2TPH Hard Rock Gold Crushing Plant In Colombia

We guarantee the high quality machine in the mineral processing industry, established in 40+ years of experience!

Project Info.

- Raw ore: hard rock gold ore

- Capacity: 2 TPH (2tons per hour)

- Maximum feed size: 300mm

- Output: 0-2mm

- Location: Colombia

Process

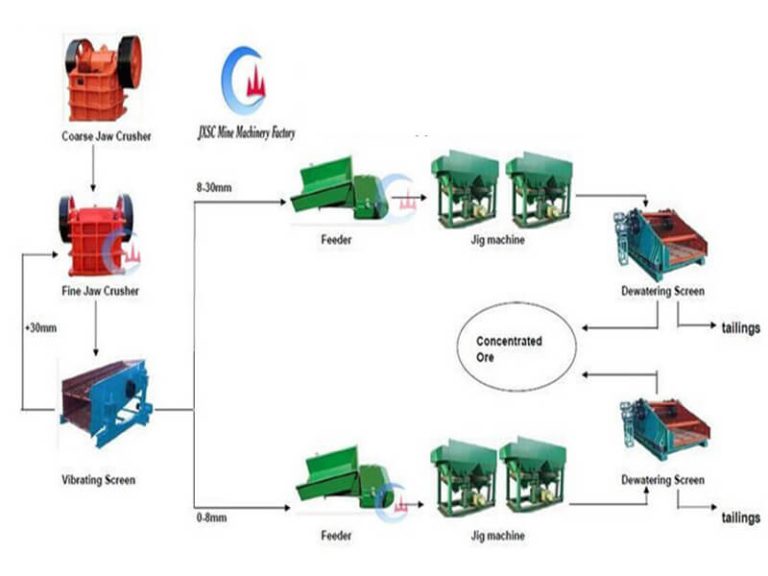

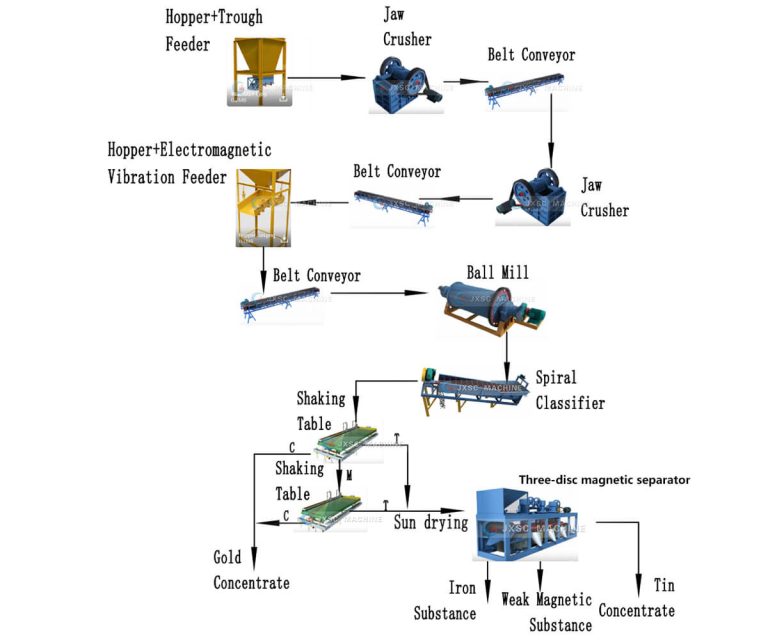

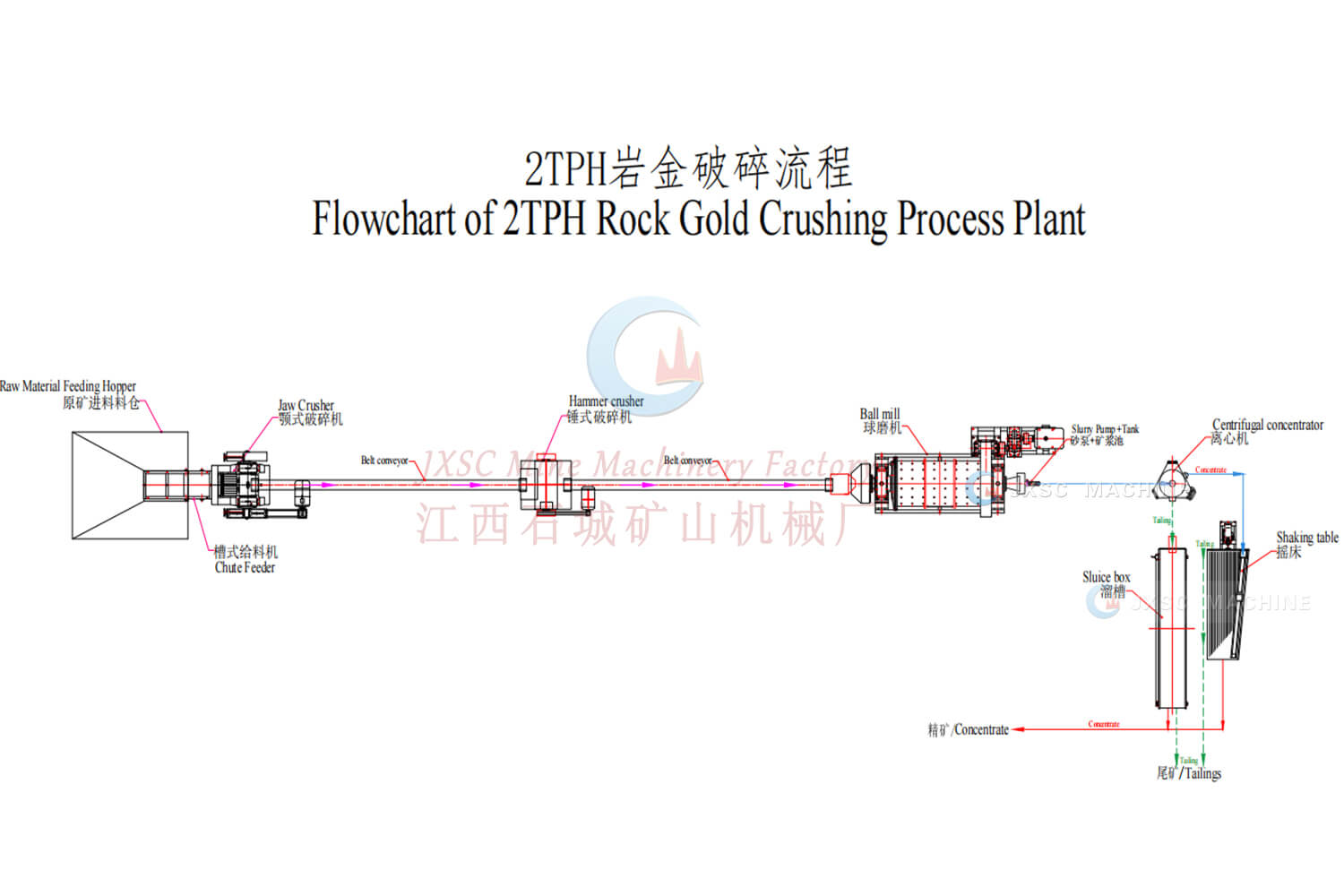

Coarse crushing – fine crushing – grinding – gravity separation (centrifugal concentrator, shaking table, sluice box)

process flow

2TPH Hard Rock Gold Crushing Plant

This is a 2-ton/hour hard rock gold crushing plant designed by JXSC. Configured specifically for the characteristics of hard rock gold mines in the Colombian region, it utilizes crushing, grinding, and gravity separation technologies and equipment to achieve automated, continuous production of concentrate from raw ore, combining high efficiency and practicality. The specific process flow is as follows:

