20TPH Rock Gold Crushing Process Plant In Mozambique

We guarantee the high quality machine in the mineral processing industry, established in 40+ years of experience!

Project Info.

- Raw Ore: Rock gold ore, large lump size

- Processing capacity: 20 TPH

- Location: Mozambique

Process

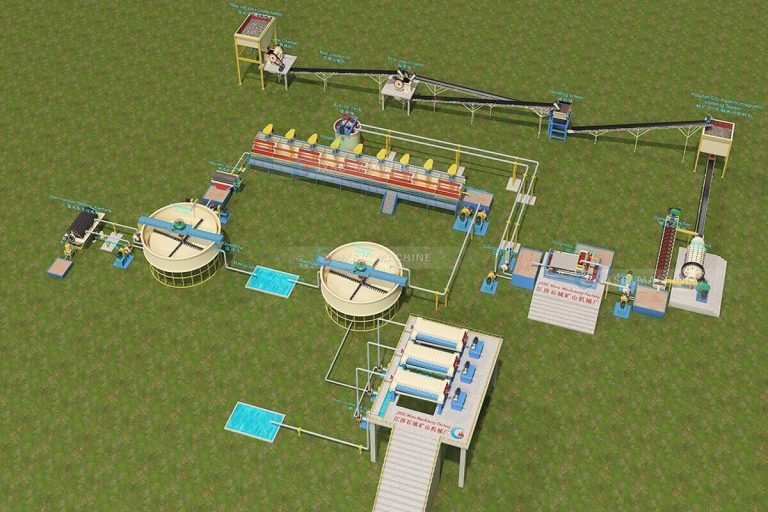

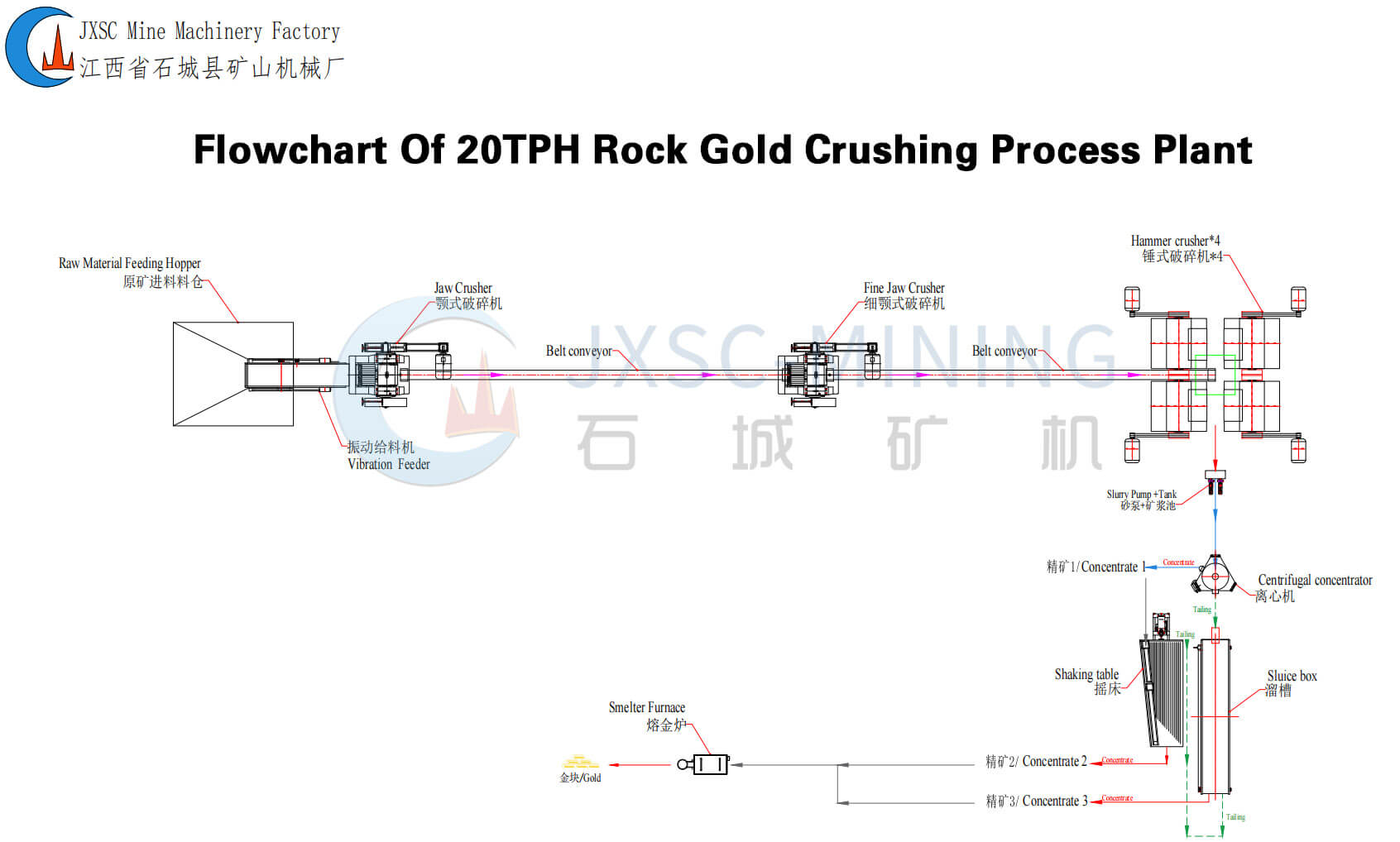

Three-stage crushing (coarse crushing – medium crushing – fine crushing) + full gravity separation (centrifugal Concentrator separation – shaking table separation – sluice box sweeping separation) + concentrate smelting

process flow

20TPH Rock Gold Crushing Process Plant

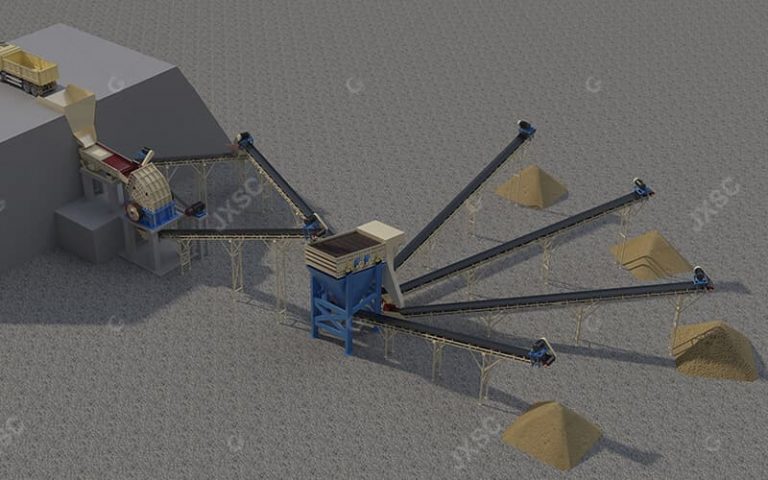

JXSC designed a complete 20TPH rock gold crushing process solution for a client in Mozambique. This plant combines three-stage crushing with multiple gravity separation processes and concentrate smelting, achieving efficient conversion from raw ore to gold ingots. This project is a combined production line of rock gold crushing and gravity beneficiation. JXSC provides a full set of equipment that integrates high-efficiency separation, low-consumption environmental protection, and automated control technologies to provide customers with green and economical gold beneficiation solutions.

20TPH Rock Gold Crushing Process Flow

1. Feeding stage: Ore feed silo, vibrating feeder

Ore (maximum particle size ≤600mm) is discharged into the feed silo. The vibrating feeder at the bottom, using an eccentric shaft, evenly and continuously feeds the ore to the jaw crusher, preventing overloading of subsequent equipment. The feed rate can be adjusted via a frequency converter to match the crushing system’s processing capacity.

2. Primary Crushing: PE series coarse jaw crusher

The ore is crushed to a particle size of 100-150mm, with a reduction ratio of approximately 5-6. The crushed ore is then conveyed to the secondary crushing stage via a belt conveyor.

3. Secondary Crushing: PEX fine jaw crusher

The primary crushed product enters the fine jaw crusher for further crushing to 30-50mm, with a reduction ratio of approximately 3-4. This reduces ore hardness and reduces energy consumption during the fine crushing process.

