Log Washer

Capacity: 1-100TPH

Feeding size: ≤70

Applicable materials: Log washer is widely used for washing of manganese ore, iron ore, phosphate rock, copper ore, barite, hard kaolin, river pebble, granite, basalt, limestone, calcite, silica, quartz stone, diabase and other ores, stones.

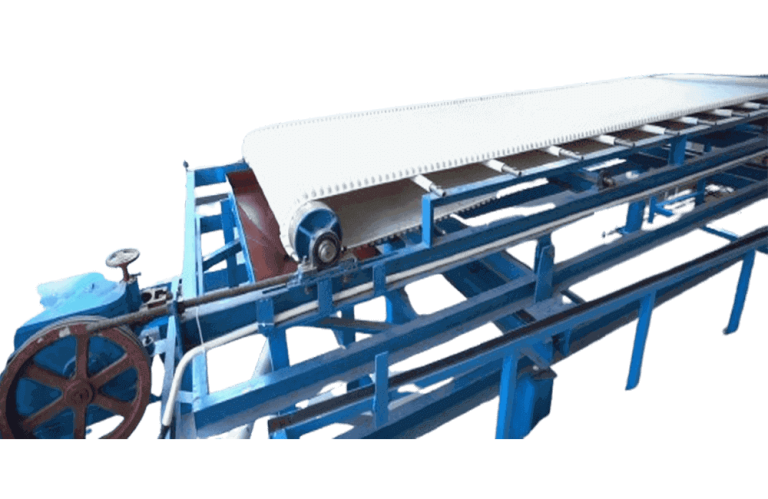

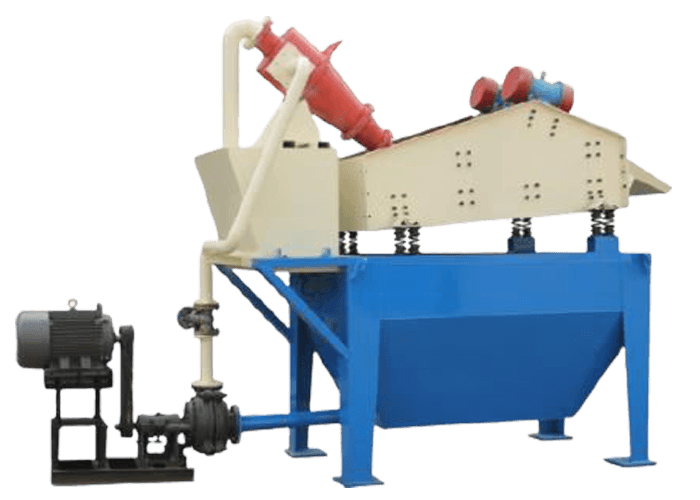

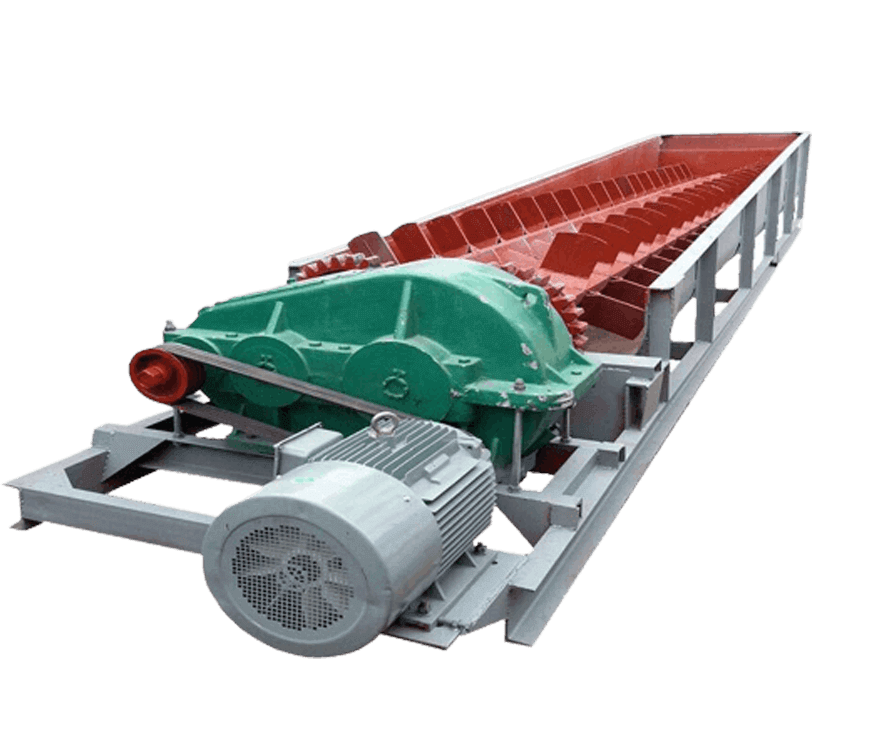

Products display

Introduction of log washer

Log washer or trough washing machine is a kind of ore washing equipment widely used in various large pieces of easy-to-wash and hard-to-wash clay, mud or soft ore/stone. Such include washing and separating mud in ferrous and non-ferrous metal mines, construction, sand and gravel, stone plants, etc. This trough ore washer is particularly suitable for processing difficult-to-clean minerals such as kaolin and clay, efficiently breaking up and loosening small clumps. Its core function is to remove over 20% of the silt in the ore, preventing clogging of subsequent crushing and screening equipment. It also separates soluble, useful, and harmful components, providing clean raw materials for subsequent mineral processing(crushing, gravity separation, magnetic separation, and flotation).

JXSC supports provide single/double shaft log washers, which are especially effective for breaking up viscous mud and stone material, and the washing and desliming effects are very significant. Its processing capacity is large, and it is an ideal washing equipment for enterprises that meet high productivity requirements on the cleanliness of ores and stones.

Principle and structure of log washer

Working principle

The log washer realizes ore separation and washing by gravity, water flow and vibration. The ore and water enter the tank from the feed port, and are agitated by the screw shaft impeller to achieve the purpose of ore cleaning, stirring and transportation. The force of the water flow will wash away the lighter impurities and mud; while the heavier ore will be deposited at the bottom of the tank and discharged from the discharge port.

