25TPH Placer Tin Ore Washing & Separation Plant In Nigeria

We guarantee the high quality machine in the mineral processing industry, established in 40+ years of experience!

Project Info.

- Raw ore: placer tin ore

- Capacity: 25TPH

- Maximum feed size: 200mm

- Output: 0-2mm

- Location: Nigeria

Process

washing & Screening – gravity separation – Magnetic Separation

process flow

25TPH Placer Tin Ore Washing & Separation Plant

This is a complete placer tin ore washing & separation plant solution successfully designed by JXSC, with a processing capacity of 25 tons per hour (TPH). The process combines washing, screening, gravity separation, and magnetic separation technologies to maximize the enrichment and recovery of tin ore resources by classifying ores of different particle sizes. The entire system is compact, highly automated, and fully considers local resource conditions and environmental requirements.

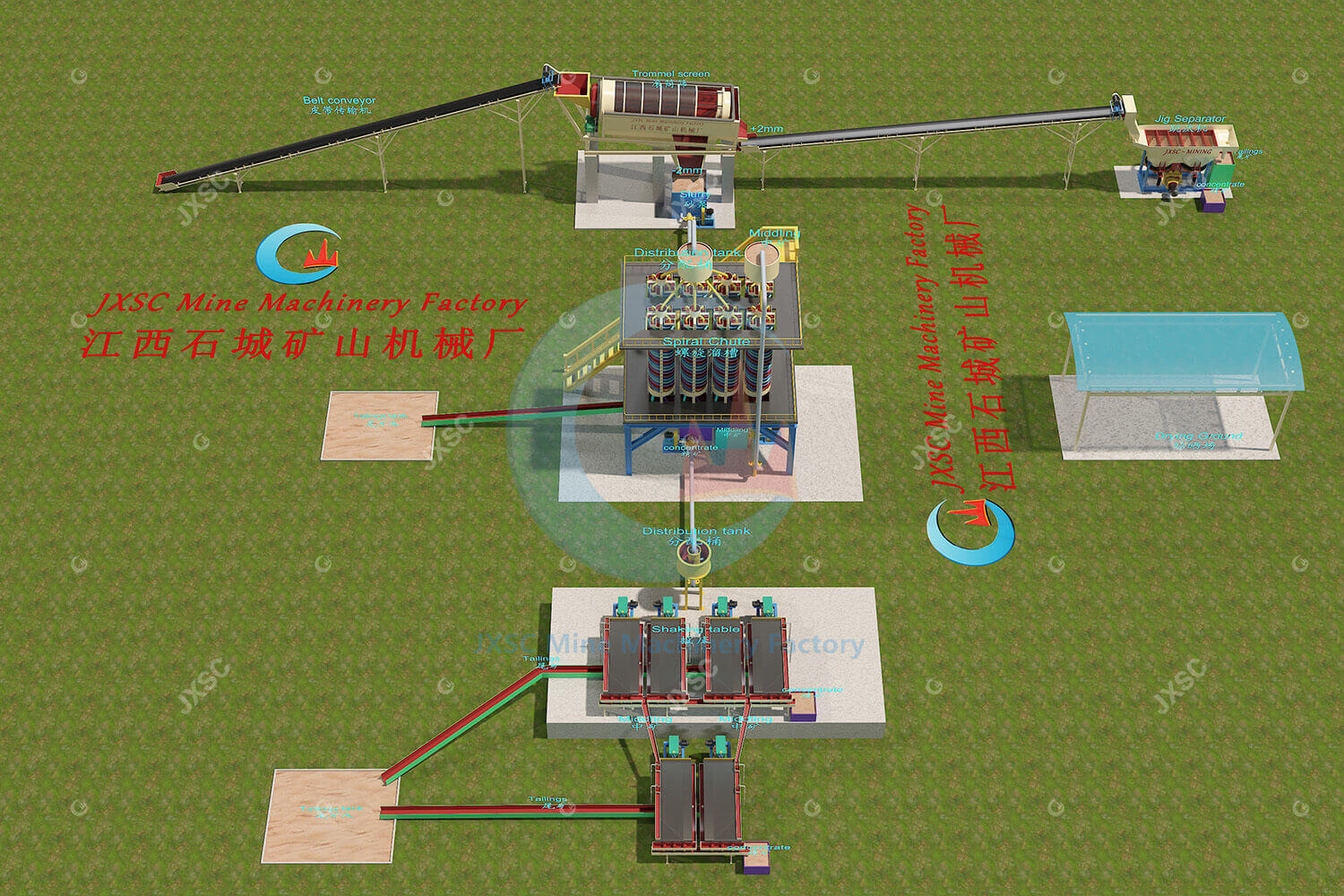

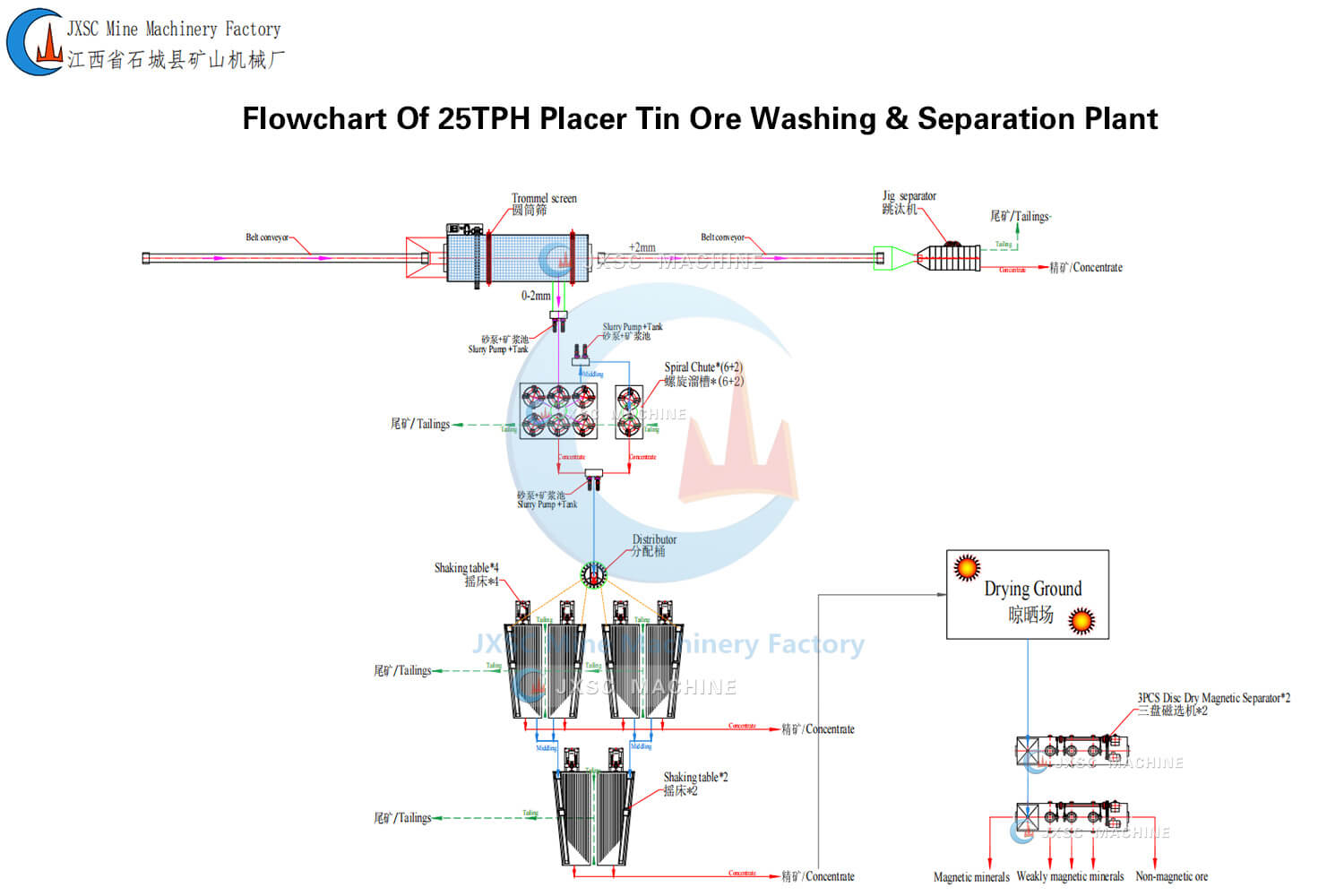

