Placer Gold Processing

Providing efficient and reliable one-stop solutions for alluvial/ placer gold processing plants worldwide.

Placer gold, or alluvial gold, is mixed with mud, sand, and gravel. The common placer gold beneficiation process includes washing & screening, gravity separation, melting, mercury amalgamation, etc. Focus on extracting natural gold particles from sedimentary deposits such as river beds and alluvial deposits. JXSC also offers modular gold washing plants for rapid, movable, and deployable use. It has a high recovery rate and low cost, making it the preferred technology for small-large scale gold plants.

Application: The alluvial/ placer gold processing plant is mainly for separating and beneficiation of seaside placers, riverside sand, alluvial ore, chrome, manganese ore, copper, etc.

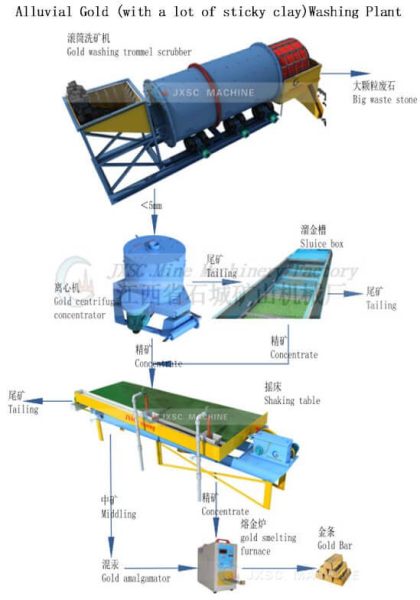

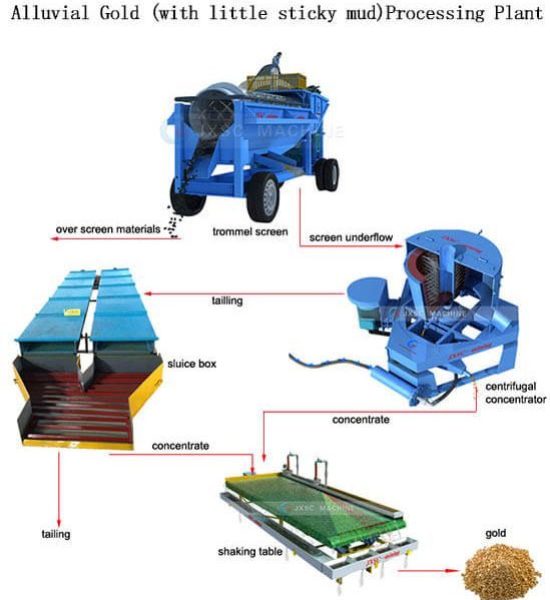

Placer gold beneficiation process

The placer/alluvial gold mining process is designed to maximize the recovery of gold and associated heavy minerals from gangue. Then, gold is separated from associated heavy minerals through a combined mining scheme of gravity, flotation, magnetic, and electrostatic separation. Complete placer gold processing plant including feeding, screening, washing, and concentration equipment.

Custom Placer/ Alluvial Gold Process

- Placer gold washing operation: The important process before the placer gold separating operation. Its main purpose is to separate the gravel, sand and granular soil, and wash the fine mud adhering to the gravel and the gold ore mixed in it.

- Placer gold screening operation: Main purpose for screening the placer gold ore after washing, and screening out large pieces of gravel without gold, so as to improve the gold recovery efficiency.

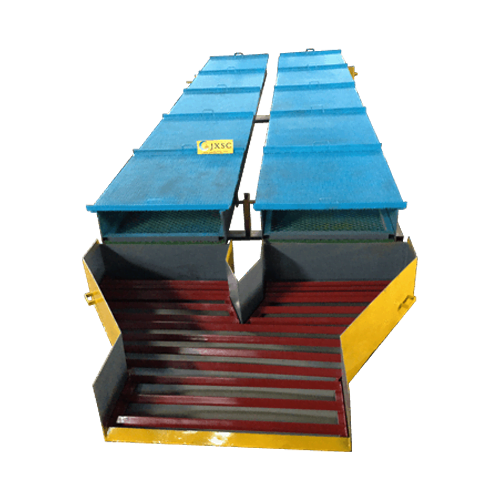

- Placer gold gravity separation process: Since gold is in a free state in placer gold, and the specific gravity difference between gold and sand is obvious, the gold gravity separation method is ideal for extracting gold from placer ore.

