20TPH Alluvial & Rock Tin Ore Process Plant In Zimbabwe

We guarantee the high quality machine in the mineral processing industry, established in 39+ years of experience.

Project Info

1. Materials: alluvial & rock tin tantalite ore, each accounting for 50%, contain clay

2. Capacity: 20TPH

3. Feed size: 2.0-50mm

4. Discharge size: Above 10mm, 2-10mm, Below 2mm

5. Location: Zimbabwe

Process

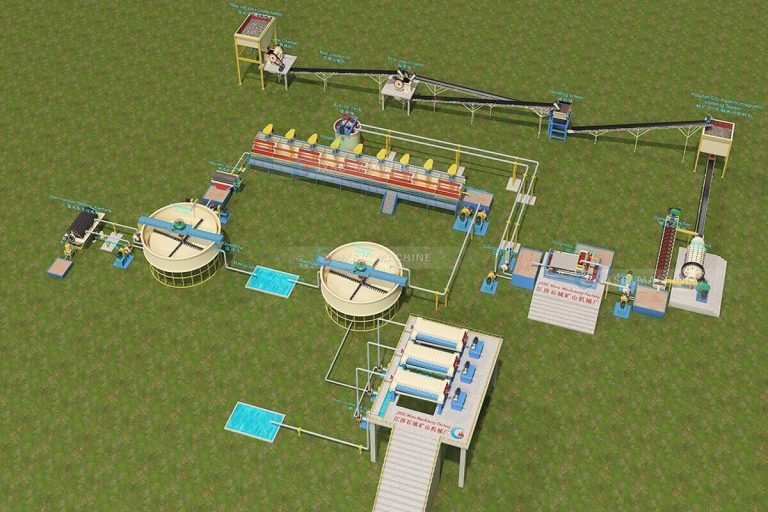

Washing – Crushing – Screening – Gravity Separation – Magnetic Separation

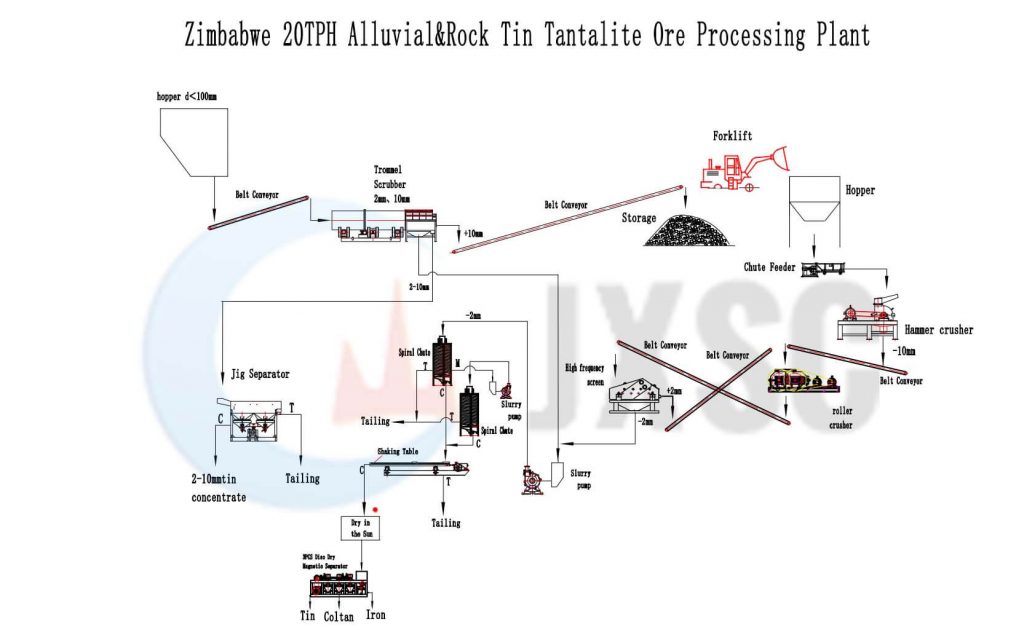

process flow

20TPH Alluvial & Rock Tin Ore Process plant flow

The customer requires that the impurities on the surface of the ore be washed first to remove iron impurities, and the final concentrate recovery rate must reach 95%. JXSC has developed a complete set of tin ore process plant equipment lines based on customer needs. The following is the specific process flow:

