Alluvial tin deposits are mostly found in river alluvial layers, beaches, or terrace placers, and are widely distributed in Southeast Asia, Africa, and South America. Compared to traditional hard rock deposits, these placer deposits have finer grain sizes and fewer associated minerals, offering advantages such as lower mining costs and easier separation. However, they also present challenges such as complex ore layers and difficulties in recovering fine-grained cassiterite. Therefore, due to the unique characteristics of placer tin deposits, a series of specially designed mining equipment is required, ranging from initial excavation machinery to core separation and concentrate dewatering equipment. Each stage of the processing plays a decisive role in the final recovery rate and economic benefits.

Professional alluvial tin mining processes typically include excavation, slurry transportation, ore beneficiation through screening, and tailings treatment. Key equipment for alluvial tin process includes rotary scrubbers, jig separators, shaking tables, three-disc magnetic separators, and dewatering screens. JXSC’s process can meet environmental requirements and improve efficiency, and can be customized based on scale, ore quality, budget, and other specific conditions.

Characteristics of alluvial tin deposits?

Alluvial tin deposits are not primary ore deposits, but rather secondary deposits formed from primary tin ore through long-term weathering, erosion, and transportation by water, accumulating in low-lying areas such as river alluvial plains, beaches, or terraces. The cassiterite particles are often loose ore layers, fine-grained and frequently coexist with associated minerals such as tungsten and titanium. This means that mining requires addressing the challenges of “fine-particle separation” and “separation of associated minerals.”

Furthermore, alluvial tin deposits are mostly distributed in areas near water, and the mining environment is greatly affected by hydrological conditions, requiring equipment with a certain degree of water resistance or adaptability. The sand and impurity content varies in different mining areas. However, it is necessary to understand these characteristics in order to more accurately select the best mining plan for alluvial tin deposits and avoid affecting the design of the ore processing flow.

Basic Process of Alluvial Tin Mining

Alluvial tin mining is not simply a matter of crude excavation and ore dressing; it requires following a standard process flow. The ore dressing equipment at different stages must be matched to the characteristics of the ore, otherwise it may lead to decreased recovery rates or soaring processing costs. It is essential to understand the entire process, from raw ore extraction and transportation to ore dressing, enrichment, and tailings treatment, in order to accurately select the appropriate equipment types and models and avoid wasted investment.

first: Proccess, Second: Equipment

(1) Ore Mining

Mining equipment is a fundamental part of the sand and tin ore mining process. Choosing the right equipment can reduce the amount of waste rock mixed in, which means higher purity of the raw ore and less pressure on subsequent ore processing.

(2) Transportation

The extracted ore is usually mixed with a large amount of sand and gravel and needs to be transported to the processing plant via slurry pumps or conveyor belts. For land-based mines, dry sand can be transported using conveyor belts. For water-based mines, sand pumps are needed to pump the slurry to the shore.

Choosing the appropriate transportation equipment is a crucial link connecting “extraction” and “mineral processing,” and a prerequisite for the tin sand mining and processing process.

(2) Mineral Processing and Concentration

The mineral processing stage typically utilizes particle size classification and gravity separation to concentrate cassiterite.

The efficiency of the mineral processing and concentration equipment directly affects the mine’s profitability; therefore, suitable alluvial tin mining equipment must be selected based on the characteristics of the ore.

(3) Tailings Treatment

The tailings after mineral processing often contain a small amount of cassiterite, but direct disposal may pollute the environment. Modern mines usually employ tailings backfilling, dry stacking technology (dewatering with filter presses), or secondary recovery processes to reduce resource waste. For example, some mining areas use gravity separation and magnetic separation processes to reprocess the tailings, reducing tin loss. This not only reduces environmental pollution but also improves the comprehensive utilization rate of resources, creating additional benefits for the enterprise.

core equipment for alluvial tin mining

1. Ore Collection Equipment

- For sand deposits on riverbeds, beaches, or terraces, excavators can be used to transfer the raw ore (a mixture of tin sand, waste rock, and water) to transport vehicles or slurry ponds using their buckets.

