Diamond Mining Process

- Capacity: 1-300TPH+ (customize)

- Alternative name: diamond wash plants, diamond processing plants, diamond separation plant, or diamond recovery plants.

Diamond mining processes are beneficiation systems specifically designed for extracting diamonds from primary ore. It is very popular in the processing of various alluvial, placer gold, or kimberlite diamond ores in Angola, Brazil, South Africa, Burundi, Congo, Tanzania, and other countries. The aim is to recover every diamond from rivers, beaches, and diamond-rich deposits.

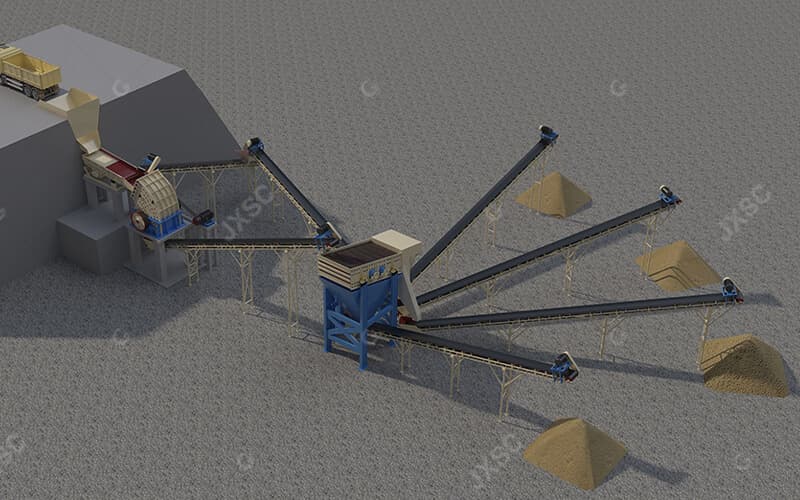

Diamond processing plant mainly involves energy-efficient and environmentally friendly crushing, washing, screening, jig gravity separation, or mobile jig plant (small diamond process plant), DMS hydrocyclone, dewatering, and tailings technologies.

Diamond Processing Solutions

Diamonds often exist in the form of alluvial and also contain rock ore. A diamond processing plant is a facility used in the mining industry to separate diamonds from surrounding gravel or ore. Diamond processing solutions are usually achieved by crushing, washing, screening, dense media and jig separation, magnetic separation, etc.

Diamond Separation Process

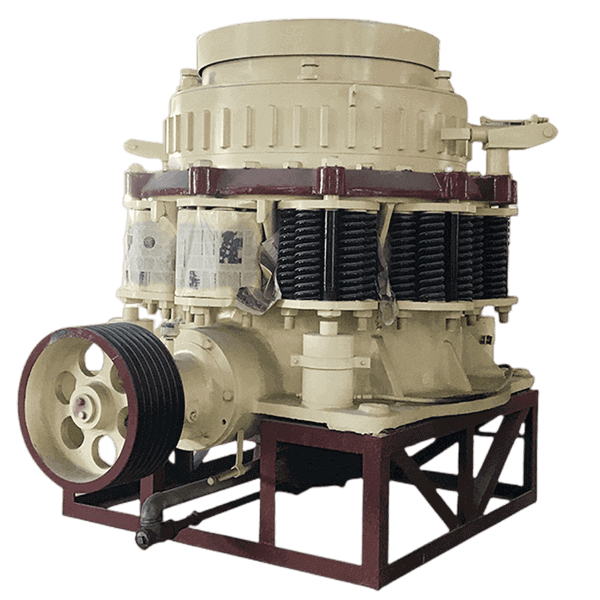

1. Crushing: For primary ore and kimberlite, open-pit or underground mining techniques are typically used to extract the ore from the pipe. The ore is then fed to crushers for coarse crushing (such as jaw crushers) and fine crushing (such as cone crushers) to ensure that diamond crystals are released without being damaged.

