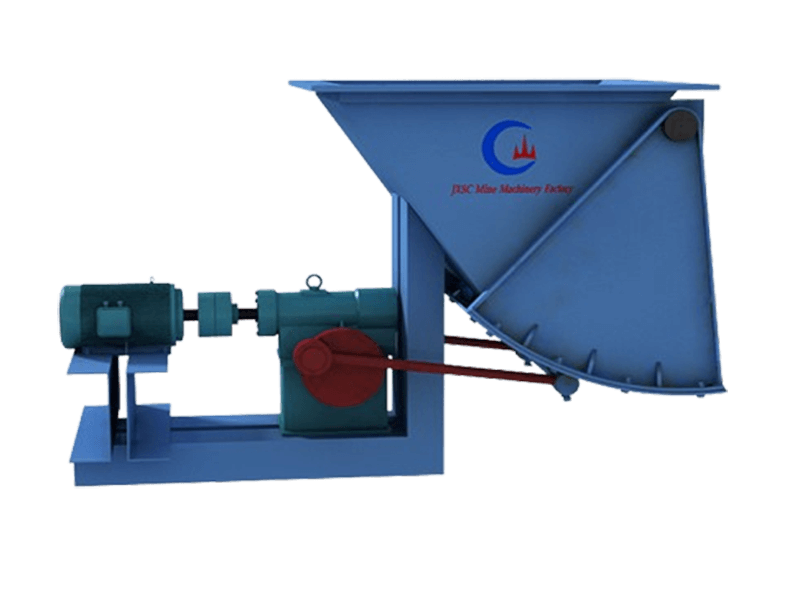

Swing Ore Feeder

Feeding capacity: 4.5-80 TPH (tons per hour)

Motor power: 0.55-1.5 KW

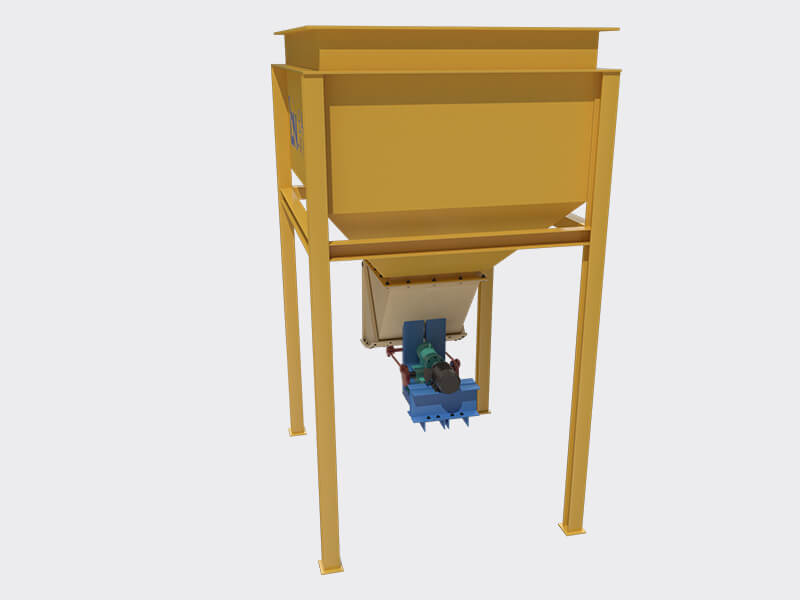

Application: The swing ore feeder (pendulum feeder) is a periodic reciprocating feeding device specifically designed for fine-grained materials. It is commonly used in mineral processing plants, cement production lines, and aggregate plants; for example, in crushing and screening feeding scenarios for minerals or aggregates such as coke, iron ore, and limestone.

