10TPH Alluvial Tungsten-Tin Ore Beneficiation Plant In Tanzania

We guarantee the high quality machine in the mineral processing industry, established in 40+ years of experience.

Project Info.

- Raw ore: tungsten-tin ore with less contain sticky clay

- Capacity: 10TPH

- Maximum feeding size: 150 mm

- Output size: 0-2mm

- Location: Tanzania

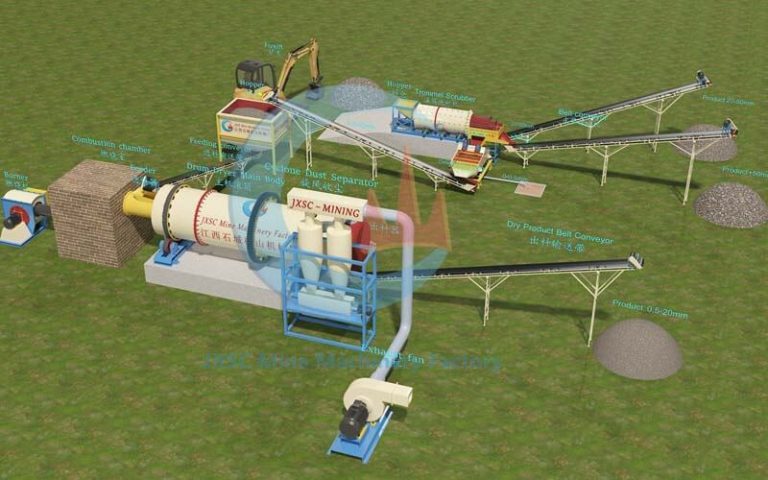

Process

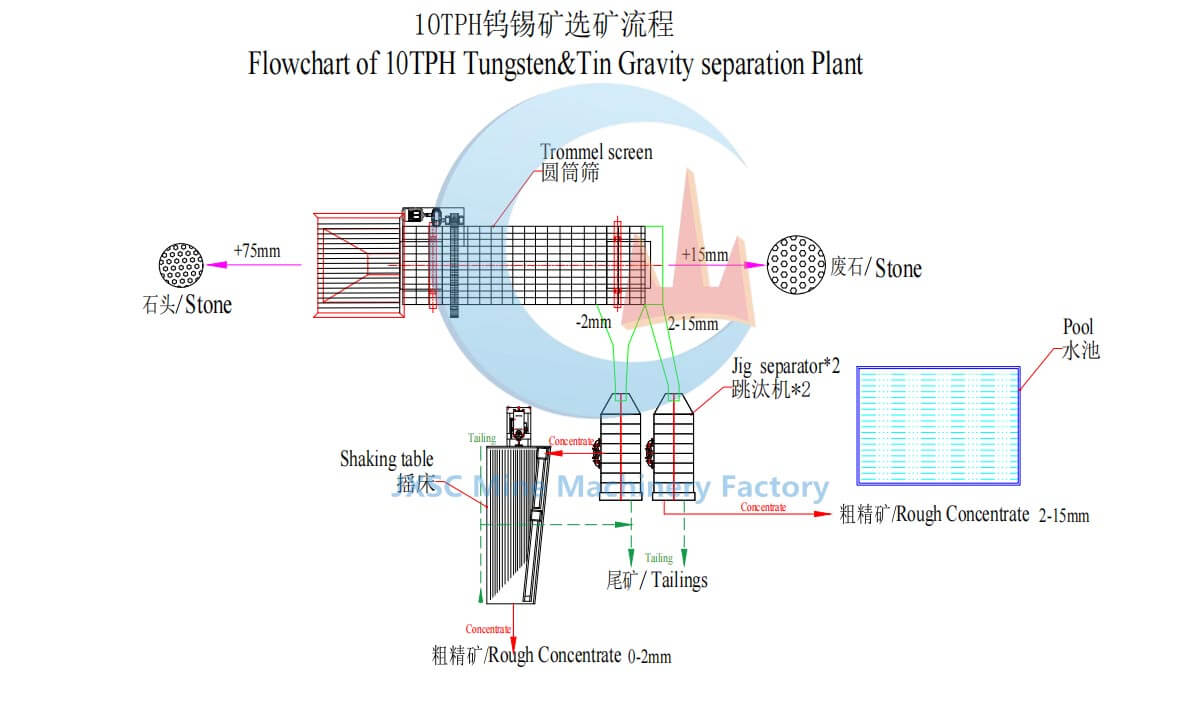

Washing – Gravity Separation (jig concentrators, shaking table)