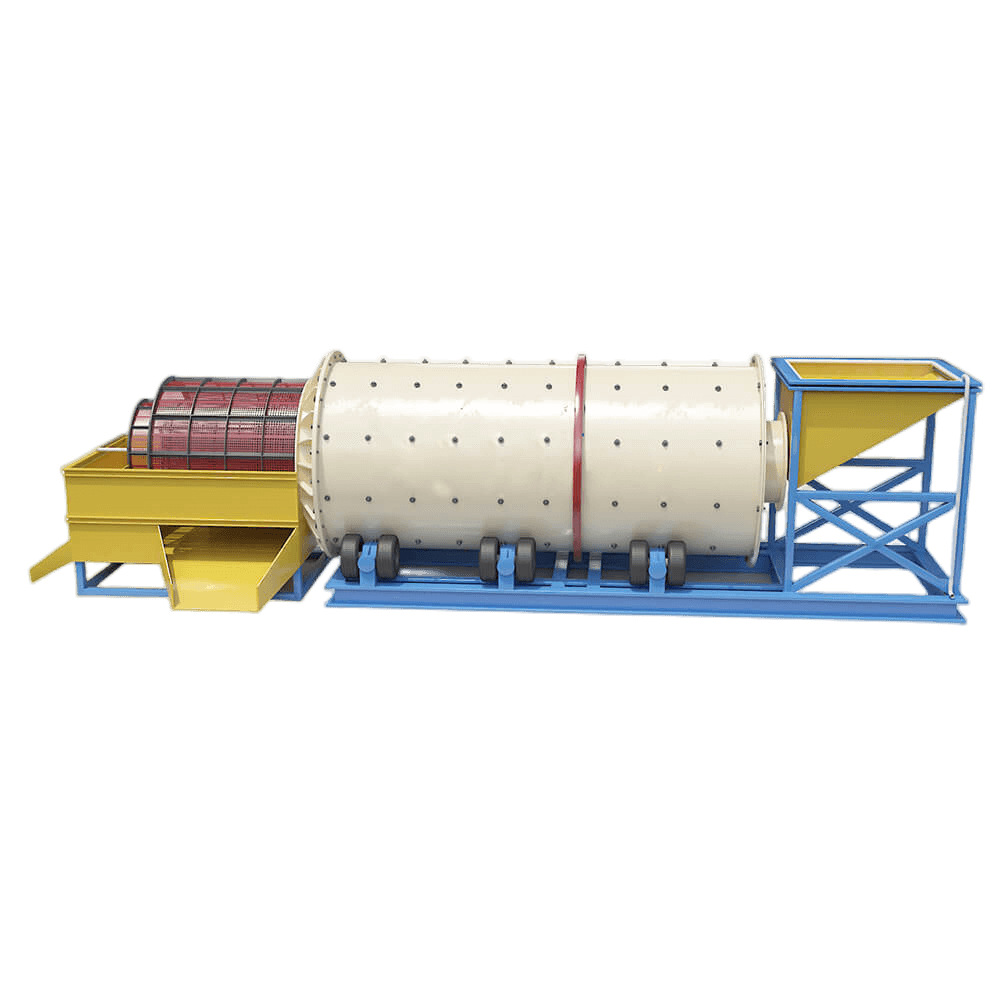

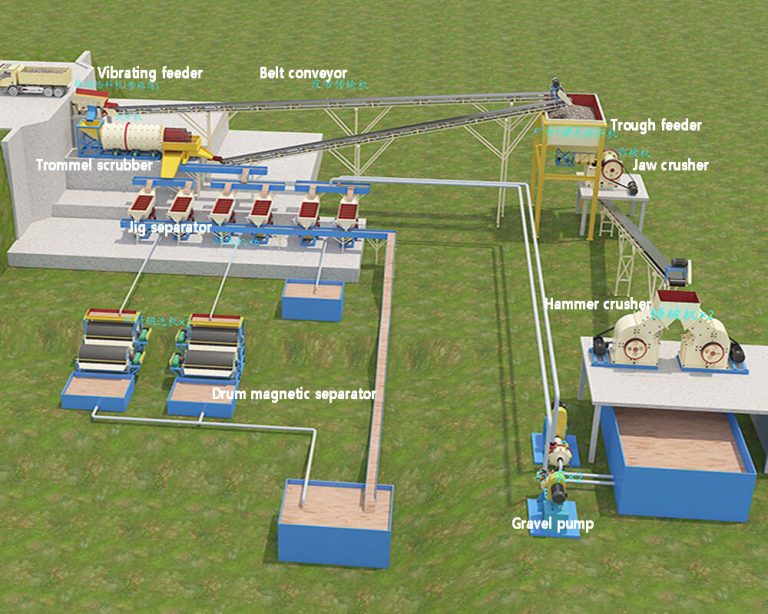

1. Washing stage: trommel scrubber

A loader or excavator feeds the materials into a hopper, and a drum washing machine (with 2mm and 10mm screens) cleans and screens the raw ore.