25TPH Placer Tin Ore Washing & Separation Flow

1. Tin Ore Washing and Screening Stage:

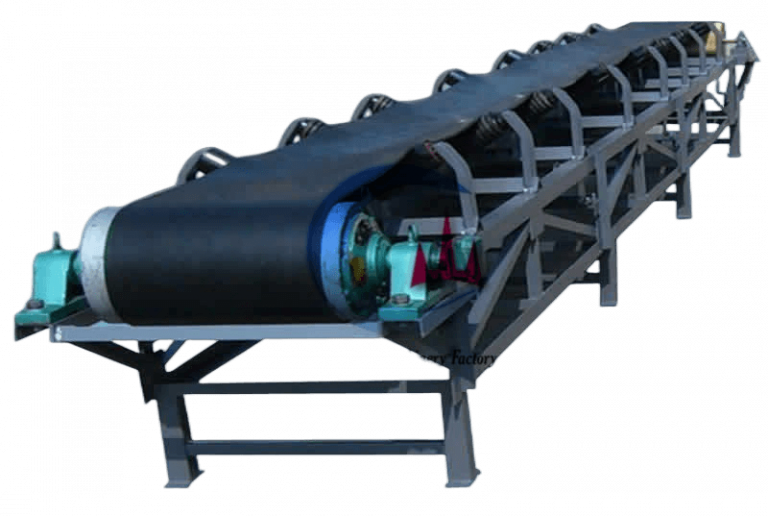

The raw ore is conveyed to a trommel screen via a belt conveyor for washing, impurity removal, and classification.

- Oversize product (+2mm): Coarse particles larger than 2mm are directly conveyed to a jig separator for roughing.

- Undersize product (0-2mm): Fine particles smaller than 2mm enter the slurry pump-tank, ready for subsequent spiral chute-fine particle separation.

