150TPH Heavy Minerals Concentration Plant In Senegal

We guarantee the high quality machine in the mineral processing industry, established in 40+ years of experience!

Project Info.

- Raw ore: heavy minerals with less contain sticky clay, including zircon, rutile, ilmenite.

- Capacity: 150TPH

- Maximum feeding size: ≤100 mm

- Output size: 0-2mm

- Location: Senegal

Process

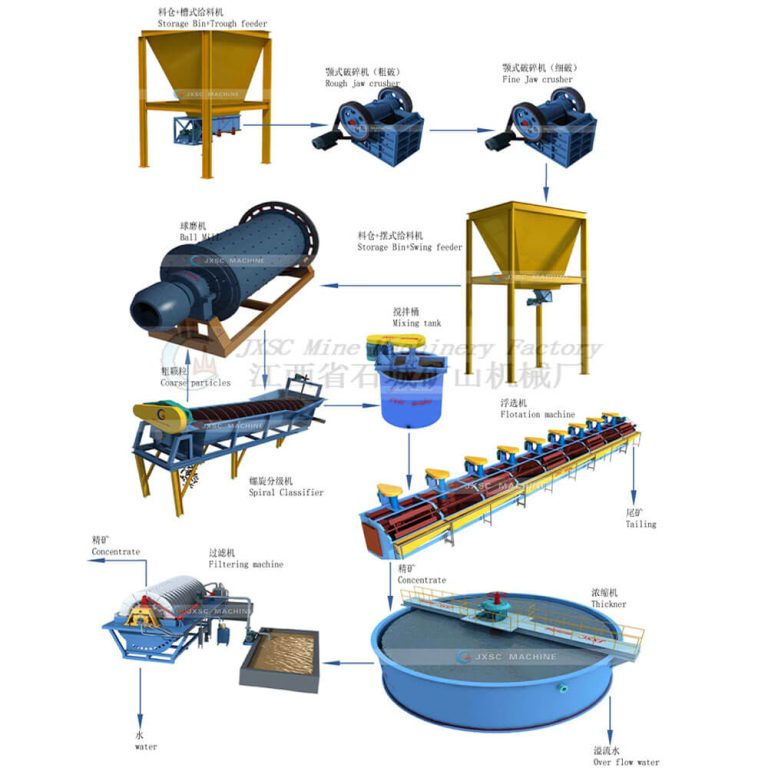

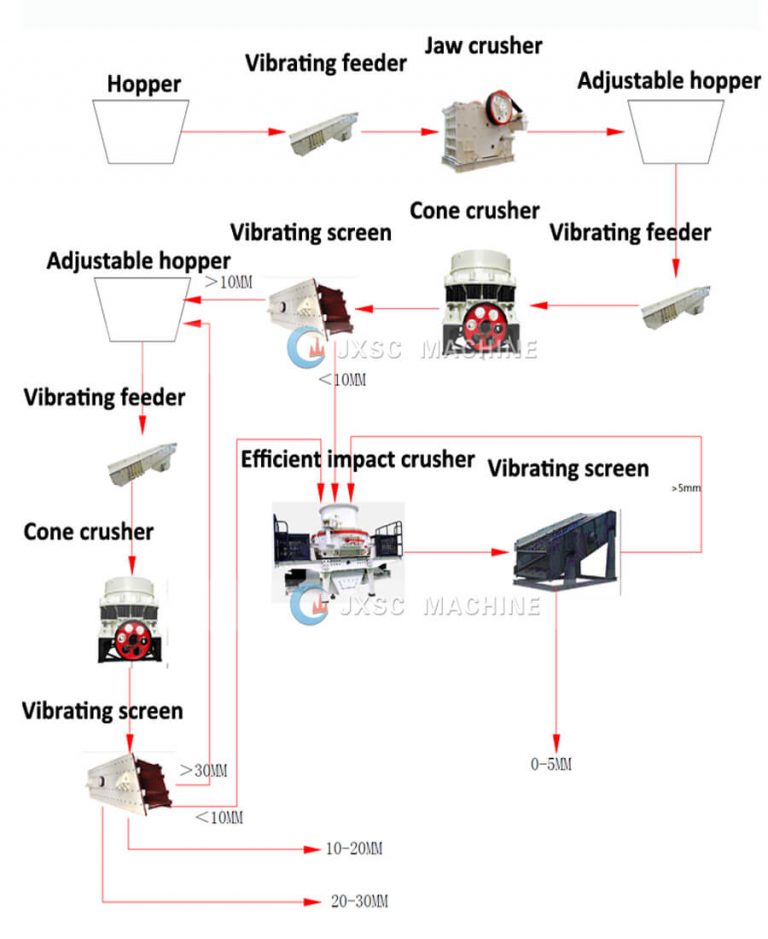

Washing (trommel screen) – Gravity Separation (spiral chutes)

