We guarantee the high quality machine in the mineral processing industry, established in 40+ years of experience.

Project Info

1. Material: coal mine containing clay impurities

2. Capacity: 40-50TPH

3. Feed size: 0-150 mm

4. Discharge size: 0-20mm; 20-50mm; Above 50mm

5. Location: Indonesia

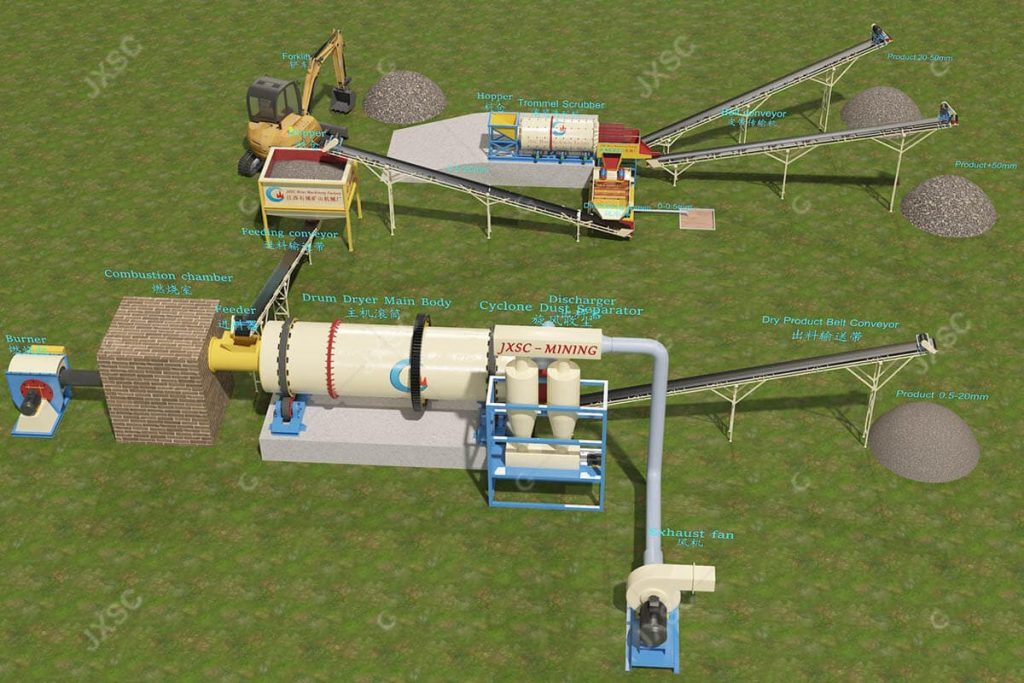

Process

Washing & Screening – Dewatering – Drying

process flow

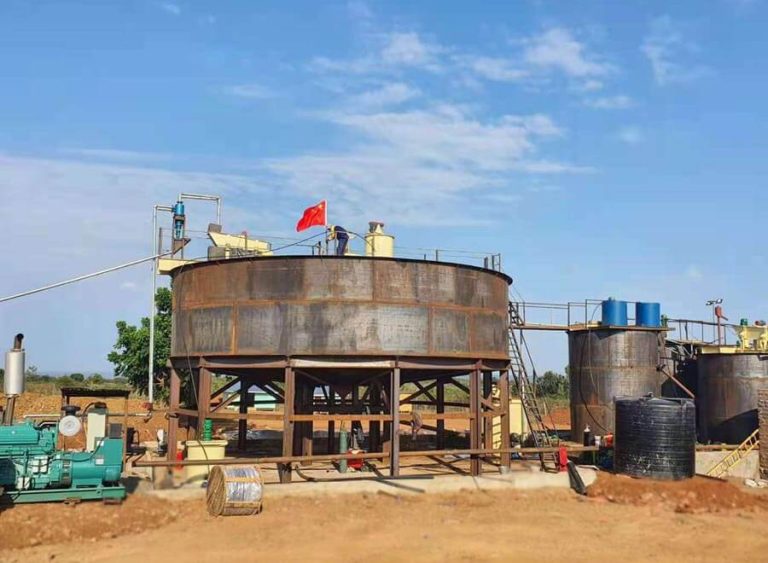

40-50TPH Coal Washing & Drying Plant

The customer requested that the mud impurities on the coal mine be first cleaned and screened into three particle sizes. Materials of 0- 20 mm use the height difference to flow automatically to the dewatering screen for dehydration; a belt conveyor transports away the dry material on the screen. JXSC has specially designed a complete set of 40-50TPH coal washing and drying equipment for Indonesian customers, mainly to improve the quality of raw coal by removing impurities and moisture.

