ZD, ZDH, ZDSH Cylindrical Gear Reducer

1. The transmission speed of the high-speed shaft is not more than 1500 rpm;

2. The ambient temperature of the reducer is -40℃~+45℃;

3. The reducer is suitable for forward and reverse operations.

Types: ZD, ZDH, ZDSH cylindrical gear reducers

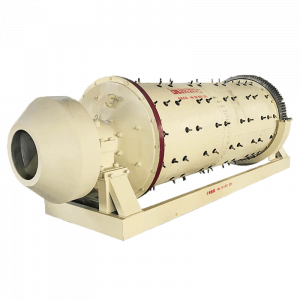

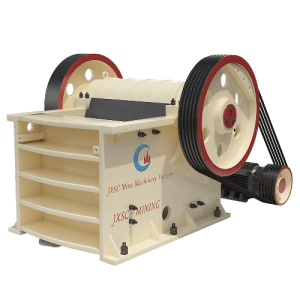

Application: the cylindrical gear reducers are widely used in the transmission systems of equipment in mining, metallurgy, chemical industry, environmental protection and other industries, such as belt conveyors, conveyor lines, ball mills, ore washers, etc., providing reliable power guarantee.

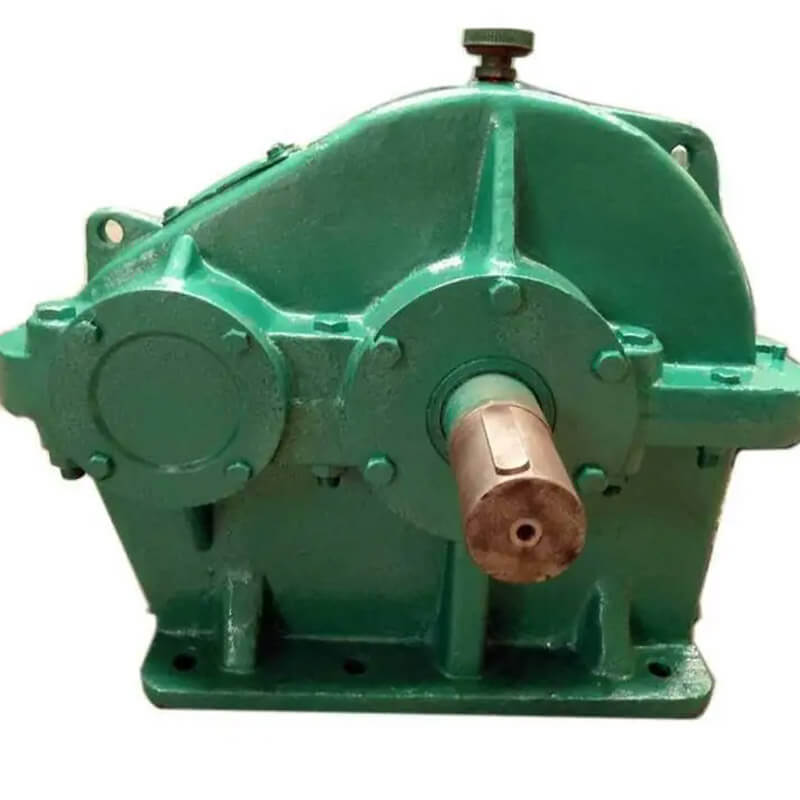

Introduction of ZD,ZDH, ZDSH Cylindrical Gear Reducer

ZD, ZDH, ZDSH series cylindrical gear reducer, also known as hardened cylindrical gear reducer, ZD type cylindrical arc gear reducer is a mechanical reduction device that uses parallel shaft hardened gear transmission.

Its main function is to provide power transmission, speed regulation and torque amplification functions for various mechanical equipment, such as power transmission components in ball mills and trommel scrubbers. It is precision machined from high-quality alloy steel and undergoes heat treatment and grinding processes to ensure excellent transmission efficiency and long service life. It can be equipped in mining machinery such as belt conveyors, crushers, grinders, ore washers, etc., and performs well in environments with high dust and strong vibration.

ZD series cylindrical gear reducers are usually single-stage (ZDY), two-stage (ZDZ), or multi-stage combinations to meet different speed ratio requirements. The gears have high precision (usually 7 or more), and the transmission efficiency can reach 95%-98%. They have the characteristics of small size, large transmission ratio and strong load-bearing capacity.

Types Of ZD, ZDH, ZDSH cylindrical gear reducer

ZD Cylindrical Gear Reducer

Structural features: Usually single-stage cylindrical gear design, compact and simple.

Gear features: Standard tooth surface, suitable for general industrial applications.

Application: Widely used in small and medium-sized mechanical equipment.

ZDH cylindrical gear reducer

Structural features: Similar to ZD, but with hardened tooth surface design.

Gear features: High-strength gears, enhanced load-bearing capacity.

Application: Suitable for high-strength and high-load occasions.

