Linear Vibrating Screen

Application industries: Linear vibrating screen is widely used in mining, coal, chemical industry, metallurgy, building materials, and other industries.

Applicable materials: Classification and screening of various non-sticky, dry powdery materials such as limestone, quartz, gypsum, sand, rocks, aggregates, coal, ores and other bulk solids.

Products display

Introduction of linear vibrating screen

The linear vibrating screen is a high-efficiency screening equipment that uses dual vibration motors to drive reciprocating motion along a directional straight line. It mainly uses double vibration motors or exciters to produce linear reciprocating vibration, so that the material can make a linear jumping motion on the screen surface, realizing efficient screening and grading mechanical equipment. Mainly suitable for classification and screening of bulk materials and small and medium-sized granular and powdery materials; or dry and wet screening and dehydration, remediation, and desliming of medium and fine-grained materials.

Linear vibrating screens are commonly used in mining, metallurgy, building materials, chemical industry, and environmental protection industries. For example: pre-screening of iron ore, copper ore, and gold ore; grading of sand and gravel aggregates, etc.

It can provide a uniform material flow for downstream processes. Among them, the small linear vibrating screen can be installed under the crusher to realize an integrated crushing and screening machine, which is suitable for small production lines. The vibrating screen has the characteristics of multi-size screening, precise particle control, durability, and energy saving, and is the core screening equipment solution for screening medium and fine particle materials.

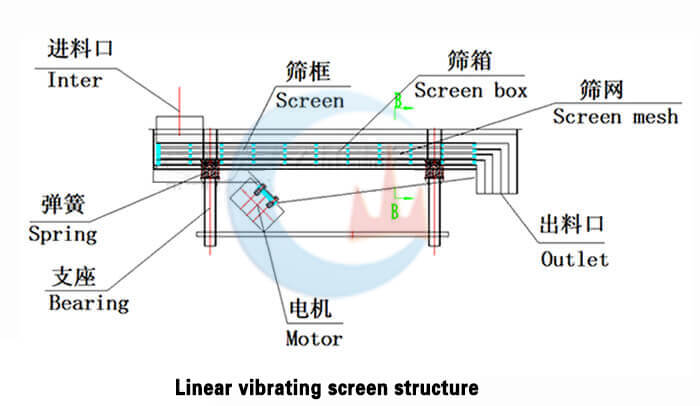

principle & structure of linear vibrating screen

working principle

It mainly comprises a screen box, screen frame, screen mesh, vibration motor, motor base, vibration damping spring, bracket, etc. Dual vibration motors drive the linear vibrating screen. Driven by the excitation force and the self-gravity of the material, the machine body and the screen surface shift forward and backward, and the material on the screen surface is thrown up and jumps forward in a straight line. The materials pass through the multi-layer screen to produce various specifications of over- and under-sieve materials discharged from their respective outlets, respectively, thereby achieving the purpose of screening and grading the materials.

Structural features

- Vibration system: Dual motor self-synchronizing technology achieves linear motion.

- Screen assembly: Multi-layer screen structure (1-5 layers optional), mesh size customizable.

- Shock absorber: Spring or rubber damper installed at the bottom.

- Screen box structure: Welded with wear-resistant steel plates.

- Inlet/outlet: Flexible connectors (silicone/canvas).

- Support structure: Consists of pillars and channel steel to ensure stable operation.

why choose JXSC linear vibrating screen

Features & advantages

1. The linear motion trajectory prolongs the material residence time and the screening efficiency reaches over 95%.

2. It has low energy consumption, high output, simple structure, and easy maintenance.

3. No dust spillage, automatic discharge, high screening efficiency, and good energy saving effect.

4. The screening efficiency is high, the screen surface angle is adjustable, and the screen mesh is made of wear-resistant rubber material with long service life.

5. It can screen out materials of various particle sizes at one time, suitable for automated production lines;

6. The number of screen layers and screen hole size can be customized according to needs.

models & specifications

| Model | Screening Size (m²) | Vibration Amplitude (mm) | Motor Model | Motor Power | Rotating speed (r.p.m) |

| DZS0410 | 0.4*1.0 | 2-4 | YZO-3-6 | 0.25 | 960 |

| DZS0412 | 0.4*1.2 | 2-4 | YZO-3-6 | 0.25 | 960 |

| DZS0415 | 0.4*1.5 | 2-4 | YZO-3-6 | 0.25 | 960 |

| DZS0612 | 0.6*1.2 | 3-5 | YZO-3-6 | 0.25 | 960 |

| DZS0718 | 0.7*1.8 | 3-5 | YZO-10-6 | 1 | 960 |

| DZS0815 | 0.8*1.5 | 4-6 | YZO-18-6 | 1.1 | 960 |

| DZS0918 | 0.9*1.8 | 4-6 | YZO-20-6 | 2 | 960 |

| DZS0922 | 0.9*2.2 | 4-6 | YZO-20-6 | 2*1.5 | 960 |

| DZS1018 | 1.0*1.8 | 4-6 | YZO-16-6 | 2*1.1 | 960 |

| DZS1020 | 1.0*2.0 | 4-6 | YZO-16-6 | 2*1.1 | 960 |

| DZS1225 | 1.25*1.25 | 4-6 | YZO-20-6 | 2*2 | 960 |

| DZS1530 | 1.5*3.0 | 4-6 | YZO-36-6 | 2*3 | 960 |

| DZS21530 | 1.5*3.0 | 4-6 | YZO-36-6 | 2*3 | 960 |

| DZS1536 | 1.5*3.6 | 4-6 | YZO-36-6 | 2*3 | 960 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.