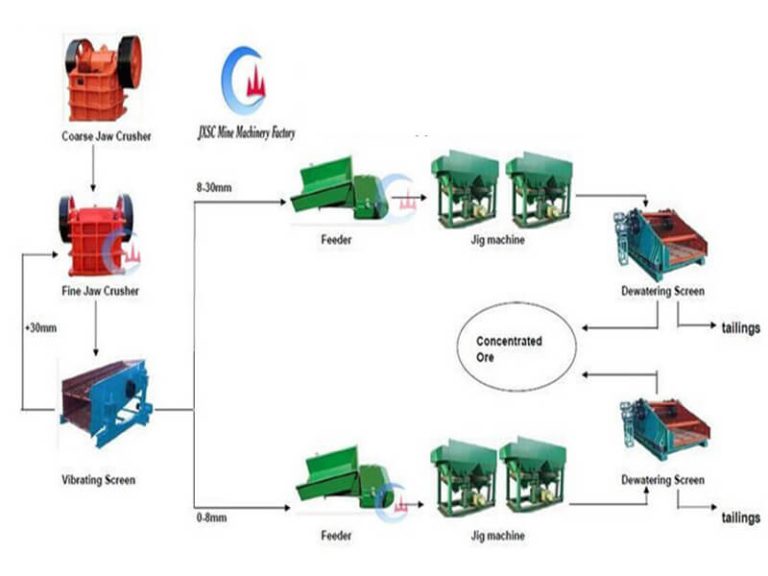

2. Coarse Particle Separation (+2mm):

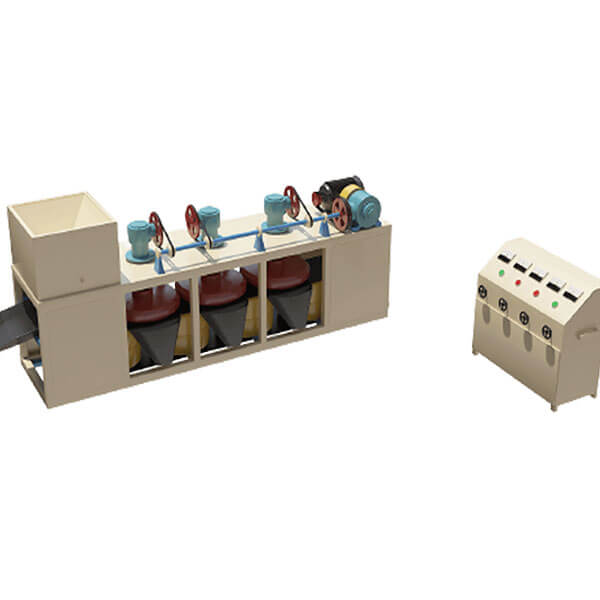

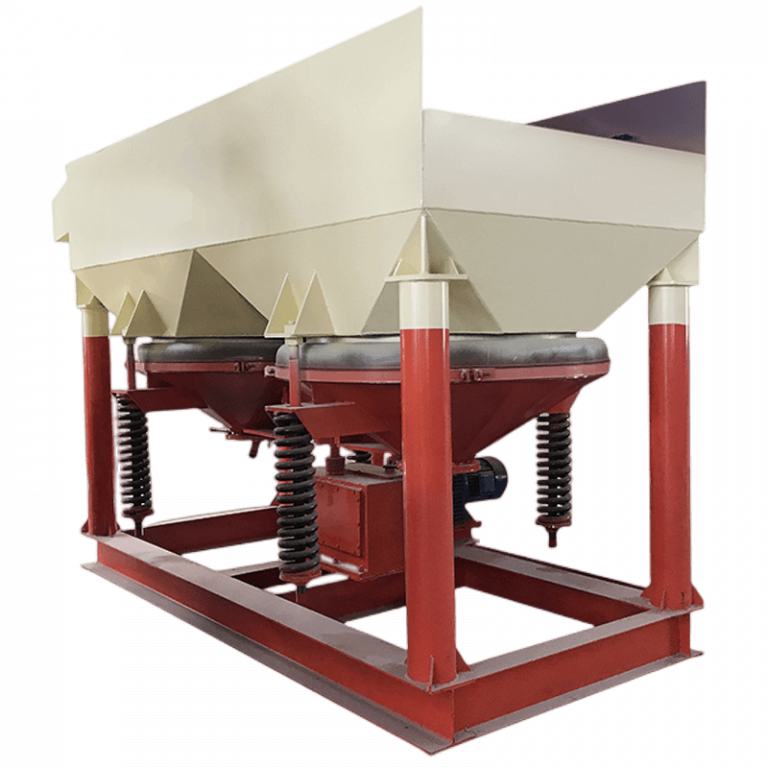

Jig separation: The coarse particles separated from the screen enter the jig. The jig separator uses vertical alternating water flow to stratify the mineral particles according to density. The denser tin mineral particles are enriched to form a coarse concentrate, while the less dense gangue is discharged as tailings.