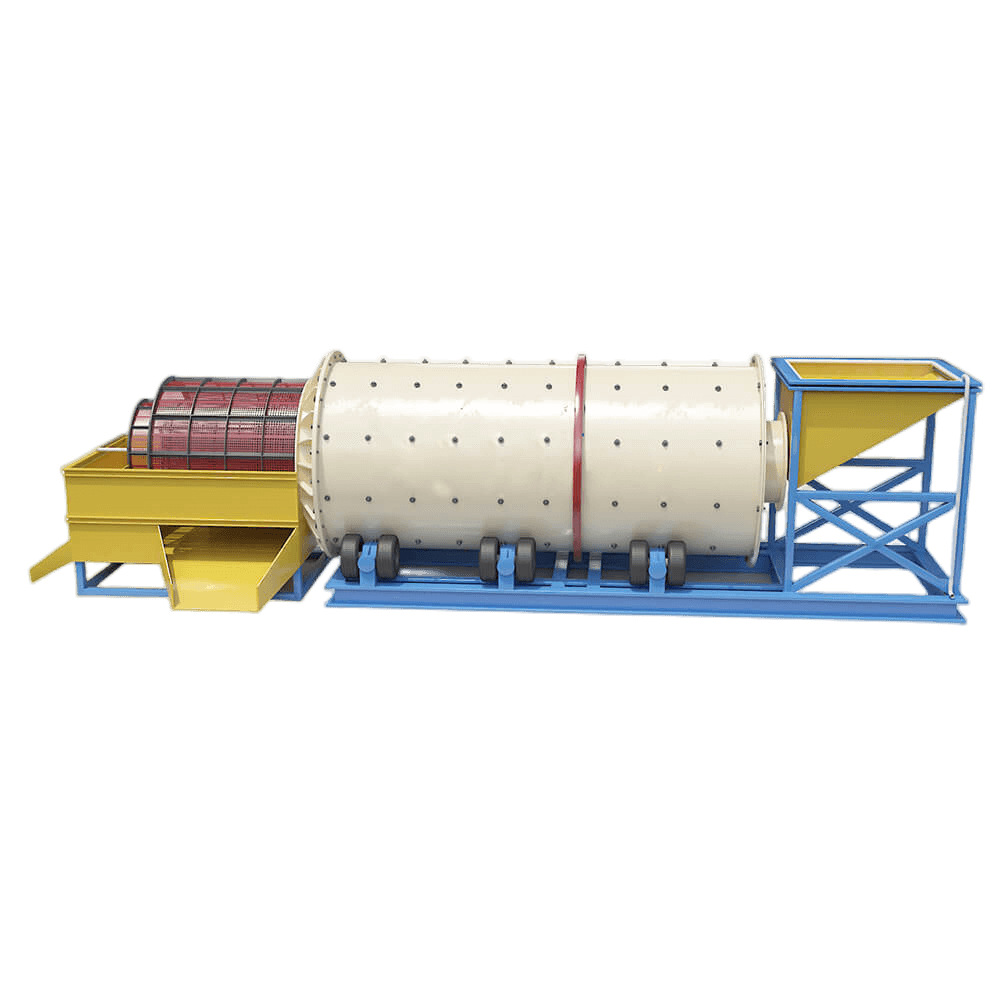

1. Washing & screening stage: trommel scrubber

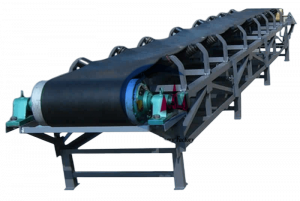

The excavator or loader feeds the raw materials into the hopper of the trommel scrubber, which has a 2-layer screen at the end. After washing the clay from the coal mine, three types of materials are screened: above 50mm, 20-50mm, and below 20mm. Materials exceeding 50 mm and 20-50 mm are transported to another place by belt conveyor.