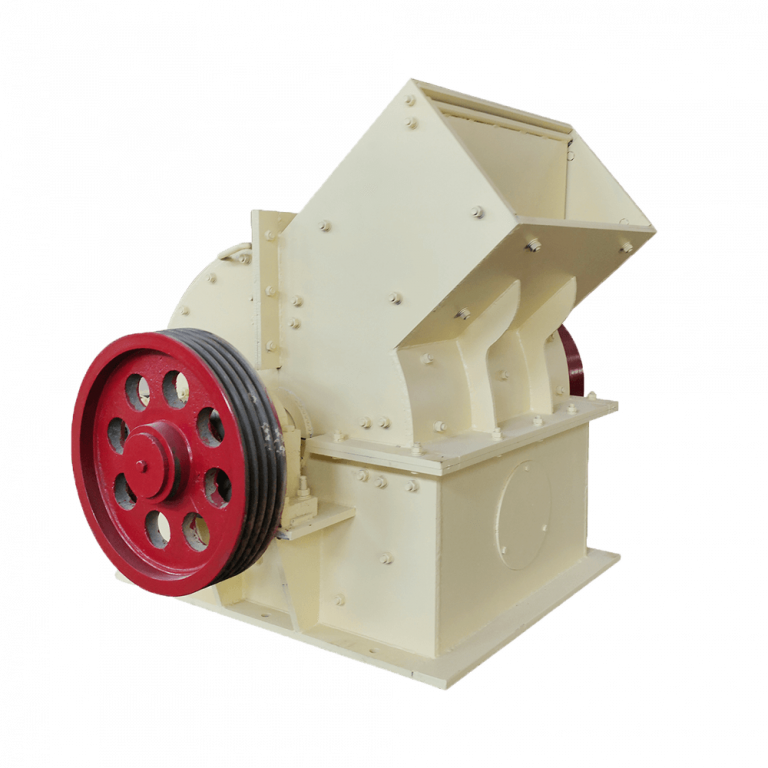

4. Fine Crushing: 4 sets hammer crusher

The four hammer crushers operate in parallel (total processing capacity 24 TPH, with redundancy reserved). High-speed rotating hammers impact and grind the ore, thoroughly separating gold particles from gangue. The crushed product is screened (with an internal screen). Qualified ore is fed to the next stage, while coarse particles return to the hammer crusher for further crushing.

5. Slurry Transportation: Mortar pump + Slurry tank

The finely crushed ore enters the slurry tank, where water is added according to the solid-to-liquid ratio to form a slurry with a concentration of 30%-35%. The slurry pump pressurizes the slurry and transports it to the gravity separation system. Piping is constructed of wear-resistant materials (such as high-chromium cast iron) to minimize wear.

6. Gravity Stage: Centrifugal concentrator, Shaker table, and Gold sluice box

- The slurry enters the high-speed rotating drum of the centrifugal concentrator. Under the influence of centrifugal force (approximately 30-50 times the acceleration of gravity), high-density gold particles quickly settle to the drum wall, forming coarse concentrate (Concentrate 1). Low-density gangue is discharged from the overflow outlet with the ore flow (tailings).

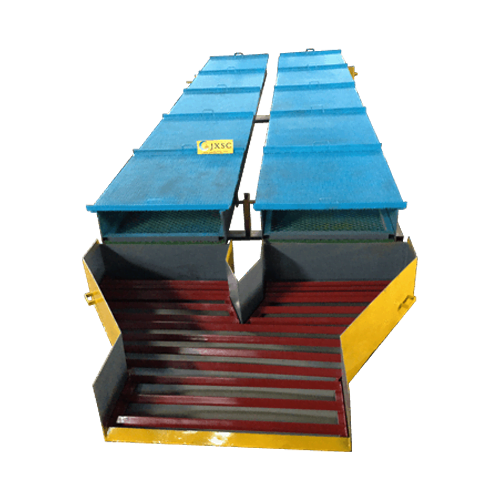

- The tailings from the centrifugal concentrator enter the shaker table. The combined effects of the longitudinal reciprocating vibration of the bed and the lateral water flow cause the fine gold particles to separate into layers on the bed due to density differences. The upper layer contains light minerals (tailings), the middle layer contains medium minerals (returned for re-selection), and the lower layer contains fine concentrate (Concentrate 2).

- The shaker tailings enter the sluice box, where gravity and the water velocity gradient are used to recover fine gold (-200 mesh) and a small amount of contiguous gold, resulting in Concentrate 3, further improving the overall recovery rate.