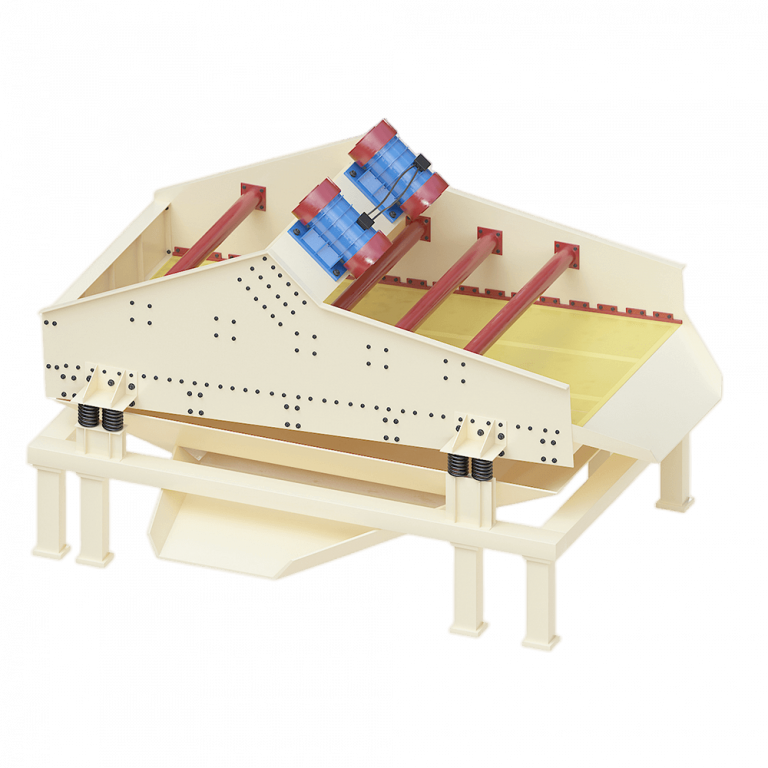

2. Washing and desliming: Scrubbing and sieving remove clay, dirt, and other contaminants that may adhere to diamonds, helping to break down the material and release the diamonds. Commonly used equipment: trommel scrubber + high-frequency vibrating screen. This process is especially important when processing placer diamond mines.

3. Separation process

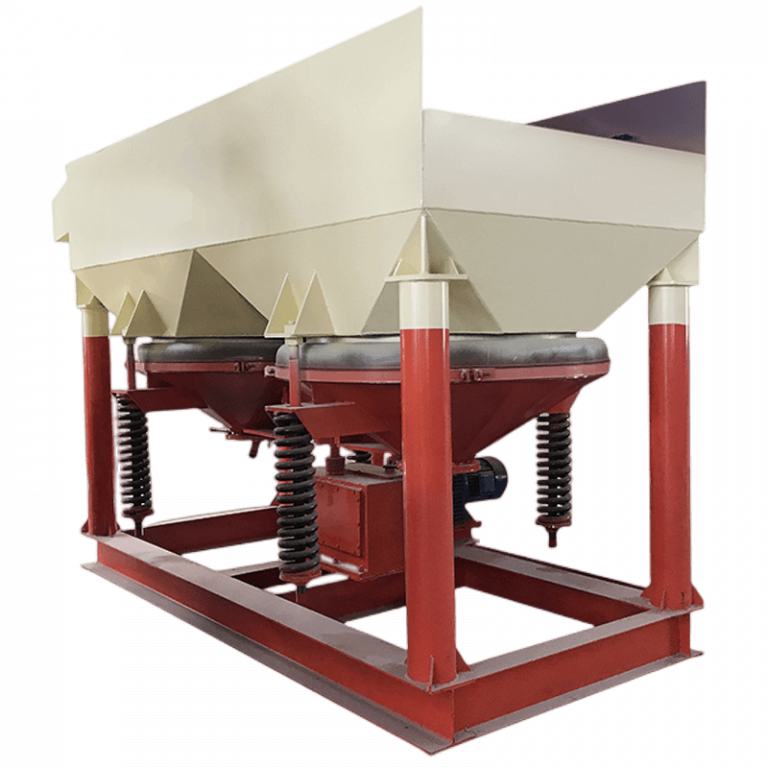

- Jig separator uses the action of water flow and vibration, diamonds and heavier impurities settle to the bottom or heavier layers, while lighter impurities float above the water flow.

- Dense Media Separation(DMS)sorting uses a suspension medium (such as heavy liquid or magnetic liquid) as the sorting medium. The raw ore is soaked in the suspension medium, and diamonds and heavier impurities will settle to the bottom, while lighter impurities float above the suspension medium.

The specific choice of which process to use depends on the characteristics of the raw ore, the expected separation effect and economic considerations. These two processes can also be combined in practical applications to improve the sorting effect and efficiency.

4. Diamond recovery: The heavy fraction containing the diamonds is further processed to recover the diamonds. Various methods can be employed, including X-ray sorting, grease tables, and hand sorting, depending on the size and quality of the diamonds.

5. Final grading: Recovered diamonds are sorted according to size, shape, color and clarity. They may undergo further grading and evaluation to determine their value and potential use in the diamond market.

JXSC provide professional mineral processing equipment configuration and flow design for each diamond mine type. Contact our diamond processing experts now for technical consultation and quotation!

Diamond processing Plant

1. alluvial diamond wash plant

100TPH alluvial diamond wash process & 30TPH DMS separation plant

- Feeding: Dump truck/loader → hopper → vibrating feeder (75mm grating to remove waste >75mm) → 0-75mm feeds to trommel scrubber.

