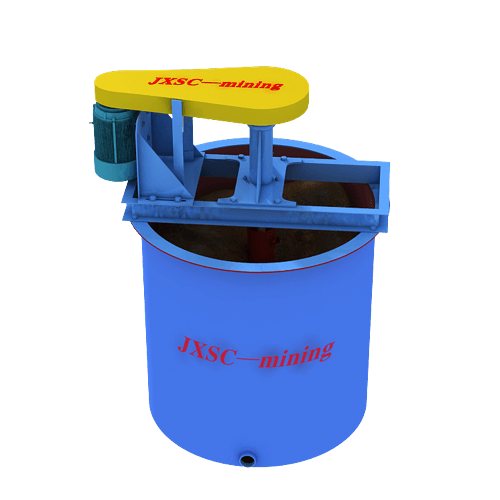

Mining Mixing Tank

Speed: 230-530 r/min

Capacity: 0.58-30 m³

Application: Mining mixing operations in mineral processing, leaching plants, and various chemical industries; especially suitable for mixing and stirring powdery, granular, and small materials with low controllability, such as building materials, cement, stones, sand, and clay , ores, minerals, etc.

Products display

introduction of mining mixing tank

A mining mixing tank, also called an agitator tank or mining mixer, is a mineral mixing tank with an agitator mixer. Its task is to stir, mix and homogenize the slurry and chemicals thoroughly. It is often used as mixing equipment before the flotation or leaching process; it can also mix and stir various minerals, such as gold, silver, copper, iron, lead, zinc, aluminum and limestone, gypsum, and sulfide ores. This equipment generates turbulence or agitation mechanically or pneumatically, which prevents the slurry from settling or stratifying, resulting in a high-quality finished product. Our mineral mixing tanks facilitate optimization to increase mineral extraction and recovery rates.

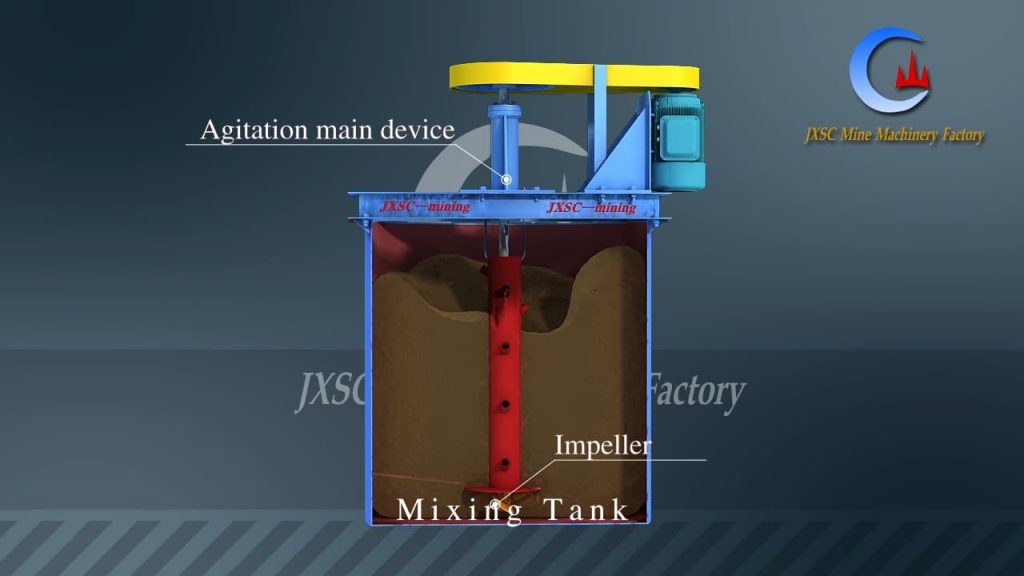

Working principle of Mining Mixing Tank

The mining agitator mixer comprises a rotating cylinder, lining plate, agitator, transmission system and discharge port. First, the ground ore is mixed into a slurry by adding water and necessary chemicals through the stirring tank, then poured into the slurry tank where the stirring begins. When the mixing tank works, the motor pulls the V-belt transmission device to drive the impeller to rotate. The slurry and the agent are mixed under the uniform stirring action of the impeller, which increases the reaction time of the agent to the slurry. Then, the mixed ore pulp is discharged from the discharge port for use in subsequent process steps.

why choose JXSC mining mixing tank

features & Advantages of mining mixing tank

1. The mineral mixing tank has a compact structure and good sealing, which effectively prevents debris and dust from entering;

2. JXSC mixing tank is made of high-strength steel, which can withstand high-intensity use and chemical corrosion, wear-resistant and has a long service life.

3. The blades in this mixing equipment are fan-shaped and have a large contact area with the medium during mixing, thereby achieving uniform mixing of the materials;

4. Our mining agitator mixing equipment has advanced performance, stable product quality and rapid discharging, which is convenient and time-saving.

models & specifications

Model | XB1000 | XB1500 | XB2000 | XB2500 | XB3000 | XB3500 |

Diameter of tank (m) | 1 | 1.5 | 2 | 2.5 | 3 | 3.5 |

Height (m) | 1 | 1.5 | 2 | 2.5 | 3 | 3.5 |

Volume of tank (m³) | 0.58 | 2.2 | 5.46 | 11.2 | 19.1 | 30 |

Impeller diameter (m) | 0.24 | 0.4 | 0.55 | 0.65 | 0.7 | 0.85 |

Impeller speed (r/min) | 530 | 320 | 230 | 200 | 210 | 230 |

Power (kw) | 1.1 | 3 | 5.5 | 18.5 | 22 | 30 |

Weight (ton) | 0.44 | 1.08 | 1.67 | 3.44 | 4.61 | 7.28 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.