Slurry Pump

Head: 9.1-66.99 M

Capacity: 4.5-3300 (m³/h)

Applications: Slurry pump is widely used in mining, metallurgy, power generation, chemical industry, dredging, and other industries. These pumps are used to transport various ore slurries (gold, iron, copper, lead, zinc, tungsten, tin, lithium, etc.); ash and coal slurries from thermal power plants; slag and steel slag from metallurgical plants; river sludge; sand and gravel aggregates, construction waste slurries, and seabed ore sand; corrosive chemical slurries; construction mortar; and other liquid-solid mixtures containing solid particles.

Products display

introduction of Slurry Pump

Slurry pumps are specialized industrial auxiliary equipment designed for conveying high-concentration slurries containing solid particles. It can efficiently handle a variety of high-concentration, high-temperature, and corrosive slurries. It is commonly used in applications such as slurry transportation, hydraulic ash removal, river dredging, and tailings treatment. Available in a variety of configurations: single-stage, multi-stage, horizontal, and vertical. It can adapt to a variety of extreme operating conditions. Variable frequency drive technology enables precise flow control. These slurry pumps can be connected to silos, crushers, filters, and other equipment to continuously transfer solid-liquid mixtures such as slurry and ash, replacing manual or inefficient conveying methods.

Powered by centrifugal force, these pumps utilize a highly wear-resistant double-layer pump casing and composite sealing system. They are key equipment for efficiently conveying high-concentration, large-particle, and highly corrosive solid-liquid mixtures in industries such as mining, power generation, and environmental protection. It offers core advantages such as long life, low energy consumption, and adaptability to extreme operating conditions. Their modular design makes them the preferred feeding solution for slurry conveying operations under harsh conditions.

Features Of slurry pump

1. Metal Material: anti-wear, abrasion, anti-wear and abrasion resistance.

2. High efficiency, long life, smooth operation.

3. Drive mode: directly connect the drive (DC), Fluid coupling drive (HC), and belt drive (CR, CL, ZV, CV).

4. Structure Features: The pump body adopts a double-layer pump shell mechanism. The double-shell pump shell structure is vertical in the open type. The water outlet position can be 45° of an interval, rotating 8 different installations.

5. Outlet diameter optional: 350mm, 300mm, 250mm, 200mm, 150mm, 100mm, 80mm, 65mm, 50mm, 40mm.

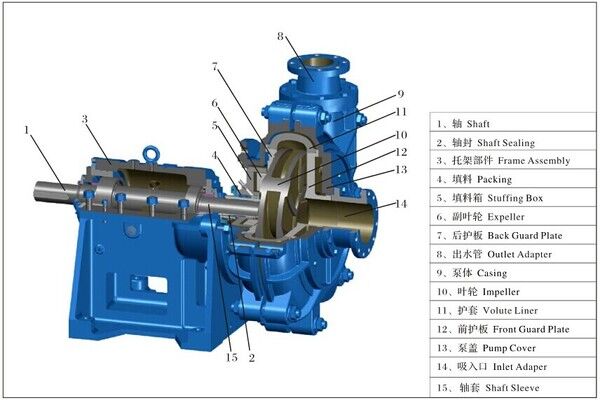

Principle and structure of slurry pump

working principle

The motor drives the impeller at high speed. Centrifugal force propels the medium inside the impeller into the volute-shaped pump chamber, creating a negative pressure zone at the center of the impeller. External slurry, under atmospheric pressure, enters the impeller through the suction pipe. Simultaneously, the ejected medium decelerates and pressurizes within the volute, converting kinetic energy into static pressure energy before ultimately being discharged through the outlet pipe. The auxiliary impeller balances axial forces, and the shaft seal system prevents leakage. Frequency conversion speed regulation is used to achieve a continuous “suction-pressurization-delivery” cycle, with both flow rate and head controlled by the variable frequency drive.

Structural characteristics

- Pump Casing: Single-piece high-chromium alloy casting with a double-casing design.

- Impeller: High-chromium-molybdenum alloy, available in closed, semi-open, or open configurations.

- Shaft Seal: Mechanical seal, stuffing box, or dynamic seal configurations.

