Mineral Processing » Equipment » Gold Mining Equipment

Gold Mining Equipment

Maximize recovery rate with our professional gold mining equipment – Custom solutions for small to large-scale plants.

90%+ Recovery Rate

Modular or mobile types optional

100% Factory Direct Price

Customized mining equipment

24/7 Free Consulting

Multiple models, flexible configuration

Best-selling equipment

JXSC Gold Mining Equipment Solutions

JXSC gold mining equipment is primarily used in the processes of processing, enrichment, extraction, melting, and refining gold from quartzite ore, alluvial/placer/clay ore, rock/vein ore, and sulfide ore. Then, smelting of gold into ingots or bars. The main equipment typically includes the following:

Crushing & screening –> washers –> grinding mills –> classifiers –> gravity separators –> flotation –> magnetic separators –> electrostatic separators –> dewaters –> thickening & filtration systems –> dryers –> leaching/ CIP/ CIL machines –> melting.

Our mining machinery covers every stage of gold mineral processing, and the finished product achieves high recovery precision and a purity rate of 90%+. Whether you need sulfide, alluvial (placer), or hard rock gold mining equipment, JXSC provides customizable small to large-scale turnkey plant solutions and ensuring cost-effective beneficiation operations and maximizing gold recovery rates.

gold mining equipment for sale

JXSC’s washing and screening technology efficiently removes impurities from the ore surface, with a desludging efficiency of 85%+. Designed specifically for weathered gold ores with high mud content, it is ideal for the pre-treatment equipment of placer/alluvial gold processing.

All of which can be modular or mobile designs and comply with the new global carbon emission regulations. It is widely used in coarse crushing of various vein gold ores, pretreatment of placer gold ores, and pre-crushing of difficult-to-treat sulfide gold ores.

Our grinding mills and classification systems ensure proper gold ore liberation and particle size distribution. It can form a complete closed-circuit circulation device, and provide qualified ore pulp for the subsequent mineral processing stage.

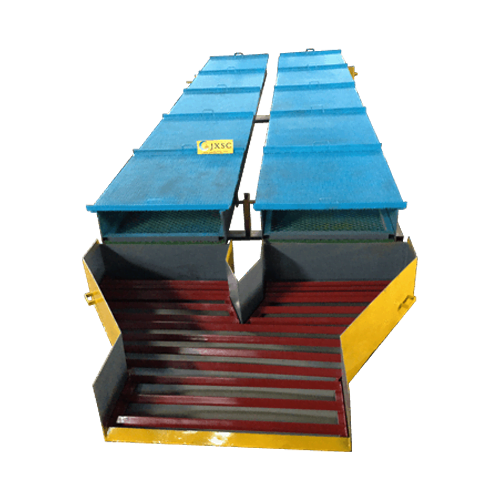

JXSC gravity separation equipment is an effective and eco-friendly method that recovers coarse and fine gold particles using their density differences. It is commonly used in rough separation of small and medium-sized alluvial and hard rock gold plants, and tailings recovery of vein gold mines.

These are particularly suitable for separating sulfide-rich ores and complex associated gold ores, or tailings purification treatment. It’s often used in conjunction with gravity separation to form a complementary process and improve gold recovery & grade.

Our thickening and dewatering tech is widely used in gold concentrate concentration and tailings dry discharge processes. It is particularly well-suited for gold concentrate dehydration, achieving efficient water recycling and meeting environmental standards in the gold industry.

How to choose the right gold mining equipment? JXSC professional engineers will tailor-make efficient, durable, and environmentally friendly machine models to meet your specific requirements.

Gold Mining Processing Solutions

Whether it’s river gold, vein gold, sulfide gold, or placer/rock mixed ore, JXSC supports custom complete gold process & mining equipment according to your specific ore characteristics, capacity, budget, or other production requirements.

Why Choose JXSC Gold Mining Equipment

High Recovery Rate

Our advanced technology achieves up to 90%+ gold recovery rate, maximizing your profits.

Durable Construction

Built with heavy-duty materials & quality components for long life in harsh mining plants.

Energy Efficient

Optimized designs reduce power consumption while maintaining high processing capacity.

Environment Friendly

Recycling water systems and mercury-free gold recovery methods for sustainable mining.

Full Support

From equipment selection to installation and maintenance, our experts guide you every step.

Global Installations

Successful cases in over 40 countries with diverse mining projects.

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.