- For deep underwater riverbeds and lake bottoms, sand pump dredgers/suction dredgers can be used to extract sand from depths of 5-30 meters underwater and transport it to the shore, allowing for the mining of deep-water sand deposits without the need for dewatering.

- For mini-scale mining operations by individual farmers or in small mines, traditional collection tools such as shovels, manual sieves, and bamboo baskets can be used. The surface sand is manually excavated and then separated using sieves.

2. Slurry Transportation Equipment

Slurry Pump

Slurry pumps are commonly used for transporting mineral slurries in aquatic mining operations or pipeline transportation in land-based mines. They can transport slurries with a sand content of 30%-50% through centrifugal force and are a core transportation tool connecting the extraction point to the mineral processing equipment. The quartz sand in the slurry continuously wears down the pump body, requiring the use of wear-resistant and clog-resistant materials.

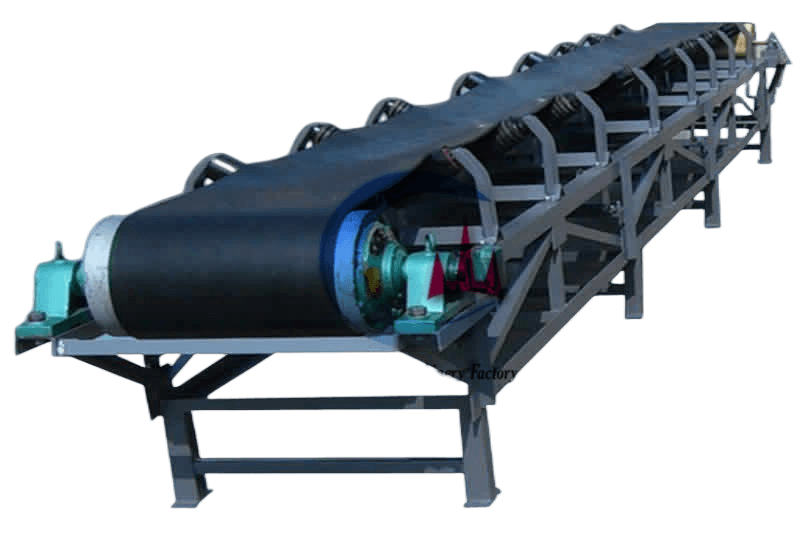

Conveyor Belt

Conveyor belts, driven by electric motors, transport dry sand ore (sand content ≥80%) and are suitable for scenarios where the mine and processing plant are separated, offering low transportation costs. Belt conveyors are suitable for any size of land-based mineral transportation, and their capacity, transport distance, and direction can be freely adapted. They are particularly suitable for areas with dry ore layers and no significant moisture. Their advantages include low transportation costs and the ability to incorporate magnetic separators to pre-separate some ferromagnetic impurities.

3. Mineral Processing Equipment

Spiral Chute

The spiral chute is mainly used in the roughing/scavenging stages of alluvial tin mining with a particle size of 0.074-2mm, and is especially suitable for small and medium-sized placer deposits with few associated minerals and a uniform distribution of cassiterite. After the ore slurry flows into the top of the chute, the cassiterite, being heavier than the waste sand, will accumulate towards the center along the spiral line at the bottom of the chute, and finally be discharged from the concentrate outlet at the bottom. The waste sand flows out from the tailings outlet on the side. Subsequent fine separation using a shaking table can improve the recovery rate.