- Bearing Assembly: Heavy-duty bearing housing with automatic lubrication system.

- Drive System: Direct drive, belt drive, or gearbox drive options.

- Bracket: Cast iron or cast steel.

Adjustment: Axial clearance adjustment mechanism.

Why Choose JXSC slurry pump

Ultra-wear-resistant: Flow-through components are made of high-chromium cast iron, ensuring a long impeller life. Replaceable wear-resistant bushings significantly reduce maintenance costs.

Adaptable: It can be directly docked with the silo bottom, eliminating the need for additional buffers. It adapts to high and low temperature ranges, and humidity has no significant impact on operation.

Flexible Installation: It supports tilting from 0° to 25° to accommodate various silo layout requirements.

Wide Compatibility: It can transport aerated slurries, high-temperature slag, and strong acid and alkali media, meeting specialized requirements for deep-sea mining and lithium extraction from salt lakes.

models & specifications

Type | Allowable Max. Power of ass. Motor(Kw) | Clear Water Performance | Handled Particle Dia. Max. (mm) | Pump Weight (Kg) | ||||

Capacity (m3/h) | Head (m) | Speed (r/min) | Max.eff. (%) | (NPSH)r (m) | ||||

350ZJ-I-F100 | 560 | 526-2339 | 14.9-62.8 | 300-590 | 77.6 | 4.4 | 96 | 5465 |

350ZJ-I-C104 | 560 | 1335-3300.6 | 36.6-66.9 | 490-590 | 77.6 | 7.3 | 180 | 5465 |

350ZJ-I-C100 | 710 | 834-3502 | 11.1-60.0 | 300-593 | 73.0 | 7.4 | 160 | 7120 |

350ZJ-I-A85 | 710 | 1025-3741 | 12.3-62.3 | 400-742 | 77.2 | 10.5 | 100 | 5461 |

350ZJ-I-A80 | 630 | 837-3575 | 8.4-56.4 | 400-742 | 75.7 | 10.5 | 92.8 | 4920 |

300ZJ-I-A100 | 450 | 464-1826 | 15.3-65.2 | 300-590 | 81.1 | 3.0 | 88 | 5265 |

300ZJ-I-A95 | 400 | 441-1735 | 13.8-58.8 | 300-590 | 78.1 | 3.0 | 88 | 5220 |

300ZJ-I-A90 | 560 | 505-1844 | 21.2-79.9 | 400-730 | 82.8 | 3.9 | 85 | 5005 |

300ZJ-I-C90 | 400 | 604-2392 | 10.9-50.9 | 300-590 | 78.6 | 3.6 | 160 | 6290 |

300ZJ-I-A85 | 450 | 477-1742 | 18.9-71.3 | 400-730 | 79.8 | 3.8 | 85 | 4965 |

300ZJ-I-A70 | 630 | 635-2333 | 16.0-76.8 | 490-980 | 80.4 | 3.9 | 92 | 3560 |

300ZJ-I-A65 | 500 | 589-2166 | 13.8-66.2 | 490-980 | 77.4 | 3.7 | 92 | 3531 |

300ZJ-I-A56 | 250 | 395-1568 | 9.7-46.0 | 490-980 | 80.9 | 3.5 | 96 | 3030 |

250ZJ-I-A103 | 560 | 402-1573 | 29.7-110.5 | 400-730 | 74.5 | 2.8 | 69 | 5085 |

