Why is copper ore concentration a key factor in mine profitability? Throughout the copper mining process, the concentration process directly determines the final product grade, recovery rate, and overall operating costs. With high-grade copper ore resources dwindling, increasing the value of low-grade ore through scientific and efficient beneficiation processes has become a core issue for the industry. This article will delve into the five key steps of copper concentration, from crushing, grinding, flotation, dewatering, to tailings treatment, to explain how refined management can improve copper recovery.

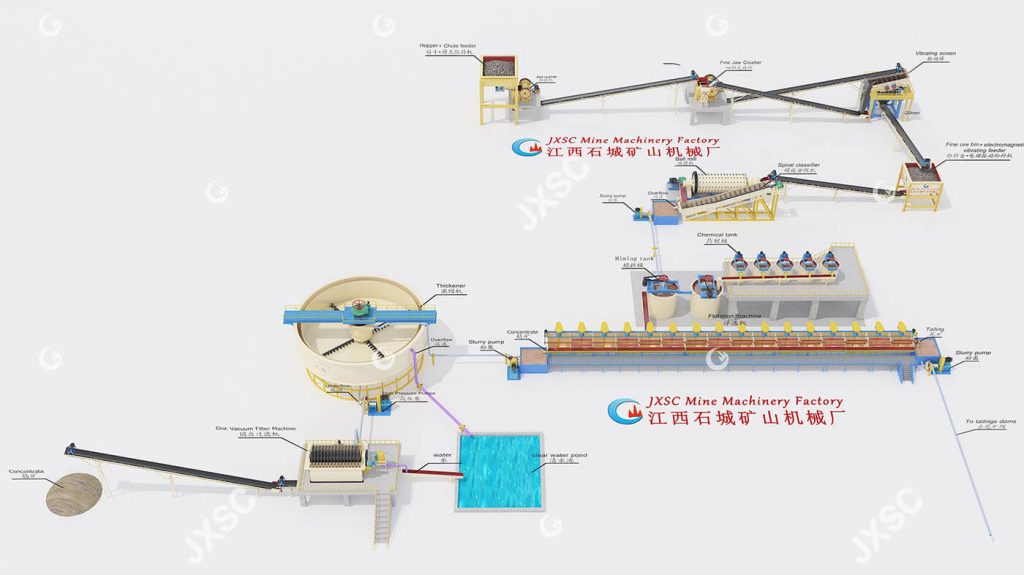

Copper ore concentration primarily involves five core processes: particle size optimization during the crushing stage; grinding fineness control; coarse particle gravity recovery and fine particle flotation tailings removal; efficient dewatering methods; and environmentally friendly tailings treatment. These processes contribute to efficient and environmentally friendly copper beneficiation production, improving copper concentrate grade and recovery.

Copper Ore Concentration Process

Copper ore concentration is a key step in improving ore grade and reducing smelting costs. This core process, which primarily converts low-grade ore into high-grade copper concentrate, comprises the following five steps, each of which directly impacts final recovery and economic benefits:

- Crushing: A two-stage/three-stage crushing process is used to reduce ore particle size, providing a suitable feed for the grinding process.

- Grinding and Classification: A closed-circuit system of ball mills and spiral classifiers grinds the ore to an appropriate fineness (60%-80% -200 mesh) to fully dissociate the copper minerals.

- Copper ore separation: 1. Gravity separation uses gravity or centrifugal force to separate coarse copper minerals (such as native copper and coarse sulfide ores) based on differences in mineral density. 2. Flotation selectively separates copper minerals (such as chalcopyrite) by utilizing differences in mineral surface properties. It offers high separation efficiency and can process low-grade, fine-grained, and complex ores. It is the mainstream separation process for sulfide copper ores, while oxide copper ores require sulfidation before flotation.

- Concentration and Dehydration: Reduce concentrate moisture (≤12%), reducing transportation and smelting costs.

- Tailings Reprocessing: Safely dispose of waste residues (dry stacking/backfilling), reducing environmental pollution. Valuable metals (such as gold and silver) can also be recovered from the tailings, improving resource utilization.

Copper Ore Concentration Steps

Step 1: Copper Ore Crushing

Crushing is the first critical step in the copper ore concentrating process and is divided into two stages: primary crushing and tertiary crushing. Primary crushing uses a jaw crusher to reduce the raw ore to 100-200mm, reducing the primary particle size and preparing for subsequent tertiary crushing. Tertiary crushing typically uses a cone crusher or impact crusher to further refine the ore to 10-30mm.