Structural characteristics

It primarily consists of a trough (semi-circular chute), a spiral blade shaft, a transmission system (motor, reducer, gears), an overflow trough, a bracket, and water inlet components. The trough is typically tilted at an angle of 10-14°, forming a sedimentation basin that facilitates the overflow and separation of muddy materials.

- Blade design: Discontinuous paddle-shaped blades with a spiral line connecting the vertices. Made of thickened manganese steel, it is durable and sturdy.

- Bearings and seals: The bearings are isolated from water and materials, and the lower bearing utilizes a packing water seal.

why choose JXSC log washer

features & Advantages of log washer

1. The processing capacity is large, and the washing material is less lost; the cleanliness of ores and stones is high, which can well meet the requirements of high-grade materials;

2. It adopts thickened steel, which is not easy to wear; it adopts copper core motor, which has sufficient power and strong overload capacity;

3. Bearings, water, and materials are separated to avoid premature damage to the machine due to pollution and rust;

4. The structure is simple, the operation is stable, and it can be applied to various working environments.

5. The log washer is suitable for processing different types and sizes of ores. It can adapt to various ores’ properties and processing requirements by adjusting water flow, slope and other parameters.

models & specifications

| Model | Spiral Dia. (mm) | Rotating Speed (r/min) | Feeding Size (mm) | Tank Slope (o) | Process Capacity (t/h) | Motor Power(kw) | Weight (T) |

| 2RXL320 | 750 | 28 | ≤30 | ≤12 | 10 | 4 | 0.9 |

| 2RXL400 | 750 | 23 | ≤30 | ≤12 | 20 | 5.5 | 1.9 |

| 2RXL540 | 1000 | 23 | ≤30 | ≤12 | 25 | 7.5 | 3.9 |

| 2RXL750 | 1000 | 22.7 | ≤70 | ≤12 | 50 | 40 | 17.2 |

| 2RXL800 | 1200 | 22 | ≤70 | ≤12 | 70 | 45 | 18.9 |

| 2RXL914 | 1200 | 21 | ≤70 | ≤12 | 100 | 55 | 23 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.