250ZJ-I-A96 | 560 | 403-1466 | 25.4-93.7 | 400-730 | 77.8 | 3.5 | 69 | 5035 |

250ZJ-I-A90 | 450 | 378-1374 | 22.3-82.4 | 400-730 | 73.8 | 3.4 | 69 | 4980 |

250ZJ-I-A85 | 800 | 376-1504 | 30.1-128.7 | 490-980 | 76.5 | 3.5 | 76 | 4530 |

250ZJ-I-A83 | 800 | 367-1469 | 28.7-122.7 | 490-980 | 75.5 | 3.5 | 76 | 4514 |

250ZJ-I-A80 | 710 | 354-1416 | 26.7-114.0 | 490-980 | 73.5 | 3.4 | 76 | 4490 |

250ZJ-I-C80 | 450 | 451-1790 | 7.4-38.3 | 300-592 | 75.1 | 3.3 | 144 | 5203 |

250ZJ-I-A78 | 630 | 415-1796 | 21.1-102.5 | 490-980 | 71.5 | 3.2 | 76 | 4474 |

250ZJ-I-A75 | 560 | 300-1480 | 20.8-97.5 | 490-980 | 77.5 | 3.0 | 72 | 3480 |

250ZJ-I-A73 | 500 | 292-1441 | 19.7-92.4 | 490-980 | 76.5 | 3.0 | 72 | 3466 |

250ZJ-I-A70 | 450 | 280-1381 | 18.1-84.9 | 490-980 | 74.5 | 2.9 | 72 | 3446 |

250ZJ-I-A68 | 450 | 272-1342 | 17.1-80.1 | 490-980 | 73.5 | 2.7 | 72 | 3432 |

250ZJ-I-A65 | 315 | 299-1249 | 15.4-71.0 | 490-980 | 76.9 | 3.0 | 72 | 3020 |

250ZJ-I-A63 | 315 | 290-1211 | 14.4-66.7 | 490-980 | 75.9 | 3.0 | 72 | 3008 |

250ZJ-I-A60 | 280 | 276-1153 | 13.1-60.5 | 490-980 | 73.9 | 2.8 | 72 | 2991 |

200ZJ-I-A85 | 560 | 221-907 | 32.0-133.7 | 490-980 | 70.5 | 2.8 | 54 | 4110 |

200ZJ-I-A75 | 355 | 225-900 | 22.8-102.9 | 490-980 | 74.1 | 3.0 | 56 | 3070 |

200ZJ-I-A73 | 355 | 219-876 | 21.6-97.5 | 490-980 | 73.1 | 3.0 | 56 | 3056 |

200ZJ-I-A70 | 315 | 205-976 | 19.4-86.41 | 490-980 | 75.6 | 2.8 | 56 | 2465 |

200ZJ-I-A68 | 315 | 199-948 | 8.3-81.5 | 490-980 | 74.6 | 2.8 | 56 | 2453 |

200ZJ-I-A65 | 250 | 235-950 | 16.4-72.0 | 490-980 | 79.6 | 2.5 | 62 | 2323 |

200ZJ-I-A63 | 250 | 228-921 | 15.4-67.6 | 490-980 | 78.6 | 2.5 | 62 | 2311 |

200ZJ-I-A60 | 185 | 218-870 | 13.9-62.0 | 490-980 | 83.5 | 2.5 | 62 | 2223 |

200ZJ-I-A58 | 185 | 211-841 | 13.0-57.9 | 490-980 | 82.5 | 2.5 | 62 | 2214 |

200ZJG-I-B45 | 132 | 85-538 | 10.5-72.9 | 700-1480 | 68.0 | 10.7 | 28 | 1531 |

150ZJ-I-A71 | 220 | 142-552 | 21.8-93.8 | 490-980 | 69.8 | 2.4 | 48 | 2263 |

150ZJ-I-A70 | 185 | 93-401 | 20.2-91.2 | 490-980 | 62.3 | 2.0 | 37 | 2245 |

150ZJ-I-A65 | 200 | 150-600 | 17.4-75.7 | 490-980 | 70.8 | 2.5 | 48 | 2223 |

150ZJ-I-A63 | 185 | 146-582 | 16.3-71.1 | 490-980 | 69.8 | 2.5 | 48 | 2211 |

150ZJ-I-A60 | 160 | 135-550 | 14.7-63.5 | 490-980 | 75.9 | 2.5 | 48 | 2203 |