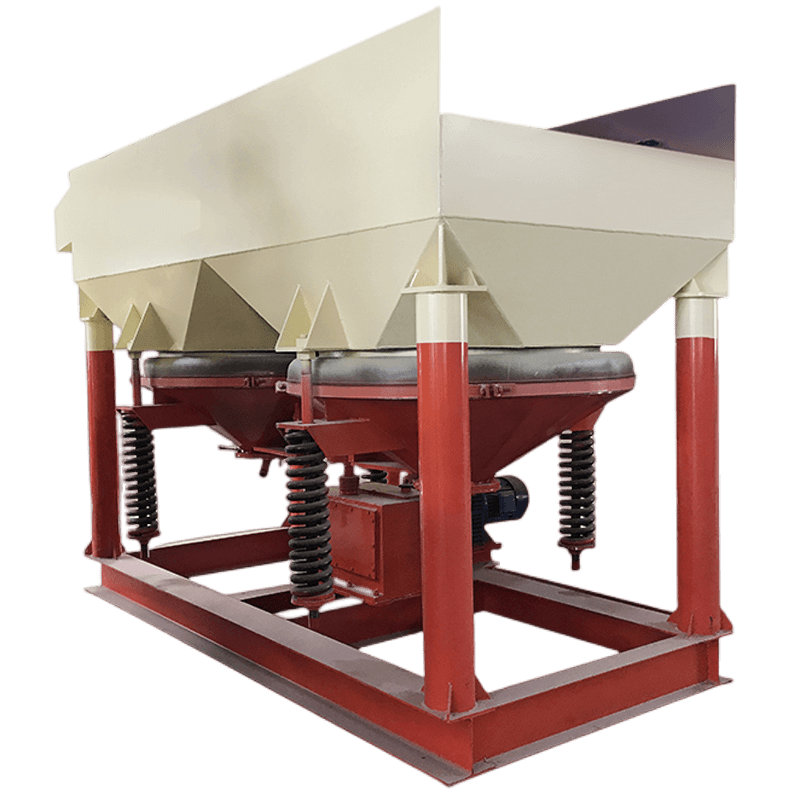

Jig Machine

Jig separators primarily utilize vertical alternating water flow to stratify mineral sands. Heavy minerals such as cassiterite settle to the bottom of the trough, while lighter minerals float on the surface and are discharged through a gate. It can simultaneously separate coarse-grained placer deposits and associated minerals (such as tungsten and titanium), making it suitable for processing complex alluvial tin deposits. It is particularly well-suited for mining operations that require the recovery of multiple minerals. Compared to spiral chutes, jigging machines are more efficient when the proportion of coarse-grained cassiterite is high.

Shaking Table

The shaking table primarily achieves fine separation of tin ore through the reciprocating vibration of the bed surface and lateral water flow. Due to its high density, cassiterite concentrates in the “concentrate zone” at the end of the bed surface, while lighter minerals are washed away to the tailings area by the water flow. It is mainly used in the fine separation stage and needs to be used in conjunction with spiral chutes or jigs. For example, after rough separation by a spiral chute/jig separator, the shaking table is used for further purification. It is especially suitable for processing fine-grained tin deposits (0.074-2mm) and placer mines with few associated minerals.

Three-Disc Magnetic Separator

The three-disc magnetic separator primarily uses three rotating permanent magnetic discs to adsorb ferromagnetic associated minerals (such as ilmenite and magnetite) from the ore pulp, achieving the separation of tin ore from magnetic impurities. It is most commonly used for processing alluvial tin ore containing magnetic minerals (such as titanium and iron), usually after gravity concentration on shaking tables, or as an auxiliary device for jigging machines. It offers fast separation speed and a high degree of automation, effectively improving the purity of tin concentrates.