process flow

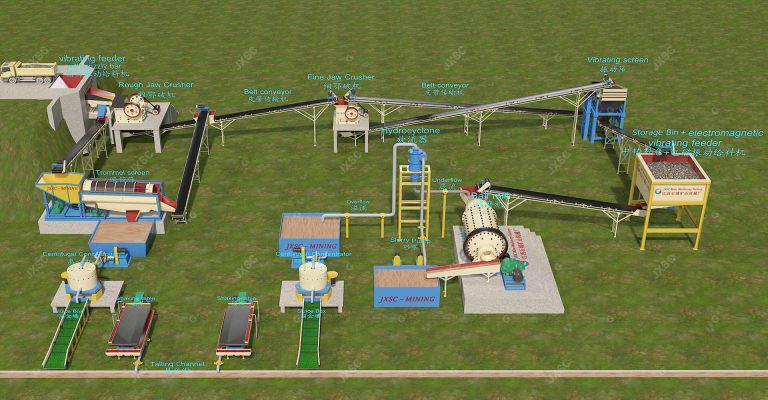

10TPH tungsten-tin ore beneficiation plant

The raw ore mined by customers will not contain large pieces, so there is no need for crushing or other pre-selection treatment. In order to extract and recycle tungsten and tin minerals more efficiently and accurately, JXSC will adopt a series of scientific and reasonable process flows, mainly including washing and re-selection.

1. Tungsten-tin Washing stage: trommel screen

The raw materials are fed into the drum screen by the excavator to wash away the clay and screen out the oversized waste rocks. The drum screen feed port is equipped with a grid with a gap of 75mm, which can screen out large waste rocks over 75mm. It also has two layers of 2mm and 15mm screens, which can screen materials of 0-2mm, 2-15mm, and +15mm. The trommel screen rolls the ore in the screen drum through its own rotational motion. Fine-grained ore smaller than the size of the screen hole will fall through the screen hole, while coarse-grained ore larger than the size of the screen hole will be discharged from the other end of the screen drum. Among them, materials larger than 15mm are waste rocks and are discharged.

