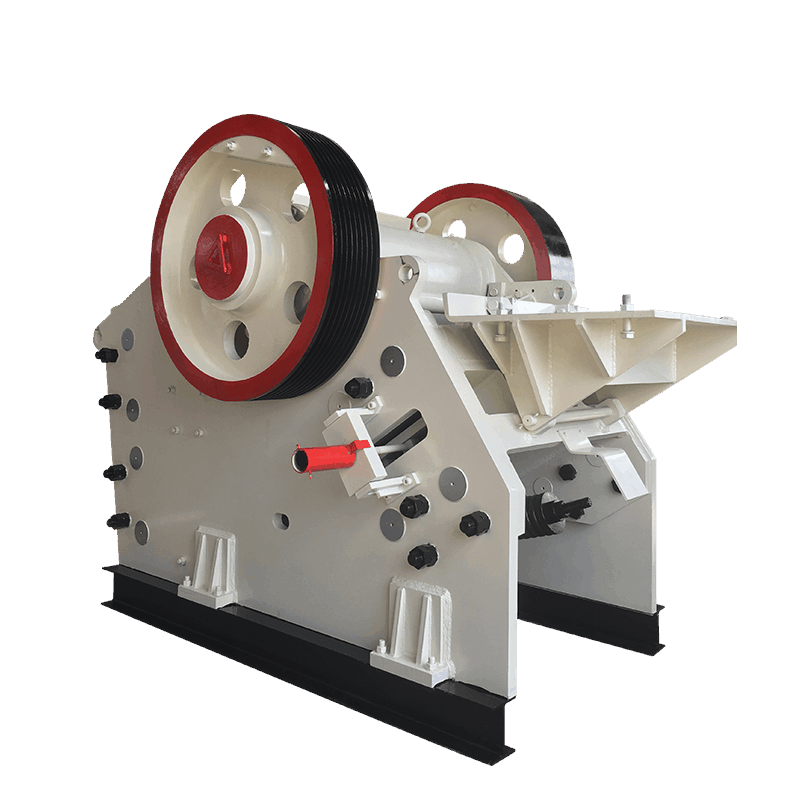

PEV European Jaw Crusher

Processing capacity: 55-675 TPH (tons per hour)

Product granularity: 0-225mm

Infeed width: 750-2000 mm

Application: The PEV European jaw crusher is widely used in mining, construction engineering, water conservancy and hydropower, construction waste treatment, highways, railways, and other fields; such as primary or secondary crushing of various ores, including iron ore, gold ore, copper ore, granite, marble, basalt, limestone, and quartz.