- Placer gold concentration operation: When gold contains various metal minerals or impurities, it can use gravity separation, magnetic separation, flotation, electric separation or combined processes to separate each other to further improve the grade of gold.

Placer Gold Processing plant

Placer/alluvial gold process plant

Placer Gold Processing Flow

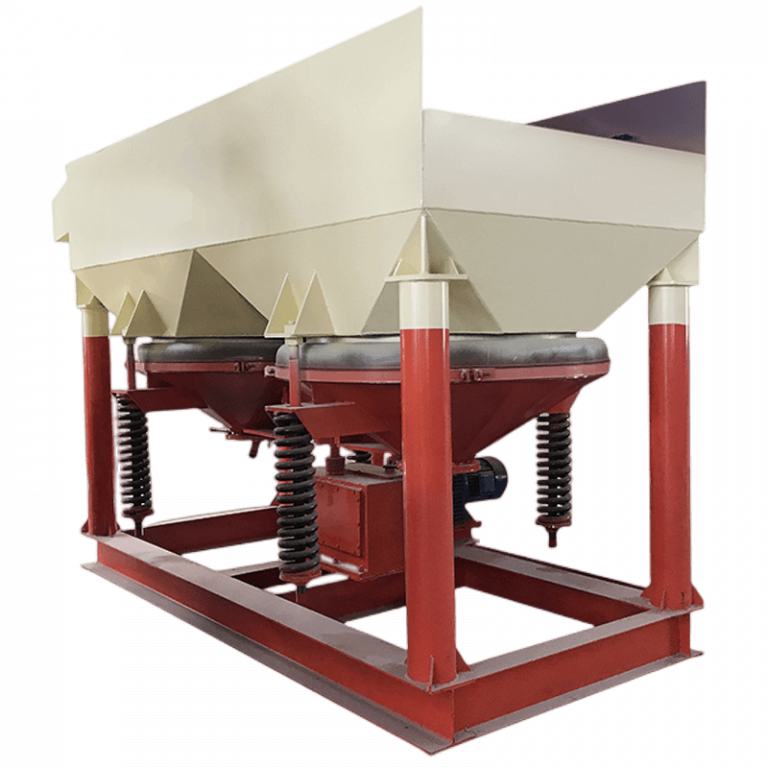

1. Feeding stage: The truck unloads the material into the hopper, and enters the vibrating feeder from the lower part of the hopper; the +100mm waste materials will be separated by the vibrating feeder grate, and transferred to the stockyard by the belt conveyor.

