How can we achieve high gold recovery rates while being environmentally friendly and efficient? This is precisely the revolutionary solution that the carbon-in-pulp (CIP) process brings to modern mining! The carbon-in-pulp process, a closed-loop process that involves directly adding activated carbon to the cyanide pulp to adsorb gold, has become the core gold extraction technology for over 80% of oxidized gold mines and fine-grained disseminated gold deposits worldwide. This article will break down the advantages and application scenarios of the carbon-in-pulp method, from its principles to the entire process, helping you fully master the key technologies of this high-efficiency gold recovery process.

The Carbon-In-Pulp process achieves a recovery rate of 90%-95%+ through cyanide leaching, activated carbon adsorption, and desorption purification. Its cyanide usage is controllable and environmentally friendly, making it suitable for the beneficiation of oxidized gold ores and fine-grained disseminated gold ores. JXSC also supports small to large-scale modular plant designs, helping you balance recovery efficiency, costs, and compliance requirements for sustainable gold production.

What is the Carbon-In-Pulp process?

Carbon-In-Pulp (CIP) is a hydrometallurgical technique that utilizes activated carbon to adsorb dissolved gold, primarily used for the efficient recovery of gold from cyanide leaching solutions. Unlike traditional methods, CIP avoids the solid-liquid separation step, allowing gold ions to be efficiently concentrated on the surface of the activated carbon, significantly improving the recovery rate. Finely ground gold ore undergoes cyanide leaching, and the core of this process lies in utilizing the porous structure of activated carbon to selectively adsorb gold cyanide complexes while minimizing interference from impurities. Due to its high recovery rate (typically over 95%), CIP technology is particularly suitable for processing low-grade ores (1-3 g/t), making it a standard in modern gold refining & extraction plant .

Basic Principles

Step 1: Dissolving Gold: After the ore is ground into a fine powder slurry, a cyanide solution is added. The cyanide acts as a “solvent,” transforming the solid gold into a fluid “gold cyanide complex.”

Step 2: Capturing Gold: Activated carbon is added to the slurry – the surface of the activated carbon is covered with small pores, allowing it to separate the gold from the slurry.

Step 3: Purifying Gold: The activated carbon is “washed” with a high-temperature, high-pressure chemical solution to desorb the gold, and then pure gold powder is obtained through electrolysis. The entire process is closed-loop and controllable, achieving both high efficiency and reduced cyanide pollution, thus enabling green recycling.

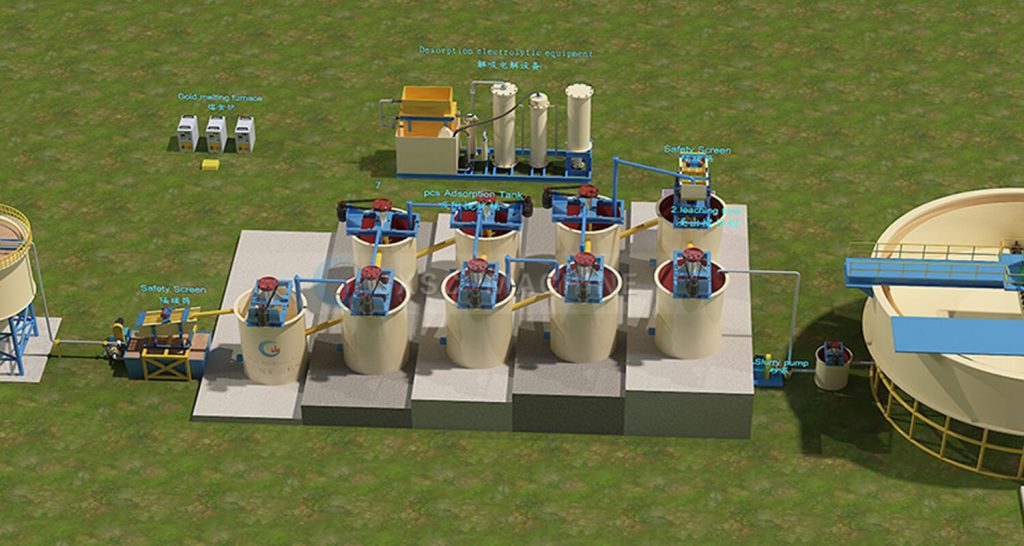

Analysis Of the Gold Carbon-In-Pulp Process

1. Slurry Preparation

(Crushing, Screening, Grinding, and Classification): From Ore to Qualified Slurry

The gold recovery efficiency of the carbon-in-pulp method highly depends on the particle size of the ore; therefore, crushing, screening, grinding, and classification are crucial pretreatment steps. The ore is first coarsely crushed using a jaw crusher, cone crusher, or other mineral crushing machines to reduce the particle size to below 20 mm. Subsequently, screening equipment is used for particle size classification, and oversized particles are returned for further crushing. Then, a ball mill is used for further fine grinding to liberate the gold mineral particles to the optimal leaching particle size (-200 mesh). The control of grinding fineness directly affects the cyanide leaching rate; if the particles are too large, gold dissolution will be hindered. If they are too fine, it will easily lead to mud formation, increasing the difficulty of the subsequent adsorption process. Therefore, the grinding stage is usually equipped with classification equipment (such as spiral classifiers and hydrocyclones) to ensure the optimal particle size distribution of the slurry.

2. Gold Cyanide Leaching

The process of gold dissolution

Cyanide leaching is the core step in the process of converting gold from a solid state to a soluble state. The ore pulp is mixed with a sodium cyanide solution. In an alkaline environment, the sodium cyanide solution reacts with the gold ore, forming a gold cyanide complex. The leaching process is typically carried out in a series of stirred tanks, with a residence time of generally 6-24 hours, depending on the type of ore and the gold’s occurrence state.