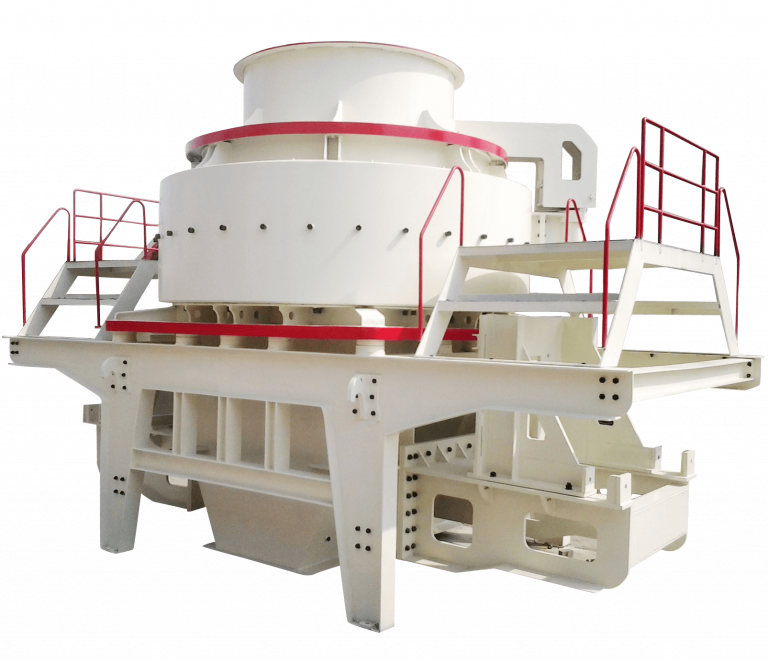

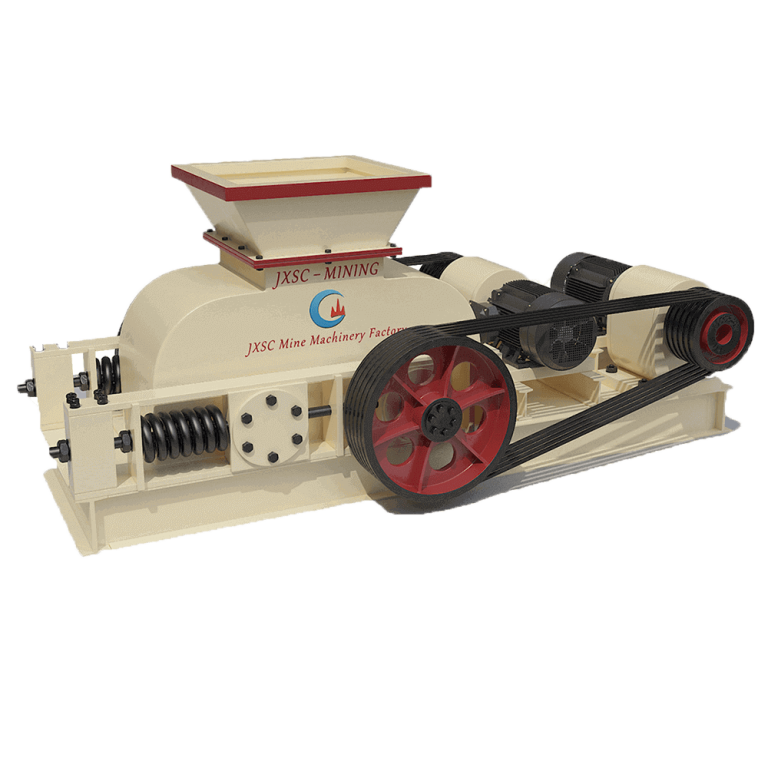

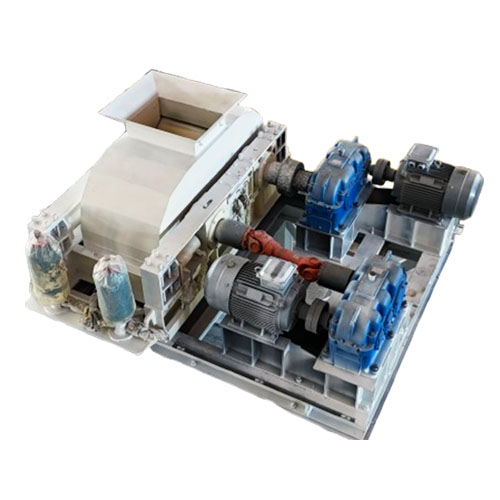

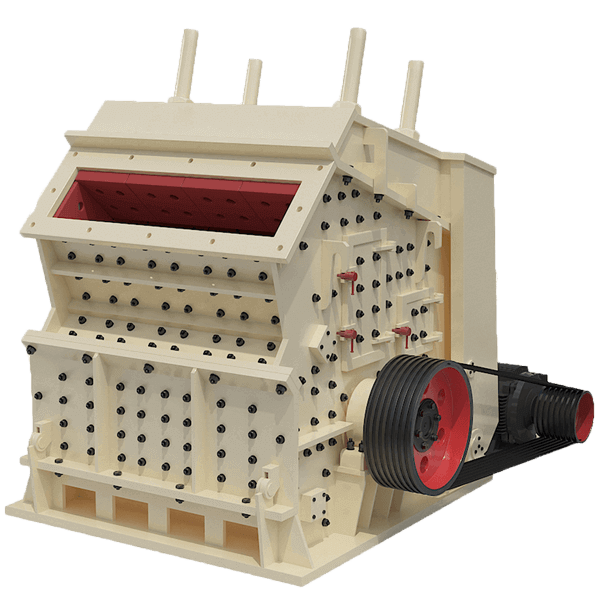

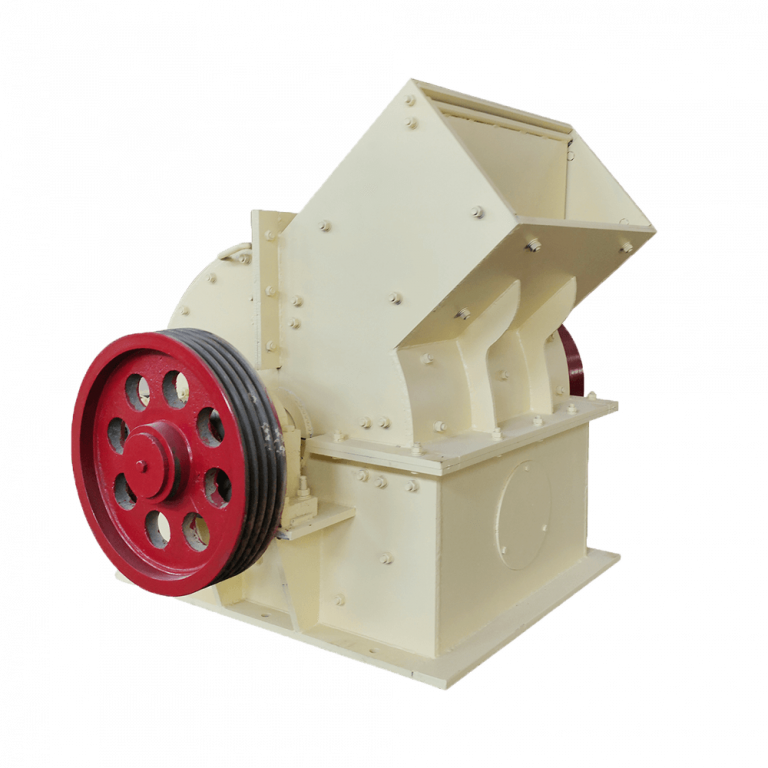

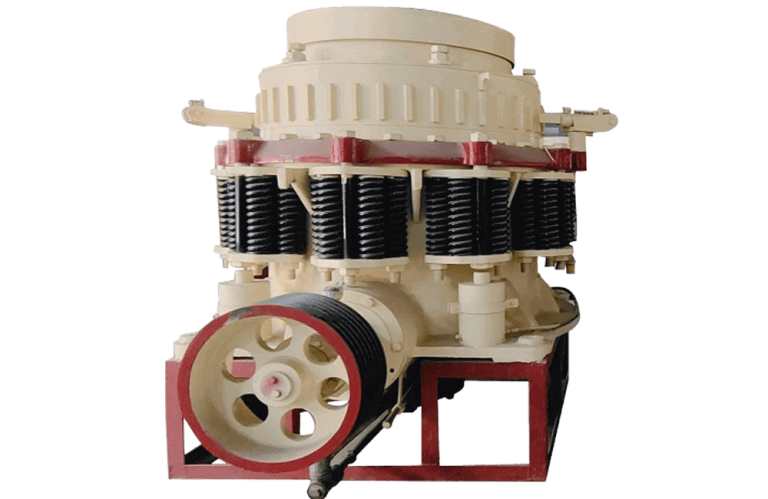

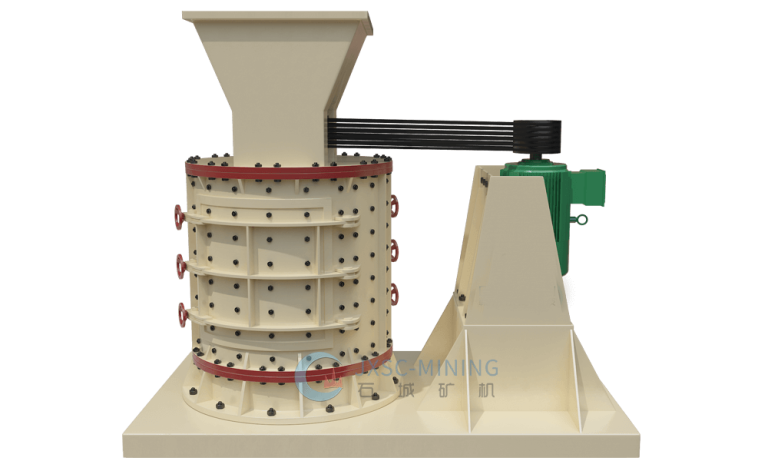

Products display

Introduction of PEV European Jaw Crusher

The PEV European jaw crusher is a new type of hydraulic jaw crusher developed after the PE series jaw crushers. It is a high-efficiency crushing equipment that integrates internationally advanced crushing technology and manufacturing processes. It is specifically designed for crushing stone materials used in engineering construction projects such as highways, railways, and airport runways, as well as for material crushing needs in mining, metallurgy, and building materials industries. It is particularly suitable for coarse or medium crushing of ores, rocks, and slag with compressive strength ≤320MPa. Combining modern mechanical optimization and wear-resistant material technology, it