2TPH Hard Rock Gold Crushing Flow

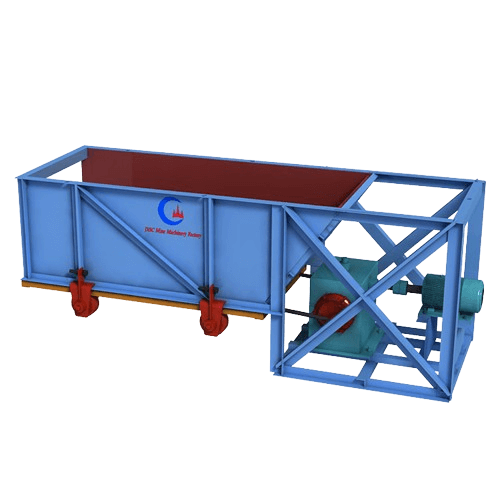

1. Ore Feeding Stage

The ore bin stores the raw hard rock gold ore awaiting processing. A trough feeder, through reciprocating motion, evenly and quantitatively conveys the raw ore to the jaw crusher, ensuring stable feeding to subsequent equipment and preventing equipment overload or inefficiency caused by uneven feeding.

2. Coarse Crushing Stage

The jaw crusher utilizes the relative movement of the movable and fixed jaws to crush large pieces of raw ore, reducing the ore size from a large dimension to a size suitable for subsequent fine crushing. This is the first crucial step in the entire crushing process, reducing the workload for subsequent operations.

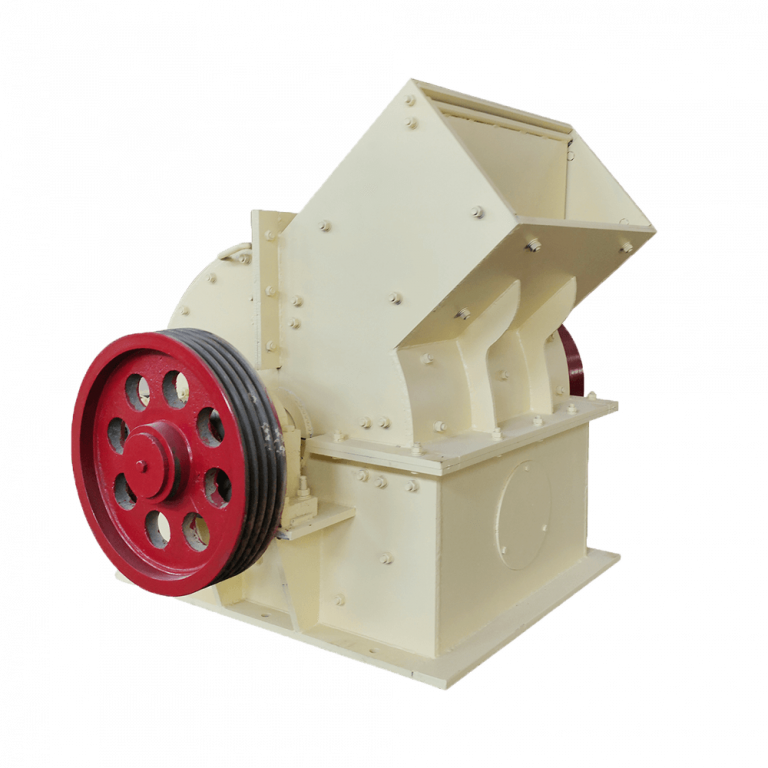

3. Fine Crushing Stage

The high-speed rotating hammers of the hammer crusher impact and shear the ore, further crushing the coarsely crushed ore to a finer particle size. This initially separates the gold-bearing minerals from the gangue and provides a suitable feed size for the ball mill, improving grinding efficiency.