4. Dewatering Equipment

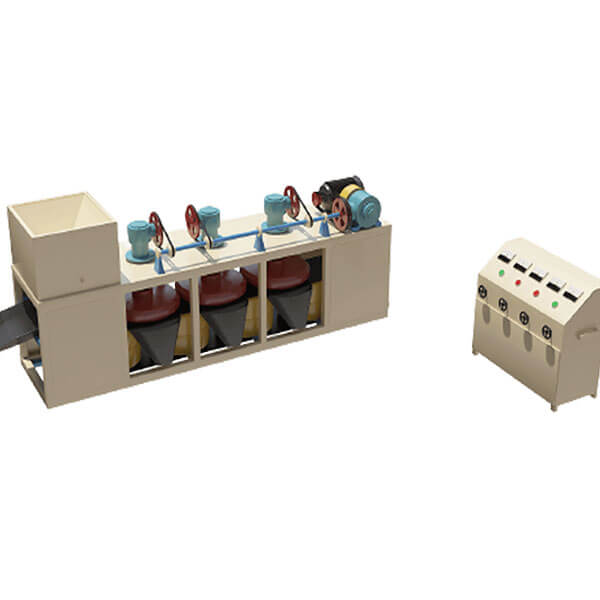

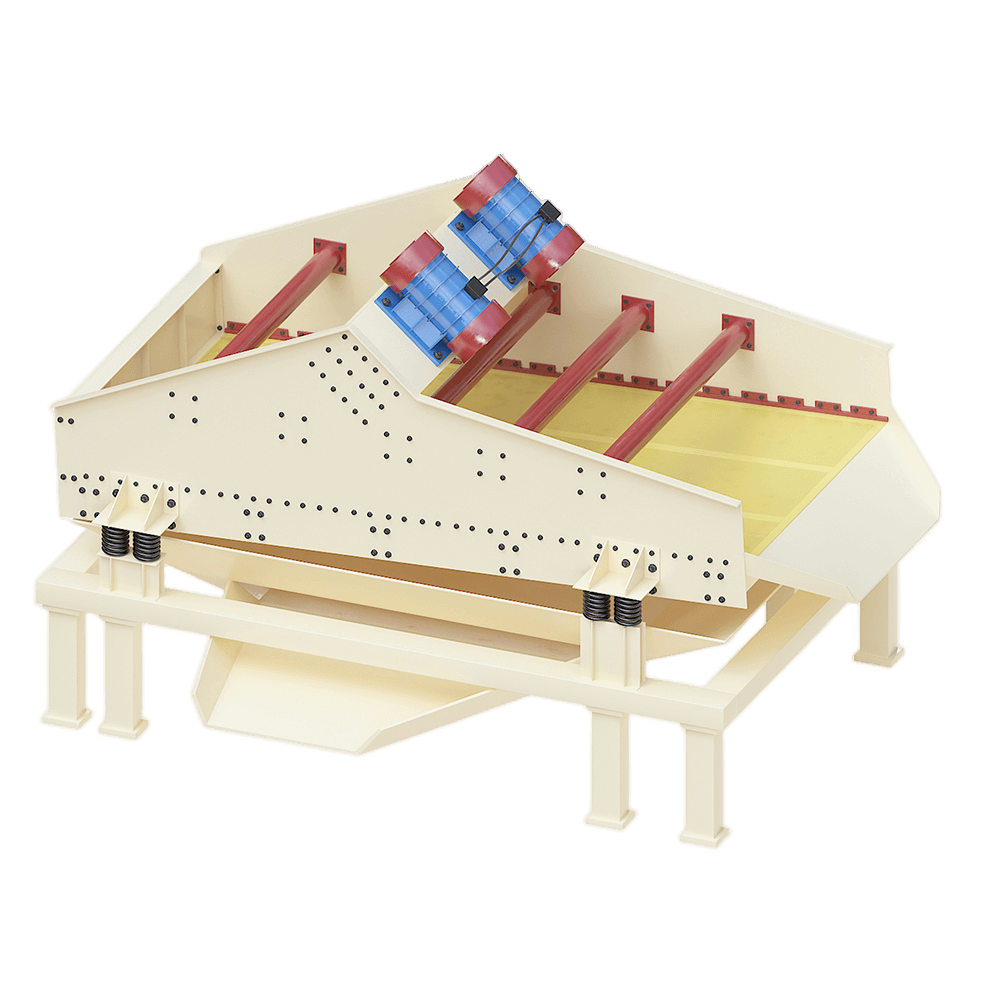

Dewatering Screen

The dewatering screen separates water from the tailings through high-frequency vibration, reducing the moisture content of the processed tin concentrate from 60% to below 20%, facilitating transportation and storage. If the tailings after tin beneficiation have a high water content or the mine is located in an arid region, the wastewater can be recycled for mineral processing, saving water resources.