- Clay washing: Trommel scrubber (25mm single-layer screen) removes waste >25mm → 0-25mm feeds to high-frequency vibrating screen.

- Fine washing and screening: High-frequency vibrating screen (1mm PU screen + water spray) removes 0-1mm muddy water → 1-25mm feeds to DMS pre-storage silo.

- Cyclone DMS separation system: 1-25mm re-washing screen (removes 0-1mm) → cone trough with ferrosilicon sand → pumped into hydrocyclone (diamond underflow discharge, light waste overflow discharge); Concentrate/tailings dewatered separately (concentrate sent to X-ray separation, tailings stockpiled).

- Iron recovery: 0-1mm slurry discharged from dewatering screen → cone trough → hydrocyclone (underflow discharge of heavy iron) → overflow magnetic separator to recover remaining iron → recycling.

- Auxiliary: Additional conical grooves are required to add initial ferrosilicon sand.

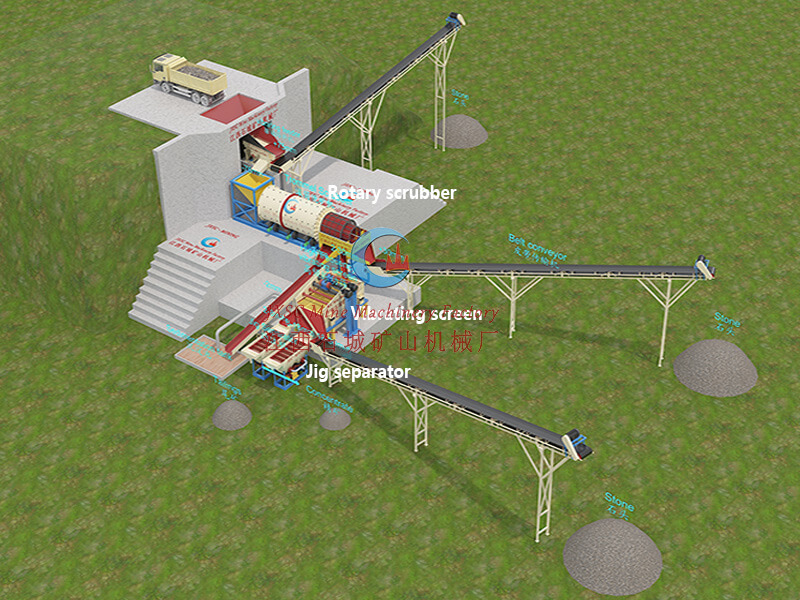

50TPH Diamond wash plant process

- First, use a vibrating feeder with sieve bars to remove large stones.

- Washing stage: Smaller particles enter the trommel scrubber (2 layers of screens of 2mm and 25mm) to clean the diamond ore.

- Screening stage: Because the 2-25mm material is likely to be mixed with some particles of other sizes. Therefore, it is necessary to use a high-frequency vibrating screen to separate the 2-25mm material again and remove the -2mm and +25mm particles.

- Jig separation: jig separators recover diamond ore.

Note: The plant is also used for washing and separation from kimberlite and other alluvial diamonds. If the material is not very sticky, the drum scrubber can be replaced with a trommel screen. It is also possible to design a one-stop small diamond washing plant (jig + trommel screen/rotary scrubber). →→Contact us to customize suitable diamond wash plant solutions tailored to your specific needs.