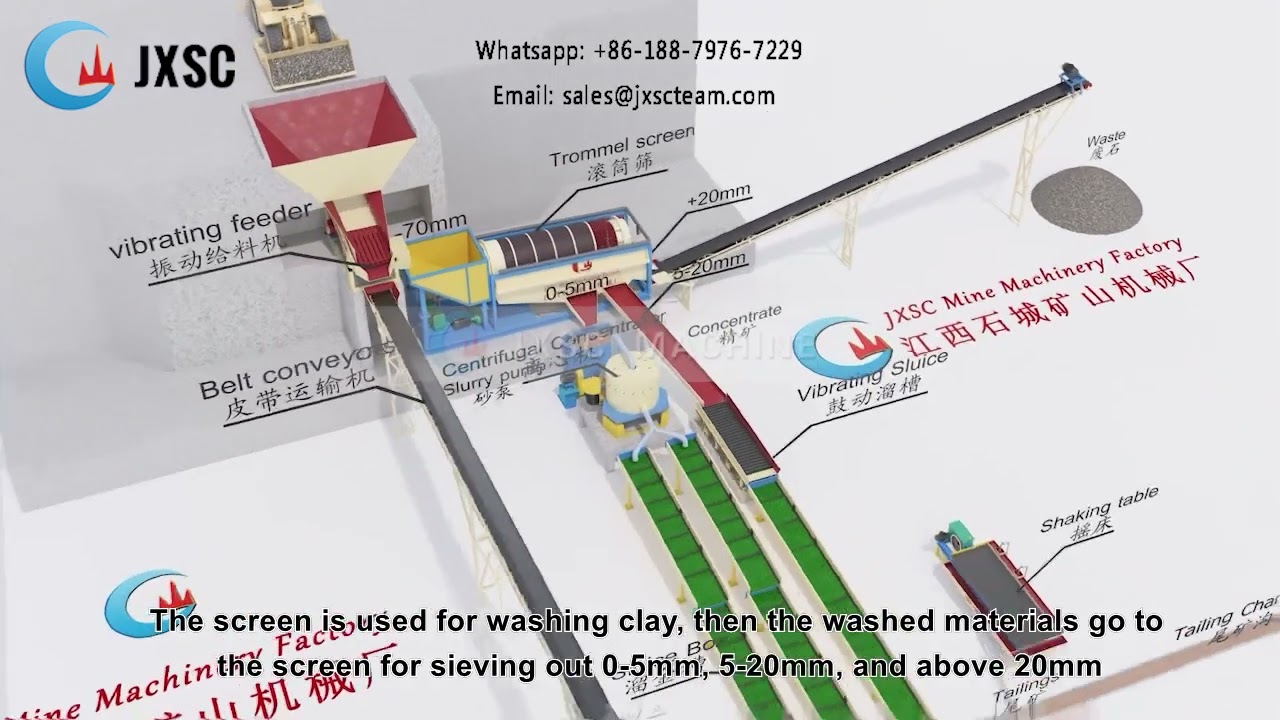

2. Washing stage: The vibrating feeder evenly feeds the -100mm material into the trommel scrubber for washing. Among them, the trommel scrubber has two layers of screens with meshes of 2mm and 10mm.