4. Grinding Stage

In the rotating cylinder of the ball mill, steel balls impact and grind the ore as the cylinder rotates, grinding the finely crushed ore to a particle size that meets the requirements of the beneficiation process. This ensures sufficient liberation of the gold-bearing minerals from the gangue, creating favorable conditions for subsequent separation. The slurry discharged from the ball mill is then transported to the centrifugal concentrator, ensuring the continuity of the beneficiation process.

5. Rough Concentration Stage

The centrifugal concentrator uses centrifugal force to enhance the gravity separation process. In the high-speed rotating cone, denser gold particles quickly settle to the cone wall, becoming concentrate, while less dense gangue is discharged from the upper part of the cone with the slurry as tailings, achieving preliminary gold enrichment.

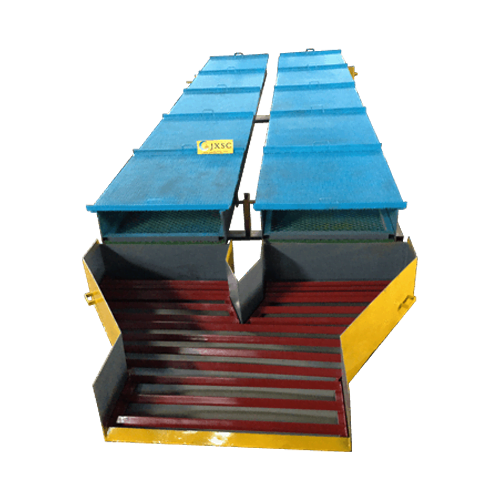

6. Fine Concentration Stage

- The rough concentrate produced by the centrifugal concentrator is sent to a shaking table for further refinement. Through the reciprocating asymmetrical motion of the table surface and the washing action of the transverse water flow, minerals of different densities and particle sizes are separated into different zones on the table surface, ultimately producing high-grade gold concentrate. Simultaneously, the entrained gangue and other impurities are discharged as tailings.

- Gold sluice box: The tailings discharged from the centrifugal concentrator are further processed for recovery, maximizing gold recovery. Finally, the concentrates from the shaking table and gold recovery trough are collected.

The tailings are collected in a tailings ditch and transported to a designated location to prevent environmental pollution. Comprehensive utilization of the tailings can also be considered.

JXSC fully considered the local small-scale mining environment, resource characteristics, and production needs in Colombia, and developed a complete 2TPH rock gold crushing plant equipment. While ensuring high-efficiency mineral processing indicators, the system also prioritizes energy saving, environmental protection, and ease of maintenance, providing customers with an economical, reliable, and sustainable rock gold ore processing solution. JXSC offers various types of gold ore processing solutions, such as alluvial gold, quartz-bearing gold ore, vein gold ore, and sulfide gold ore. Contact us to help you design process flow and maximize the value of your resources.