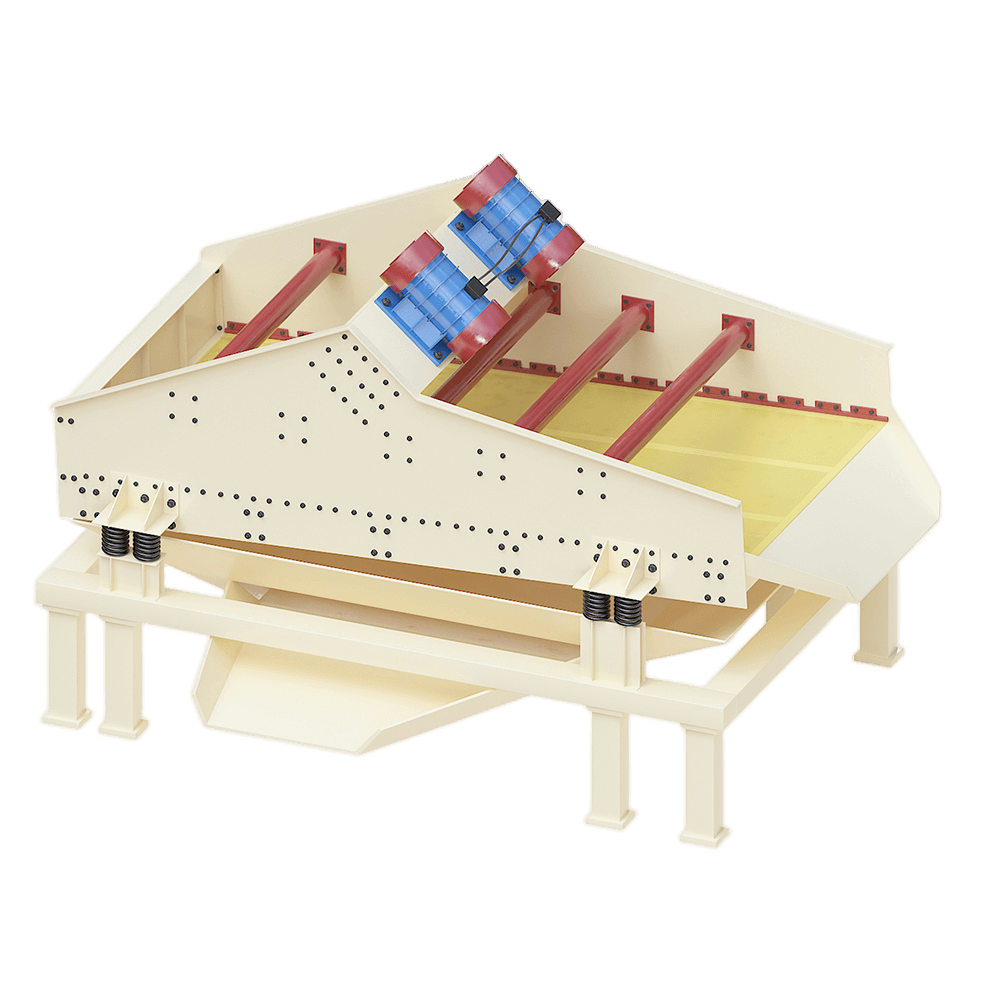

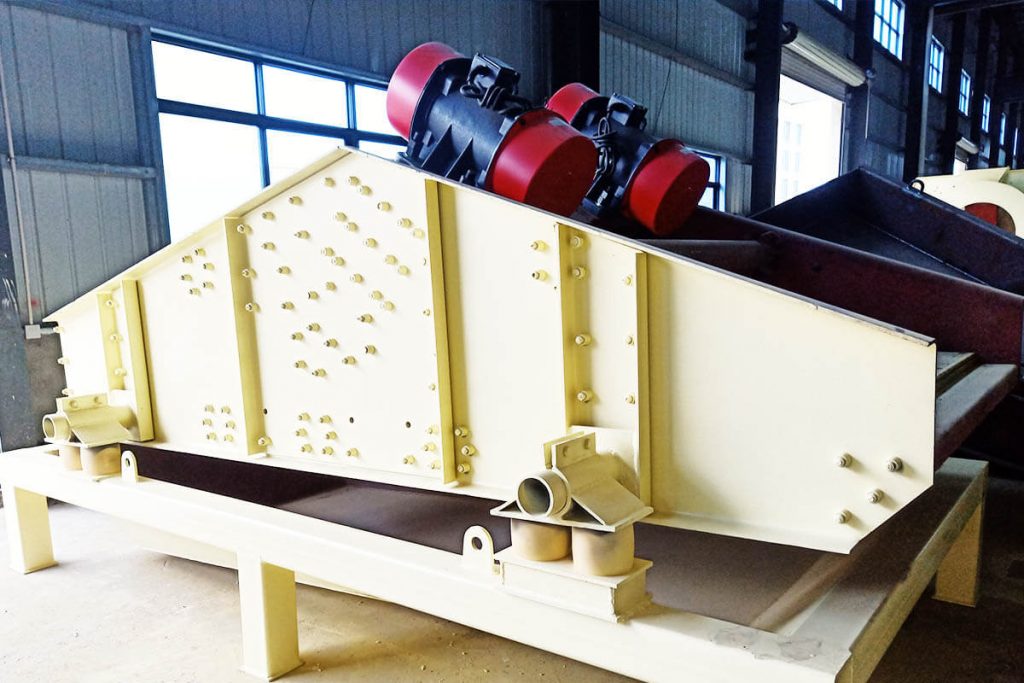

2. Dewatering stage: dewatering screen

0-20mm material enters the dewatering screen through gravity flow. Here, the dewatering screen is placed lower than the drum scrubber so that the slurry can flow to the dewatering screen through the height difference.