3. Fine Particle Separation (0-2mm):

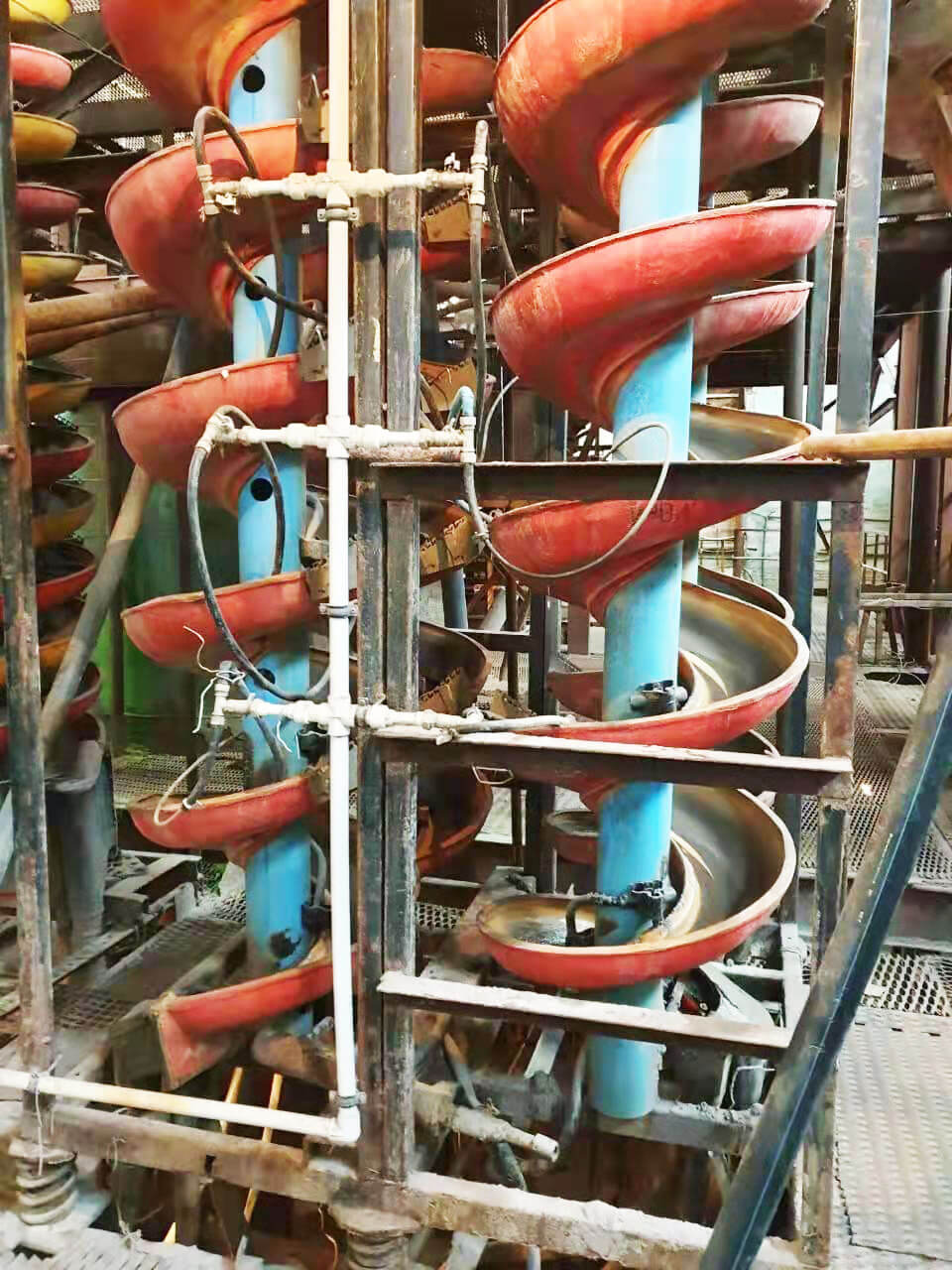

The fine particle slurry is pumped from the slurry pump to the spiral chute assembly via a sand pump. The spiral chutes utilizes centrifugal force and gravity to stratify tin particles according to density during spiral motion, initially enriching tin minerals and discarding some tailings.

The concentrate from the spiral chute is then fed into multiple shaking tables for further refining. The shaking tables, through the reciprocating motion of the table surface and lateral water flow, further finely separate tin minerals from gangue, ultimately producing high-quality tin concentrate. Tailings are discharged from the side or end of the shaking tables.

4. Tin Concentrate Purification and Drying (Optional/Supplementary)

- Drying: All tin concentrate produced by the shaking tables can be naturally dried in a drying ground or processed using other drying equipment for storage and transportation.

- Magnetic Separation Purification: The dried concentrate can be directly fed into a 3-disc magnetic separator for magnetic purification. This step removes magnetic impurities (such as iron minerals) that may be present in the concentrate, resulting in a higher purity tin concentrate.

This 25TPH tin ore washing & separation process is specifically designed for the characteristics of placer tin ore, making full use of the high density of cassiterite. Employing gravity separation (jigging, spiral sluice, shaking table) as the primary process, it effectively recovers tin minerals of different particle sizes, ensuring a high metal recovery rate. JXSC’s design is reasonable, and its technology is mature, providing investors with a reliable and environmentally friendly tin ore beneficiation solution, successfully achieving efficient conversion from raw ore to high-quality tin concentrate.