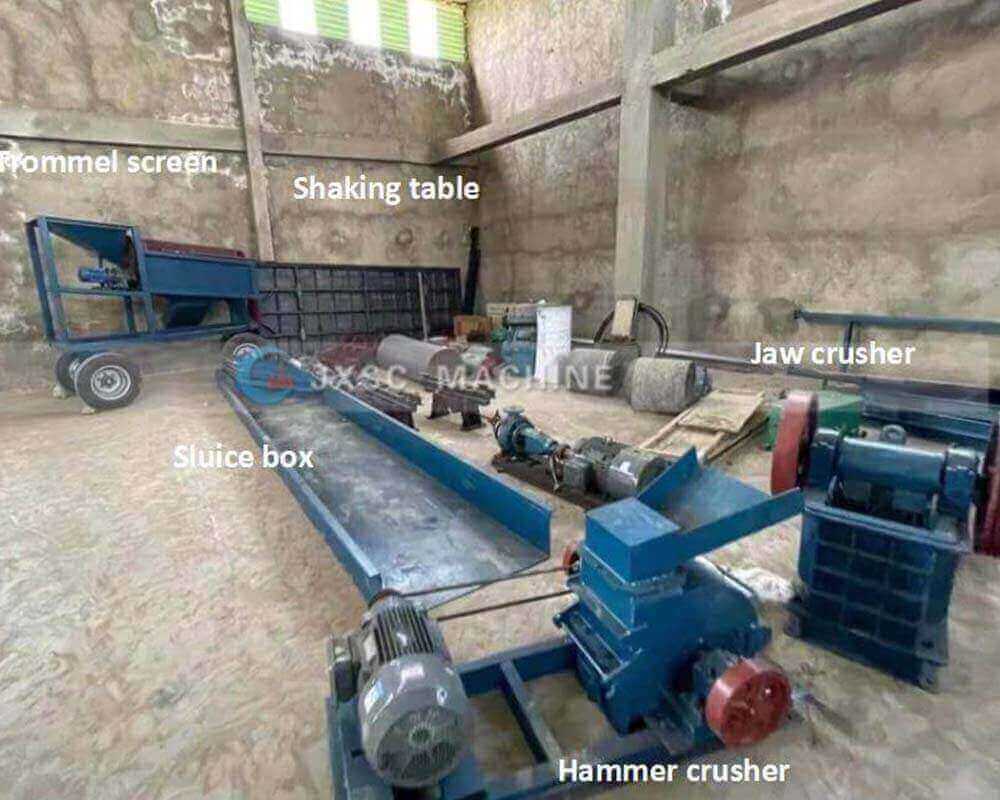

Process Site

2TPH Hard Rock Gold Crushing Plant Site

Advantages Of JXSC 2TPH Hard Rock Gold Crushing Plant Design

√ Precise Matching of Ore Properties: Addressing the characteristics of hard rock gold ore, such as high hardness and fine gold particle size, a two-stage crushing process and a three-stage separation combined process are employed to effectively achieve gold liberation and recovery, resulting in excellent beneficiation indicators.

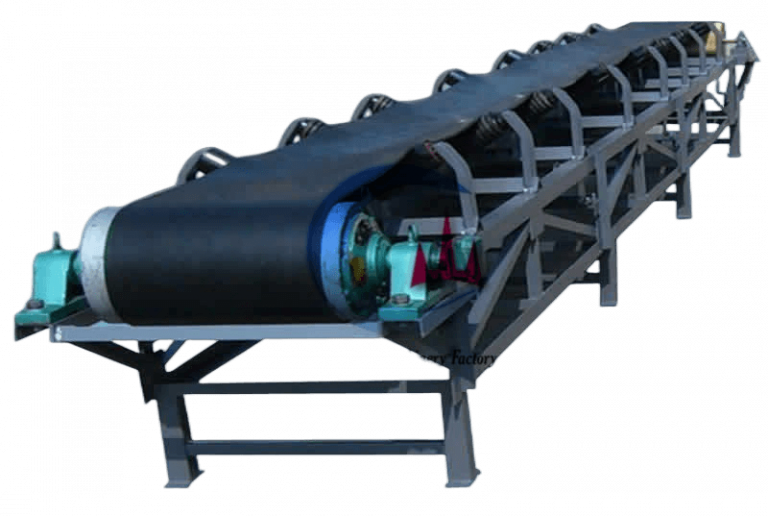

√ High Degree of Automation: The use of trough feeders, belt conveyors, and sand pumps enables automated material handling, significantly reducing labor intensity and costs.

√ Compact Process: Each stage is closely integrated, saving space and reducing infrastructure investment while meeting production requirements. Equipment layout can be flexibly adjusted according to mine scale and ore grade variations.

√ Durable Equipment: Core equipment is manufactured from high-quality materials, featuring robust construction and excellent wear resistance, enabling it to withstand the harsh operating environment of hard rock gold mines with a low failure rate.

√ Energy Saving and Environmental Protection: The gravity separation technology avoids chemical reagent pollution, minimizing water and energy consumption while ensuring optimal beneficiation results; tailings can be reprocessed, meeting the requirements of green mining practices.

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.