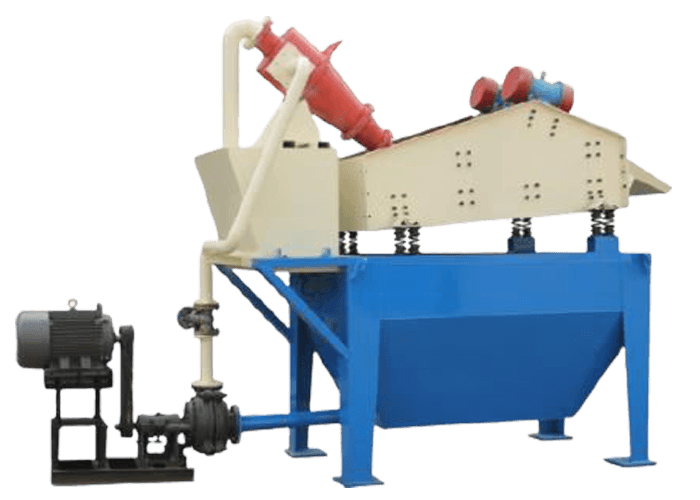

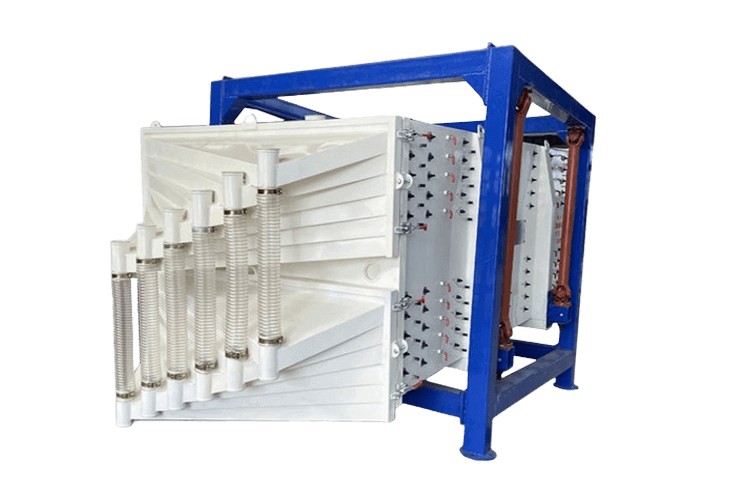

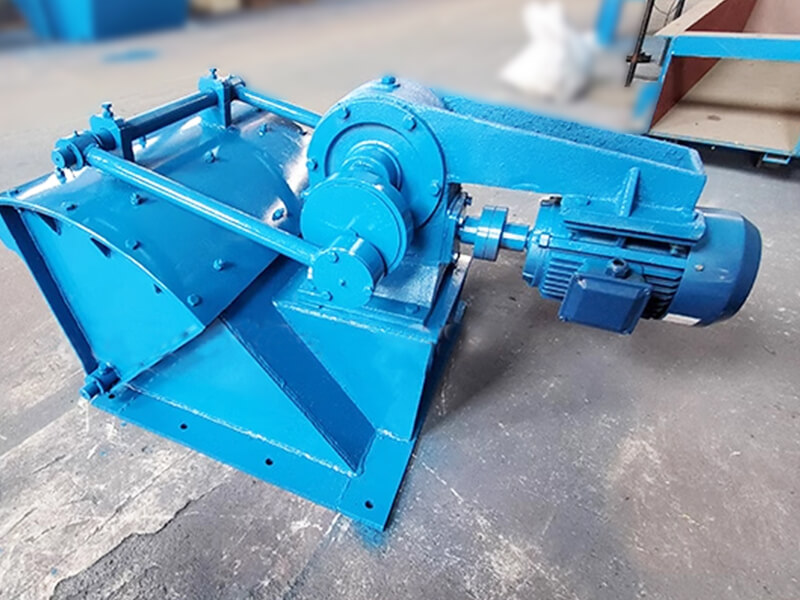

Products display

Introduction of Swing Ore Feeder

A swing ore feeder, also known as a pendulum feeder or oscillating feeder, is a conveying & feeding machine auxiliary device specifically designed for short-distance, quantitative conveying of small pieces or granular materials. It is widely used in industries such as mining, metallurgy, building materials, power generation, chemicals, and logistics. The swing ore feeder uses a reciprocating or oscillating feed trough or swing arm to uniformly, quantitatively, and stably transport materials from storage bins or hoppers to downstream equipment (such as crushers, screening machines, ball mills, or conveyor belts). It is particularly suitable for materials with a high specific gravity, dryness, and non-caking properties, such as ores and coal particles. However, it is not suitable for conveying dry powdery or oversized materials.

Swing ore feeders are typically installed below hoppers or bins. Their design emphasizes reliability, and the feed rate can be precisely and flexibly controlled by adjusting the oscillation frequency or amplitude (by adjusting the eccentricity of the eccentric wheel or the height of the discharge gate). Compared to traditional vibrating feeders, pendulum feeders have a simpler structure, lower maintenance costs, lower noise, and less wear. The swing ore feeder can also be used as a locking device when the machine is stopped to prevent material from flowing out. Swing feeders are particularly suitable for crushing or mineral processing production lines, and are well-suited for operating conditions requiring high equipment stability.