ZDSH cylindrical gear reducer

Structural features: Emphasis on noise reduction and vibration reduction.

Gear features: Hardened tooth surface combined with optimized gear design.

Application: Low noise environment and high efficiency transmission requirements.

1. ZD Series:

Standard cylindrical gear reducer, suitable for conventional industrial environments (such as temperature -15°C~45°C), widely used in transmission systems of small and medium-sized mechanical equipment.

2. ZDH Series:

Optimized design based on ZD; single-stage hardened cylindrical gear reducer, suitable for applications requiring high strength and durability.

- Heavy load capacity: gear material or heat treatment process upgraded, suitable for higher loads.

- Special seal: better dust and water resistance.

- Customization: can be adapted to variable frequency motors or non-standard installation requirements.

3. ZDSH Series:

Double arc cylindrical gear reducer with single-stage transmission, with enhanced hardened tooth surface design, has the characteristics of efficient transmission and low noise.

why choose Our ZD, ZDH, ZDSH Cylindrical Gear Reducer

features & Advantages

1. Excellent transmission efficiency

ZD, ZDH, ZDSH gear reducers adopt hardened gear design, with a transmission efficiency of more than 96%, significantly reducing energy consumption costs.

2. Super load capacity

High-strength alloy steel materials combined with precision processing technology enable our reducers to withstand heavy load conditions and frequent start-stop tests.

3. Super long service life

The unique oil lubrication system and high-quality bearing configuration ensure that the equipment can maintain stable performance in harsh environments.

4. Compact structure

The box body is mostly cast iron or welded steel structure, which is light but rigid and easy to install.

5. Modular design

Multi-stage transmission combination design can flexibly configure speed ratios and installation forms according to customer needs, perfectly adapting to various types of mechanical equipment.

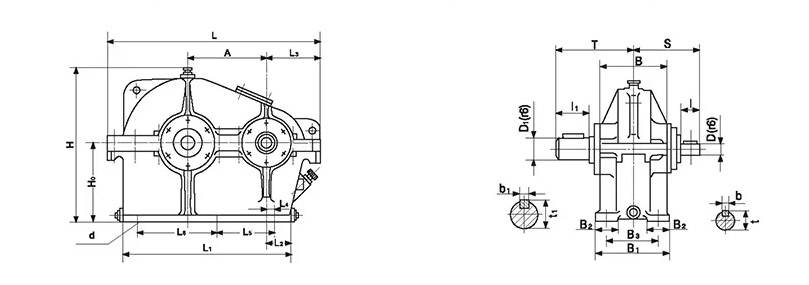

models & specifications

Structure and parameters of ZD type cylindrical gear reducer

Type | center distance | center height | outer size(H*L*B) | B1 | B2 | L1 | L2 | Lower margin screw | ||||||

n-d | B3 | L4 | L5 | L6 | ||||||||||

ZD10 | 100 | 130-0.5 | 240 | 335 | 140 | 150 | 140 | 48 | 245 | 4-M16 | 110 | 10 | / | 195 |

ZD15 | 150 | 200-0.5 | 355 | 450 | 210 | 450 | 210 | 220 | 70 | 6-M16 | 160 | 10 | 80 | 200 |

ZD20 | 200 | 250-0.5 | 495 | 575 | 250 | 575 | 250 | 250 | 80 | 6-M16 | 170 | 10 | 130 | 220 |

ZD25 | 250 | 300-0.5 | 595 | 710 | 270 | 710 | 270 | 290 | 90 | 6-M20 | 210 | 10 | 160 | 295 |

ZD30 | 300 | 350-0.5 | 685 | 835 | 300 | 835 | 300 | 320 | 100 | 6-M24 | 240 | 20 | 205 | 350 |

ZD35 | 350 | 400-0.5 | 780 | 955 | 350 | 955 | 350 | 360 | 110 | 6-M24 | 280 | 20 | 250 | 400 |

ZD40 | 400 | 450-0.5 | 880 | 1085 | 390 | 1085 | 390 | 400 | 120 | 6-M24 | 310 | 20 | 280 | 470 |

ZD45 | 450 | 500-0.5 | 975 | 1210 | 430 | 1210 | 430 | 450 | 130 | 6-M30 | 340 | 35 | 325 | 525 |

ZD50 | 500 | 550-1.0 | 1105 | 1320 | 470 | 1320 | 470 | 500 | 140 | 6-M36 | 390 | 40 | 355 | 600 |

ZD60 | 600 | 650-1.0 | 1300 | 1550 | 540 | 1550 | 540 | 540 | 145 | 6-M36 | 430 | 40 | 440 | 700 |

ZD70 | 700 | 750-1.0 | 1495 | 1820 | 580 | 1820 | 580 | 610 | 150 | 6-M42 | 500 | 55 | 550 | 790 |

ZD80 | 800 | 835-1.5 | 1650 | 2040 | 620 | 2040 | 620 | 650 | 150 | 6-M48 | 545 | 55 | 650 | 860 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.