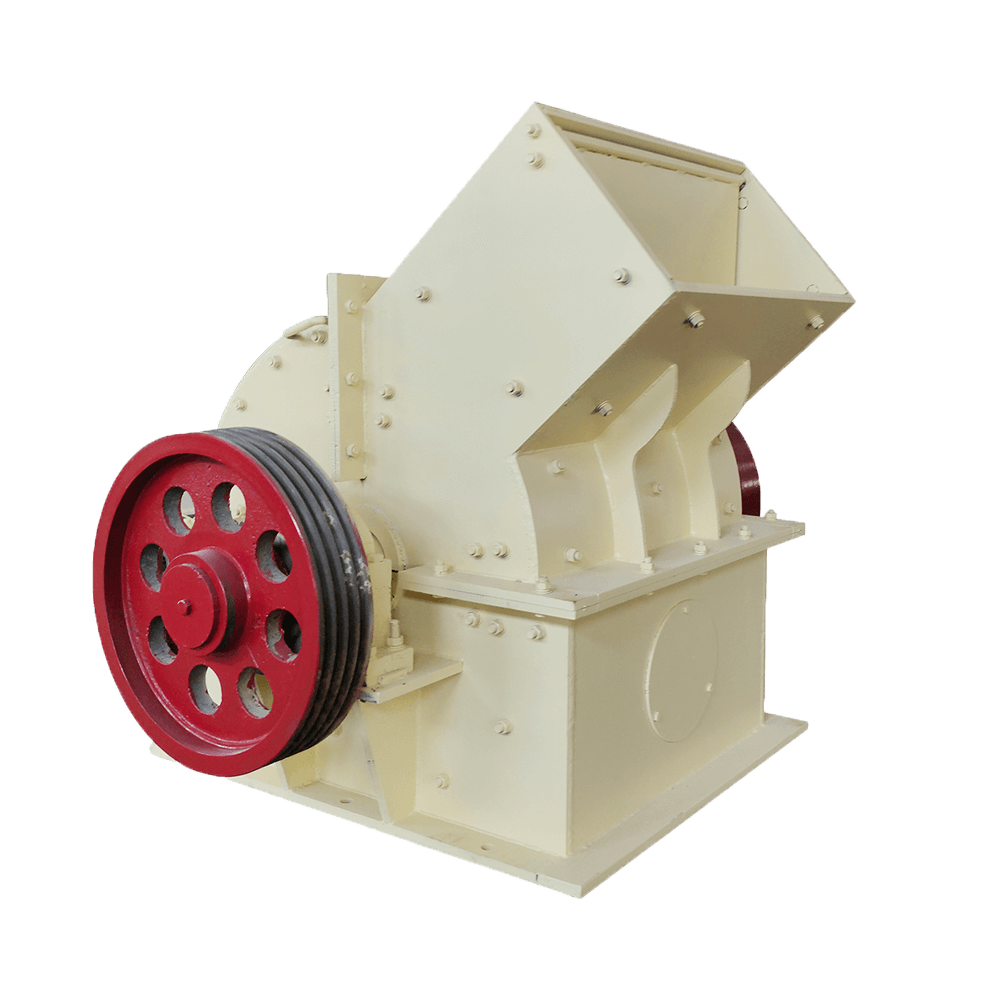

Hammer Crusher

Capacity: 1-110t/h

Feeding size: <350mm

Output size: <10-35mm

Application: The hammer crusher is used for fine crushing gold, copper, manganese, iron ore, limestone, coal, slag, coke, gypsum, bricks and tiles, coal gangue, granite, basalt, dolomite, etc.

