Vibrating Screen

Capacity: 10-250t/h

Layer: 1-4 available

Screen mesh: customized

Application: Vibrating screens are mainly used to classify materials into different grades according to particle size. They are often used for the primary selection of various ores and the classification of sand and gravel aggregates; for example, the screening of gold, iron ore, copper ore, manganese, diamond, lithium, manganese, limestone, granite, marble, etc.

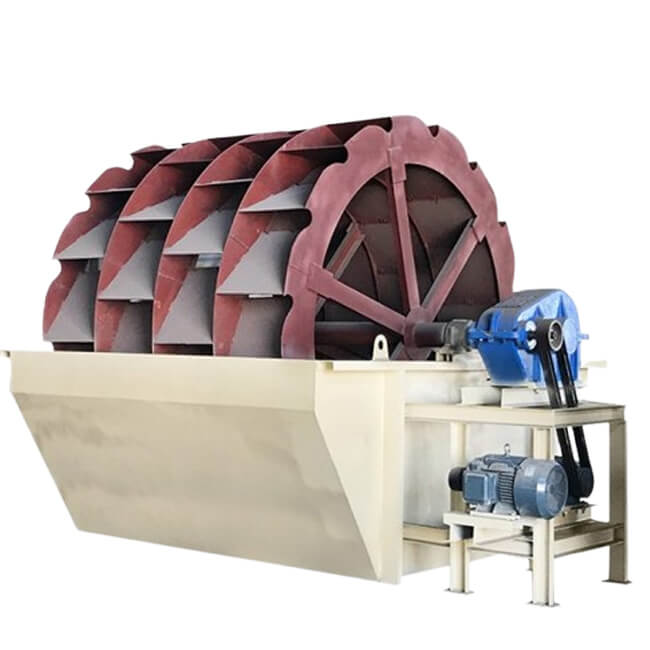

Products display

Introduction of Vibrating Screen

The vibrating screen is a mechanically efficient screening equipment for material classification, dehydration and impurity removal. High-frequency screens are widely used in mineral processing, such as screening of iron ore, tin, tungsten, tantalum, niobium, alluvial diamond, etc. It is an efficient, accurate and multifunctional screening equipment. It is often used for dry and wet screening, classification, and dehydration of various materials in coal preparation, mining, and mineral processing industry, sand making, aggregate production, sand and gravel, quarry plant, etc.

According to the different vibration modes, vibrating screen is mainly divided into:

- Linear vibrating screen: the material moves in a straight line, suitable for medium and fine particle classification.

- Circular vibrating screen: the material moves in a spiral, suitable for coarse particle screening.

- High-frequency vibrating screen: used for dehydration of fine particles or micro powder classification.

This vibrating screen mainly uses reciprocating, rotating, or linear vibration to make the material jump and move on the screen surface to achieve the separation of particles of different sizes. It is an efficient, accurate, and multifunctional equipment. Such as coal, iron ore, copper ore, gold ore, manganese ore, limestone, granite, basalt, marble, and other minerals or sand and gravel aggregate particle size classification.

JXSC supports customized screening equipment such as linear vibrating screens, circular vibrating screens, and high-frequency vibrating screens, all have the advantages of high efficiency and energy saving, durability, reliability, and strong adaptability.

principle and structure of vibrating screen

working principle

Main parts of the high frequency screen are mainframe, screen, electric vibrators, electric motor, rub spring and coupler.

The screening decks are capable of single to triple decks, greatly improve the screening efficiency and capacity. Besides, providing a thin and loose bed of particles, which as well as do a good effect on the screen.

Sieving is one of the oldest and most widely used physical size separation methods and is widely used in industry. In the continuous screening process, high frequency and low amplitude features lead to the vertical elliptical movement, the particles that fall from the feed hopper and reach the surface of the screen are sorted under the action of gravity. Oversized particles rebound along the screen, and most undersized particles pass through the holes.

Structural characteristics

- Screen box: Constructed from welded high-strength steel plates, it’s wear-resistant and deformation-resistant.

Vibration Source: Available with an eccentric block vibrator (single-axis or dual-axis), a vibration motor, or an electromagnetic vibrator. - Screen: Available in multiple layers, made of polyurethane, stainless steel, rubber, and other materials to accommodate different materials.

- Shock absorption system: Utilizes rubber springs for vibration reduction.

- Intelligent control: Vibration parameters can be adjusted in real time, and the discharge opening size is adjustable.

why choose JXSC Vibrating Screen

Features & advantages of vibrating screen

1. Multi-layer screen design (1-5 layers) completes multi-level classification at one time.

2. High-frequency screen can be used for sand washing and dehydration of materials after ore dressing.

3. Usually nylon or stainless steel screen plates are used, which have a long service life.

4. High-frequency screens have large processing capacity, high efficiency, small amplitude and high screening frequency.

5. Whether processing minerals, aggregates or industrial by-products, solving various material screening equipment.

6. Ensuring that finer particles can pass through the screen openings, thereby increasing overall productivity and throughput.

7. Generally, nylon or stainless steel screen plates are used, which have long service life.

models & specifications

| Model | JXSC-1036 | JXSC-1236 | JXSC-1536 | JXSC-1545 | JXSC-1836 | JXSC-1845 | JXSC-2045 | JXSC-2460 |

| Capacity(t/h) | 10-15 t/h | 18-65 t/h | 30-90 t/h | 30-90 t/h | 40-120 t/h | 40-120 t/h | 60-160 t/h | 80-250 t/h |

| Screening Surface Size (mm) | 1000*3600 | 1200*3600 | 1500*3600 | 1500*4500 | 1800*3600 | 1800*4500 | 2000*4500 | 2400*6000 |

| Sieve Size(mm) | Customized according to customer requirements | |||||||

| Double Amplitude(mm) | 0-5 | 0-5 | 0-5 | 0-5 | 0-5 | 0-5 | 0-5 | 0-5 |

| Powder(kw) | 2*1.1 | 2*2.2 | 2*5 | 2*5 | 2*7.5 | 2*7.5 | 2*11 | 2*15 |

| Voltage(v) | 380 | 380 | 380 | 380 | 380 | 380 | 380 | 380 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.