Step 2: Copper Ore Grinding

The grinding stage determines the slurry fineness, which directly impacts flotation performance. Ball mills use steel balls to achieve a 60%-80% -200 mesh fraction. However, rod mills are suitable for situations where over-grinding is necessary, such as with brittle ores. Too coarse grinding reduces copper mineral dissociation, while too fine grinding increases energy consumption and the risk of mudification. The primary goal is to reduce ore particle size to prepare for subsequent separation.

Step 3: Copper ore concentration process

(1) Gravity Separation Process

This process utilizes mineral density differences (gravity/centrifugal force) for separation. Gravity separation is primarily suitable for processing native copper, coarse-grained copper sulfide ores (particle size >0.1mm), and associated heavy minerals such as gold and silver. It is chemical-free and suitable for areas with water shortages or strict environmental protection requirements.

(2) Flotation Process

Flotation is a separation process based on differences in the physical and chemical properties of mineral surfaces. Its core principle is to use a collector to render the copper mineral surface hydrophobic, allowing it to attach to bubbles and float upward, while gangue (such as quartz and calcite) remains in the slurry. This step directly determines the grade and recovery of the copper concentrate and is particularly effective for the separation of fine-grained, complex ores, such as fine-grained copper sulfide ores (such as chalcopyrite and chalcocite), copper oxide ores (which require sulfidation before flotation), and polymetallic ores (such as copper, lead, and zinc ores). For copper sulfide ores (such as chalcopyrite), conventional flotation is used, requiring the addition of a xanthate collector and pine oil frother. Oxide copper ores (such as malachite) require sulfidation to render their surfaces hydrophobic.

However, gravity separation has a low recovery rate for fine-grained minerals and relies on the degree of dissociation of the ore monomers. It is only suitable for minerals with significant density differences (such as native copper and gangue), in areas with water scarcity, or where environmental protection is critical. It is not suitable for complex polymetallic ores. Therefore, gravity separation is typically used as a low-cost, roughing and enrichment method. However, flotation can maximize the recovery of fine-grained valuable minerals and increase concentrate grade (from 0.5% in the original ore to 20-30%), meeting the high-purity concentrate requirements of smelting.

In summary, copper ore concentration plants often use a combined “gravity separation + flotation” process (e.g., coarse-gravity recovery followed by flotation tailings for fine-grained minerals) to balance efficiency and cost.

Step 4: Concentration and Dehydration (Optional)

The moisture content of copper concentrate after flotation is approximately 20%-30%. Concentration and dehydration are required to reduce the moisture content to below 10% to prevent concentrate loss and meet smelting requirements. Slurry concentration can be achieved using a high-efficiency thickener. Flocculants are added to accelerate settling, and underflow concentrations can reach 50%-60%. Ceramic filters or plate and frame filter presses are commonly used in the dehydration process. The concentrate moisture content must be reduced to below 12% to reduce transportation costs.

Step 5: Tailings Treatment

Tailings are solid waste generated during the mineral processing process. They typically contain 0.1%-0.3% copper and associated metals (gold, silver, iron, etc.). Direct storage not only occupies land but also may contaminate soil and groundwater due to heavy metal leaching. Tailings treatment and resource recovery can achieve the goals of “reduction, resource utilization, and harmlessness.” Dry stacking uses dewatering screening and filtration to reduce the moisture content of tailings to less than 15%, significantly reducing the risk of dam failure. However, the investment cost is 30% higher than wet stacking. Tailings with a copper grade of 0.2% or higher require reprocessing, which can be recovered using a combined gravity separation, magnetic separation, and flotation process.

Copper ore concentration primarily involves five key steps: crushing, grinding, beneficiation, dewatering, and tailings treatment. Flotation and gravity separation are core separation technologies, with concentration and dewatering serving as auxiliary optimization steps. The choice between gravity separation and flotation depends on ore size, mineral composition, and economic costs. Coarse-grained, high-density ores are prioritized for gravity separation process, while fine-grained, complex ores (especially sulfide ores) are preferred for flotation process. For practical production, please contact us for customized mineral beneficiation solutions and equipment to maximize efficiency and recovery.