7. Concentrate Smelting Stage: Gold melting furnace

After Concentrates 1, 2, and 3 are combined, they are concentrated (to a concentration of 60%-70%) and filtered (to a filter cake moisture content of ≤15%) to remove excess water and reduce smelting energy consumption. The dried, mixed concentrate is then added to a flux and melted at high temperatures. Impurities form slag and rise to the surface, while the molten gold sinks to the bottom of the melting furnace. After casting and cooling, high-purity gold nuggets are obtained.

This complete 20TPH rock gold crushing process system utilizes a process combination of three-stage crushing, multiple gravity separation, and smelting to efficiently process rock gold ore. It features complete dissociation, high recovery rates, low energy consumption, and environmental friendliness. Contact us to customize a stable, cost-effective, turnkey solution for small to large rock gold processing.

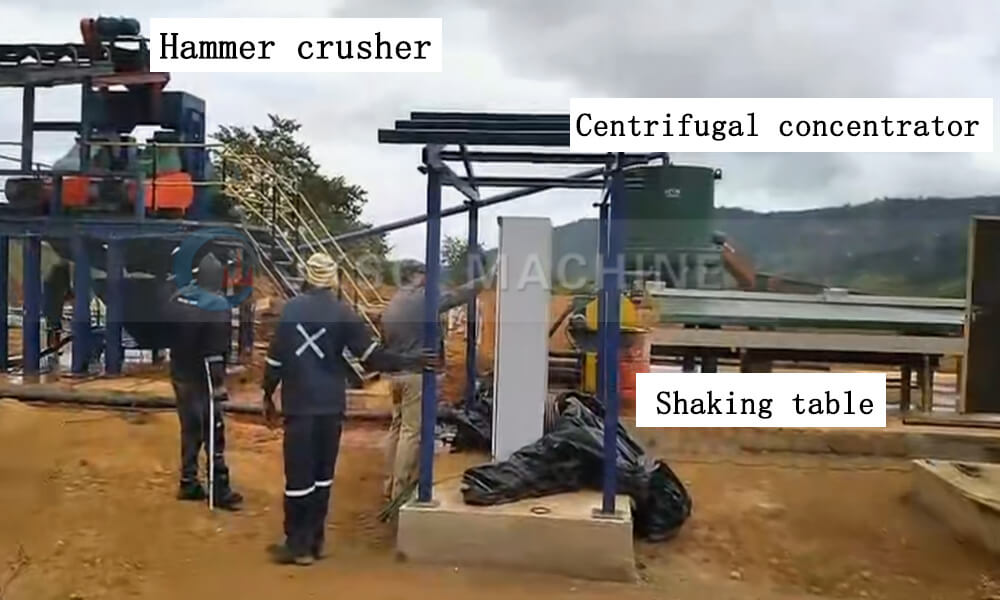

Process Site

20TPH Rock Gold Crushing Process Plant Site

Highlight Of JXSC Rock Gold Crushing Process Solution

√ High-efficiency crushing system: Utilizing a combination of jaw crusher, fine jaw crusher, and multiple hammer crushers, this system efficiently separates ore from bulk to sandy material. The crushed product achieves uniform particle size, laying the foundation for subsequent gravity separation.

√ Triple Gravity Recovery: Integrated with a centrifuge, shaker, and chute, this three-stage gravity separation system provides a step-by-step recovery of gold particles of varying particle sizes (coarse, fine, and ultra-fine), achieving a total gold recovery rate of 92%-95%.

√ Low-energy, environmentally friendly design: Dry crushing reduces water consumption throughout the entire process, gravity separation requires no chemicals, and tailings can be reused after dewatering, meeting green mine construction standards.

Main Equipment

Item No. | Product Name | Model | Detail Description of Product | Quantity (Sets) |

1 | 2400*700 |

| 1 | |

2 | Rough jaw crusher | PE400*600 |

| 1 |

3 | PEX250*750 |

| 1 | |

4 | Hammer mill | PC600*400 |

| 4 |

5 | DT75-650*15m |

| 2 | |

6 | Slurry pump | 4/3 inch |

| 1 |

7 | Gold centrifugal concentrator | STLB80 |

| 1 |

8 | 4500*1850mm |

| 1 | |

9 | Sluice box | 6m*1m*0.3m |

| 1 |

10 | Gold smelting furance | 15A |

| 1 |

11 | Back wash water pump | IS80 |

| 1 |

12 | Big water pump | IS100 |

| 1 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.