Mineral Processing » Solutions » Molybdenum Flotation Process

Molybdenum Flotation

Molybdenum is a refractory metal—mainly including molybdenite, pyrite and chalcopyrite. Among them, molybdenite is the disulfide of molybdenum and is the most important molybdenum resource. Flotation separation is often used to recover and beneficiate valuable minerals from molybdenum ore.

Our molybdenum flotation process can be customized, large enrichment rate and improves valuable minerals’ utilization rate.

Molybdenum Flotation Process

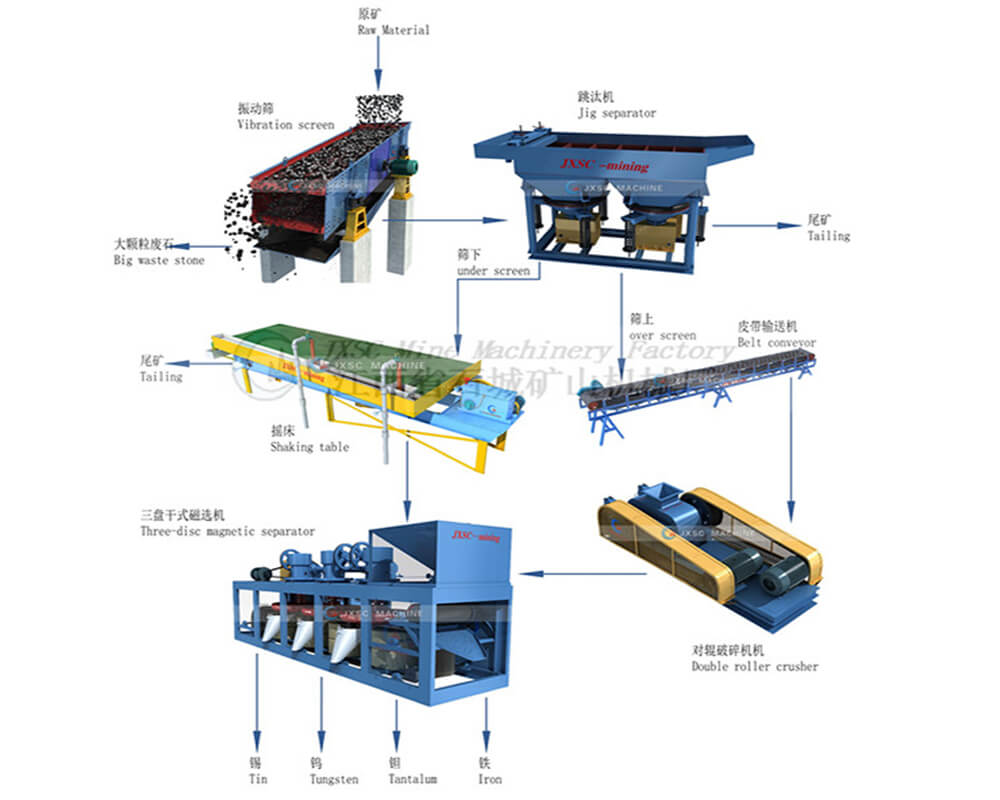

Molybdenum ore mainly includes molybdenite single ore, copper-molybdenum ore, molybdenum-containing polymetallic ore, etc. Flotation is the main method, sometimes combined with gravity and magnetic separation. Specifically, the molybdenum ore process should be selected according to the nature of the mineral.

Molybdenum Spapration Process

Molybdenite separation:

Molybdenite is generally lamellar and easy to float. However, the content of molybdenum in molybdenum ore is very low, generally 0.01% to 0.4%. Two-stage regrinding of coarse concentrate and multiple flotation processes are adopted. High grade concentrate and less environmental pollution.

Copper-molybdenum ore separation:

Copper-molybdenum ore is one of the main sources of molybdenum. Copper-molybdenum deposits dominated by copper are usually porphyry-type copper deposits with low ore grades and fine grain size. Priority flotation and mixed flotation processes are mainly used. In priority flotation, the method of molybdenum first and then copper is more widely used. In mixed flotation, the method of separating molybdenum from copper-molybdenum concentrate is more commonly used.