process flow

150TPH Heavy Minerals Concentration Plant

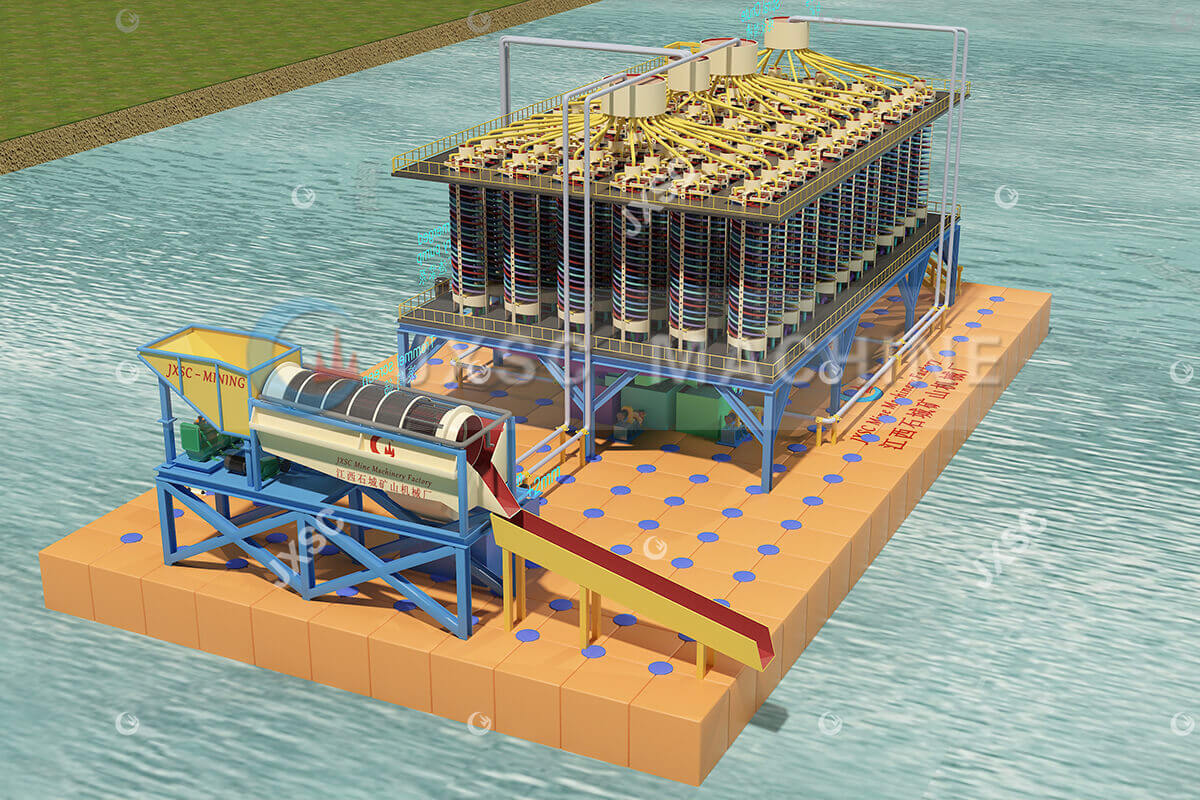

This 150TPH heavy mineral concentration plant in Senegal specializes in processing alluvial deposits with peat layers for zircon, rutile, and ilmenite recovery. The complete plant features a 3-stage spiral separation system with customized solutions for peat clay conditions. Designed to process 150 tons per hour (TPH), the plant combines 87 spiral chutes with precise slurry density control (25-30%) for optimal heavy mineral recovery.