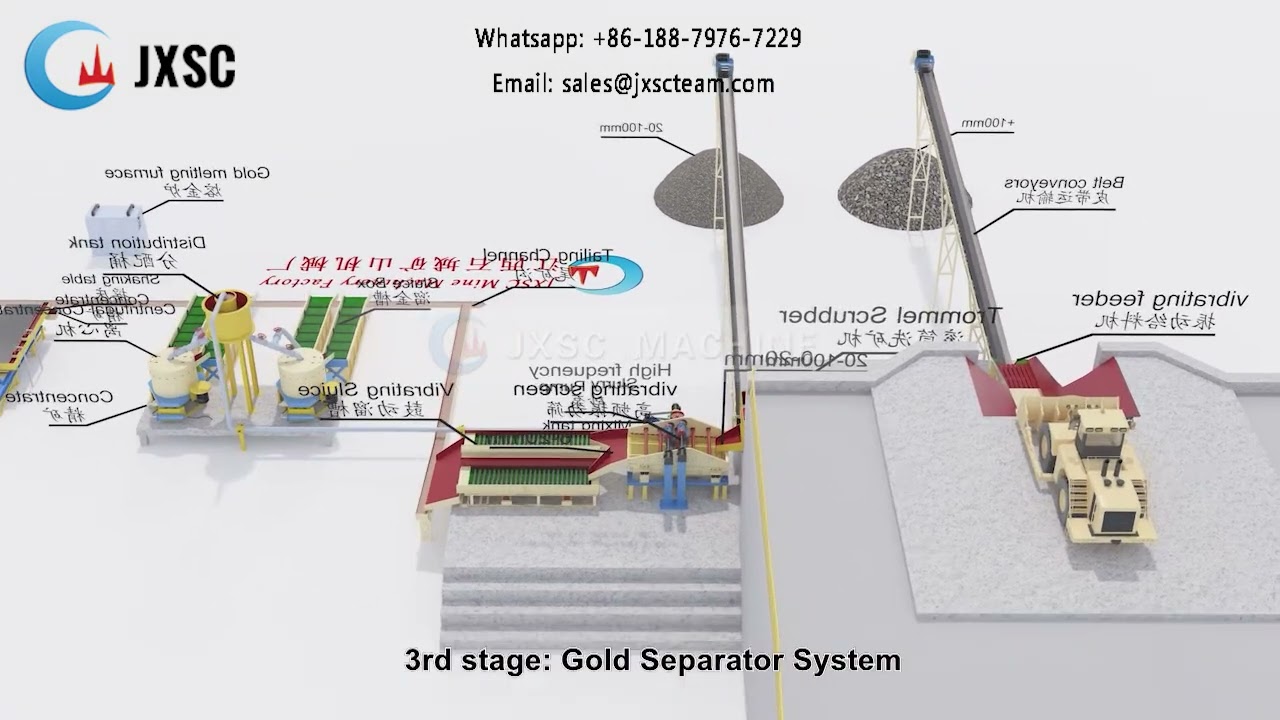

3. Gravity Separation: The 2-10mm material will flow to the gold sluice box, so the 2-10mm gold particles can be captured. And the +10mm material will be sent to the waste pile. The pool’s 0-2mm material will be pumped from the slurry to the centrifuge concentrator. Among them, the tailings of the centrifuge concentrator flow to the gold sluice box for concentration. Finally, the gold concentrate flows into a shaking table for further concentration. All gold concentrates can be smelted in a melting furnace to obtain gold nuggets.

Custom Alluvial/ Placer Gold Plant

3:08

2:29

1:45

3:16

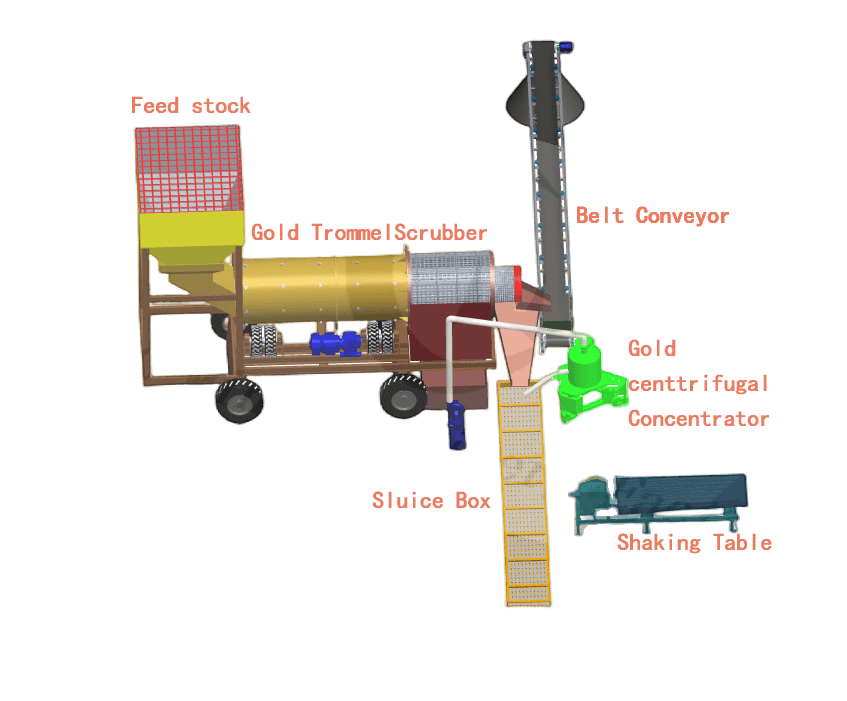

100TPH Alluvial/Placer Gold Recovery Process Plant: trommel screen (remove a small amount of soil impurities), gold centrifugal concentrator, six sluice boxes, a shaking table, and two belt conveyors.

200TPH Placer/Alluvial Gold Washing & Tailings Processing Plant: trommel scrubber (removes a lot of clay from the surface), vibrating screen, sluice box, shaking table, centrifugal concentrator, spiral dewatering machine, thickener, filter press.

Custom 40-100TPH Mobile Placer/Alluvial Gold Processing Plant: portable/mobile type rotary scrubber/ trommel screen, centrifugal conecentrator, sluice box, mobile shaking table, melting furnace.

Custom 250TPH Placer/Alluvial Gold Processing Plant: rotary scrubber, high frequency vibrating screen, vibrating chute box, mixing tank, centrifugal concentrators, shaking tables, and melting furnace.

The process has the characteristics of environmental protection and can directly discharge tailings, which greatly reduces the construction cost of the entire processing plant. JXSC also provides mobile and one-stop alluvial gold wash plants, suitable for small/ medium-scale gold processing plants, with flexible, low cost, and high recovery efficiency. Contact our experts to customize alluvial/ placer gold processing turnkey solutions and get the mining equipment at 100% factory price.

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.