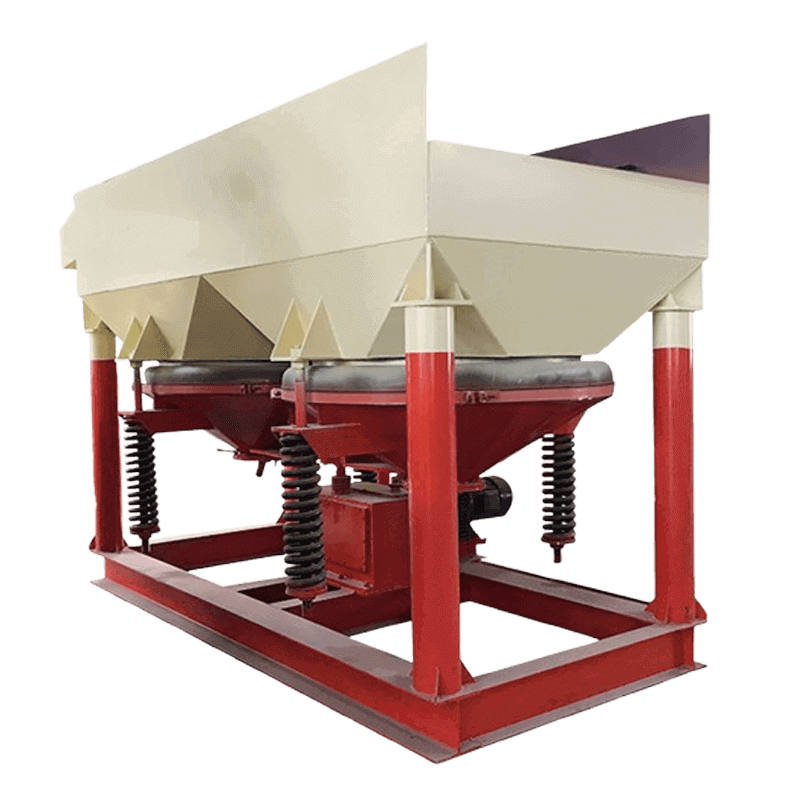

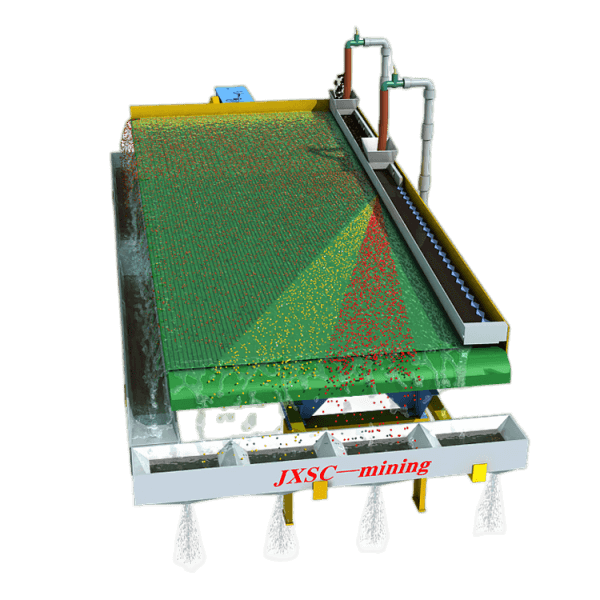

2. Tungsten-tin Gravity separation stage: jig concentrator, shaking table

- The 0-2mm slurry screened out by the drum automatically flows to one of the jig concentrators under the action of gravity, initially enriching tungsten and tin ores and greatly removing gangue minerals. In the jig, by periodically changing the water flow speed and direction, the tungsten and tin ore particles, due to their relatively large density, will gradually settle to the bottom of the jig under the action of the water flow to form heavy products; while the gangue minerals with lower density are brought to the upper layer with the rising water flow and discharged as light products. The concentrate is discharged from the bottom of the jig screen. Then it enters the shaking table for concentrating to improve the ore grade and obtain 0-2mm tin concentrate.

- The 2-15mm material screened out by the drum enters another jig, and the concentrate is discharged from above the jig screen to obtain 2-15mm tungsten concentrate.