Separation of polymetallic molybdenum ores:

Common tungsten-molybdenum-bismuth ores, quartz vein gold-molybdenum-lead-sulfur polymetallic ores. Generally, flotation is used to produce mixed rough concentrate, and then the mixed rough concentrate is separated according to the different properties of associated metals. It is commonly used in combination with magnetic separation, gravity separation and leaching.

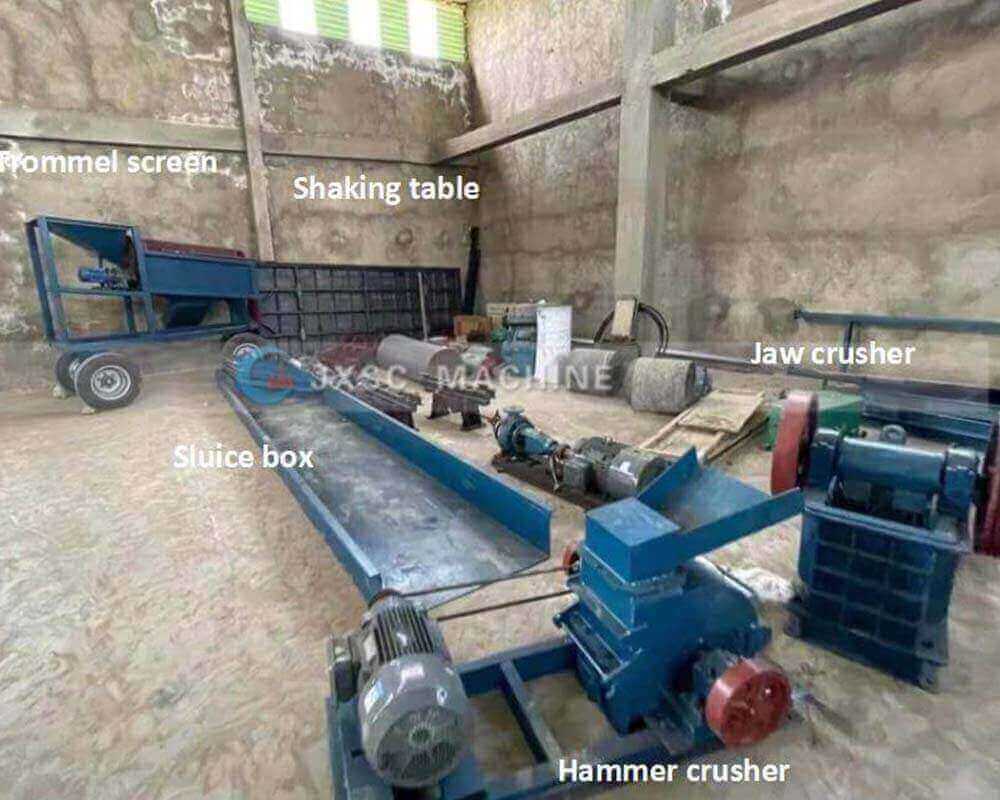

Molybdenum Processing Plant

Molybdenum flotation process plant

1. Crushing: The molybdenum ore is coarsely crushed by the jaw crusher, and then crushed to a reasonable particle size by the fine jaw crusher.

2. Grinding: The feeder is evenly fed into the ball mill, and the ore is ground to below 200 mesh by the ball mill + classifier. Make the particle size meet the requirements of flotation process.

3. Flotation separation: After passing through the mixing tank, it is sent to the flotation machine for flotation operation. Add various flotation reagents according to different mineral characteristics and stir and adjust for mineral separation.

4. Drying: Use a high-efficiency thickener to remove the water in the concentrate to obtain molybdenum concentrate.

Molybdenum concentrate mainly comes from single molybdenite, copper-molybdenum ore, molybdenum-bismuth concentrator or other associated molybdenum ore concentrator. Molybdenum ore processing lines and equipment are suitable for sorting various types of complex and sulfide minerals. Contact us to get more details!

Related Equipment

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.