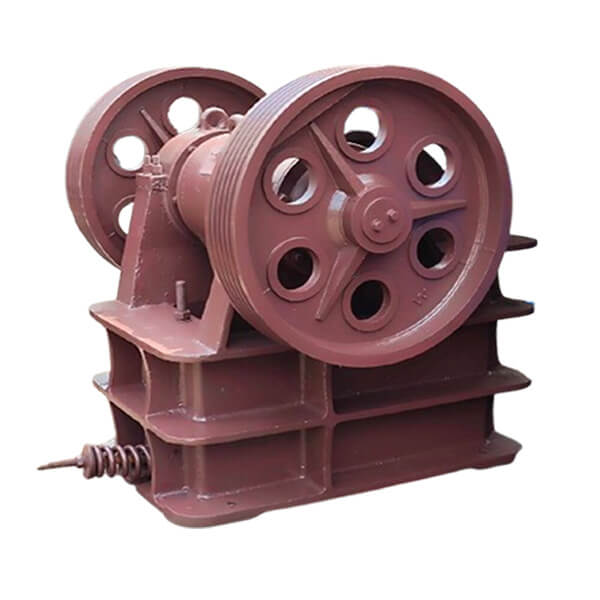

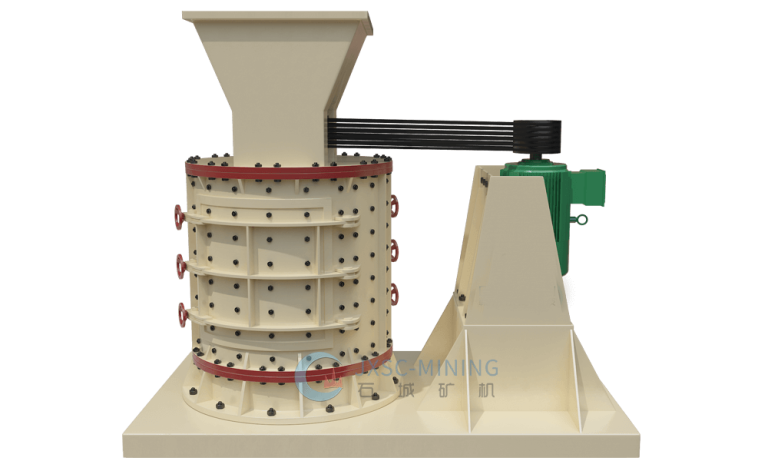

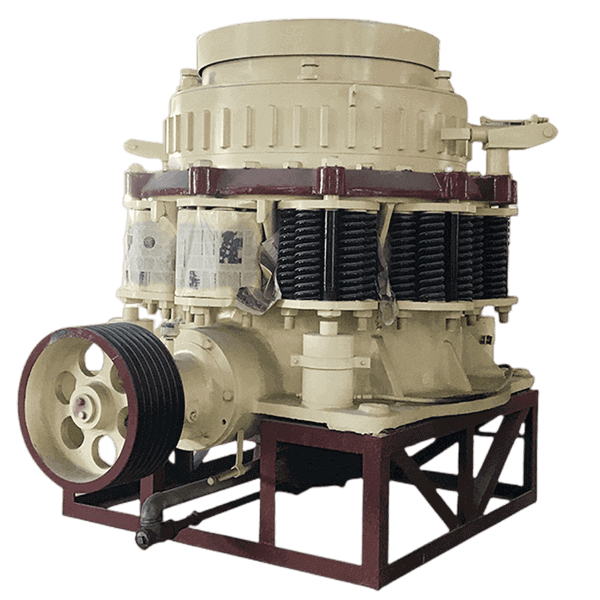

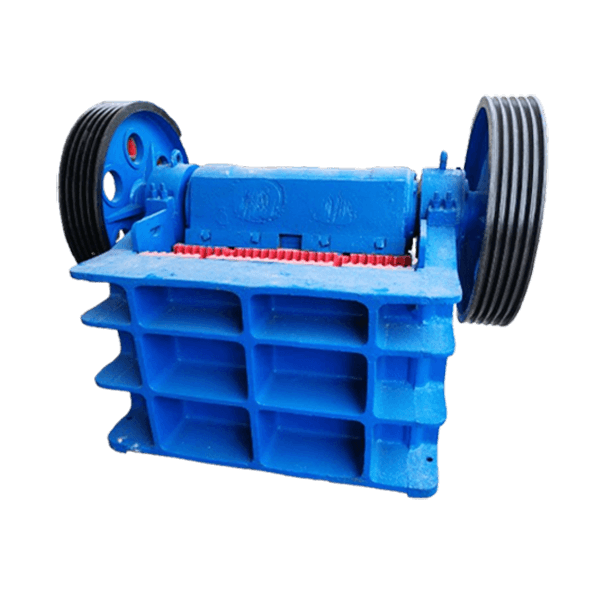

Products display

Introduction of Hammer Crusher

Hammer crusher is a kind of mechanical equipment that uses high-speed rotating hammers to impact and crush materials. It is mainly used for medium and fine crushing of medium-hardness and brittle materials. The particle size of the material can be adjusted. It is widely used in mining, building materials, the chemical industry, metallurgy, and other industries. It can realize both dry and wet crushing, such as gold, copper, iron ore, limestone, coal, gypsum, shale, etc.