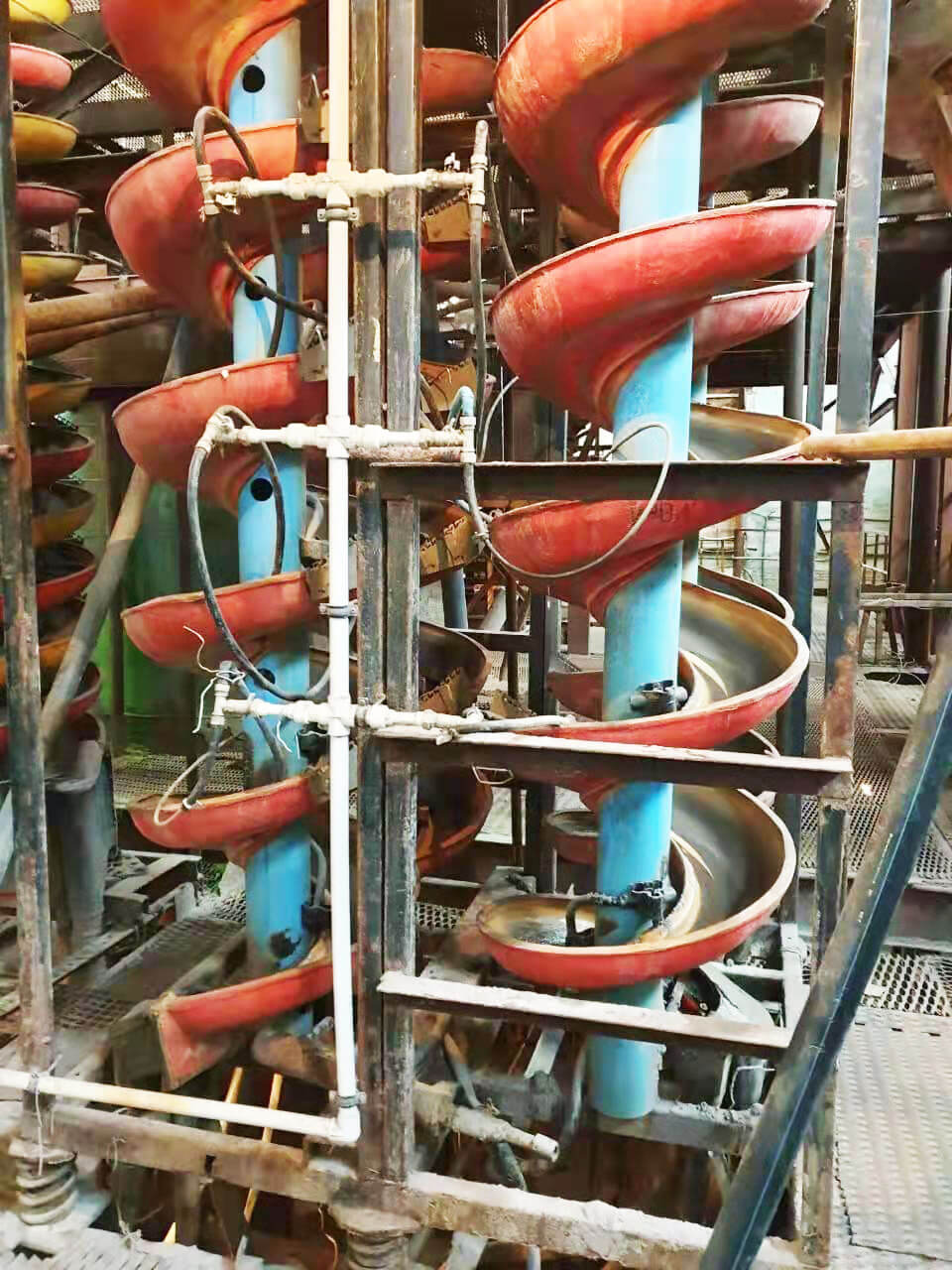

Process Site

tungsten-tin ore beneficiation plant Site

The synergy of the process and equipment in this plant enables the ore beneficiation plant to operate stably and efficiently and accurately extract high-quality tungsten-tin concentrate products from tungsten-tin ore. Because of different mine situations and requirements, the tungsten–tin ore beneficiation solutions will be different. The processing capacity can be designed based on your requirements. →→ Contact us to customize the tungsten-tin ore beneficiation plant and equipment for you.

Main Equipment

No. | Machine | Spare Parts list | Quantity (Set) |

1 | Trommel Screen (JXSC-813) | 2mm mesh Mn Steel screen | 4 |

2 | Jig Separator (JT2-2) | Spring ( piece) | 2 |

Rubber Diagram (Piece) | 2 | ||

Speed controller (piece) | 2 | ||

adjustable-speed motor (piece) | 1 | ||

3 | Shaking Table (4500*1850mm) | Bushing+Oil tube+Oil seal+V | 1 |

4 | Water Pump (3 inch ) | Impeller(set) | 3 |

shaft sleeve(set) | 3 | ||

Bearing ( unit : set, 2 pcs per set) | 3 | ||

ring (piece) | 3 | ||

materil cover (piece) | 3 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.