has become one of the preferred equipment for continuous crushing of hard and high-strength materials. It is widely used in large-scale stone production lines and mineral processing plants for primary or secondary crushing of materials such as gold ore, iron ore, granite, basalt, and marble, providing materials of suitable particle size for subsequent beneficiation and processing.

Large Hard Rock crushing solution

Compared to traditional jaw crushers (such as the PE and PEX series), the PEV European jaw crusher adopts a deep cavity crushing structure and modular design, offering unparalleled advantages in service life, maintenance rate, and failure rate. The equipment is also equipped with a hydraulic discharge opening adjustment system, making operation simpler and faster. Compared to the cone crushers and stone shaping machines used in conjunction with it, its cost is lower, and it has a wider range of feed particle sizes. It can fully meet the production needs with high requirements for capacity, energy consumption, scale, and finished product particle shape, making it an ideal crushing equipment for sand and gravel aggregate production, water conservancy projects, and construction waste treatment.

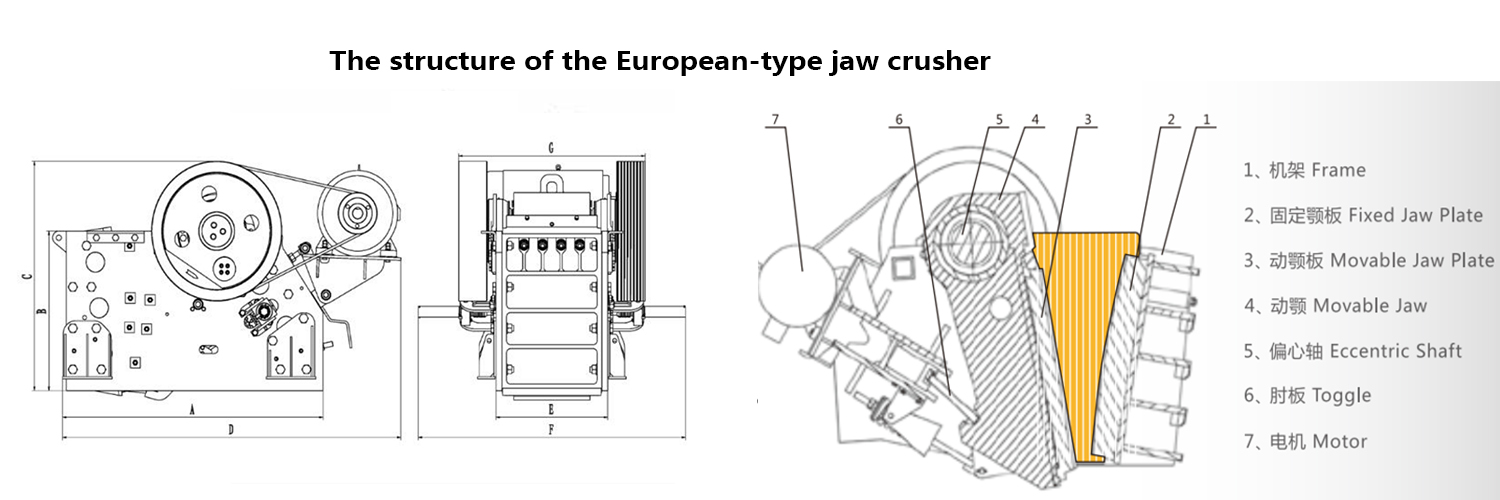

Structure & principle Of PEV European Jaw Crusher

Working principle

The PEV European jaw crusher is driven by an electric motor, which rotates an eccentric shaft, causing the movable jaw to perform a periodic reciprocating motion. When the movable jaw approaches the fixed jaw, the material is crushed by compression and splitting. When the movable jaw moves away, material smaller than the discharge opening falls due to gravity, completing the discharge process. Its crushing chamber features a symmetrical “V” shape design, ensuring more uniform stress on the material and preventing uneven wear. Simultaneously, a hydraulic adjustment device is used to control the size of the discharge opening in real time, ensuring that the finished product particle size remains stable within the range of 40-150mm.