Some models can directly crush large pieces of material to the required particle size (one-time forming) without multi-stage crushing. A single machine can achieve coarse to fine crushing, reducing production processes. Hammer crusher is the most common crushing equipment choice for crushing medium-soft and brittle materials due to its high crushing ratio, simple structure, and low cost. The finished products after crushing are mostly uniform cubes or regular particles, which are suitable for high-standard aggregate needs.

JXSC also supports the combination of vibrating screen and feeder to form a mobile hammer crusher. Its integrated and flexible design can be applied to various operating scenarios.

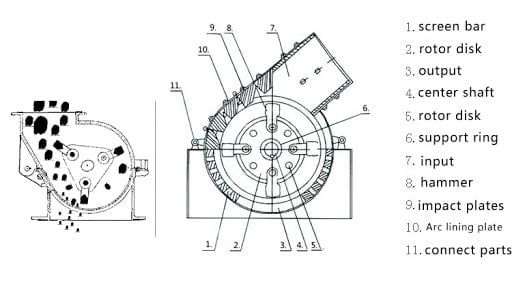

working principle & structure of Impact Crusher

Working principle

The motor drives the rotor to rotate at high speed in the crushing cavity. The material is fed into the machine from the upper feed port and crushed by the impact, shearing and grinding of the high-speed hammer.

In the lower part of the rotor, there is a sieve plate, the particle size of the crushed material that is smaller than the size of the sieve hole is discharged through the sieve plate, and the coarse particle size larger than the sieve hole size is retained on the sieve plate to continue to be hit and grinded by the hammer, and finally passes the sieve plate out of the machine.

Structural features

- Hammer head design: high manganese steel or composite material casting, wear-resistant and impact-resistant.

- Rotor: high-speed rotation provides crushing power.

- Screen plate/grate bar: control the particle size of the discharge material, the gap is adjustable.

- Crushing chamber: adopts reasonable geometric shape design to ensure that the material is fully crushed in the chamber.

- Feed inlet: large size can ensure smooth entry of large pieces of material and reduce blockage.

Why choose JXSC hammer crusher

features & Advantages

- The hammer head of JXSC hammer crusher is cast from high manganese steel, which has high density, wear resistance and impact resistance.

- The production capacity is high, and the finished products are uniform; the required discharging granularity can be adjusted according to customer requirements.

- The machine body structure is sealed, which solves the problems of dust pollution and ash leakage in the crushing workshop.

- Simple and durable structure: no complex transmission parts, easy maintenance, low failure rate.

- Strong adaptability to wet and sticky materials: the non-screen bottom design can handle materials with high moisture content (such as clayey coal gangue).

- Low energy consumption: compared with jaw crusher and cone crusher, the power consumption per unit output is reduced by 15%-30%.

- One-step forming: Some models can directly produce finished products of qualified particle size without the need for secondary crushing.

- We can customize fixed or mobile types and heavy-duty hammer crushers for large crushing production lines.

models & specifications

Model | Speed | Feed size | Out-put size | Capacity | Weight | Power |

PC-400×300 | 1450 | ≤40 | 0-10 | 1-3 | 0.8 | 11 |

PC-600×400 | 1000 | ≤220 | 0-15 | 5-25 | 1.5 | 22 |

PC-800×600 | 980 | ≤350 | 0-15 | 10-50 | 3.1 | 55 |

PC-800×800 | 980 | ≤350 | 0-15 | 10-60 | 3.5 | 75 |

PC-1000×800 | 1000 | ≤400 | 0-13 | 20-75 | 7.9 | 115 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.