150TPH Heavy Minerals Concentration Plant Flow

Stage 1: Primary Separation & Classification

- The dredge pump will send the slurry to trommel screen hopper,slurry density is better to be about 25-30%. and the slurry pressure (flowing speed) shall not be too big.

- The trommel screen with a 2mm mesh screen, will remove the +2mm waste sand discharging directly to nearby, 0-2mm slurry will first go to an agitation tank (2000*1500mm), because the slurry flow capacity is big from trommel screen, it is necessary to agitate the slurry before sending to 1st stage spiral group, so the solid material in slurry can be distributed evenly to spirals.

Stage2: Multi-Level Spiral Concentration

- The slurry from the mixing tank will be sent to 1st stage spiral chute group by two slurry pumps (8/6E-AH), 1st stage spiral total of 48 sets, divided into two groups, each group 24 sets spiral, so one pump for one spiral group, each spiral group has one big distribution tank (1800*2000mm).

- The middling slurry discharged from 1st stage spiral chute will go to two slurry tanks, then use two slurry pumps (4/3C-AH) to send the middling slurry to 2nd stage spiral chute total of 16 sets, only ONE spiral group, with one big distribution tank( 1500*1500mm).

- The Concentrate ore discharged from 1st stage spiral chute will go to two slurry tanks, and then two slurry pumps(3/2C-AH) sent to 3rd stage spiral for final concentration.

- The tailings discharge from the 1st stage spiral chute will go to two tailing tanks, and then two slurry pumps (6/4D-AH) sent to the tailing dump which is about 100 meters far away.

- The concentrate ore discharged from 2 nd stage spiral chute will go to one slurry tank, then use one slurry pump (3/2C-AH) to send the concentrate ore to the big distribution tank (1000*1200mm) of 3rd stage spiral with 6 sets spiral chutes.

- The tailings discharge from 2nd stage spiral chute will go to a slurry tank, and then use a slurry pump (6/4D-AH) send it to the tailing dump which is 100 meter far away.

- The final heavy minerals concentrate product that is discharged from 3rd stage spiral chutes will go to one slurry tank, then use a slurry pump (1.5/1C-HH) sent to the concentrate heap on the ground which is 150-200 meters far away.

Note: Considering there is a peat layer in the mine place, which is dark, clay organic matter, an extra submerged slurry pump (model 80-65-160) is necessary to provide extra water to the trommel screen when such material goes through a trommel and spray high pressure water on the material, so the clay can go through trommel more easy and avoid-stuck sieve. So this plant needs a total of 12 sets of slurry pumps on use at the same time.

This full heavy mineral concentration plant demonstrates effective handling of complex geological conditions through three-stage-separated spirals and targeted pumping systems. With 97% system uptime recorded in the first year of operation, the configuration provides reliable recovery rates for West African mineral sands. Optimized for processing high clay content deposits, medium-scale production, and modular upgradability.

Whether targeting zircon, rutile, ilmenite, or garnet sands, JXSC will design turnkey heavy minerals concentration plant (HMCP) solutions tailored to your ore type, capacity, and terrain. Contact us today for a free process design and get the equipment latest qoute!

Process Site

150TPH Heavy Minerals Concentration Plant Site

Need a Reliable Heavy Minerals Processing Plant Solution?