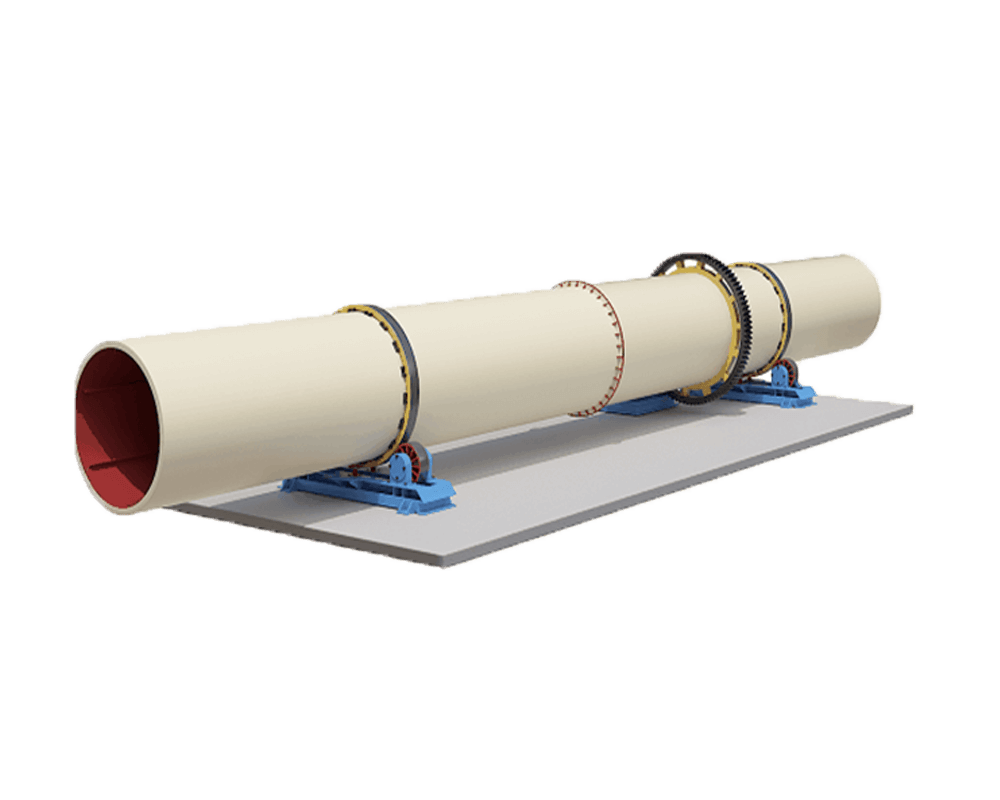

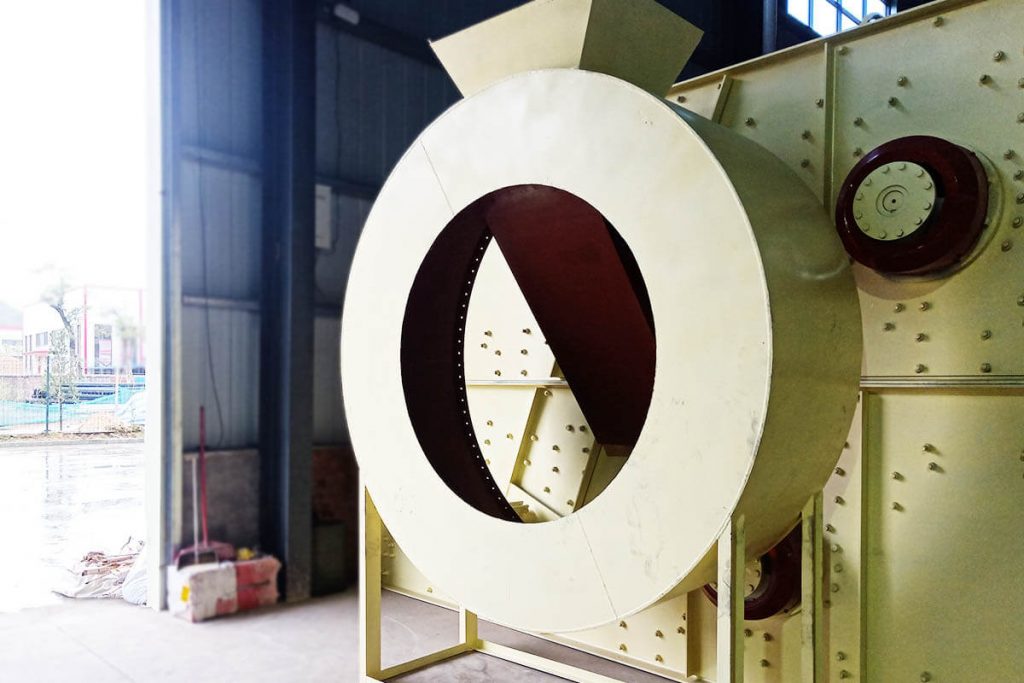

3. Drying stage: rotary dryer, cyclone dust

- The materials on the dewatering screen are sent to the rotary drying system through the feeding conveyor for coal drying. The high-temperature environment within the rotary dryer helps evaporate water, ensuring that the coal meets prescribed standards for combustion and handling. Dust and fine particles are generated when coal is processed and need to be extracted from the exhaust gases.

- The cyclone dust collector is responsible for separating dust from the airflow, preventing it from entering the atmosphere and causing pollution, and operating with the exhaust fan to facilitate better heat transfer within the dryer. Creates negative pressure within the dryer system, allowing for proper airflow and efficient dust collection. Finally, the discharging conveyor transported the dried finished product to the designated place.

The process increases coal’s energy content and reduces environmental impact by minimizing emissions during combustion. Contact us to design coal washing plants by JXSC, which uses advanced technology to produce higher-quality clean coal products more suitable for various industrial applications. Not only does it improve air quality, but it also enhances safety by reducing fire hazards associated with coal dust buildup.

Need a Reliable Coal Washing Plant Solution & Equipment?

Main Equipment

Contact Us Now

Ask us about mineral processing configuration and equipment quote! (No job, No investment)

Notice:

- We only provide mineral processing equipment and solutions; not buy and sell minerals/ ores/ materials.

- We do not recruit, don’t offer jobs, no rental/ leases, and are not interested in investments or partnerships.

- We value your privacy and keep your information safe.