300TPD (12TPH) Gold CIP Processing Plant in Kenya

We guarantee the high quality machine in the mineral processing industry, established in 40+ years of experience!

Project Info.

1. Raw ore: Rock gold

2. Capacity: 12TPH

3. Location: Kenya

4. Input size: >210mm

Process

Feeding – Crushing – Grinding – Leaching – activated carbon adsorption processing – Gold-loaded carbon desorption and electrolytic – Tailings water recovery

process flow

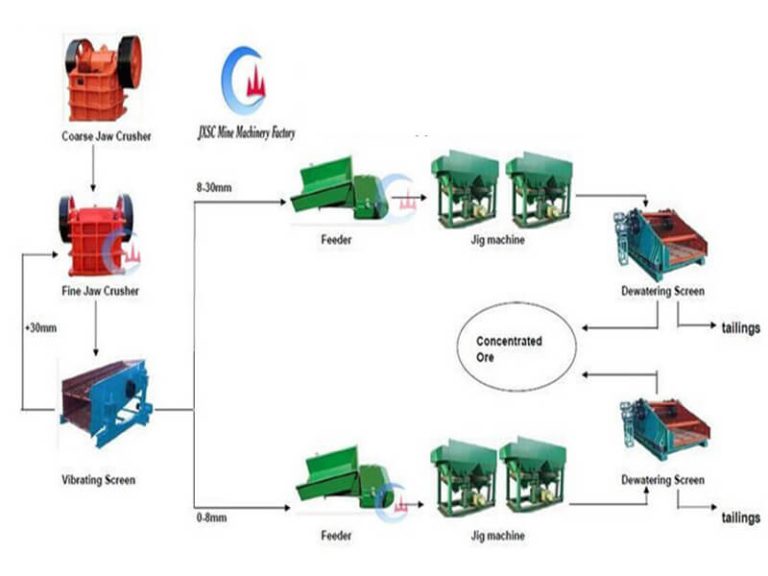

12TPH (300TPD) Gold CIP Processing Plant flow

1. Feeding & Crushing system:

Crush rock gold from 210mm to below 5mm: Feeding hopper + Chute Feeder + Rough jaw crusher + Belt conveyor + Fine jaw crusher + Vibrating screen + Roller Crusher

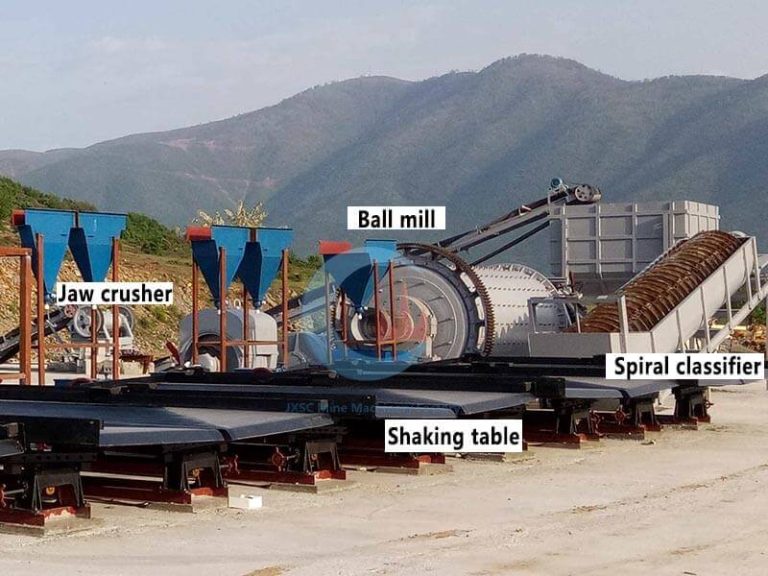

2. Grinding system:

Grinding material to small powder 200mesh: Storage bin + Electromagnetic vibration feeder + Belt conveyor + Ball mill + Hydrocyclone

3. Leaching pretreatment:

Thickener + Agitation tank (for adjusting the density of the slurry after the thickener) + Liner vibrating screen

4. Leaching and activated carbon adsorption processing:

2pcs double impeller Leaching agitation tank + 7pcs double impeller Adsorption agitation tanks + Roots blower (work for adsorption agitation tank)+ Liner vibrating screen for tailing dewatering + Liner vibrating screen for screening carbon + Cabon extractor + Cabon screen

5. Gold-loaded carbon desorption and electrolytic Stage:

Normal temperature, normal pressure elution & electrolysis system + Drying oven for gold mud + Gold smelting furnace

6. Carbon kiln for carbon regeneration

7. Tailing water recycling system:

High-pressure slurry pump + plate filter press + cone slurry tank (for making a suitable density of slurry before sending to the filter press)

8. Five-reagent adding device system:

Each system includes a reagent agitation tank + a reagent slurry pump + a reagent tank

- Flocculant make-up system for thickener

- Sodium cyanide reagent make-up system for 2pcs leaching agitation tank

- Lime make-up system for 2pcs leaching agitation tank (for PH control)

- sodium hydroxide&hydrochloric acid reagent make-up system for cone agitation tank

- Sodium hydroxide, clean water, and sodium cyanide reagent make-up system for the Elution & Electrolysis system

9. Other auxiliary accessories:

- Water pumps for the water supply to the complete plant

- Slurry Pumps for the plant

- Complete set of electric control panels

- Complete set of cables & wires

- Diesel Generator for the plant machines’ power

- Complete set of water pipes &slurry pipes

JXSC designed the flow chart, equipment, and all accessories of a complete gold processing plant for a Kenyan client. We also provide after-sales engineering services, sending engineers to mines for installation, commissioning, and guidance. The CIP process is a gold beneficiation method widely used at present. Contact us to get more gold CIP plant details!

12TPH (300TPD) Gold CIP Processing Site

Main Equipment

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.