150ZJ-I-A58 | 132 | 131-532 | 13.7-59.3 | 490-980 | 74.9 | 2.5 | 48 | 2033 |

150ZJ-I-C58 | 160 | 134-596 | 12.8-61.0 | 490-980 | 69.1 | 2.0 | 75 | 2063 |

150ZJ-I-A57 | 110 | 95-427 | 13.2-56.3 | 490-980 | 67.8 | 1.8 | 32 | 2023 |

150ZJ-I-A55 | 110 | 124-504 | 12.3-53.4 | 490-980 | 72.9 | 2.3 | 48 | 2019 |

150ZJ-I-A50 | 75 | 115-460 | 9.5-43.1 | 490-980 | 76.8 | 2.5 | 48 | 1735 (1648) |

150ZJ-I-A48 | 75 | 111-442 | 8.7-39.7 | 490-980 | 75.8 | 2.5 | 48 | 1728 (1641) |

150ZJG-I-B45 | 110 | 105-458 | 10.9-72.5 | 700-1480 | 65.4 | 7.3 | 25.6 | 1576 (1433) |

150ZJ-I-C42 | 132 | 142-550 | 12.1-62.8 | 700-1480 | 77.1 | 2.2 | 69 | 1605 (1518) |

100ZJ-I-A50 | 160 | 85-360 | 20.5-100.2 | 700-1480 | 69.6 | 2.5 | 34 | 1475 (1388) |

100ZJ-I-A46 | 132 | 79-331 | 17.3-84.8 | 700-1480 | 67.6 | 2.3 | 34 | 1461 (1374) |

100ZJ-I-A42 | 90 | 66-275 | 14.7-70.8 | 700-1480 | 71.0 | 2.5 | 35 | 1075 (1021) |

100ZJ-I-A39 | 75 | 61-255 | 12.6-61.0 | 700-1480 | 39.0 | 2.4 | 35 | 1064 (1010) |

100ZJ-I-B42 | 90 | 83-365 | 12.7-66.8 | 700-1480 | 71.6 | 2.5 | 40 | 1085 (1031) |

100ZJG-I-B42 | 75 | 45-205 | 9.7 | 700-1480 | 63.2 | 1.8 | 18 | 1080 (990) |

100ZJ-I-A36 | 55 | 61-245 | 49.5 | 700-1480 | 71.6 | 2.0 | 32 | 1010 (956) |

100ZJ-I-A33 | 45 | 56-225 | 8.2-41.6 | 700-1480 | 69.6 | 1.8 | 32 | 1003 (949) |

80ZJ-I-A52 | 160 | 51-242 | 22.1-109.8 | 700-1480 | 56.3 | 2.1 | 21 | 1465 (1378) |

80ZJ-I-A42 | 75 | 61-204 | 14.4-70.4 | 700-1480 | 66.7 | 2.5 | 24 | 1053 (963) |

80ZJ-I-A39 | 55 | 57-189 | 12.4-60.7 | 700-1480 | 64.7 | 2.4 | 24 | 1042 (952) |

80ZJ-I-A36 | 45 | 46-190 | 9.6-51.4 | 700-1480 | 67.7 | 2.5 | 24 | 980 (926) |

80ZJ-I-A33 | 37 | 43-174 | 8.0-43.2 | 700-1480 | 65.7 | 2.3 | 24 | 973 (919) |

65ZJ-I-A30 | 15 | 23-79 | 7.4-34.8 | 700-1460 | 63.5 | 2.0 | 19 | 504 (512) |

65ZJ-I-A27 | 11 | 20-71 | 6.0-28.2 | 700-1460 | 61.5 | 1.8 | 19 | 500 (508) |

50ZJ-I-A50 | 90 | 27-111 | 22.3-110.7 | 700-1480 | 45.1 | 3.0 | 13 | 1378 |

50ZJ-I-A46 | 55 | 23-94 | 17.9-85.8 | 700-1480 | 44.7 | 1.4 | 14 | 1082 (992) |

50ZJ-I-A33 | 18.5 | 12-54 | 7.7-42.5 | 700-1480 | 42.1 | 2.9 | 13 | 537 (545) |

40ZJ-I-A19 | 15 | 8.0-34.9 | 12.8-57.1 | 1430-2930 | 58.8 | 1.3 | 11 | 173 |

40ZJ-I-A17 | 7.5 | 4.5-23.4 | 9.1-44.6 | 1400-2900 | 52.4 | 2.5 | 11 | 121 (127) |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.