Main Equipment

| No. | Equipment Name | Model | Specifications and Requirements | Quantity |

| 1 | Trommel Screen | 2200*6000 | 1. Processing capacity: 180TPH 2. Screen drum diameter: 2.2m; Length: 6m 3. Motor power: 30kW 4. Single-layer stainless steel screen,sieve hole : 2mm 5. With hopper, fixed type | 1 |

| 2 | Spiral Chutes | 5LL-1200 | 1. Processing capacity: 3T/H 2. Feed size: 0-2mm; Diameter: 1200mm 3. First stage: 48 units, second stage: 16 units, third stage: 6 units (70 units in total, 17 units reserved as spares) | 87 |

| 3 | #1 Distribution Tank | 1500*1500 | 1. Used at the top of the second-stage spiral chutes 2. Second-stage spiral chutes: 16 units, sharing one distribution tank 3. Factory pre-drilled holes before delivery | 1 |

| 4 | #2 Distribution Tank | 1800*2000 | 1. Used at the top of the first-stage spiral chutes 2. First-stage spiral chutes: 48 units, 24 units per distribution tank 3. Factory pre-drilled holes before delivery | 2 |

| 5 | #3 Distribution Tank | 1000*1200 | 1. Used at the top of the third-stage spiral chutes 2. Third-stage spiral chutes: 6 units, sharing one distribution tank 3. Factory pre-drilled holes before delivery | 1 |

| 6 | Mixing Device | 2000*1500 | 1. Mixing tank dimensions: 221.5m (welded on-site) 2. Mixer: 7.5kW 3. Used for stirring ore pulp after trommel screen and conveying to the first-stage spiral chutes | 1 |

| 7 | #1 Slurry Pump | 8/6E-AH | 1. Inlet size: 8 inches / Outlet size: 6 inches 2. Head: 22m 3. Flow rate: 299m³/h 4. Motor power: 37kW | 3 |

| 8 | #2 Slurry Pump | 4/3C-AH | 1. Inlet size: 4 inches / Outlet size: 3 inches 2. Head: 21m 3. Flow rate: 125m³/h 4. Motor power: 22kW | 3 |

| 9 | #3 Slurry Pump | 3/2C-AH | 1. Inlet size: 3 inches / Outlet size: 2 inches 2. Head: 20m 3. Flow rate: 25m³/h 4. Motor power: 5.5kW | 3 |

| 10 | #4 Slurry Pump | 6/4D-AH | 1. Inlet size: 6 inches / Outlet size: 4 inches 2. Head: 15m 3. Flow rate: 187m³/h 4. Motor power: 30kW | 3 |

| 11 | #5 Slurry Pump | 3/2C-AH | 1. Inlet size: 3 inches / Outlet size: 2 inches 2. Head: 25-28m 3. Flow rate: 17-25m³/h 4. Motor power: 4kW | 2 |

| 12 | #6 Slurry Pump | 6/4D-AH | 1. Inlet size: 6 inches / Outlet size: 4 inches 2. Head: 15m 3. Flow rate: 227m³/h 4. Motor power: 37kW | 2 |

| 13 | #7 Slurry Pump | 1.5/1C-HH | 1. Inlet size: 1.5 inches / Outlet size: 1 inch 2. Head: 25m 3. Flow rate: 12-15m³/h 4. Motor power: 15kW | 2 |

| 14 | Diesel Generator | Standard 500KW | 1. Power: 500KW 2. Brand: Weichai | 1 |

| 15 | Control Cabinet | / | 1. For the entire processing line (all above equipment) 2. All buttons/switches labeled in Chinese and English | 1 |

| 16 | Submersible Slurry Pump | 65QV-SP(R) | 1. Head: 22.5m 2. Flow rate: 40-50m³/h 3. Motor power: 11kW | 1 |

| 17 | Mobile Belt Feeder | B800*3500 | 1. Motor power: 11kW 2. Variable frequency motor 3. Belt dimensions: 800mm3500mm (widthlength) | 1 |

| 18 | Mobile Belt Conveyor | B800*12m | 1. Motor power: 7.5kW 2. Equipped with movable wheels 3. Belt dimensions: 800mm12m (widthlength) | 1 |

| 19 | Control Cabinets & Cables | / | 1. Mobile belt feeder: dedicated variable frequency control cabinet 2. Mobile belt conveyor: dedicated standard control cabinet 3. Complete cables for both 4. All buttons/switches labeled in Chinese and English | 1 |

| 20 | Diesel Generator | 50KW | 1. Power: 50KW 2. Brand: Weichai 3. With silencer | 4 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.