Structural features

Integral frame

Adopts an integral casting structure, providing stronger vibration and impact resistance.

With the assistance of a hydraulic system, automated adjustment is achieved.

why choose JXSC PEV European Jaw Crusher

features & Advantages

√ High crushing efficiency: The optimized “V” shaped crushing chamber and high oscillation frequency effectively increase the crushing area, resulting in a 20-30% increase in production capacity compared to traditional PE series crushers.

√ Stable structure and reliable performance: The integrated cast steel bearing housing and heavy-duty eccentric shaft design improve the overall structural stability and reliability of the machine, enabling it to withstand long-term, high-intensity crushing operations and reducing malfunctions and downtime.

√ Extra-long service life: Key components (bearings, liners) are made of high-quality materials such as high-manganese steel, resulting in superior wear resistance.

√ Quick discharge opening adjustment: The discharge opening size can be adjusted quickly and precisely to control the output particle size, adapting to different production needs. The adjustment process is simple, safe, and fast.

√ Wide range of applications: It can process a variety of hard and highly abrasive materials, meeting the crushing needs of various industries such as mining, construction, and water conservancy.

√ Strong adaptability: It can be installed in a fixed location or integrated into a mobile crushing plant, flexibly adapting to different working conditions.

models & specifications

| Series | PEV | PEV | PEV | PEV | PEV | PEV | |

| Model | 500*750 | 600*900 | 750*1060 | 950*1250 | 1200*1600 | 1500*2000 | |

| Infeed width(mm) | 750 | 900 | 1060 | 1250 | 1600 | 2000 | |

| Outlet depth(mm) | 500 | 600 | 750 | 950 | 1200 | 1500 | |

| Motor power (kw) | 55-75 | 75-90 | 132 | 160 | 250 | 400 | |

| Weight of main body (kg, without motor) | 9080 | 12700 | 23800 | 42220 | 76330 | 131000 | |

| Product granularity(mm) | Tight edge discharge port(mm) | Process capacity(TPH, tons per hour) | |||||

| 0-60 | 40 | 55-80 | / | / | / | / | / |

| 0-75 | 50 | 70-90 | / | / | / | / | / |

| 0-90 | 60 | 80-110 | 120-155 | / | / | / | / |

| 0-105 | 70 | 105-130 | 140-180 | 155-200 | / | / | / |

| 0-120 | 80 | 120-150 | 160-210 | 175-230 | / | / | / |

| 0-135 | 90 | 130-170 | 180-235 | 200-260 | / | / | / |

| 0-150 | 100 | 150-190 | 200-260 | 220-290 | 290-380 | / | / |

| 0-185 | 125 | 190-260 | 250-325 | 280-365 | 350-455 | / | / |

| 0-225 | 150 | 250-340 | 300-390 | 335-435 | 410-535 | 520-675 | / |

Frequently Asked Questions

FAQs About Buy PEV European Jaw Crusher

The price typically ranges from tens of thousands to hundreds of thousands of RMB. The exact price needs to be determined after detailed communication with the JXSC manufacturer, based on your production requirements, such as processing capacity and feed size, as well as the equipment configuration, such as whether it is equipped with a hydraulic cavity clearing system, centralized lubrication system, etc.

Generally, it is recommended that the moisture content of the material be kept below 10%. If the moisture content is higher, it is advisable to perform appropriate drying treatment before crushing, such as air drying or oven drying, to ensure the stable operation of the equipment.

Of course. For example: PEV+vibrating screen, PEV+cone crusher, PEV primary crushing + cone crusher secondary crushing + vertical shaft impact crusher for shaping, etc. Specific configurations require information such as material hardness, target particle size, and site dimensions. Please contact JXSC experts for a customized solution.

The PE series is typically used as the primary crushing equipment in mineral processing lines, while the PEX series is used for secondary fine crushing or final product shaping. Together, they form a complete crushing process. The PEV series performs even better in handling high-hardness materials, maintaining stable, continuous operation, and offering ease of operation, making it particularly suitable for the production needs of large, modern mineral processing plants.

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.