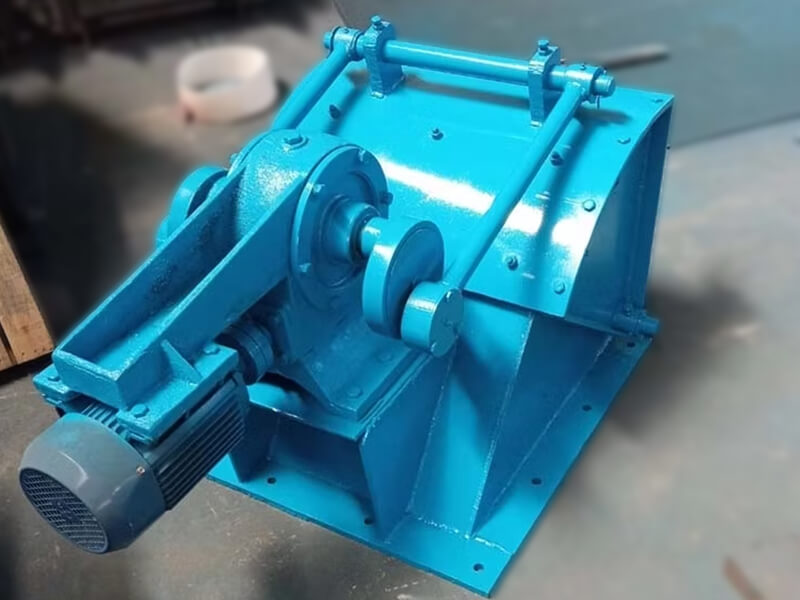

Principle and structure of Swing Ore Feeder

Working principle

The swing ore feeder uses an electric motor to drive an eccentric shaft, which in turn drives a linkage mechanism to cause the pendulum arm to swing periodically. When the pendulum arm swings forward, the feeding trough fixed to the arm pushes the material towards the front. During the return swing, the material naturally slides down to the lowest point of the trough due to gravity, forming a continuous conveying cycle. Under the influence of gravity, the material is pushed uniformly and quantitatively to the discharge port along with the movement of the pendulum base plate, and finally falls into the subsequent receiving device.

Structural characteristics

- Swing arm assembly: A high-strength steel plate welded structure that supports the reciprocating motion of the feeding trough.

- Drive unit: Includes an electric motor and reducer, providing power to the equipment and reducing its speed to ensure the swing mechanism receives appropriate torque and movement frequency.

- Discharge port gate: Installed at the discharge port, its size is adjusted by raising and lowering to control the feeding rate.

- Base and housing: The frame structure supporting the entire equipment, providing a closed operating environment and preventing material splashing.

why choose JXSC Swing Ore Feeder

features & Advantages

√ High cost-effectiveness: Compared to other feeding equipment, the swing ore feeder has a lower manufacturing cost, making it suitable for small and medium-sized enterprises or budget-sensitive projects.

√ Uniform feeding: Periodic quantitative feeding is achieved through mechanical oscillation, resulting in a low error rate and stable material flow.

√ Wide applicability: Made of wear-resistant and corrosion-resistant materials, it can operate stably for extended periods in high-dust, high-abrasion environments such as mines and chemical plants.

√ Simple installation: The swing ore feeder has a small footprint and can be directly installed under a silo or hopper, requiring no complex foundation work, saving space and installation costs.

√ Flexible adjustment: Supports both coarse adjustment (eccentricity) and fine adjustment (gate) for adjusting the feeding rate, adapting to different material characteristics and production needs.

√ Interlocking function: When the machine stops, the swing base plate closes, blocking material flow within the silo and preventing leakage and impact during no-load startup.

√ Low operating noise: The mechanical structure operates smoothly without high-frequency vibration or noise pollution, meeting the environmental protection requirements of modern industrial production.

√ Easy to maintain: The equipment consists of a few core components and has no complex electrical control system. Routine maintenance only requires checking worn parts and lubrication.

models & specifications

| Model | Feed Inlet L×W (mm) | Discharge Outlet L×W (mm) | Eccentric Wheel Stroke (mm) | Oscillation Frequency (r/min) | Maximum Feed Particle Size (mm) | Feeding Capacity (t/h) | Motor Model | Motor Power (kw) | Motor Speed (r/min) | Weight (kg) |

| BG250×250 | 250×250 | 250×30 – 125 | 0 – 90 | 46 | 25 | 4.5 | Y80L – 4 | 0.55 | 1390 | 130 |

| BG300×300 | 300×300 | 300×30 – 125 | 0 – 90 | 46 | 30 | 6.5 | Y802 – 4 | 0.75 | 1390 | 150 |

| BG400×400 | 400×400 | 400×50 – 130 | 0 – 170 | 45.5 | 35 | 12 | Y90S – 4 | 1.1 | 1410 | 300 |

| BG600×600 | 600×600 | 600×50 – 150 | 0 – 157 | 48 | 50 | 40 – 80 | Y100L – 4 | 1.5 | 940 | 450 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.