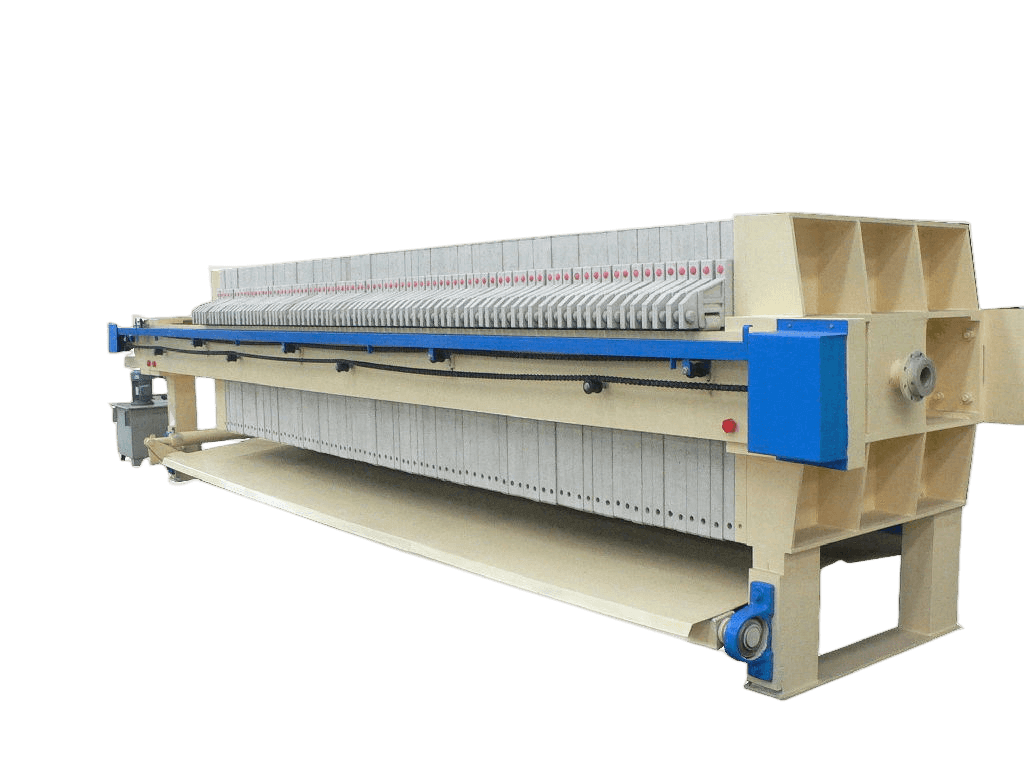

Filter Press

For mines with strict environmental requirements or scenarios requiring the recovery of associated minerals from the tailings, a filter press can be used. A high-pressure pump is used to press the tailings slurry into the filter plates, allowing water to seep out through the filter cloth, forming a filter cake with a moisture content of ≤15%, meeting environmentally friendly tailings discharge requirements.

Buyer's Guide: How to Choose the Right Alluvial Tin Mining Equipment?

JXSC Alluvial Tin Mining Equipment Type | Core Function | Applicable Scenario |

Slurry Pump | Transport slurry (ore pulp) | Slurry transportation (ship-to-shore / pulp pool-to-processing plant) |

Conveyor Belt | Transport dry sand ore | Mine-separation plant separation (daily capacity ≥ 100 tons) |

Spiral Chute | Rough separation of tin ore | Roughing of 0.074-2mm ore sand |

Shaking Table | Fine separation to improve grade | Fine separation of fine-grained ore (≤ 0.5mm) |

Jig Separator | Coarse-grained separation | Coarse-grained ore (2-10mm) separation |

Three-Disc Magnetic Separator | Separate magnetic associated minerals | Associated magnetic minerals (titanium/iron) separation |

Dewatering Screen | Dewater tailings/concentrate | Reduce moisture content of tailings/concentrate |

Tailings Filter Press | Deep dewatering (compliance with regulations) | Mines with high environmental protection requirements |

Conclusion

Efficient extraction of alluvial tin ores relies on scientifically configured core equipment. Actual equipment selection requires a comprehensive assessment considering the characteristics of the ore (particle size, associated minerals), production requirements, and environmental standards. If you require a customized placer tin processing solution, or assistance with equipment selection and optimizing recovery rates, JXSC Mine Machinery Factory will provide you with suitable tin processing equipment to help your project operate efficiently and in compliance with environmental regulations.