We understand that every mine has unique ore properties, geographical conditions, and investment budgets. We strongly recommend that you contact JXSC’s professional technical team. Whether it’s placer tin, vein tin, or other metal ores, we will tailor the most cost-effective mining equipment and solutions for you based on your ore sample testing reports, production capacity requirements, specific site conditions, cost assessments, and other factors!

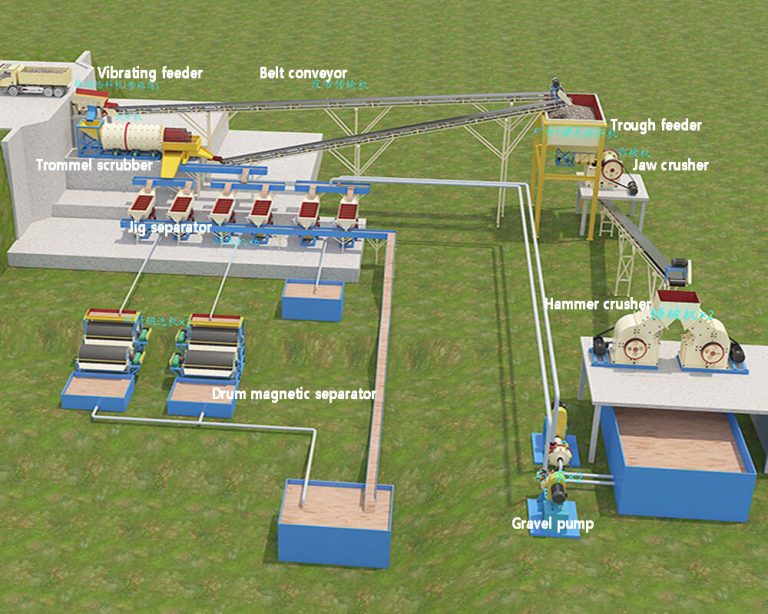

Process Site

25TPH Placer Tin Ore Washing & Separation Plant Site

Advantages Of JXSC Placer Tin Ore Washing & Separation Plant

√ Highly targeted and with high recovery rates: Specifically designed for placer tin ore, it utilizes gravity separation technology to efficiently recover tin minerals of different particle sizes; with magnetic separation as a supplement, it can stably produce qualified concentrate.

√ Grading and optimized efficiency: The raw ore is separated into coarse and fine particle sizes using a drum screen. Coarse particles are processed by a jig, while fine particles are processed by a spiral chute and a shaking table, optimizing the overall processing effect.

√ Energy-saving and environmentally friendly: The main equipment, such as the shaking table and spiral chute, has relatively low energy consumption. It primarily uses physical separation and does not involve complex chemical reagents, making it environmentally friendly.

√ Flexible equipment configuration: The processing capacity can be designed according to needs. The equipment configuration can be adjusted based on the ore properties and market demand, such as the number of shaking tables and whether to add magnetic separation.

Main Equipment

No. | Name | Model No. | Detailed Description of Product | Power (KW) | Quantity (Sets) |

1 | GT1230 |

| 7.5 | 1 | |

2 | Slurry Pump | 4/3C-AH |

| 7.5 | 1 |

3 | 1# Distribution tank | 1000*1000 |

| 0 | 1 |

4 | Slurry Pump | 3/2C-AH |

| 5.5 | 1 |

5 | 2# Distribution tank | 800*800 |

| 0 | 1 |

6 | 5LL-1200 |

| 0 | 8 | |

7 | Slurry Pump | 3/2C-AH |

| 5.5 | 1 |

8 | 3# Distribution tank | 1000*1000 |

| 0 | 1 |

9 | 6S |

| 4.4 | 4 | |

10 | 3PC-600 |

| 6.2 | 2 | |

11 | Electric Control Panel | / | For control the above machines’ start and stop. | 0 | 1 |

12 | JT4-2 |

| 7.5 | 1 | |

13 | Shaking Table | 6S |

| 2.2 | 2 |

14 | Belt Conveyor | B650*18m |

| 11 | 1 |

B650*12m |

| 5.5 | 1 |

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.