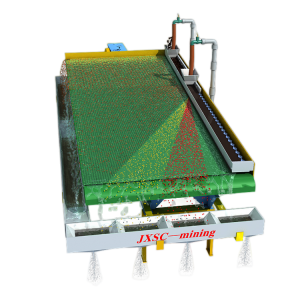

2. Alluvial tin tantalite oreprocess: jig separator

Gravity separation: Put the 2-10mm stone into the jig machine and select the 2-10mm tin concentrate.

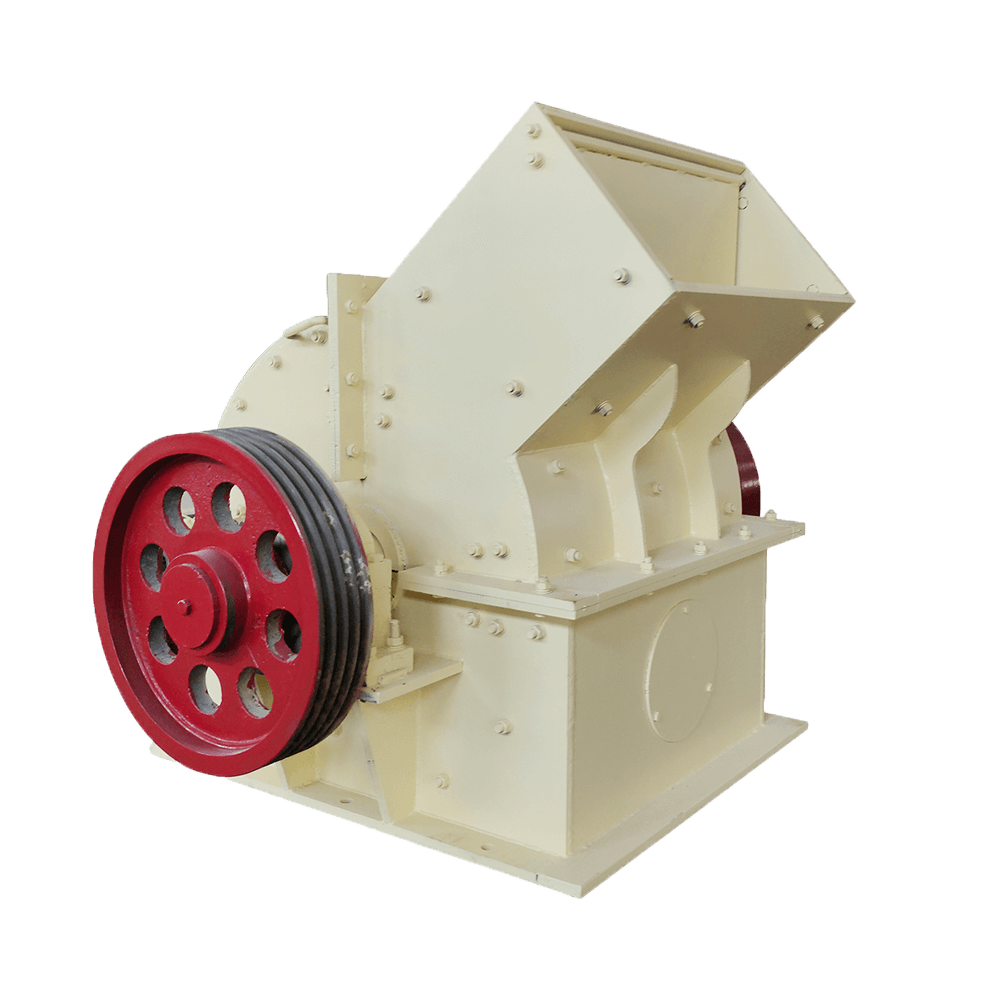

3. Rock tin tantalite ore process: hammer crusher, roll crusher, vibrating screen, shaking table, three-disc magnetic separator

- Crushing stage: After being cleaned by the drum washing machine, stones larger than 10 mm are transported to the warehouse through a belt conveyor. Then use a forklift to feed the stone into the hopper and a trough feeder to feed the stone into the hammer crusher. The crushed stone is less than 10mm and then transported to the roller crusher using a belt conveyor for fine crushing. The crushed stone is 0-2 mm, enters the high-frequency screen for screening, and the material larger than 2 mm returns to continue crushing.