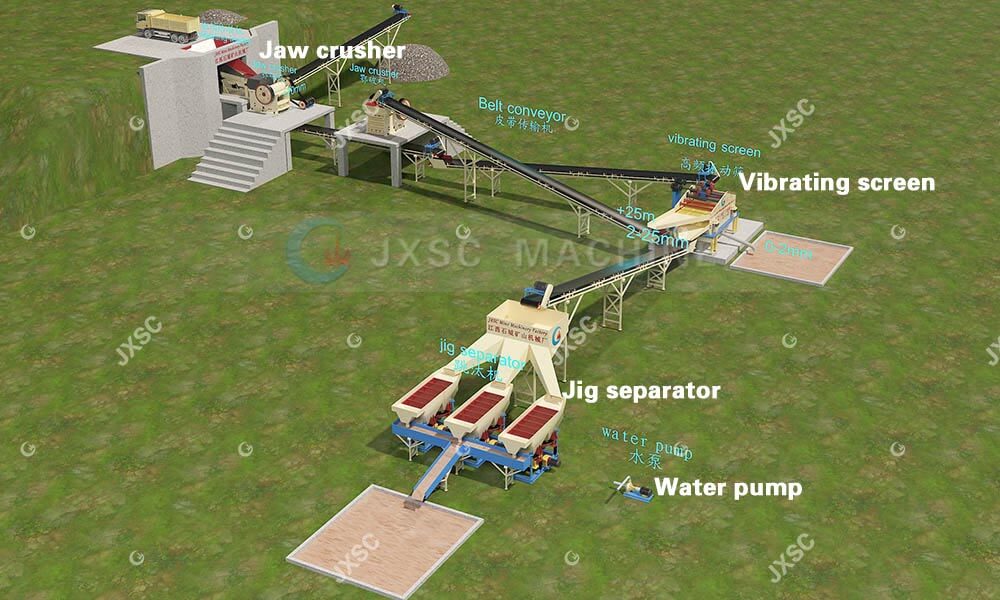

2. Rock Diamond Processing Plant

50TPH rock diamond processing Flow

1). Feeding: An excavator or loader delivers raw ore into a hopper, where it is evenly fed into the No. 1 jaw crusher via a vibrating feeder equipped with a grizzly screen. Waste rock larger than 70mm is discharged directly to the waste rock pile via a belt conveyor.

2). Crushing and Screening: The discharge from the No. 1 jaw crusher passes through a belt conveyor onto a high-frequency vibrating screen. The screened ore is separated into particles of 0-2mm (for the slurry pool), 2-25mm (for the next stage), and particles larger than 25mm (for further crushing in the No. 2 jaw crusher before returning to the vibrating screen).

3). Diamond Recovery: The 2-25mm material screened by the vibrating screen passes through a transfer hopper and enters a jig concentrator, where the diamonds are recovered by gravity.

This complete diamond processing equipment set features streamlined configuration, strong adaptability, and low operating costs.→→Contact JXSC to design small to large rock diamond processing solutions based on the characteristics of the ore!

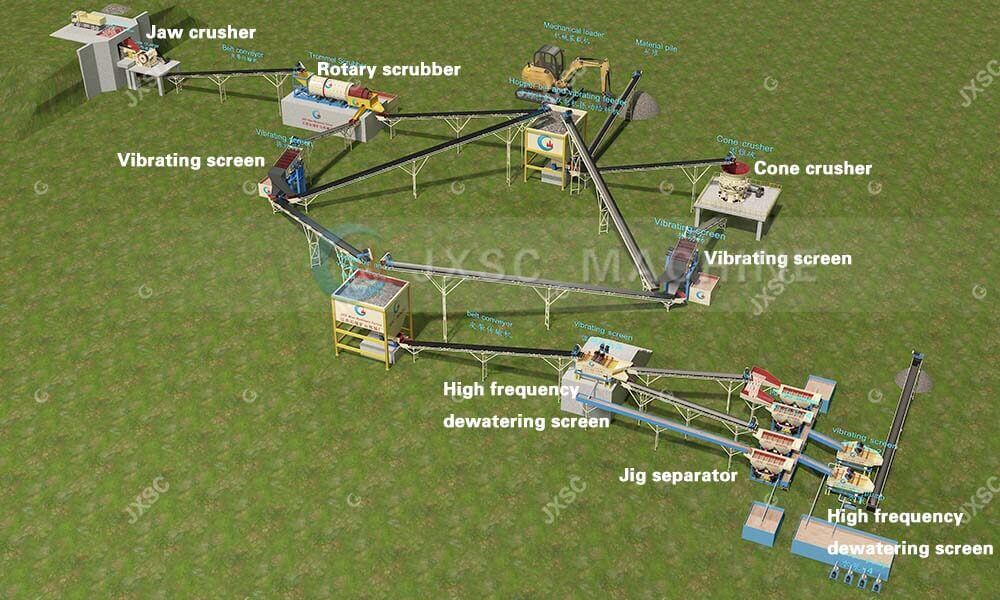

3. Alluvial & Rock Diamond Mining Process

- Feeding & primary crushing: Grid hopper, vibrating feeder, jaw crusher

- Washing and classification: rotary scrubber + vibrating screen

- Crushing and secondary screening: cone crusher, vibrating screen

- Dewatering and sorting: dewatering screen, jig

Upgrade your diamond Ore Recovery Rate

JXSC diamond processing equipment is highly popular in major diamond-producing regions such as South Africa, Angola, Congo, Botswana, Canada, Brazil, and Tanzania. We professionally design crushing, washing, and screening systems, jigs, or DMS media recovery, tailings treatment systems, widely used for processing various types of diamond mines, including kimberlite, alluvial, and lamproite pipes. We also support modular jig plant configurations suitable for mobile diamond processing needs.

Regardless of the method, the core objective of JXSC's custom diamond mining process technology is to efficiently separate diamond crystals from the ore, ensuring high diamond recovery rates and purity while minimizing costs and environmental impact.

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.