3. Activated Carbon Adsorption

The “Capture Net” for Gold

The gold-containing solution after leaching flows into the CIP adsorption system, where it comes into contact with activated carbon to achieve gold enrichment. The selection of activated carbon is crucial, considering factors such as particle size, porosity, and mechanical strength to avoid particle breakage and loss. Coconut shell carbon is often preferred due to its high microporosity and abrasion resistance. The adsorption kinetics follow a diffusion-surface reaction mechanism, where the gold cyanide complex diffuses from the solution to the carbon surface and is chemically adsorbed. The CIP system typically uses 5-8 stages of countercurrent adsorption tanks in series to improve the gold adsorption rate to 99%.

4. Gold-Loaded Carbon Desorption

Separation and Purification of Gold

Desorption and electrolysis is the processes of separating and purifying gold from the activated carbon. High-temperature and high-pressure desorption: A high-pressure mixture of sodium hydroxide and sodium cyanide is used to “wash” the activated carbon, desorbing the gold complex from the pores.

5. Activated Carbon Regeneration

Recycling for Cost Reduction

Activated carbon regeneration is a crucial method for reducing costs and improving efficiency in the carbon-in-pulp process. The core process is thermal regeneration: first, the activated carbon is washed with water to remove residual pulp, then it is sent to a rotary kiln at approximately 800°C for calcination, burning off adsorbed organic matter and residual impurities, and restoring the pore structure and activity. The regenerated activated carbon can achieve more than 90% of the adsorption capacity of new carbon and can be reused, significantly reducing raw material costs and minimizing solid waste emissions, thus meeting environmental requirements. This step is a key technology for achieving a closed-loop process and improving economic efficiency.

6. Electrolysis and Smelting

The gold-rich desorption solution enters the electrolysis system, where electrolytic deposition is carried out for 24-48 hours using a stainless steel cathode. During this process, gold ions are reduced to gold powder at the cathode, with a purity of approximately 90-95%. The resulting gold sludge is then acid-washed to remove impurities and sent to an induction melting furnace to be cast into gold ingots (purity >99.5%). The final product is suitable for direct refining or trading.

Advantages and application scenarios of carbon-in-pulp process

Advantages of CIP Process:

√ High-Efficiency Gold Extraction: Recovery rate reaches 90%-95%+, more than 20% higher than traditional heap leaching. Simply put, the Carbon-In-Pulp process can extract nearly one-fifth more gold from low-grade ore.

√Environmentally Friendly and Compliant: The cyanide solution is used in a closed-loop system, requiring only 60% of the amount used in traditional cyanidation. There is virtually no risk of external discharge, easily meeting green mining standards.

√Strong Site Adaptability: The modular equipment design requires a smaller footprint, making it particularly suitable for projects in mountainous mining areas or urban areas with limited space, saving land costs and reducing transportation challenges.

Applications Of the CIP Method:

The carbon-in-pulp process is best suited for processing low-grade gold ores (1-5 g/t) or tailings, especially those containing interfering substances such as clay and organic matter. It has a natural suitability for two types of ore: oxidized gold ore, where the surface is free of sulfide encapsulation, allowing cyanide to easily penetrate and dissolve the gold; and fine-grained disseminated gold ore, where activated carbon can accurately capture micron-sized gold particles, preventing losses associated with traditional processes.

Compared to traditional methods, CIP can adapt to fine-grained disseminated gold ores and reduce recovery losses caused by the complex nature of the ore. Furthermore, because the CIP process does not require a solid-liquid separation step (such as filtration), it has advantages in processing high-clay slurries. However, CIP process has certain requirements for ore grinding fineness and cyanide concentration, typically requiring grinding to below -200 mesh, and strict control of leaching conditions to ensure the highest gold recovery rate.

carbon-in-pulp vs. CIL vs. Other Gold Recovery Methods

Process Type | Extraction Efficiency | Process Difference | Suitable Ore Type | Environmental Risk | Operational Cost |

95%-99% | First cyanide leaching, then carbon adsorption (two independent steps) | Oxidized gold ore, fine-grained disseminated gold ore | Low (cyanide closed-loop recycling) | Medium to high | |

90%-95%+ | Leaching and adsorption carried out simultaneously (one-step operation) | Coarse-grained gold ore | High (easy to leak) | Medium | |

Heap Leaching | 70%-80% | Pile low-grade ore → spray cyanide solution | Low-grade large oxidized ore | Medium (waste liquid treatment pressure) | Low |

85%-95% | Reagent foam separation (gold particles attach and float up) | Associated sulfide ore, fine-grained disseminated gold ore | Medium (reagent residue) | Medium | |

70%-85% | Physical gravity separation (shaking table/jig machine) | Coarse-grained placer gold ore or rock gold ore | Extremely low (no chemical reagents) | Low |

Conclusion

The Carbon-in-Pulp (CIP) process is a highly efficient gold processing technology suitable for oxidized ores and finely disseminated ores. It achieves a recovery efficiency of over 95% through processes such as pulp preparation, cyanide leaching, and activated carbon adsorption. The closed-loop circulation of cyanide minimizes environmental risks. When selecting a process, factors such as ore properties (gold particle size, occurrence state), investment budget, and environmental requirements must be considered to achieve economically efficient gold recovery. Whether it’s the conventional processing of placer gold, vein gold, or sulfide gold, or the beneficiation of polymetallic ores, JXSC can provide you with the optimal mining equipment & technical solution to help your gold mining project operate efficiently and compliantly!