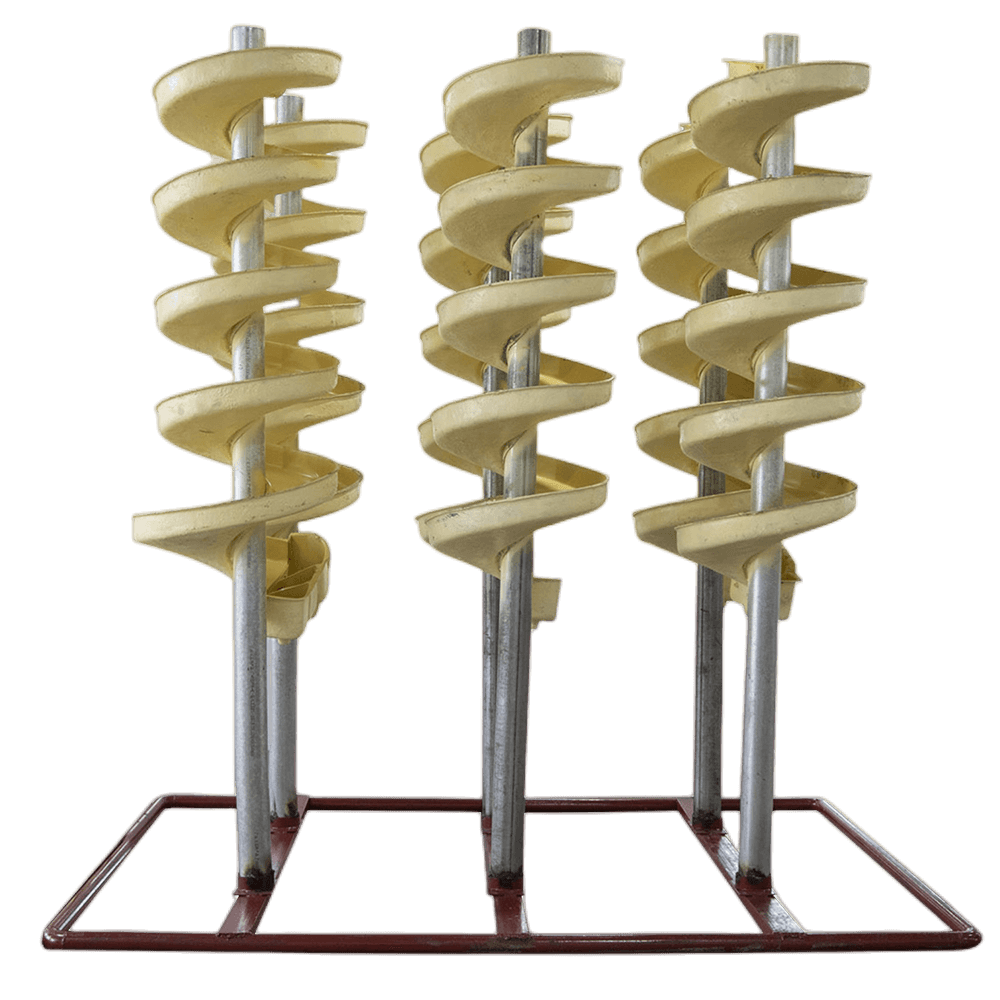

- Gravity separation: The slurry pump sends 0-2mm stones into two spiral chutes, and then enters the shaker for selection.

- Magnetic separation: Finally, the tin concentrate is dried in the sun, and then a three-disk dry magnetic separator separates the tin, tantalite, and iron in one go.

This tin-ilmenite processing plant has a precise process design, low operating costs, no pollution, and high-efficiency sorting. We are committed to providing high-quality mining equipment to achieve the best tin mineral processing solutions.

Main Equipment

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.